Tamper Evidence Full Test Report for Red Flag LXR June 25, 2010

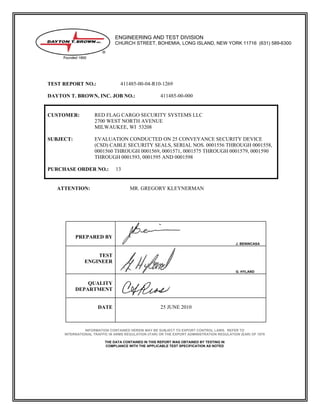

- 1. ENGINEERING AND TEST DIVISION CHURCH STREET, BOHEMIA, LONG ISLAND, NEW YORK 11716 (631) 589-6300 TEST REPORT NO.: 411485-00-04-R10-1269 DAYTON T. BROWN, INC. JOB NO.: 411485-00-000 CUSTOMER: RED FLAG CARGO SECURITY SYSTEMS LLC 2700 WEST NORTH AVENUE MILWAUKEE, WI 53208 SUBJECT: EVALUATION CONDUCTED ON 25 CONVEYANCE SECURITY DEVICE (CSD) CABLE SECURITY SEALS, SERIAL NOS. 0001556 THROUGH 0001558, 0001560 THROUGH 0001569, 0001571, 0001575 THROUGH 0001579, 0001590 THROUGH 0001593, 0001595 AND 0001598 PURCHASE ORDER NO.: 13 ATTENTION: MR. GREGORY KLEYNERMAN PREPARED BY J. BENINCASA TEST ENGINEER G. HYLAND QUALITY DEPARTMENT DATE 25 JUNE 2010 INFORMATION CONTAINED HEREIN MAY BE SUBJECT TO EXPORT CONTROL LAWS. REFER TO INTERNATIONAL TRAFFIC IN ARMS REGULATION (ITAR) OR THE EXPORT ADMINISTRATION REGULATION (EAR) OF 1979 THE DATA CONTAINED IN THIS REPORT WAS OBTAINED BY TESTING IN COMPLIANCE WITH THE APPLICABLE TEST SPECIFICATION AS NOTED

- 2. TABLE OF CONTENTS Subject Paragraph Page No. Abstract 1.0 2 References 2.0 2 Administrative Information 3.0 3 Test Program Outline 4.0 3 Test Results 5.0 4 Page Number No. of Photos Component Names and Descriptions Test and Results 4 1 Opening the Seal by Ratcheting Method Test and Results 6 1 Opening the Seal by Picking Method Test and Results 8 1 Opening the Seal by Changing the Cable Test and Results 10 2 Opening Seals by Freezing Method Test and Results 13 1 Test Equipment List and Test Item Photo 15 1 10-1269 Pg 1 of 16

- 3. 1.0 ABSTRACT This test report details the results of freight container mechanical seal evaluation conducted on Cable Seals, under reference (a) to the requirements of reference (c). Results of the tests are detailed in the following text. Exceptions/deviations during tests are as follows: None Test data pertinent to this program will remain on file at Dayton T. Brown, Inc. for 90 days. The testing and results contained in this report are in accordance with the testing requirements called out in reference (c) and are only applicable to the specific units identified in the test report and do not address any individual manufacturer's compliance or non-compliance with all the requirements of reference (c), which are the sole responsibility of each manufacturer and not part of the testing performed and recorded in this test report. Dayton T. Brown, Inc. is not involved in any production quality inspections. All tests are based on the samples that are selected by the manufacturer and provided to Dayton T. Brown, Inc. without any Dayton T. Brown, Inc. involvement in said selection. Dayton T. Brown, Inc. performs testing to the requirements of reference (c).under laboratory conditions. These tests do not measure and are not intended to measure all possible applications or installations of the seal assembly or components. In that event, the report will describe the particular application tested in detail. Dayton T. Brown, Inc. is not responsible for actual performance of any seal assembly as installed in any application. This report shall not be reproduced, except in full, without the written approval of Dayton T. Brown, Inc. 2.0 REFERENCES (a) Customer Purchase Order No.: 13 (b) Dayton T. Brown, Inc. Job No.: 411485-00-000 (c) Quote Letter: ISL-10-0542 10-1269 Pg 2 of 16

- 4. 3.0 ADMINISTRATIVE INFORMATION Customer Red Flag Cargo Security Systems LLC 2700 West North Avenue Milwaukee, WI 53208 Sample Type Cable Seals Sample Name Conveyance Security Device (CSD) (As Provided By Customer) Serial Nos. 0001556 through 0001558, 0001560 through 0001569, 0001571, 0001575 through 0001579, 0001590 through 0001593, 0001595, and 0001598 Quantity Received 28 Quantity Tested 25 Date Received 5 April 2010 Dates Tested 15 through 16 April 2010 4.0 TEST PROGRAM OUTLINE Test Test Item Description Results Component Names and Conveyance Security Device (CSD), See Page 4. Descriptions Serial Nos. 0001556 through 0001558, 0001560 and 0001598. Opening the Seal by Conveyance Security Device (CSD), See Page 6. Ratcheting Method Serial Nos. 0001561 through 0001565. Opening the Seal by Picking Conveyance Security Device (CSD), See Page 8. Method Serial Nos. 0001566 through 0001569 and 0001571. Opening the Seal by Conveyance Security Device (CSD), See Page 10. Changing the Cable Serial Nos. 0001575 through 0001579. Opening Seals by Freezing Conveyance Security Device (CSD), See Page 13. Method Serial Nos. 0001590 through 0001593 and 0001595. Test Equipment List and Conveyance Security Device (CSD), See Page 15. Test Item Photo 10-1269 Pg 3 of 16

- 5. 5.0 TEST RESULTS Component Names and Descriptions Test and Results TEST REQUIREMENT The component names and descriptions test shall be conducted in accordance with reference (c). TEST RESULTS A pretest visual inspection of the test items revealed no anomalies. All testing was performed in accordance with the referenced specification. Test room ambient conditions: 23.9ºC and 50.8%RH TEST DATA Date: 15 April 2010 Component Names and Descriptions Test Confirm that all components are present and Belong to the Seal Independent Locking Polypropylene Flower Mech. Filled with Washer Steel Shaped NLGI Grade 2 Med. Specimen No. 2pcs. Washer Washer Lubricant 0001556 Yes Yes Yes Yes 0001557 Yes Yes Yes Yes 0001558 Yes Yes Yes Yes 0001560 Yes Yes Yes Yes 0001559 Yes Yes Yes Yes Tech: JB TEST PROCEDURE Cut the seal wall from the top about 2mm and open the cap. Following components should be there: • Polypropylene washer, two pieces. • Steel washer. • Flower shape washer. • Independent locking mechanism filled with NLGI Grade 2 Medium Lubricant. 10-1269 Pg 4 of 16

- 6. JOB NO. 411485-00-000 15 APRIL 2010 COMPONENT NAMES AND DESCRIPTIONS TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15177 10-1269 Pg 5 of 16

- 7. Test for Opening the Seal by Ratcheting Method Test and Results TEST REQUIREMENT The opening the seal by ratcheting method test shall be conducted in accordance with reference (c). TEST RESULTS A pretest visual inspection of the test items revealed no anomalies. All testing was performed in accordance with the referenced specification. Test room ambient conditions: 23.9ºC and 47.7%RH * A post-test visual inspection of the test items revealed marks on the cable from the gripping pliers. TEST DATA Date: 15 April 2010 Opening the Seal by Ratcheting Method Test Applied Cable Force Movement Specimen No. (lbf) (cm) Remarks 0001561 20 None * 0001562 20 None * 0001563 20 None * 0001564 20 None * 0001565 20 None * Tech: SD TEST PROCEDURE Lock the seal by inserting the Cable to the Cap to the desired loop. Mark horizontally around the Cable where it enters the Cap. Using a Vise Grips, clamp the Cable and pull up away from the Cap with a force equal to 20 lbf while rotating the Cable and Vise Grips. Rotate for five full minutes. Measure the line elevation above the cap. Record movement of line and equate to time. Movement should be zero because the internal mechanism will rotate and not release the Cable. 10-1269 Pg 6 of 16

- 8. JOB NO. 411485-00-000 15 APRIL 2010 PHOTO OF THE OPENING THE SEAL BY RATCHETING METHOD TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15178 10-1269 Pg 7 of 16

- 9. Opening the Seal by Picking Method Test and Results TEST REQUIREMENT The opening the seal by picking method test shall be conducted in accordance with reference (c). TEST RESULTS A pretest visual inspection of the test items revealed no anomalies. All testing was performed in accordance with the referenced specification. Test room ambient conditions: 23.9ºC and 48.6%RH * A post-test visual inspection of the test items revealed no anomalies due to testing. The pin was only able to be inserted a small amount. TEST DATA Date: 15 April 2010 Opening the Seal by Picking Method Test Pin Cable Manipulation Movement Specimen No. Time (min.) (cm) Remarks 0001566 5 None * 0001567 5 None * 0001568 5 None * 0001569 5 None * 0001571 5 None * Tech: SD Take a common paper clip or safety pin, file or flatten the tip to .014 and attempt to insert into a Seal that has the Cable inserted into its mechanism. Manipulate the pin for 5 min. and measure the cable movement. 10-1269 Pg 8 of 16

- 10. JOB NO. 411485-00-000 15 APRIL 2010 PHOTO OF THE OPENING THE SEAL BY PICKING METHOD TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15179 10-1269 Pg 9 of 16

- 11. Opening the Seal by Changing the Cable Test and Results TEST REQUIREMENT The opening the seal by changing the cable test shall be conducted in accordance with reference (c). TEST RESULTS A pretest visual inspection of the test items revealed no anomalies. All testing was performed in accordance with the referenced specification. Test room ambient conditions: 23.9ºC and 51.9%RH * A post-test visual inspection of the test items revealed marks on the seal body from clamping in the vise and damage to the cable from drilling and hammering with a punch. **The cable could not be removed using the prescribed methods. TEST DATA Date: 15 April 2010 Opening the Seal by Changing the Cable Test Cable Removal Method Cable Specimen No. Drilling Hammering Dia. (mm) Remarks 0001575 ** ** 5.20 * 0001576 ** ** 5.19 * 0001577 ** ** 5.21 * 0001578 ** ** 5.18 * 0001579 ** ** 5.21 * Tech: SD Take a Seal and measure the diameter of the cable, it should be 5.2 mm. Cut the Cable at the Lug using a cable cutter. Remove the remaining end of the Cable that is compressed into the Lug using small drills to remove left over Cable. Try to insert a new Cable in the Lug. Did the replacement cable go into the lug? Attempt to pound a 5.2mm Cable flat on one end to match the new hole. Can the Lug be re- compressed to hold a new Cable tight? Can you re-compressed without damaging the Logo on either side of the Lug? 10-1269 Pg 10 of 16

- 12. JOB NO. 411485-00-000 15 APRIL 2010 PHOTO OF THE OPENING THE SEAL BY CHANGING THE CABLE TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15181 10-1269 Pg 11 of 16

- 13. JOB NO. 411485-00-000 15 APRIL 2010 PHOTO OF THE OPENING THE SEAL BY CHANGING THE CABLE TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15180 10-1269 Pg 12 of 16

- 14. Opening the Seal by Freezing Method Test and Results TEST REQUIREMENT The opening the seal by freezing method test shall be conducted in accordance with reference (c). TEST RESULTS A pretest visual inspection of the test items revealed no anomalies. All testing was performed in accordance with the referenced specification. * A post-test visual inspection of the test items revealed no anomalies due to testing. TEST DATA Date: 16 April 2010 Opening the Seal by Freezing Method Freezing Movement Specimen No. Time (min.) (cm) Remarks 0001590 5 None * 0001591 5 None * 0001592 5 None * 0001593 5 None * 0001595 5 None * Tech: JB Lock the seal by inserting the Cable to the Cap to the desired loop. Take a syringe with a pre- measured amount of water and push it into a Seal with the Cable inserted. Seal the cable exit with duct seal (water tight). Attempt to inject the water into the Seal mechanism. Fill until water flows out the top of the lock. Using liquid CO2, freeze the seal body for 3 to 5 min. until frozen. Attempt to remove the cable by pulling and rotating. Measure the cable movement. 10-1269 Pg 13 of 16

- 15. JOB NO. 411485-00-000 16 APRIL 2010 PHOTO OF THE OPENING THE SEAL BY FREEZING METHOD TEST SET UP 411485-00-04-R10-1269 FILE NO. 10-15328 10-1269 Pg 14 of 16

- 16. Test equipment utilized for the program reported herein was within its assigned interval of calibration. Details are on file at Dayton T. Brown, Inc. and will be made available upon request. TEST: EVALUATION CONDUCTED ON TWENTY FIVE CONVEYANCE SECURITY DEVICE Last Cal Cal Due Item Manufacturer Model DTB No. Accuracy Date Date CONDITIONING DAYTON T. BROWN N/A 04S-001 N/A N.C.R. ROOM - LOGGER, RH HART SCIENTIFIC 1620A 12-39 59 TO 95°F ± 11/23/2009 11/21/2010 AND 0.75°F; 10 TO TEMPERATURE 70% RH ± 2% RH TIMER, DIGITAL FISHER SCIENTIFIC 14-649-17 47-55 ± 0.01% 01/22/2010 01/16/2011 GAUGE, CHATILLON DFS-050 61-8 VENDOR 06/26/2009 06/20/2010 DIGITAL FORCE 50 LBS. FULL SCALE CALIPER, MITUTOYO CD-4" CS 68-273 ± .0005" 06/02/2010 05/29/2011 DIGIMATIC 4" PROTRACTOR, PRO PRODUCTS PRO 3600 68-279 ± 0.2° OF 04/13/2010 04/10/2011 DIGITAL RANGE TAPE LUFKIN HV1035CME 68-349 MFR 10/05/2009 N.P.C.R. MEASURE, 16' X 3/4" 10-1269 Pg 15 of 16

- 17. JOB NO. 411485-00-000 11 MAY 2010 CSD CABLE SEAL 411485-00-04-R10-1269 FILE NO. 10-15182 10-1269 Pg 16 of 16