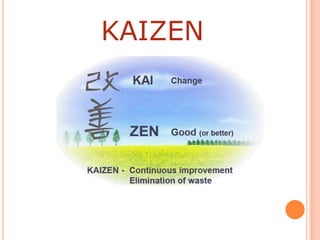

Kaizen

- 1. KAIZEN

- 2. AGENDA Introduction Introduction: Man Behind Kaizen Introduction: Who does Kaizen? Why ? Kaizen Methodology Gemba Kaizen 1. Housekeeping 2. Muda elimination 3. Standardization Toyota Example Summary/Benefits of Kaizen 2

- 3. INTRODUCTION: MAN BEHIND KAIZEN Masaaki Imai is known as the developer of Kaizen. He is known as the “Lean Guru” and the father of Continuous Improvement According to him In simple words Kaizen means improvement. Kaizen strategy calls for never-ending efforts for improvement involving everyone in the organization – managers and workers alike. Author of books like Kaizen(1986)Key to Japans Competitive success and Gemba Kaizen(1997) 3 http://en.wikipedia.org/wiki/Masaaki_Imai

- 4. INTRODUCTION: WHO DOES KAIZEN ? WHY ? WHY ? Maintenance Objective of the maintenance function is to maintain current technological, managerial, and operating standards Innovation Improvement function is aimed at improving current standards. WHO ? Kaizen Ongoing improvement involves everyone Top management Managers Workers 4 http://www.kaizen.com/

- 5. KAIZEN METHODOLOGY Finding out the pain area Analysis of the pain area 3M„s Considered with the 4M„s 3M‟s MURA, MURI, MUDA muda ("non-value-adding work") muri ("overburden") mura ("unevenness") 4M‟s MAN, MACHINE, MATERIAL, METHOD 5 http://en.wikipedia.org/wiki/Kaizen

- 6. TYPES OF WASTES • Mura(Unevenness) is avoided through Just In Time systems which are based on little or no inventory, by MURA supplying the production process with the right part, at the right time, in the right amount • Muri(overburden) can be avoided through MURI standardized work. To achieve this a standard condition or output must be defined to assure effective judgment of quality. • Muda(non-value-adding work) Can be avoided by MUDA identifying and eliminating non value adding and unnecessary activities 6 http://en.wikipedia.org/wiki/Lean_manufacturing#Types_of_waste

- 7. GEMBA KAIZEN Gemba is a Japanese word meaning 'real place,' where the real action takes place. In business, Gemba is the „shop floor‟ or „production place‟ where the value-adding activities to satisfy the customer are carried out. 3 Ground rules for practicing Kaizen in Gemba are: - 1. Housekeeping, 2. Muda elimination. 3. Standardization. 7 http://www.gemba.com/

- 8. 1. HOUSEKEEPING 5S is a method for organizing a workplace, especially a shared workplace (like a shop floor or an office space), and keeping it organized. To take the concept of Kaizen performance to its ultimate level of simplicity, it offered the following "5S" steps Sorting- keeping only essential items Simplifying - Eliminates extra motion. Sweeping- keep the workplace clean Standardizing -Standardized work practices Sustaining - Maintaining and 8 reviewing standards http://www.gemba.com/

- 9. 2. MUDA ELIMINATION 9 http://www.gemba.com/

- 10. 3. STANDARDIZATION Standards may be defined as the best way to do the job Products or services are created as a result of a series of processes. Certain standard must be maintained at each process in order to assure quality. Standards also can prevent recurrence of the same problem 10 http://www.gemba.com/

- 11. TOYOTA EXAMPLE Management Philosophy Respect for People & Continuous Improvement The success of the Toyota Production System can be attributed to Eliminating wasted time and resources Building quality into workplace systems Finding low-cost but reliable alternatives to expensive new technology Perfecting business processes Building a learning culture for continuous improvement 11 Source : The Toyota Way, Jeffrey K. Liker

- 12. BENEFITS OF KAIZEN Kaizen Reduces Waste like inventory waste, time waste, workers motion Kaizen Improves space utilization, product quality Results in higher employee moral and job satisfaction, and lower turn-over. Toyota is well-known as one of the leaders in using Kaizen. In 1999 at one U.S. plant, 7,000 Toyota employees submitted over 75,000 suggestions, of which 99% were implemented. 12 http://en.wikipedia.org/wiki/Kaizen

Notes de l'éditeur

- Kaizen (改善) Japanese for "improvement" or "change for the better", refers to philosophy or practices that focus upon continuous improvement of processes in manufacturing, engineering, supporting business processes, and management. It has been applied in healthcare,[1] psychotherapy,[2] life-coaching, government, banking, and many other industries. When used in the business sense and applied to the workplace, kaizen refers to activities that continually improve all functions, and involves all employees from the CEO to the assembly line workers. It also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain.[3] By improving standardized activities and processes, kaizen aims to eliminate waste (see lean manufacturing). Kaizen was first implemented in several Japanese businesses after the Second World War, influenced in part by American business and quality management teachers who visited the country. It has since spread throughout the world[4] and is now being implemented in many other venues besides just business and productivity. INRODUCTIONKaizen is a daily process, the purpose of which goes beyond simple productivity improvement. It is also a process that, when done correctly, humanizes the workplace, eliminates overly hard work ("muri"), and teaches people how to perform experiments on their work using the scientific method and how to learn to spot and eliminate waste in business processes. In all, the process suggests a humanized approach to workers and to increasing productivity: "The idea is to nurture the company's human resources as much as it is to praise and encourage participation in kaizen activities."[5] Successful implementation requires "the participation of workers in the improvement."[6] People at all levels of an organization participate in kaizen, from the CEO down to janitorial staff, as well as external stakeholders when applicable. The format for kaizen can be individual, suggestion system, small group, or large group. At Toyota, it is usually a local improvement within a workstation or local area and involves a small group in improving their own work environment and productivity. This group is often guided through the kaizen process by a line supervisor; sometimes this is the line supervisor's key role. Kaizen on a broad, cross-departmental scale in companies, generates total quality management, and frees human efforts through improving productivity using machines and computing power.[citation needed]While kaizen (at Toyota) usually delivers small improvements, the culture of continual aligned small improvements and standardization yields large results in the form of compound productivity improvement. This philosophy differs from the "command and control" improvement programs of the mid-twentieth century. Kaizen methodology includes making changes and monitoring results, then adjusting. Large-scale pre-planning and extensive project scheduling are replaced by smaller experiments, which can be rapidly adapted as new improvements are suggested.[citation needed]In modern usage, a focused kaizen that is designed to address a particular issue over the course of a week is referred to as a "kaizen blitz" or "kaizen event". These are limited in scope, and issues that arise from them are typically used in later blitzes.[

- Types of waste: muda ("non-value-adding work"), muri ("overburden"), and mura ("unevenness")Mura is avoided through Just In Time systems which are based on little or no inventory, by supplying the production process with the right part, at the right time, in the right amount, and first-in, first out component flow. Just in Time systems create a “pull system” in which each sub-process withdraws its needs from the preceding sub-processes, and ultimately from an outside supplier. When a preceding process does not receive a request or withdrawal it does not make more parts. This type of system is designed to maximize productivity by minimizing storage overhead.Muri can be avoided through standardized work. To achieve this a standard condition or output must be defined to assure effective judgment of quality. Then every process and function must be reduced to its simplest elements for examination and later recombination. The process must then be standardized to achieve the standard condition. This is done by taking simple work elements and combining them, one-by-one into standardized work sequencesMuda (無駄)[1] is a traditional Japanese term for an activity that is wasteful and doesn't add value or is unproductive, etymologically none (無)+ trivia or un-useful (駄) in practice or others. It is also a key concept in the Toyota Production System (TPS) and is one of the three types of waste (muda, mura, muri[2]) that it identifies. Waste reduction is an effective way to increase profitability. Toyota merely picked up these three words beginning with the prefix mu-,[3] which in Japan are widely recognized as a reference to a product improvement program or campaign. A process adds value by producing goods or providing a service that a customer will pay for. A process consumes resources and waste occurs when more resources are consumed than are necessary to produce the goods or provide the service that the customer actually wants. The attitudes and tools of the TPS heighten awareness and give whole new perspectives on identifying waste and therefore the unexploited opportunities associated with reducing waste.

- Housekeeping is an indispensable ingredient of good management. Through good housekeeping, employees acquire and practice self-discipline. Employees without self-disciplines make it difficult to provide products or services of good quality to the customer.In Japanese, the word mudameans waste. Any activity that does not add value is muda. People in gemba either add value or do not add value. This is also true for other resources, such as machines and materials. Muda elimination can be the most cost-effective way of improving productivity and reducing operating costs. Waste of over production – This is regarded as the worst type of waste. If you produce more than your customer needs, you have extra pieces that need to be taken care of, such as handling and keeping in stock.Waste of inventory – This is the result of over production. If you process only Produces what the next process needs, you can eliminate mudaof inventory altogether.Waste of waiting – How often do you see operators just waiting for the material to arrive or the machine to start? No value is added when operators are waiting and looking.Waste of motion – When the operator is moving around, looking for tools or going to get the work pieces, no value is added.Wasteof transportation – When materials are moving on the trucks, forklifts, or on the conveyer, no value is added.Wasteof producing rejects – Producing rejects leads to rework, or else rejects must be thrown away, a big muda.Waste of processing – By rearranging the working sequence, often you can eliminate a particular process. The third ground rule of kaizen practices in gemba is standardization. Standards may be defined as the best way to do the job.Products of services are created as a result of a series of processes. Certain standard must be maintained at each process in order to assure quality. Standards also can prevent recurrence of the same problem.

- Phases of 5SThere are 5 primary phases of 5S: sorting, straightening, systematic cleaning, standardizing, and sustaining. Additionally, there are three other phases sometimes included; safety, security, and satisfaction.Sorting (Seiri)Eliminate all unnecessary tools, parts, and instructions. Go through all tools, materials, and so forth in the plant and work area. Keep only essential items and eliminate what is not required, prioritizing things as per requirements and keeping them in easily-accessible places. Everything else is stored or discarded.Straightening or setting in order / stabilize (Seiton)There should be a place for everything and everything should be in its place. The place for each item should be clearly labeled or demarcated. Items should be arranged in a manner that promotes efficient work flow, with equipment used most often being the most easily accessible. Workers should not have to bend repetitively to access materials. Each tool, part, supply, or piece of equipment should be kept close to where it will be used – in other words, straightening the flow path. Seiton is one of the features that distinguishes 5S from "standardized cleanup". This phase can also be referred to as Simplifying[1].Sweeping or shining or cleanliness / systematic cleaning (Seiso)Keep the workplace tidy and organized. At the end of each shift, clean the work area and be sure everything is restored to its place. This makes it easy to know what goes where and ensures that everything is where it belongs. A key point is that maintaining cleanliness should be part of the daily work – not an occasional activity initiated when things get too messy.Standardizing (Seiketsu)Work practices should be consistent and standardized. All work stations for a particular job should be identical. All employees doing the same job should be able to work in any station with the same tools that are in the same location in every station. Everyone should know exactly what his or her responsibilities are for adhering to the first 3 S's.Sustaining the discipline or self-discipline (Shitsuke)Maintain and review standards. Once the previous 4 S's have been established, they become the new way to operate. Maintain focus on this new way and do not allow a gradual decline back to the old ways. While thinking about the new way, also be thinking about yet better ways. When an issue arises such as a suggested improvement, a new way of working, a new tool or a new output requirement, review the first 4 S's and make changes as appropriate