The IMD Equipment Guides

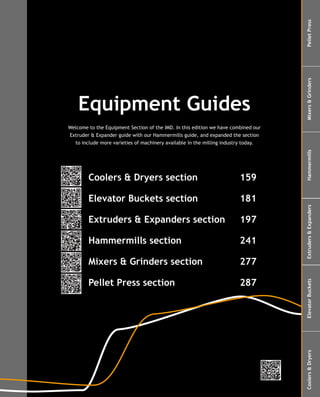

- 1. Pellet Press Mixers & Grinders Equipment Guides Welcome to the Equipment Section of the IMD. In this edition we have combined our Extruder & Expander guide with our Hammermills guide, and expanded the section to include more varieties of machinery available in the milling industry today. Hammermills Coolers & Dryers section 159 Elevator Buckets section 181 Extruders & Expanders Extruders & Expanders section 197 Hammermills section 241 Mixers & Grinders section 277 Pellet Press section 287 Elevator Buckets Equipment Guides Coolers & Dryers International Milling Directory 2011/12 | 157

- 2. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Extruder & Expander Guide 158 | International Milling Directory 2011/12

- 3. Pellet Press Mixers & Grinders Hammermills Extruders & Expanders Elevator Buckets Coolers and Dryers Guide Coolers & Dryers This section contains comparison charts for the major Coolers and Dryers manufacturers International Milling Directory 2011/12 | 159

- 4. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Consergra F40 F160TD F250TD F450TD 250 450 Cooling capacity (tonnes/24 hours) 40 minimum 160 minimum minimum minimum Drying to 20-15% (tonnes/24 hours) Drying capacity (tonnes/24 hours) Dimensions (height/width/length Power requirement - Electrical power (kw) Power requirement - Motors Power requirement - Burners 160 | International Milling Directory 2011/12 Flexible connection tube ✔ ✔ ✔ ✔ Tyres (instead of caster wheels) ✔ ✔ ✔ ✔ Dust filter ✔ ✔ ✔ ✔ Weather protection roof ✔ ✔ ✔ ✔ Sound isolation for suction filter ✔ ✔ ✔ ✔ Casing ✔ ✔ ✔ ✔

- 5. Protection grid against animals ✔ ✔ ✔ ✔ Winter and summer thermostat ✔ ✔ ✔ ✔ Programmable control ✔ ✔ ✔ ✔ Electrical heating ● ● ● ● Start-up - briefing ✔ ✔ ✔ ✔ Rotary-field monitoring (message) ✔ ✔ ✔ ✔ Signal lamp ✔ ✔ ✔ ✔ Condenser broom ● ● ● ● Fork-lift slots ✔ ✔ ✔ ✔ ● =Optional ✔ = Yes / ✘ = No Unit supports - lockable (4 pcs.) ● ● ● ● Cable support ✘ ✘ ✘ ✘ 2 Telesensors- without ex-protection ● ● ● ● International Milling Directory 2011/12 | 161 Company name Consergra Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 6. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Delux Mfg Co Cooling capacity (tonnes/24 hours) up to 3,360 Drying to 20-15% (tonnes/24 hours) Drying capacity (tonnes/24 hours) Dimensions (height/width/length Power requirement - Electrical power (kw) Power requirement - Motors Power requirement - Burners 162 | International Milling Directory 2011/12 Flexible connection tube • Tyres (instead of caster wheels) Dust filter ✘ Weather protection roof ✔ Sound isolation for suction filter ✔ Casing ●

- 7. Protection grid against animals ✔ Winter and summer thermostat ✔ Programmable control ✔ Electrical heating ✘ Start-up - briefing • Rotary-field monitoring (message) • Signal lamp • Condenser broom ✘ Fork-lift slots Lifting Hooks ● =Optional ✔ = Yes / ✘ = No Unit supports - lockable (4 pcs.) Cable support Not Required 2 Telesensors- without ex-protection International Milling Directory 2011/12 | 163 Delux Mfg Co Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 8. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Frigortec KK 80 AHY (with HYGROMATTM) KK 145 AHY (with HYGROMATTM ) KK 160 Tropic (with HYGROMATTM) KK 200 AHY (with HYGROMATTM ) KK 280 AHY (with HYGROMATTM ) KK 280 Tropic (with HYGROMATTM) KK 400 AHY (with HYGROMATTM ) KK 400 Tropic (with HYGROMATTM) Cooling capacity (tonnes/24 hours) 65 – 120 130– 170 160 – 270 180 – 330 270 – 450 280 – 470 395 –630 415 – 630 Drying to 20-15% (tonnes/24 hours) Drying capacity (tonnes/24 hours) - - - - - - - - Dimensions (height/width/length Power requirement - Electrical power (kw) Power requirement - Motors Power requirement - Burners 164 | International Milling Directory 2011/12 Ø 300 mm Ø 300 mm Ø 400 mm Ø 400 mm Ø 400 mm Ø 400 mm Ø 600 mm Ø 600 mm Flexible connection tube 3000 mm 3000 mm 3000 mm 3000 mm 3000 mm 3000 mm 5000 mm 5000 mm length length length length length length length length single axle single axel single axel single axel bi-axial with bi-axial with bi-axial with bi-axial with Tyres (instead of caster wheels) with draw with draw with draw with draw steering steering steering steering shaft shaft shaft shaft shaft shaft shaft shaft 1 set pocket 1 set pocket Dust filter 1 filter 1 filter 1 filter 1 filter 1 filter 1 filter filter filter Weather protection roof ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Sound isolation for suction filter ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Casing ● ● ✔ ✔ ● ✔ ● ✔

- 9. Protection grid against animals ✘ ✘ ● ● ● ● ✘ ✘ summer- summer- summer Winter and summer thermostat ✔ ✔ ✔ ✔ on request thermostat thermostat thermostat Programmable control ✔ ✔ Siemens S7 Siemens S7 Siemens S7 Siemens S7 on request on request Electrical heating ✔ ✔ ● ✔ ✔ ● ✔ ● Start-up - briefing ● ● ● ● ● ● ● ● Rotary-field monitoring (message) ● ● ✔ ✔ ✔ ✔ ✔ ✔ Signal lamp ✘ ✘ ● ● ● ● ✘ ✘ Condenser broom ● ● ● ● ● ● ● ● Fork-lift slots ● ● ● ● ● ● ● ● ● =Optional ✔ = Yes / ✘ = No Unit supports - lockable (4 pcs.) ✘ ● ● ● ✘ ✘ ✘ ✘ Cable support ● ● ● ● ● ● ● ● 2 Telesensors- without ex-protection ✘ ✘ ● ● ● ✘ ✘ ✘ International Milling Directory 2011/12 | 165 Frigortec Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 10. Frigortec GmbH FRIGORTEC GmbH PROFILE The GRANIFRIGORTM grain cooling system was developed together with the University Düsseldorf/ Germany and since then the grain cooling units have been built in series. From 2003 onwards the GRANIFRIGORTM exists in its 3rd generation and has already been supplied in more than 70 countries. Grain cooling with the GRANIFRIGORTM - system is the most natural, safe and efficient way of grain preservation. Several thousands of GRANIFRIGORTM units, successfully in operation, are cooling wheat, barley, maize, rape seed, rye, mixed feed, oats, rice, soy bean, peas, potatoes, grass seeds, paddy, millet, cacao beans, coffee beans, etc. The product series include 8 various unit sizes. The biggest unit is designed for storage capacities of more than 10,000 tons. For tropic regions, we offer a special tropic-unit type. On request, all units are also available for different voltages 50/ 60 Hz, 220/ 400/ 440V. Ad- ditional equipment can be ordered like a modular system. If needed, the GRANIFRIGORTM grain coolers can be equipped with a programmable control (direct digital control DDC), or with a conventional safety circuit. Our employees - skilled specialists in the field of refrigeration engineering, electrics and machine engineering - in our own production in Amtzell / GERMANY are manufacturing cooling units and heat pumps. Quality is FrigorTec’s main subject. Each device passes through a quality inspection with multi-stage test runs according to our quality-management system. In this way, each prod- uct is tested under its individual conditions relevant to the installation, to ensure that it fulfils in reality its purpose: namely to provide reliable cooling. FrigorTec GmbH is certified according to DIN EN ISO 9001:2000. 166 | International Milling Directory 2011/12

- 11. Grain cooling GRANIFRIGOR ™ The most natural way of grain preservation: • Protection against insects and microbes • Without chemical treatment • Short amortisation period • Low energy costs • Independent of ambient weather conditions Fr i g o r Te c G m b H • H u m m e l a u 1 • 8 8 2 7 9 A m t ze l l / G e r m a n y Tel.: +49 7520/91482-0 • Fax: +49 7520/91482-22 • E-Mail: info@frigortec.de www.frigortec.com International Milling Directory 2011/12 | 167

- 12. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Mathews Company - Legacy Series Specifications-Corn L1250 L1350 L2250 L2650 L2700 L3100 L3105 L4145 L5175 Holding capacity 16.6 25.0 31.7 35.8 35.8 46.5 46.5 57.3 68.1 Grain Column Thickness (cm) 30.5 30.5 30.5 30.5 30.5 30.5 30.5 30.5 30.5 Grain Column Length (m) 4.9 7.3 7.3 7.3 7.3 7.3 7.3 7.3 7.3 168 | International Milling Directory 2011/12 Burner Capacity (heat + cool, kW thermal) 962 1160 2180 3019 3019 4808 4942 4185 5579 Burner Capacity (all heat, kW thermal) 1464 2049 3086 3946 3946 5848 5813 6453 7847 Number of fans 2 2 3 3 4 4 6 6 7 Total fan motor size (kW) 18.8 26.3 41.3 48.8 52.5 75.0 78.8 108.8 131.3 Level Auger Motor Size (kW) 2.3 3.8 3.8 3.8 3.8 3.8 3.8 7.5 7.5 Unload Auger Motor Size (kW) 1.1 1.1 1.1 2.3 2.3 2.3 2.3 2.3 2.3 Overall Height (m) 5.3 5.3 6.9 7.8 7.8 10.2 10.2 12.6 15.1 Overall length (m) 7.5 9.9 10.8 11.2 11.2 11.2 11.2 11.2 11.2

- 13. Overall width (m) 2.3 2.3 2.3 2.5 2.5 2.5 2.5 2.5 2.5 Electrical load (380V/3PH/50HZ, Amps) 72 Amps 93 Amps 124 Amps 143 Amps 156 Amps 207 Amps 210 Amps 271 Amps 327 Amps Capacity (shelled corn, heat+cool 6.5 9.5 15.0 17.1 18.6 25.6 29.1 31.4 40.7 25% - 15% w.b, metric tonnes/hr) Capacity (shelled corn, heat+cool 10.0 14.6 23.5 26.3 28.6 39.5 44.2 53.5 68.0 20% - 15% w.b, metric tonnes/hr) Capacity (shelled corn, heat+cool 11.6 17.0 24.2 27.2 29.5 34.6 37.1 38.8 48.3 25% - 15% w.b, metric tonnes/hr) Capacity (shelled corn, heat+cool ● =Optional 14.3 21.3 30.2 34.2 37.0 43.0 45.8 57.0 70.90 22% - 15% w.b, metric tonnes/hr) ✔ = Yes / ✘ = No Capacity (shelled corn, heat+cool 16.9 25.1 39.3 44.0 47.4 54.6 70.2 86.0 97.6 20% - 15% w.b, metric tonnes/hr) *Note: Capacities in metric tonnes per hour are based on a grain bulk density of 661 kg/m3. The information is intended to assist end users in selecting the grain drying system that they believe best meets their unique preferences and needs. The performance figures and capacities presented herein are only estimates, based on calculated simulations, and do not constitute express or implied warranties. Many factors influence the grain drying process, including ambient temperature, relative humidity, grain variety, grain quality, grain temperature, dryer operating temperatures, dryer add-ons and accessories, and dryer condition, maintenance and operation. At Mathews Company, we continually to strive to improve our products. Accordingly, changes may occur that are not reflected in the specifications and capacities shown above. International Milling Directory 2011/12 | 169 Mathews Company Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 14. Company Mathews PROFILE Mathews Company T he Mathews Company (M-C) has designed, manufactured and marketed grain dryers through- out the world for nearly 60 years. Mathews Company offers both tower and modular dryers for all crops with capacities up to 100 tonnes per hour. The grain dryers are EU certified and are offered with various fuel options such as oil, natural gas, or propane. M-C offers both modular expand- able dryers and vacuum cooled energy efficient tower dryers and are operated by M-C’s state-of-the- art Pinnacle Lite™ dryer control system. LEGACY SERIES As a central part of your grain handling and management system, an M-C Legacy Series Dryer with multiple heat zones delivers increased flexibility, fuel efficiency and higher quality grain. These modular dryers are expandable and designed with multiple drying zones that deliver increased flexibility, fuel efficiency and higher grain quality. A heavy, welded steel base provides strength and support for future expansion. All modular dryers are equipped with quiet, high air flow centrifugal fans. Adjustable Venturi gas burn- ers provide maximum combustion at all operating temperatures. A gas manifold with microprocessor controlled electronic gas proportional valve allows complete control of plenum temperature for all grain types. Regardless of outside temperature changes, a constant plenum temperature is automatically maintained. Digital readout displays plenum temperature and set point during dryer operation. TOWER SERIES Energy saving M-C Tower Series Dryers are engineered to deliver the benefits that are most important to commercial dryer operators. With fewer moving parts and vacuum cooling, M-C tower dryers raise the bar to set a new standard in simplicity, environmental acceptability, reliability and efficiency. The Tower Series dryers are manufactured with a solid, welded stainless steel base, and stainless steel sheeting. Premium Maxon burners offer efficient heat at low pressures throughout the plenum chamber, offering maximum efficiency. In -line centrifugal fan blowers deliver air volume at low RPM for maximum motor life for efficient, quiet drying. 170 | International Milling Directory 2011/12

- 15. Vacuum cooling is key to the popularity and success of the M-C tower dryers. Reclaiming heated air from cooling the grain results in less fuel usage and significant monetary savings. After blending with ambient air drawn from outside, the pre-heated air is returned to the blowers, lowering energy con- sumption and producing maximum efficiency. Easy to operate, clean and quiet, reliable and efficient, M-C Tower Series Dryers provide the best means to lower input costs and add profit. PINNACLE LITE M-C’s simple, easy to use, Pin- nacle Lite control system with “TruDry” technology has a touch screen control panel inside a remote, NEMA IV-rated control cabinet. The Pinnacle Lite system regulates heated air temperature, fuel flow, and dryer discharge con- trol’s electrical functions with clear, easy to understand operation. Four state-of-the-art RTD sensors with signal-enhanced transmission ensure accurate grain sensing. Remote monitoring capabilities are available and USB port is standard for data transfer. Only M-C dryers come with a failsafe back-up sys- tem that is simple to engage. All M-C dryers are able to operate in manual mode in the unlikely event of PLC failure. M-C grain dryers are proven per- formers! Call 800-323-7045 for a local M-C dealer. International Milling Directory 2011/12 | 171

- 16. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Muyang SKGD2000 SKGD2400 SKGD3000A SKLN14×14A SKLN19×19A SKLN28×28A SLNF16×16A SLNF22×22A SLNF32×32A Dryer ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Cooler ✘ ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Batch ✘ ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Continuous ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Crossflow ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Counterflow ✘ ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Number of product bed/desk 4 4 4 - - - - - - 172 | International Milling Directory 2011/12 Number of processing section 3/4/5/6/8 4/6/8 - 1 1 1 1 1 1 2.0-3.0/3.0- 4-7/8-11/12- Capacity(t/h) 5.0/5.0-7.0/6- 3.0-6.0 5 10 30 7.5 15 35 16 9/9-12 Air recirculated ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Electric heating ✘ ✘ ✘ ✘ ✘ ✘ ✘ ✘ ✘ Steam heating ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Spreader ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

- 17. Cleaner ✔ ✔ ✔ ✘ ✘ ✘ ✘ ✘ ✘ Tipping plate discharger ✘ ✘ ✘ ✘ ✘ ✘ ✔ ✔ ✔ Grid discharger ✘ ✘ ✘ ✔ ✔ ✔ ✘ ✘ ✘ 31.85 / 39.85 / 66.65 / 98.25 Power (kW) 47.85 / 56.25 64.5 0.75 1.1 1.5+0.75 1.5 3+0.75 5.5+0.75 / 131.05 / 70.05 Automatic processing control ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Product flow ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Air flow ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Processing time ✔ ✔ ✔ - - - - - - Temperature ✔ ✔ ✔ - - - - - - ● =Optional ✔ = Yes / ✘ = No Poultry feed ✘ ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Livestock feed ✘ ✘ ✘ ✔ ✔ ✔ ✔ ✔ ✔ Aquafeed ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Pet food ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Expanded food ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Other available model 11×11A,16×16A,22×22A,24×24A 14×14A,19×19A,24×24A,28×28A Essential ancillary equipment avaliable Complete line International Milling Directory 2011/12 | 173 Reutilized hot air, energy saving; stable Compact structure and no death Compact structure and no death running and low breakage;detachable corner; smooth and uniform discharge corner; smooth and uniform discharge Special features /additional information structure, easy to be installed and flow;little maintenance required and flow;little maintenance required and maintained. low energy cost. low energy cost. Muyang Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 18. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide Riela RIELA-Drier GDT 240 RIELA-Drier GDT 300 174 | International Milling Directory 2011/12 5/1 10/2 15/2 12/2 16/2 20/3 24/3 28/2 Capacity of Drier (t) 12,1 22,2 30,2 28,5 38,9 49,4 57.2 62.3 Electrical power capacity (kW) 10 18 26 26 36,5 49 57 65 Amount of air (m³/h) 22500 45000 67500 67500 90000 112500 135000 157500 Drying chamber height (m) 7,12 11,10 14,42 12,42 15,07 18,3 21,05 23,04 stationary with heat exchanger power (kW) 300 1000 1000 1000 1500 1500 2000 3000 without heat exchanger power (kW) 550 1150 1500 1500 2000 2860 3200 4000

- 19. Capacity for wheat-drying with reduction of moisture level from 19 % to 15 % with heat exchanger power t/h (t/d) 5 (120) 16 (384) 16,5 (396) 16,5 (396) 27 (648) 27 (648) 35 (840) 50 (1200) without heat exchanger power t/h (t/d) 7,5 (180) 19 (456) 24 (576) 24 (576) 31 (744) 42 (1008) 50 (1200) 60 (1440) with heat exchanger power t/h (t/d) 3,3 (79) 11 (264) 11,5 (276) 11,5 (276) 19 (456) 19 (456) 25 (600) 33,3 (800) without heat exchanger power t/h (t/d) 50 (120) 12,6 (302) 16,5 (396) 16,5 (396) 21 (504) 28,2 (677) 35 (840) 42 (1008) Capacity for maize-drying with reduction of moisture level from 30 % to 15 % with heat exchanger power t/h (t/d) 1,3 (31) 4 (96) 4,5 (108) 4,5 (108) 6,6 (158) 6,6 (158) 8,8 (211) 13,3 (319) without heat exchanger power t/h (t/d) 2,4 (57) 5,2 (125) 6,8 (163) 6,8 (163) 8,2 (196) 12 (288) 14,2 (340) 17 (408) The maximum air temperatur for drying: wheat 90°C, rape 75°C, maize 130°C. The above cited figures refer to the following parameters: outside temperature 15°C, air humidity 75%, grain mature and clean, drier in continuous operation. The manufacturer reserves the right to make technical alterations. The specifications for each drier may be amended and adjusted to individual requirements. Higher capacities on request. International Milling Directory 2011/12 | 175 Riela Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 20. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide ZCME (Dryers) SHGW120X2 SHGW180X2 SHGW180X2+2 SHGW240X2 SHGW240X2+2 SHGW240X2+4 SHGW300X2 SHGW300X2+2 SHGW300X2+4 Drier capacity(T/H) 1-3 2-4 3-5 3-5 5-8 6-8 5-6 5-8 8-10 Heat recyclable ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Heater mode-steam ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Inner heater ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Punch caterpillar ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ caterpillar Frequency ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ 176 | International Milling Directory 2011/12 caterpillar width 1200mm 1800mm 1800mm 2400mm 2400mm 2400mm 3000mm 3000mm 3000mm Drier time 8m 8m 12m 8m 12m 16m 8m 12m 16m Caterpillar Drier measure 19.2m2 28.8m2 43.2m2 38.4m2 57.6m2 76.8m2 48m2 57.6 96m2 "Feeding device swinging ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Cleaning Screw-auger ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Temperature Automatic control ● ● ● ● ● ● ● ● ● Air inlet ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

- 21. Air outlet ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Main power 28Kw 36Kw 52Kw 48Kw 62Kw 94Kw 66Kw 96Kw 126Kw Poultry & Livestock feed ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Aquatic feed ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Pet feed ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Food ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Customer training ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ● =Optional "Pilot plant facility /Product development ✔ = Yes / ✘ = No Service support ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ International Milling Directory 2011/12 | 177 ZCME Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 22. Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press Coolers & Dryers Guide ZCME (Coolers) 178 | International Milling Directory 2011/12 SKLN1.5/SKLB1.5 SKLN2.5/SKLB2.5 SKLN4/SKLB4 SKLN6/SKLB4 SKLN8/SKLB8 SKLN10/SKLB10 SKLN15 SKLB12 Capacity(t/h) 3 5 10 15 20 25 35 30 Cooler form Counter-flow & Swinging Counter-flow Cooler volume(m3) 1.5 2.5 4 6 8 10 15 12 Cooling time(min) no less than 6-10 Cooled feed temerature(℃) 3-5℃ above the room temperature(maximum) Air capacity(m3/min) 34 34 34 34 34 34 34 34 Discharge system(kw) 0.75 0.75 1.5 1.5 1.5 1.5 2.2 2.2

- 23. Evener Device ✔ ✔ ✔ ✔ 0.37 0.37 0.37 ✔ Feedr Power(kw) 0.55 0.55 0.55 0.55 1.5 1.5 1.5 Rotary Air closed Feeder ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Temperature Automatic control • • • • • • • • ● =Optional Services key ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ = Yes / ✘ = No ST – Training of customers’ staff ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ Pilot plant facility /Product development ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ International Milling Directory 2011/12 | 179 ZCME Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 24. Pellet Press Coolers & Dryers related listings Mixers & Grinders Hammermills Coolers Coolers/Dryers control systems Brambati Group Andritz Feed & Biofuel (UK) COMESSA B N W Industries Export Department Condex (UK) Ltd Datastor Systems Ltd FrigorTec GmbH Intelscan GEA Barr-Rosin Zhengchang Group (ZCME) SABE Coolers/Dryers counterflow Extruders & Expanders Coolers/Dryers CPM Wolverine Proctor Andritz Feed & Biofuel Dinnissen BV B N W Industries (Indiana) Geelen Counterflow COMESSA JS Conwell Ltd - Buhlermillbank CPM Wolverine Proctor CPM Wolverine Proctor Ltd Coolers/Dryers grain Delux Mfg Co Anderson International Corp Dinnissen BV Consergra s l GEA Barr-Rosin CPM Wolverine Proctor GEA Barr-Rosin Ltd Delux Mfg Co Geelen Counterflow FrigorTec GmbH ISF Ltd Mathews Company Muyang Group Tornum AB Elevator Buckets Orthos Engineering Ltd Coolers/Dryers horizontal Ottevanger Milling Engineers B V B N W Industries Export Department Riela Karl-Heinz Knoop CPM Wolverine Proctor Sogem Energis Lodige Maschinenbau GmbH Stela-Laxhuber GmbH Teco Dryer Coolers/Dryers vertical TSC BV JS Conwell Ltd - Buhlermillbank Wenger Manufacturing Inc Wynveen International B V Coolers & Dryers

- 25. Pellet Press Mixers & Grinders Hammermills Extruders & Expanders Elevator Buckets Guide This section contains comparison charts for the major Elevator Bucket manufacturers Elevator Buckets Coolers & Dryers International Milling Directory 2011/12 | 181

- 26. 182 | International Milling Directory 2011/12 Coolers & Dryers 9x5 9 x 4.5 9x4 8x7 8.5 x 4 8 x 6.5 8x6 8 x 5.5 8x5 8 x 4.5 8x4 7.5 x 5.5 7.5 x 5 7 x 5.5 7x5 7 x 4.5 4B Braime Steel ✔ Stainless Steel Elevator bucket guide Starco (S) HDP ✔ Nylon Polyurethane Steel ✔ ✔ ✔ Elevator Buckets Stainless Steel Super Starco (SS) HDP ✔ ✔ ✔ Nylon Polyurethane Starco Jumbo (SJ) Steel Steel ✔ ✔ GB / Spidex Stainless Steel HDP Extruders & Expanders ✔ ✔ ✔ ✔ CCS Nylon Polyurethane J - American Steel ✔ ✔ ✔ Grain Stainless Steel Steel ✔ ✔ G - Columbus Stainless Steel Hammermills ✔ ✔ A Steel Steel ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ B Stainless Steel Mixers & Grinders Pellet Press

- 27. 9 x 5.5 ✔ ✔ 9x6 ✔ ✔ ✔ 9 x 6.5 ✔ ✔ ✔ ✔ 9.5 x 5 ✔ 9.5 x 6.5 ✔ ✔ 10 x 4.5 ✔ 10 x 5 ✔ ✔ 10 x 5.5 ✔ 10 x 6 ✔ ✔ ✔ ✔ ✔ 10 x 6.5 ✔ 10 x 7 ✔ 10 x 8 ✔ 10 x 8.5 ✔ 10 x 10 ✔ 11 x 5 ✔ ✔ 11 x 6 ✔ ✔ 11 x 6.5 ✔ ✔ ✔ ✔ ✔ 11 x 7 ✔ ✔ ✔ ✔ 11 x 8 ✔ 11 x 8.5 ✔ International Milling Directory 2011/12 | 183 4B Braime Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 28. 184 | International Milling Directory 2011/12 Coolers & Dryers Braime 4B 14 x 6.5 14 x 6 13 x 10 13 x 8.5 13 x 8 13 x 7.5 13 x 7 13 x 6.5 13 x 6 13 x 5.5 12 x 8.5 12 x 8 12 x 7 12 x 6.5 12 x 6 12 x 5 11.5 x 5.5 Steel ✔ ✔ ✔ Stainless Steel Elevator bucket guide Starco (S) HDP ✔ ✔ Nylon Polyurethane Steel ✔ ✔ ✔ ✔ ✔ ✔ ✔ Elevator Buckets Stainless Steel Super Starco (SS) HDP ✔ ✔ ✔ ✔ Nylon Polyurethane ✔ Starco Jumbo (SJ) Steel Steel ✔ ✔ GB / Spidex Stainless Steel HDP Extruders & Expanders ✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔ CCS Nylon Polyurethane J - American Steel ✔ ✔ Grain Stainless Steel Steel ✔ G - Columbus Stainless Steel Hammermills ✔ A Steel Steel ✔ ✔ ✔ ✔ ✔ B Stainless Steel Mixers & Grinders Pellet Press

- 29. 14 x 7 ✔ ✔ ✔ ✔ ✔ ✔ 14 x 8 ✔ ✔ ✔ 14 x 8.5 ✔ ✔ 14.5 x 9.5 ✔ 14.5 x 10 ✔ 15 x 6 ✔ 15 x 6.5 ✔ 15 x 7 ✔ ✔ 15 x 8 ✔ 15 x 8.5 ✔ ✔ ✔ ✔ ✔ 15 x 10 ✔ 16 x 7 ✔ ✔ 16 x 8 ✔ ✔ ✔ ✔ 16 x 8.5 ✔ ✔ 17 x 8 ✔ 18 x 8 ✔ 18 x 8.5 ✔ ✔ ✔ 18 x 9.5 ✔ 19 x 10 ✔ 20 x 8 ✔ 20 x 8.5 ✔ ✔ 20 x 9 ✔ International Milling Directory 2011/12 | 185 4B Braime Coolers & Dryers Elevator Buckets Extruders & Expanders Hammermills Mixers & Grinders Pellet Press

- 30. 4B Braime 4B Braime Elevator Components www.go4b.com PROFILE 4B Braime Elevator Components has the world’s largest range of elevator components, leading the field in elevator bucket and bolt design and manufacturing the highest quality forged chain and elevator belting. 4B’s electronics division specializes in level controls, intelligent sensors and safety control systems that prevent costly downtime and minimize the risk of explosion in hazardous areas. With over 120 years of engineering experience and subsidiaries in America, Europe, Africa and Asia along with a worldwide network of distributors, 4B can provide practical solutions for any application no matter the location. 4B also offer a free design service for new or existing bucket elevators and chain conveyors and technical support from a team of specialised engineers. Elevator Bolts – The Strength of 4B Manufacturing 4B Braime is the only manufacturer of • Euro Bolts (DIN 15237)* original Ref 70, Easifit, Fang and Euro bolts. Those elevator bolts were originally developed • Ref 70 Bolts* and produced by Jackson Fasteners. - In 2006, • Fang Bolts* 4B Braime took over the complete stock, • Easifit Bolts* machinery and tooling from the previous owner, Flexco, after their decision to stop manufacturing • Accessories & Tools their range of elevator bucket bolts. Braime have built on over 100 years cold forging experience to manufacture some of the strongest bolts in the world. All bolts made are of the highest quality and well exceed the requirements of DIN 15237. Thanks to our big production volume, we can offer competitive prices and we have large numbers of elevator bolts in stock and ready to ship. * All bolts are available in a large range of sizes 4b-uk@go4b.com www.go4b.com

- 31. www.go4b.com Hazard Monitoring Systems & Level Controls Preventative maintenance can help reduce the risk of equipment failure and consequent downtime. When it comes to monitoring bucket elevators and conveyors, 4B can recommend the ideal combination of sensors and monitoring systems to suit their customers’ requirements and budget. 4B has an extensive range of ATEX / CSA / IECEx approved hazard monitoring systems, misalignment switches, bearing temperature monitors and level controls. 4B can offer anything from a replacement sensor, to a fully integrated hazard monitoring system which can be operated as a stand-alone device or connected to a PLC. • Belt underspeed monitors • Belt misalignment indicators • Bearing temperature systems • Plug chute sensors • Pulley misalignment detectors • Gate position and control • Bin level indicators Forged Chain – A complete line of drop forged chain and accessories designed for all conveying needs. 4B’s drop forged chain is made of special heat treated alloy steel case hardened to Rockwell C57 - C62 with a ductile core hardness of Rockwell C40. 4B’s superior heat treatment technique provides the optimum chain link with 4B’s Bolt ‘N’ Go flight system is a revolutionary a more resilient ductile core for shock resistance, assembly method for drop forged chain and and an extremely hard exterior surface for round link chain. Link and flight assembly is superior wear resistance. made easy by using a standard bolt and 4B offer the following chain pitches as standard: mechanical lock nut with a high strength hollow 102NA, 125NA, 142NA, 142HA, 150NA, 160NA, pin. There are no circlips and no intricate 175NA, 200NA, 216NA, 250NA, 260NA assembly required. There is no welding of flights, no need to remove chain from the conveyor for 4B also offer double and triple links for heavy duty installation, and no issues with strength. applications as well as the Bolt ‘n’ Go system. The Bolt ‘n’ Go system is easy, simple and reliable. 4b-uk@go4b.com www.go4b.com