Audit_4801 Safety Management Systems_Report Example

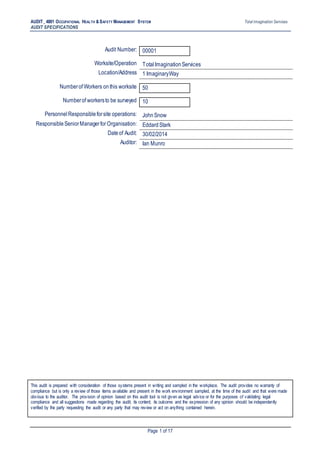

- 1. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT SPECIFICATIONS Page 1 of 17 Total Imagination Services AUDIT SPECIFICATIONS Audit Number: 00001 Worksite/Operation TotalImaginationServices Location/Address 1 ImaginaryWay Numberof Workers onthis worksite 50 Numberof workersto be surveyed 10 PersonnelResponsibleforsite operations: JohnSnow ResponsibleSeniorManagerfor Organisation: EddardStark Dateof Audit: 30/02/2014 Auditor: Ian Munro This audit is prepared with consideration of those systems present in writing and sampled in the workplace. The audit provides no warranty of compliance but is only a review of those items available and present in the work environment sampled, at the time of the audit and that were made obvious to the auditor. The provision of opinion based on this audit tool is not given as legal advice or for the purposes of validating legal compliance and all suggestions made regarding the audit; its content; its outcome and the expression of any opinion should be independently verified by the party requesting the audit or any party that may review or act on anything contained herein.

- 2. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT SPECIFICATIONS Page 2 of 17 Total Imagination Services AuditTableofContents AUDIT SPECIFICATIONS 1 Recorded Findings......................................................................................................................................... 3 4.01 GENERAL REQUIREMENTS 3 4.01.01 Specifications for General Requirements ................................................................................ 3 4.02 OHS POLICY 3 4.02.01 Specifications for OHS Policy Requirements ........................................................................... 3 4.03 PLANNING 3 4.03.01 Planning identification of hazards, hazard/risk assessment and control of hazards/risks ............. 3 4.03.02 Legal and other requirements ................................................................................................ 3 4.03.03 Objectives and targets .......................................................................................................... 4 4.03.04 OHS management plans ....................................................................................................... 4 4.04 IMPLEMENTATION 4 4.04.01 Structure and responsibility ................................................................................................... 4 4.04.01.01 Resources 4 4.04.01.02 Responsibility and accountability 4 4.04.02 Training and competency ...................................................................................................... 4 4.04.03 Consultation, communication and reporting............................................................................. 5 4.04.03.01 Consultation 5 4.04.03.02 Communication 5 4.04.03.03 Reporting 5 4.04.04 Documentation..................................................................................................................... 5 4.04.05 Document and data control.................................................................................................... 5 4.04.06 Hazard identification, hazard/risk assessment and control of hazards/risks ................................ 5 4.04.06.01 General Hazard/Risk Requirements 5 4.04.06.02 Hazard identification 5 4.04.06.03 Hazard/risk assessment 6 4.04.06.04 Control of hazards/risks 6 4.04.06.05 Evaluation 6 4.04.07 Emergency preparedness and response................................................................................. 6 4.05 MEASUREMENTAND EVALUATION 7 4.05.01 Monitoring and Measurement ................................................................................................ 7 4.05.01.01 General Monitoring and Measurement 7 4.05.01.02 Health surveillance 7 4.05.02 Incident investigation, corrective and preventive action ............................................................ 7 4.05.03 Records and records management ........................................................................................ 7 4.05.04 Safety Management System audit.......................................................................................... 8 4.06 MANAGEMENTREVIEW 8 4.06.01 Specifications for Management Review Requirements ............................................................. 8 AUDIT TABLE OF RESULTS 10 Summary of Results......................................................................................................................................10 Audit Results Spider Charts ...........................................................................................................................11 Table of Improvements..................................................................................................................................12 Audit Actions Table for Non-Conformances .....................................................................................................15

- 3. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.01 General requirements Page 3 of 17 Total Imagination Services Recorded Findings No. SECTION QUESTIONS Audit Response 4.01 General requirements No 4.01.01 Specifications forGeneralRequirements No 4.01.01.01 Has the organisation established an SMS? Yes 4.01.01.02 Is that SMS maintained in accordance with AS/NZS ISO 4801? No Comments: In the audit there were discrepancies noted between the organisations SMS and the standard. These are detailed in the following. No 4.02 OHS Policy No 4.02.01 SpecificationsforOHSPolicyRequirements No 4.02.01.01 Is there an OHS policy authorized by the organisations top management (e.g. signed by top management)? Yes 4.02.01.02 Does it clearly state the overall OHS objectives? Yes 4.02.01.03 Does it demonstrate a commitment to improving OHS performance? Yes 4.02.01.04 Does the policy comply with all of the below: No 4.02.01.05 - Appropriate to the nature and scale of the organisation’s risks Yes 4.02.01.06 - Refer to measurable objectives and targets Yes 4.02.01.07 - Refer to a commitment to comply with relevant OHS legislation and other requirements Yes 4.02.01.08 - Documented Yes 4.02.01.09 - Implemented Yes 4.02.01.10 - Maintained Yes 4.02.01.11 - Communicated to all employees No 4.02.01.12 - Available to interested parties No 4.02.01.13 - Reviewed periodically to ensure it remains relevant and appropriate to the organisation. Yes 4.02.01.14 Has the policy been approved by any other parties: O Yes O No 4.02.01.15 - OHS representatives; OHS committees; regulatory authorities; community groups; Others (list above) O Yes O No Comments: The policy has not been communicated to all employees is not distributed or available to visitors or contractors. No 4.03 Planning No 4.03.01 Planning identificationofhazards,hazard/riskassessmentand controlofhazards/risks No 4.03.01.01 Does the organisation have established implemented and maintained procedures for all the following: Yes 4.03.01.02 - Hazard identification Yes 4.03.01.03 - Risk assessment Yes 4.03.01.04 - Control of risks Yes 4.03.01.05 Are these for activities overwhich the organisation has control or influence? Yes 4.03.01.06 Do they include activities of contractors and suppliers over which the organisation has control or influence? No 4.03.01.07 Does the procedure include where necessary the following: No 4.03.01.08 - Legislative requirements Yes 4.03.01.09 - Codes of practice and standards where necessary No 4.03.01.10 - Other aspects of the safety management system (SMS) Yes 4.03.01.11 - The conditions/frequency for hazard identification/risk assessment Yes 4.03.01.12 Are assessments undertaken by persons who are: Yes 4.03.01.13 - Trained in risk assessment Yes 4.03.01.14 - Trained or experienced in the work being done Yes 4.03.01.15 Does the hazard identification/risk assessment take into account all the following: Yes 4.03.01.16 - Chemical hazards Yes 4.03.01.17 - Physical hazards Yes 4.03.01.18 - Biological hazards Yes 4.03.01.19 - Ergonomics Yes 4.03.01.20 - Psychological hazards Yes Comments: Contractors are not considered and there is no list of codes of practice that are relevant to the work being undertaken No 4.03.02 Legal and otherrequirements No 4.03.02.01 Relevant to the OHS issues of the organisation, does the organisation have a list of: No 4.03.02.02 - Legislation Yes 4.03.02.03 - Codes of practice No 4.03.02.04 - Standards (AS/NZor ISO) No 4.03.02.05 - Other guidelines or reference materials Yes 4.03.02.06 Relevant to the OHS issues of the organisation, does the organisation have access to all of the below: No 4.03.02.07 - Legislation Yes 4.03.02.08 - Codes of practice No 4.03.02.09 - Standards (AS/NZor ISO) No

- 4. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.04 Implementation Page 4 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.03.02.10 - Other guidelines or reference materials Yes Comments: There is no list of codes or standards and no evidence that all relevant codes and standards have been considered. A compliance register that shows how the SMS meets the relevant legislation, including codes and standards, may assist in showing compliance. No 4.03.03 Objectivesand targets 4.03.03.01 Does the organisation have established implemented and maintained documented OHS objectives and targets? Yes 4.03.03.02 Do they contribute to improving OHS performance? Yes 4.03.03.03 Are these consistent with the OHS Policy? Yes 4.03.03.04 Are they measurable? Yes 4.03.03.05 Aer they monitored and reviewed for currency/relevance? Yes 4.03.03.06 Are their results reported to management? Yes Comments: 4.03.04 OHSmanagementplans No 4.03.04.01 Is there an OHS Management plan that: No 4.03.04.02 - Identifies OHS responsibilities for specific people within the organisations hierarchy No 4.03.04.03 - Determine time frames for when objectives and targets are to be achieved Yes 4.03.04.04 Is the procedure for management plans to be regularly reviewed? Yes 4.03.04.05 Do the reviews occur: Yes 4.03.04.06 - At planned intervals Yes 4.03.04.07 - When change is necessary (due to changes in work, legislation or other requirements) Yes 4.03.04.08 - When new activities are undertaken Yes 4.03.04.09 Do the plans include: Yes 4.03.04.10 - Planning Yes 4.03.04.11 - Design Yes 4.03.04.12 - Production Yes 4.03.04.13 - Maintenance Yes Comments: There are no accountabilities included in the safety management plan. A list or responsible roles and their accountabilities and inclusion of these accountabilities in the relevant position descriptions may provide appropriate evidence for compliance. No 4.04 Implementation No 4.04.01 Structureand responsibility No 4.04.01.01 Resources 4.04.01.01.01 Has management identified and provided the resources required to implement, maintain, and improve the SMS? Yes 4.04.01.11.01 Do the resources include: Yes 4.04.01.21.01 - Human resources Yes 4.04.01.31.01 - Specialized skills Yes 4.04.01.41.01 - Technology Yes 4.04.01.51.01 - Financial resources Yes 4.04.01.61.01 - Resources for operational personnel Yes Comments: 4.04.01.02 Responsibility and accountability No 4.04.01.02.01 Has the organisation defined accountabilities for all personnel with OHS responsibilities? No 4.04.01.02.02 Has the organisation defined accountabilities for contractors over which the organisation has control or influence? No 4.04.01.02.03 Has management appointed specific management representatives who have responsibilities for OHS? Yes 4.04.01.02.04 Do these representatives have the responsibility to ensure that OHS requirements are: No 4.04.01.02.05 - Established No 4.04.01.02.06 - Implemented No 4.04.01.02.07 - Maintained No 4.04.01.02.08 Do these representatives have the responsibility to report on OHS performance for management review? Yes Comments: There are OHS personnel with accountabilities, these have not been defined for other roles/positions (i.e. managers, supervisors, etc) or for contractors. Inclusion of accountabilities in position descriptions and in a contractor management system may provide a means for compliance. No 4.04.02 Training and competency No 4.04.02.00.01 Is there a training matrix that details training required to perform work competently? Yes 4.04.02.00.02 Is OHS training included in that matrix? Yes 4.04.02.00.03 Are personnel assessed as competent based on their: Yes 4.04.02.00.04 - Education Yes 4.04.02.00.05 - Training Yes 4.04.02.00.06 - Experience Yes 4.04.02.00.07 Is the training requirements considered for contractors over whichthe organisation has control or influence? No 4.04.02.00.08 Is training carried out by a person who has appropriate knowledge, skills, and experience in OHS and training? Yes 4.04.02.00.09 Is there an induction that includes OHS responsibilities and applies to: Yes

- 5. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.04 Implementation Page 5 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.04.02.00.10 - Existing personnel Yes 4.04.02.00.11 - New Personnel Yes 4.04.02.00.12 - Contractors No 4.04.02.00.13 - Visitors No Comments: There is no contractor control/review procedures and competency of contractors is not considered. I contractor management policy/procedure where safety critical training is considered may provide a means for compliance. No 4.04.03 Consultation,communicationand reporting No 4.04.03.01 Consultation 4.04.03.01.01 Are the documented procedures for OHS consultation? Yes 4.04.03.01.02 Is consultation recorded and OHS issues tracked? Yes 4.04.03.01.03 Havethese been agreed to by the workers? Yes 4.04.03.01.04 Are workers given adequate opportunity and encouragement to participate in OHS matters? Yes 4.04.03.01.05 Haveworkers: Yes 4.04.03.01.06 - Been involved in the development, implementation and review of policies and procedures for hazard and risk assessment Yes 4.04.03.01.07 - Been consulted on changes that affect OHS inthe workplace Yes 4.04.03.01.08 - Haveselected representation in accordance with legislative requirements Yes 4.04.03.01.09 - Been informed as to the consultation process and safety representatives (if safety representatives are applicable) O Yes O No 4.04.03.01.10 Where there are committees and safety representatives, have they been trained in accordance with legislation? O Yes O No Comments: 4.04.03.02 Communication 4.04.03.02.01 Is there a means to receive OHS information from workers and to provide feedback to them? Yes Comments: 4.04.03.03 Reporting 4.04.03.03.01 Are there procedures for the reporting of: Yes 4.04.03.03.02 - OHS performance reporting (including results of OHS audits and reviews) Yes 4.04.03.03.03 - Reporting of incidents and system failures Yes 4.04.03.03.04 - Reporting on hazard identifications Yes 4.04.03.03.05 - Reporting on hazard/risk assessment Yes 4.04.03.03.06 - Reporting on preventive and corrective action Yes 4.04.03.03.07 - Statutory reporting requirements Yes 4.04.03.03.08 Are incidents reported in accordance with AS 1885.1 or as required by legislation? No Comments: 4.04.04 Documentation 4.04.04.01 Is there a means (paper or electronic) to: Yes 4.04.04.02 - Describe the core elements of the management system and their interaction Yes 4.04.04.03 - Provide direction to related documentation. Yes Comments: 4.04.05 Documentand datacontrol No 4.04.05.01 Are there procedures to ensure that all relevant documentation is: No 4.04.05.02 - Readily accessible No 4.04.05.03 - Periodically reviewed Yes 4.04.05.04 - Approved for adequacy by competent and responsible personnel Yes 4.04.05.05 - Current, with all obsolete materials removed from points of issue No 4.04.05.06 - Archived where necessary for reference or legal purposes Yes 4.04.05.07 - Legible and dated for version and revision control Yes 4.04.05.08 - Only created or changed under appropriate approval Yes Comments: There is no means of making OHS information readily available to contractors and visitors. There is also some old forms identified as in use. A systems where forms and policies/procedures are kept that is readily accessible to personnel (e.g. intranet) may assist in compliance. No 4.04.06 Hazard identification,hazard/riskassessmentand control ofhazards/risks No 4.04.06.01 General Hazard/Risk Requirements 4.04.06.01.01 Are there established, implemented and maintained documented procedures for: Yes 4.04.06.01.02 - Hazard identification Yes 4.04.06.01.03 - Hazard/risk assessment Yes 4.04.06.01.04 - Control of hazards/risks Yes 4.04.06.01.05 - Evaluation of effectiveness of these steps Yes Comments: 4.04.06.02 Hazard identification No 4.04.06.02.01 Do hazard identification procedures take into account: Yes 4.04.06.02.02 - The situation or events or combination of circumstances that has the potential to give rise to injury or illness Yes 4.04.06.02.03 - The nature of potential injury or illness relevant to the activity, product or service Yes

- 6. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.04 Implementation Page 6 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.04.06.02.04 - Past injuries, incidents and illnesses Yes 4.04.06.02.05 Does the hazard identification process include consideration of the: No 4.04.06.02.06 - Way work is organized, managed, carried out and any changes that occur in this Yes 4.04.06.02.07 - Design of workplaces, work processes, materials, plant and equipment Yes 4.04.06.02.08 - Fabrication, installation and commissioning and handling and disposal (of materials, workplaces, plant and equipment) Yes 4.04.06.02.09 - Purchasing of goods and services Yes 4.04.06.02.10 - Contracting and subcontracting of plant, equipment, services and labour including contract specification and responsibilities to and by contractors No 4.04.06.02.11 - Inspection, maintenance, testing repair and replacement (of plant and equipment) Yes Comments: Contractors are not considered in hazard identification. A contractor management policy/procedure enabling contractors to report hazards may provide a means for compliance. No 4.04.06.03 Hazard/risk assessment No 4.04.06.03.01 Are controls applied based on the level of risk that they will mitigate i.e. most effective control applied first? Yes 4.04.06.03.02 Do hazard/risk assessments consider that arise in: Yes 4.04.06.03.03 - Normal operating conditions Yes 4.04.06.03.04 - Abnormal operating conditions (e.g. shut-down, start-up, inclement weather, misuse) Yes 4.04.06.03.05 - Incidents and emergency situations Yes 4.04.06.03.06 - Past, current and planned activities Yes 4.04.06.03.07 Is there a documented hazard identification/reporting system and are records kept? No 4.04.06.03.08 Is there a documented risk assessment system and are records kept? Yes 4.04.06.03.09 Do risk assessments contribute to organisational targets and goals? Yes 4.04.06.03.10 Do OHS management plans include risk assessment and hazard reporting? Yes 4.04.06.03.11 Are workers consulted on the results of risk assessments and d hazard reporting? Yes 4.04.06.03.12 Are workers undertaking risk assessment trained in risk assessment techniques? Yes Comments: Not all hazards are reported or documented. Although hazard reporting is mentioned in policy there isn't a documented process for reporting and documenting the hazard or the action taken to resolve it. No 4.04.06.04 Control of hazards/risks No 4.04.06.04.01 Is a hierarchy of controls used? Yes 4.04.06.04.02 Is the hierarchy in the following order; Eliminate; Substitute; Isolate; Engineering; Administrative; PPE? Yes 4.04.06.04.03 Are controls identified at the design stage of the product? Yes 4.04.06.04.04 Is the requirement to comply with OHS legislation and relevant Standards considered? Yes 4.04.06.04.05 Where there are work instructions have they been developed in consultation with persons competent in the work? Yes 4.04.06.04.06 Is there a Permit to Work system for high risk tasks (Work at height, confined space, etc)? Yes 4.04.06.04.07 Is PPE considered? Yes 4.04.06.04.08 Is training considered? Yes 4.04.06.04.09 Is their appropriate worker supervision relative to the workers capabilities? Yes 4.04.06.04.10 Is there a maintenance schedule for plant/equipment that includes inspections, maintenance, repairs and alterations? Yes 4.04.06.04.11 Are there appropriate controls for plant/ equipment that is in the process of being maintained? Yes 4.04.06.04.12 Are there procedures for unsafe plant/equipment to be identified and withdrawn from service? Yes 4.04.06.04.13 Is there a process for plant/equipment isolation? No 4.04.06.04.14 Where training is required are there procedures to ensure only trained personnel undertake a task? Yes Comments: There is no isolation process for plant under maintenance or that is out of service. A policy/procedure with the necessary tagging system may provide a means for compliance. No 4.04.06.05 Evaluation No 4.04.06.05.01 Is there a process in place that control measures are reviewed: Yes 4.04.06.05.02 - On a regular basis Yes 4.04.06.05.03 - When there has been a failure Yes 4.04.06.05.04 - Givena change in the work process Yes 4.04.06.05.05 - Givena change in OHS policy Yes 4.04.06.05.06 Is there a process to monitor and review the safety performance of contractors? No Comments: The safety performance of Contractors is not considered in hazard identification. A contractor management policy/procedure enabling contractors to report hazards may provide a means for compliance. No 4.04.07 Emergencypreparednessand response No 4.04.07.01 Havepotential emergency situations been identified? No 4.04.07.02 Are there emergency procedures documented for preventing and mitigating associated illness and injury? Yes 4.04.07.03 Is there a method of review of emergency preparedness and response procedures? Yes 4.04.07.04 Does it include review after the occurrence of incidents or emergency situations? Yes 4.04.07.05 Are the emergency procedures tested periodically i.e. drills and preparedness testing? No 4.04.07.06 Are there responsibilities allocated to specific personnel for control of emergency situations? No 4.04.07.07 Havethese responsibilities been communicated to these personnel? No 4.04.07.08 Has relevant training been identified and have these personnel undertaken such training? No

- 7. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.05 Measurement and evaluation Page 7 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.04.07.09 Haveemergency instructions and emergency contacts been clearly communicated throughout the organisation? No 4.04.07.10 Is emergency equipment, exit signs and alarm systems inspected, tested and maintained at regular intervals? No 4.04.07.11 Has the location and accessibility of emergency equipment been assessed by competent persons? No Comments: There is an emergency policy but no detailed and documented procedures for what to do in emergencies. With multiple sites, each site should have a relevant emergency management plan. No 4.05 Measurement and evaluation No 4.05.01 Monitoring andMeasurement No 4.05.01.01 General Monitoring and Measurement 4.05.01.01.01 Has the organisation established and implemented documented procedures to monitor and measure the operations and activities that can cause illness and injury? Yes 4.05.01.01.02 Is appropriate equipment for monitoring and measuring health and safety risks: Yes 4.05.01.01.03 - Identified Yes 4.05.01.01.04 - Calibrated Yes 4.05.01.01.05 - Maintained Yes 4.05.01.01.06 - Stored as necessary Yes 4.05.01.01.07 Does the organisation have and maintain procedures to monitor: Yes 4.05.01.01.08 - OHS Performance Yes 4.05.01.01.09 - Effectiveness of controls Yes 4.05.01.01.10 - Conformance with the organisation’s objectives and targets Yes 4.05.01.01.11 - Compliance with relevant OHS legislation Yes 4.05.01.01.12 Does monitoring consider inspections of: Yes 4.05.01.01.13 - Potentially hazardous processes to ensure that controls have been effective Yes 4.05.01.01.14 - Plant e.g. pressure vessels to ensure conformity with regulatory requirements Yes 4.05.01.01.15 - Work areas to ensure that specific site safety rules are followed Yes 4.05.01.01.16 - Work sites to ensure that controls are effective and to demonstrate the commitment of management to SMS Yes 4.05.01.01.17 - Environmental e.g. flammable gases, fire hazards Yes 4.05.01.01.18 - Personal e.g. noise dosimetry, health monitoring Yes Comments: 4.05.01.02 Health surveillance No 4.05.01.02.01 Has the organisation identified those situations where employee health surveillance is required? No 4.05.01.02.02 Are appropriate health reviews conducted? No 4.05.01.02.03 Do employees have access to their own individual results? No 4.05.01.02.04 Where specified by legislation, is the health of employees exposed to specific hazards monitored and recorded? No Comments: There is no identified process for assessing if health surveillance is necessary. A risk assessment that considers the organisations operations and work processes that requires mandatory testing e.g. exposure to noise, isocyanates; asbestos, etc may provided a basis for assessing if health surveillance is required and defining what circumstances and controls are required to either precipitate surveillance or mitigate its requirement. No 4.05.02 Incidentinvestigation,correctiveand preventiveaction 4.05.02.01 Has the organisation established procedures for: Yes 4.05.02.02 - Investigating, responding to, and taking action to minimize any harm caused from incidents Yes 4.05.02.03 - Investigating and responding to system failures Yes 4.05.02.04 - Initiating and completing appropriate corrective and preventive action Yes 4.05.02.05 - Identifying the root causes of incidents Yes 4.05.02.06 - Implementing or modifying controls necessary to avoid repetition of the incident Yes 4.05.02.07 - Recording any changes in written procedures resulting from the corrective action Yes 4.05.02.08 Does the organisation record any changes in the SMS resulting from incident investigations? Yes 4.05.02.09 Are there escalations in the level of investigation based on risk? Yes 4.05.02.10 Do investigations include frontline managers and supervisors? Yes 4.05.02.11 Are there personnel trained in incident investigation? Yes 4.05.02.12 Are responsibilities assigned for implementing corrective actions to identified personnel? Yes 4.05.02.13 Are corrective actions discussed with personnel affected prior to implementation? Yes 4.05.02.14 Are corrective actions evaluated to determine their effectiveness? Yes Comments: 4.05.03 Recordsand recordsmanagement No 4.05.03.01 Is there a system for the management of OHS records? No 4.05.03.02 Does it include audits and reviews? Yes 4.05.03.03 Are OHS records: Yes 4.05.03.04 - Legible Yes 4.05.03.05 - Identifiable Yes 4.05.03.06 - Traceable to the activity Yes 4.05.03.07 Are OHS records readily retrievable and protected against damage, deterioration or loss? Yes 4.05.03.08 Are retention times established and recorded? No

- 8. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.06 Management review Page 8 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.05.03.09 Do the OHS records include: No 4.05.03.10 - External (e.g. legal) and internal (i.e. OHS performance) requirements Yes 4.05.03.11 - OHS training records Yes 4.05.03.12 - Permits to work and other employee qualification information Yes 4.05.03.13 - Process information Yes 4.05.03.14 - Product information (including composition) Yes 4.05.03.15 - Equipment information Yes 4.05.03.16 - Inspection, maintenance and calibration records Yes 4.05.03.17 - Monitoring data Yes 4.05.03.18 - Pertinent contractor and supplier information No 4.05.03.19 - Details of incidents, complaints and follow-up action Yes 4.05.03.20 - Information of emergency preparedness and response No 4.05.03.21 - Hazard identification and hazard/risk assessments Yes 4.05.03.22 - Audit results Yes 4.05.03.23 - Management reviews Yes Comments: Records management appears ad hoc, with no policy/procedure that identifies what records must be kept; for how long; and how. No 4.05.04 SafetyManagementSystemaudit No 4.05.04.01 Are there procedures for periodic SMS audits? Yes 4.05.04.02 Are these carried out by a competent person? Yes 4.05.04.03 Are the audits used to determine whether the SMS: Yes 4.05.04.04 - Conforms to the requirements of this Standard Yes 4.05.04.05 - Has been properly implemented and maintained Yes 4.05.04.06 - Is effective in meeting the organisations policies, objectives and targets for continual OHS improvement Yes 4.05.04.07 - Meets legislative requirements Yes 4.05.04.08 Are audit results: No 4.05.04.09 - Reviewed by management Yes 4.05.04.10 - Made available to employees No 4.05.04.11 Does the audit program consider the importance of the activity concerned, and the results of previous audits? Yes 4.05.04.12 Does the audit procedures include the: Yes 4.05.04.13 - Scope - Activities and areas to be considered in audits Yes 4.05.04.14 - Frequency Yes 4.05.04.15 - Methodology for how audits will be conducted Yes 4.05.04.16 - Competencies for auditors Yes 4.05.04.17 - Responsibilities and requirements for conducting audits and reporting results Yes 4.05.04.18 - Communication of audit findings Yes 4.05.04.19 Are audits conducted competently, impartially and objectively? Yes 4.05.04.20 Are internal audits conducted? Yes 4.05.04.21 Are external audits conducted? No 4.05.04.22 Is the audit process audited? No 4.05.04.23 Are auditors independent of the process being audited? Yes Comments: Audit results are not available to all employees and there are no external audits conducted of the workplace, work processes or the audit process itself. No 4.06 Management review 4.06.01 SpecificationsforManagementReviewRequirements 4.06.01.01 Is the SMS reviewedfor continuing, suitability, adequacy and effectiveness, by top management? Yes 4.06.01.02 Does this occur at identified intervals (least every two years)? Yes 4.06.01.03 Is the review documented? Yes 4.06.01.04 Where appropriate, does management suggest changes to SMS policy, objectives, responsibilities or other areas? Yes 4.06.01.05 Is the review of the SMS carried out by the level of management that defined them? Yes 4.06.01.06 Does the review include: Yes 4.06.01.07 - Result from audits Yes 4.06.01.08 - The extent to which objectives and targets have been met Yes 4.06.01.09 - The continuing suitability of the SMS inrelation changing conditions and information Yes 4.06.01.10 - Concerns of relevant interested parties Yes 4.06.01.11 Does the review also take into consideration: Yes 4.06.01.12 - Health and safety performance reports Yes 4.06.01.13 - Incident reports Yes 4.06.01.14 - Hazard identification Yes 4.06.01.15 - Statutory OHS performance Yes 4.06.01.16 - Corrective action reports Yes 4.06.01.17 - Changes to regulatory requirements Yes

- 9. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM 4.06 Management review Page 9 of 17 Total Imagination Services No. SECTION QUESTIONS Audit Response 4.06.01.18 - Changes to OHS standards Yes 4.06.01.19 - Community expectations Yes 4.06.01.20 Is the work authorised by a manager who controls the workplace? Yes Comments:

- 10. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 10 of 17 Total Imagination Services AUDIT TABLE OF RESULTS Summary ofResults Thefollowingisasummaryof complianceagainsttheauditcriteriawith the Resultscolumnasapercentageof compliance. Section Title Results 4.01 General Requirements 50.00% 4.0101 SpecificationsforGeneral Requirements 50.00% 4.02 OHS Policy 83.33% 4.0201 SpecificationsforOHSPolicyRequirements 83.33% 4.03 Planning 81.88% 4.0301 Planningidentificationof hazards,hazard/riskassessmentandcontrol of hazards/risks 87.50% 4.0302 Legal and otherrequirements 50.00% 4.0303 Objectivesandtargets 100.00% 4.0304 OHS managementplans 90.00% 4.04 Implementation 80.78% 4.0401 Structure and responsibility 44.44% 4.040101 Resources 100.00% 4.040102 Responsibilityandaccountability 33.33% 4.0402 Trainingandcompetency 72.73% 4.0403 Consultation,communicationandreporting 95.24% 4.040301 Consultation 100.00% 4.040302 Communication 100.00% 4.040303 Reporting 85.71% 4.0404 Documentation 100.00% 4.0405 Documentanddata control 71.43% 4.0406 Hazard identification,hazard/riskassessmentandcontrol of hazards/risks 90.53% 4.040601 General Hazard/RiskRequirements 100.00% 4.040602 Hazard identification 88.89% 4.040603 Hazard/riskassessment 90.91% 4.040604 Control of hazards/risks 92.86% 4.040605 Evaluation 80.00% 4.0407 Emergencypreparednessandresponse 27.27% 4.05 MeasurementandEvaluation 76.87% 4.0501 MonitoringandMeasurement 100.00% 4.050101 General MonitoringandMeasurement 100.00% 4.050102 Healthsurveillance 0.00% 4.0502 Incidentinvestigation,corrective andpreventive action 100.00% 4.0503 Recordsand recordsmanagement 76.20% 4.0504 SafetyManagementSystemaudit 85.00% 4.06 ManagementReview 100.00% 4.0601 SpecificationsforManagementReview Requirements 100.00%

- 11. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 11 of 17 Total Imagination Services AuditResults SpiderCharts Thefollowingspidergraphsshowthelevels of complianceforeachsectionsandsubsection. Thepurposeofthespider graphis to providea visual referenceforcompliance. Eachaxislinerepresentsa 10% incrementincompliancewhereas the progressionof colourfrom redto greenprovides a colorimetricdisplayi.e.as a higherpercentageincomplianceis achievedthe datalinemoves from the redregionsto the green.

- 12. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 12 of 17 Total Imagination Services TableofImprovements Thefollowingtablerelatesto thoseaudit criteriathat werenot successfullymet. Thistableformsthe basis for the followingActionsTable Section Title Compliant 4.01 General Requirements 4.0101 SpecificationsforGeneral Requirements No 4.010102 Is that SMS maintainedinaccordance withAS/NZSISO4801? No 4.02 OHS Policy 4.0201 SpecificationsforOHSPolicyRequirements No 4.020104 Doesthe policycomplywithall of the below: No 4.020111 - Communicatedtoall employees No 4.020112 - Available tointerestedparties No 4.03 Planning 4.0301 Planningidentificationof hazards,hazard/riskassessmentand control of hazards/risks No 4.030106 Do theyinclude activitiesof contractorsandsuppliersoverwhichthe organisationhas control or influence? No 4.030107 Doesthe procedure include where necessarythe following: No 4.030109 - Codesof practice and standardswhere necessary No 4.0302 Legal and otherrequirements No 4.030201 Relevanttothe OHS issuesof the organisation,doesthe organisation have a listof: No 4.030203 - Codesof practice No 4.030204 - Standards(AS/NZorISO) No 4.030206 Relevanttothe OHS issuesof the organisation,doesthe organisation have access toall of the below: No 4.030208 - Codesof practice No 4.030209 - Standards(AS/NZorISO) No 4.0304 OHS managementplans No 4.030401 Is there anOHS Managementplanthat: No 4.030402 - IdentifiesOHSresponsibilitiesforspecificpeople withinthe organisationshierarchy No 4.04 Implementation 4.0401 Structure and responsibility No 4.040102 Responsibilityandaccountability No 4.04010201 Has the organisationdefinedaccountabilitiesforall personnel with OHS responsibilities? No 4.04010202 Has the organisationdefined accountabilitiesforcontractorsover whichthe organisationhascontrol or influence? No 4.04010204 Do these representativeshave the responsibilitytoensure thatOHS requirementsare: No 4.04010205 - Established No 4.04010206 - Implemented No 4.04010207 - Maintained No 4.0402 Trainingandcompetency No 4.04020007 Is the trainingrequirementsconsideredforcontractorsoverwhich the organisationhascontrol or influence? No 4.04020012 - Contractors No 4.04020013 - Visitors No 4.0403 Consultation,communicationandreporting No 4.04030308 Are incidentsreportedinaccordance withAS1885.1 or as required by legislation? No 4.0405 Documentanddata control No

- 13. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 13 of 17 Total Imagination Services Section Title Compliant 4.040501 Are there procedurestoensure thatall relevantdocumentationis: No 4.040502 - Readilyaccessible No 4.040505 - Current,withall obsolete materialsremovedfrompointsof issue No 4.0406 Hazard identification,hazard/riskassessmentandcontrol of hazards/risks No 4.040602 Hazard identification No 4.04060205 Doesthe hazard identificationprocessincludeconsiderationof the: No 4.0406021 - Contractingand subcontractingof plant,equipment,servicesand labourincludingcontractspecificationandresponsibilitiestoandby contractors No 4.040603 Hazard/riskassessment No 4.04060307 Is there a documentedhazardidentification/reportingsystemand are recordskept? No 4.040604 Control of hazards/risks No 4.04060413 Is there a processforplant/equipmentisolation? No 4.040605 Evaluation No 4.04060506 Is there a processto monitorandreview the safetyperformance of contractors? No 4.0407 Emergencypreparednessandresponse No 4.040701 Have potential emergencysituationsbeenidentified? No 4.040705 Are the emergencyprocedurestested periodicallyi.e.drillsand preparednesstesting? No 4.040706 Are there responsibilitiesallocatedtospecificpersonnelforcontrol of emergencysituations? No 4.040707 Have these responsibilitiesbeencommunicatedtothese personnel? No 4.040708 Has relevanttrainingbeenidentifiedandhave these personnel undertakensuchtraining? No 4.040709 Have emergencyinstructionsandemergencycontactsbeenclearly communicatedthroughoutthe organisation? No 4.04071 Is emergencyequipment,exitsignsandalarmsystemsinspected, testedandmaintainedatregularintervals? No 4.040711 Has the locationand accessibilityof emergencyequipmentbeen assessedbycompetentpersons? No 4.05 MeasurementandEvaluation 4.0501 MonitoringandMeasurement No 4.050102 Healthsurveillance No 4.05010201 Has the organisationidentifiedthosesituationswhere employee healthsurveillance isrequired? No 4.05010202 Are appropriate healthreviewsconducted? No 4.05010203 Do employeeshave accesstotheirown individual results? No 4.05010204 Where specifiedbylegislation,isthe healthof employeesexposedto specifichazardsmonitoredandrecorded? No 4.0503 Recordsand recordsmanagement No 4.050301 Is there a systemforthe managementof OHSrecords? No 4.050308 Are retentiontimesestablishedandrecorded? No 4.050309 Do the OHS recordsinclude: No 4.050318 - Pertinentcontractorandsupplierinformation No 4.05032 - Informationof emergencypreparednessandresponse No 4.0504 SafetyManagement Systemaudit No 4.050408 Are auditresults: No 4.05041 - Made available toemployees No 4.050421 Are external auditsconducted? No

- 14. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 14 of 17 Total Imagination Services Section Title Compliant 4.050422 Is the auditprocessaudited? No

- 15. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 15 of 17 Total Imagination Services AuditActions TableforNon-Conformances Section and Sub-Section (Primary and Secondary) Audit Response Status Action Required Progress Report Action Controller Action Team Origin Date Due Date Review Date Date Complete 4.01 General requirements No 4.01.01SpecificationsforGeneralRequirements No 4.01.01.02Is that SMS maintainedinaccordancewithAS/NZS ISO 4801? No Comments: In the audit there were discrepanciesnotedbetweenthe organisationsSMSand the standard. These aredetailedinthe following. No 4.02 OHSPolicy No 4.02.01SpecificationsforOHSPolicyRequirements No 4.02.01.04Does the policycomplywithallof the below: No 4.02.01.11 - Communicatedtoallemployees No 4.02.01.12 - Available to interested parties No Comments: The policyhas not beencommunicatedto allemployeesis not distributedor availabletovisitors or contractors. No 4.03 Planning No 4.03.01Planningidentificationofhazards, hazard/risk assessmentand controlof hazards/risks No 4.03.01.06Do they includeactivitiesofcontractorsandsuppliers over whichtheorganisationhascontrolorinfluence? No 4.03.01.07Does the procedureincludewherenecessarythefollowing: No 4.03.01.09 - Codesof practiceandstandardswherenecessary No Comments: Contractorsare not consideredandthere is nolist of codesof practicethat are relevantto the work beingundertaken No 4.03.02Legaland otherrequirements No 4.03.02.01Relevant to the OHSissuesof the organisation,doesthe organisationhavea list of: No 4.03.02.03 - Codesof practice No 4.03.02.04 - Standards(AS/NZ or ISO) No 4.03.02.06Relevant to the OHSissuesof the organisation,doesthe organisationhaveaccessto allof the below: No 4.03.02.08 - Codesof practice No 4.03.02.09 - Standards(AS/NZ or ISO) No Comments: There is nolist of codesor standards andno evidencethat all relevantcodes andstandardshave beenconsidered. A compliance registerthat shows how the SMS meets the relevant legislation,including codesand standards,may assist inshowing compliance. No 4.03.04OHS managementplans No 4.03.04.01Is there anOHS Managementplanthat: No 4.03.04.02 - IdentifiesOHS responsibilitiesforspecific peoplewithinthe organisationshierarchy No Comments: There areno accountabilitiesincludedinthesafety managementplan. A list or responsiblerolesandtheiraccountabilitiesand inclusionof theseaccountabilitiesinthe relevantpositiondescriptionsmay provideappropriateevidenceforcompliance. No 4.04 Implementation No 4.04.01Structure andresponsibility No 4.04.01.02Responsibilityandaccountability No 4.04.01.02.01Has the organisationdefinedaccountabilitiesforall personnelwithOHSresponsibilities? No 4.04.01.02.02Has the organisationdefinedaccountabilitiesforcontractors over whichtheorganisationhascontrolorinfluence? No 4.04.01.02.04Do theserepresentatives have the responsibilityto ensure that OHS requirementsare: No 4.04.01.02.05 - Established No

- 16. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 16 of 17 Total Imagination Services Section and Sub-Section (Primary and Secondary) Audit Response Status Action Required Progress Report Action Controller Action Team Origin Date Due Date Review Date Date Complete 4.04.01.02.06 - Implemented No 4.04.01.02.07 - Maintained No Comments: There areOHS personnelwith accountabilities,thesehavenot beendefinedfor other roles/positions(i.e. managers,supervisors,etc) or for contractors. Inclusionof accountabilitiesinpositiondescriptionsandin a contractor managementsystem may providea meansfor compliance. No 4.04.02Trainingandcompetency No 4.04.02.00.07Is the trainingrequirementsconsideredforcontractorsover whichtheorganisationhascontrolorinfluence? No 4.04.02.00.12 - Contractors No 4.04.02.00.13 - Visitors No Comments: There is nocontractor control/reviewprocedures and competencyof contractorsis not considered. I contractor management policy/procedurewheresafety critical trainingis consideredmayprovidea meansfor compliance. No 4.04.03Consultation,communicationandreporting No 4.04.03.03.08Are incidentsreportedinaccordancewithAS 1885.1 or as requiredby legislation? No 4.04.05Documentanddatacontrol No 4.04.05.01Are there procedurestoensurethat allrelevant documentation is: No 4.04.05.02 - Readilyaccessible No 4.04.05.05 - Current, withall obsoletematerialsremovedfrom pointsof issue No Comments: There is nomeans of makingOHS informationreadily availabletocontractors and visitors. There is alsosome oldforms identifiedas inuse. A systems where forms and policies/proceduresare kept that is readilyaccessibletopersonnel(e.g. intranet)may assist in compliance. No 4.04.06Hazard identification,hazard/riskassessmentandcontrolof hazards/risks No 4.04.06.02Hazard identification No 4.04.06.02.05Doesthe hazard identificationprocessincludeconsideration of the: No 4.04.06.02.10 - Contractingandsubcontractingofplant,equipment, servicesand labourincludingcontractspecificationandresponsibilitiesto andby contractors No Comments: Contractorsare not consideredinhazardidentification. A contractor managementpolicy/procedureenablingcontractorstoreport hazardsmay providea means for compliance. No 4.04.06.03Hazard/risk assessment No 4.04.06.03.07Is therea documentedhazardidentification/reportingsystem andare recordskept? No Comments: Not allhazardsare reportedor documented. Althoughhazard reportingis mentionedinpolicythere isn't a documentedprocessfor reportinganddocumentingthe hazardor the actiontaken to resolve it. No 4.04.06.04Controlof hazards/risks No 4.04.06.04.13Is therea processfor plant/equipmentisolation? No Comments: There is noisolationprocessfor plantundermaintenanceor that is out of service. A policy/procedurewith the necessarytagging system may provideameans for compliance. No 4.04.06.05Evaluation No 4.04.06.05.06Is therea processto monitorandreview the safety performanceofcontractors? No

- 17. AUDIT_4801 OCCUPATIONAL HEALTH & SAFETY MANAGEMENT SYSTEM AUDIT TABLE OF RESULTS Page 17 of 17 Total Imagination Services Section and Sub-Section (Primary and Secondary) Audit Response Status Action Required Progress Report Action Controller Action Team Origin Date Due Date Review Date Date Complete Comments: The safety performanceof Contractorsis not consideredin hazardidentification. A contractor managementpolicy/procedure enabling contractors to report hazardsmay providea means for compliance. No 4.04.07Emergencypreparednessandresponse No 4.04.07.01Have potentialemergencysituationsbeenidentified? No 4.04.07.05Are the emergencyprocedurestestedperiodicallyi.e. drillsand preparednesstesting? No 4.04.07.06Are there responsibilitiesallocatedtospecific personnelfor controlof emergencysituations? No 4.04.07.07Have theseresponsibilitiesbeencommunicatedtothese personnel? No 4.04.07.08Has relevant trainingbeenidentifiedandhave these personnel undertakensuchtraining? No 4.04.07.09Have emergencyinstructionsandemergencycontactsbeen clearlycommunicatedthroughouttheorganisation? No 4.04.07.10Is emergencyequipment,exitsignsand alarm systems inspected,testedand maintainedatregularintervals? No 4.04.07.11Has the locationandaccessibilityof emergencyequipment beenassessedby competentpersons? No Comments: There is anemergencypolicybut no detailedanddocumented proceduresfor what to do in emergencies. Withmultiple sites, each site shouldhavea relevantemergencymanagementplan. No 4.05 Measurementand evaluation No 4.05.01MonitoringandMeasurement No 4.05.01.02Healthsurveillance No 4.05.01.02.01Has the organisationidentifiedthosesituationswhere employeehealthsurveillanceisrequired? No 4.05.01.02.02Are appropriatehealthreviews conducted? No 4.05.01.02.03Do employeeshave accessto their ownindividualresults? No 4.05.01.02.04Where specifiedbylegislation,isthe healthof employees exposedto specific hazardsmonitoredandrecorded? No Comments: There is noidentifiedprocessfor assessingif health surveillanceisnecessary. A risk assessment that considersthe organisationsoperationsandwork processesthat requiresmandatory testing e.g. exposureto noise, isocyanates;asbestos, etc may providea basisfor assessingif healthsurveillance isrequiredanddefiningwhat circumstancesand controlsare requiredto eitherprecipitatesurveillanceor mitigateits requirement. No 4.05.03Recordsandrecordsmanagement No 4.05.03.01Is there a system for the managementofOHSrecords? No 4.05.03.08Are retentiontimes establishedandrecorded? No 4.05.03.09Do the OHSrecordsinclude: No 4.05.03.18 - Pertinentcontractorandsupplierinformation No 4.05.03.20 - Informationof emergencypreparednessandresponse No Comments: Recordsmanagementappearsadhoc, with no policy/procedurethatidentifieswhat recordsmust bekept; for how long; andhow. No 4.05.04Safety ManagementSystem audit No 4.05.04.08Are audit results: No 4.05.04.10 - Madeavailableto employees No 4.05.04.21Are externalaudits conducted? No