Final poster_TSweeting (1)

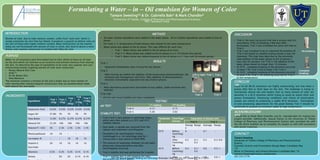

- 1. RESULTS Trial 1: • Separated immediately upon mixing the two phases. Trial 2 • After mixing, but before the addition of the preservative phenoxyethanol, the emulsion was homogenous and thick. After addition of phenoxyethanol, emulsion immediately separated into two distinct phases. Trial 3 • After alternative preservative (Germaben II) was added, stable emulsion was attained. Trial 4 &5 • pH test and visual stability test were completed. INTRODUCTION Women of color, due to high melanin content, suffer from “ashy skin” which is simply extremely dry skin that has flaked. It produces a greyish to whitish color on the skin of those with higher melanin content. Many moisturizers on the market today are not formulated with women of color in mind, who tend to desire a more thicker and creamier moisturizer to combat their flaky dry skin. PURPOSE Water-in-oil emulsions were formulated due to their ability to leave an oil layer on the skin which can function as an occlusive and prevent moisture from leaving the skin. To determine the type of ingredients to be used, four popular skin care moisturizing brands targeting women of color were researched. • Nyraju Natural Skin Care • Ambi ® • Rx for Brown Skin • Shea Moisture The emulsion contains a mixture of oils and a butter due to more women of color moving their interest towards moisturizers that are predominately made with natural oils and butter. DISCUSSION • Trial 4, the most successful trial had a viscous and rich consistency. Prior to breaking a few days after formulated, Trial 5 also exhibited the same skin feel as Trial 4. • Trial 5 was intended to be an improved formulation of Trial 4 but based on stability testing results it was not improved. This may have been due to the extremely slow addition of the water phase to the oil phase (1 hour and 30 minutes). For Trial 4, the addition of the water phase lasted no longer than 10 minutes. • At 45oC, complete breaking of the emulsion occurred at week 7 for Trial 4 and at week 3 for Trial 5. • At 25oC, complete breaking of the emulsion occurred at week 5 for Trial 5. No breaking occurred for Trial 4 at this temperature. CONTACT Water-in-oil (W/O) emulsions are highly moisturizing, but may leave a greasy after feel or thick layer on the skin. The challenge is trying to incorporate natural oils and butters that so many women of color are attracted in a W/O emulsion whilst trying to avoid an overly thick and greasy formulation. Processing conditions and choice of preservative system are critical to producing a stable W/O emulsion. Formulation or/and processing adjustments for the good-feeling Trial 4 should be performed to produce an emulsion stable at high temperature. Tamare Sweeting University of Toledo College of Pharmacy and Pharmaceutical Science Cosmetic Science and Formulation Design Major Candidate May ‘16 Minor in Chemistry and General Business Candidate May ‘16 Tamare.Sweeting@rockets.utoledo.edu 567.225.2778 Formulating a Water – in – Oil emulsion for Women of Color Tamare SweetingAB & Dr. Gabriella BakiA & Mark ChandlerB AUniversity of Toledo, College of Pharmacy and Pharmaceutical Sciences BACT Solutions Corp Ingredients Trial 1 (30g) Trial 2 (30g) Trial 3 (60g) Trial 4 (150g ) Trial 5 (100g ) Hyaluronic Acid 0.03% 0.03% 0.03% 0.03% 0.03% Argan Oil 37.8% 7% 7% 7% 7% Shea Butter 12.6% 8.27% 8.27% 8.27% 8.27% Almond Oil 25.2% 10% 10% 10% 10% Pelemol P-1263 3% 2.5% 2.5% 2.5% 2.5% Phenoxyethanol 1% 1% - - - Germaben III - - 1% 1% 1% Vitamin E Succinate 2% 1% 1% 1% 1% Allantoin 0.5% 0.2% 0.2% 0.1% 0.1% Zemea - 5% 5% 6.1% 6.1% METHOD • All water soluble ingredients were added to the water phase. All oil soluble ingredients were added to the oil phase. • For trials 2-5, temperature of both phases were heated to the same temperature. • Water phase was added to the oil phase. This step differed for each trial. • Trial 1: Water phase was added to the oil phase all at once. • Trial 2-4: Water phase was added to the oil phase in a 5-10 minute time period. • Trial 5: Water phase was added dropwise to the oil phase in a 1 hour and 30 minute period. 1st reading 2nd Reading Trial 4 4.13 4.15 Trial 5 5.58 5.63 • Trial 4 and 5 were placed in centrifuge tubes, which were then placed in a 25oC and 45oC stability cabinet. • Each week, a sample was removed from the cabinet and underwent centrifugation . • Parameters for centrifugation testing: Centrifuged in a 1ml centrifuge tube for 1 minute with a slow speed of 6000 RPM. • The amount of separation between oil and water phase was measured before and after centrifugation occurred. • Trial 4 stability test was performed for 8 weeks. • Trial 5 stability test is still ongoing but data documents the first 5 weeks. INGREDIENTS TESTING pH TEST: Left to right: Trial 1, Trial 2, Trial 3 Trial 4 Trial 5 Temperatu re Centrifuge Activity Separation of phases (cm) Trial 4 Trial 5 Averag e Range Average Range 25oC Before Centrifugi ng 0 - 0.1 - After Centrifugi ng 0.2 0.1- 0.3 0.5 0.3-0.6 45oC Before Centrifugi ng 0.3 0.1- 0.6 0.6 0.3-1 After 0.5 0.4- 0.8 0.6-1 STABILITY TEST: CONCLUSI ON ACKNOWLEDGEME NTSI would like to thank Mark Chandler and Dr. Gabriella Baki for making this project possible. Additionally, special thanks to the University of Toledo College of Pharmacy and Pharmaceutical Science who provided me with the lab which enabled me to complete my project as well with assistance with poster expenses. Complete breaking No breaking SCC 70th Annual Scientific Meeting and Technology Showcase • New York City, NY • December 10-11, 2015

Notes de l'éditeur

- Zemea Propanediol – preservative boosting humectant. Use to help allantoin an dvitamin succinate dissolve within oil phase My comments: I added the college of pharmacy and pharmaceutical sciences to the affiliations. You have to adjust the text, so that it’s left side is in line with the title of the section (I did it for you). Apply US spell check, I still found color spelled “color”. Make sure to put periods at the end of the sentences. Why did you say Pelemol was the emulsifier? I think it’s not needed since you did not identify the function of the other ingredients. I changed the color of the header in the tables to better fit the theme. What do you mean by temperature was normalized? I made a change in the sentence for results of Trial 1. In the table for the stability test, you have a column for centrifuge activity, but you only say before and after. What do you mean? You should list the parameters for the centrifuge testing. Since the project happened in the past, use simple past tense in the entire poster. Sometimes you would say, the product “has” “is”, I tried to change most of these to “had” and “was”. Double check please. I added the name, location and date of the conference to the poster.