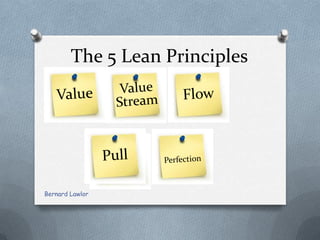

The 5 Lean Principles

- 1. The 5 Lean Principles Bernard Lawlor

- 2. O Specify value from the customer’s perspective O Divide all activities into the following groups: Value added Activity Non Value–Added Activity Necessary Non Value-Added Activity O Waste is the opposite of Value in Lean terms O There are 7 categories of waste O All areas of an organisation contain theses wastes not just production Bernard Lawlor

- 3. Value 7 Wastes Bernard Lawlor

- 4. O Value Stream Mapping: A tool used to identify and eliminate non value-added activities within their Value Streams. O Tackle Pure waste (NVA) first, with NNVA later being challenged and reduced/eliminated. O Process Efficiency is a measure of waste in Value stream and may be calculated as follows: PE = ( Value added Time / Lead Time ) * 100% Bernard Lawlor

- 5. Flow O Create continuous flow, without interruption between processes O The reduction of batch sizes to ‘Single Piece Flow’(SPF) O Product processed at each step and immediately passed to the next process O Key step to improving product flow through the value stream. Bernard Lawlor

- 6. Pull O Produce product only when required by customer – prevents over production O Concept of Pulling products through value stream can seem counter-intuitive O Batch & Queue method erroneously perceived to hold efficiencies. Bernard Lawlor

- 7. Perfection O The commitment within a Lean organisation to the relentless elimination of waste. O Get value to flow faster, exposing waste in the value stream O Barriers to flow are discovered as pull systems are implemented O Implement small improvements frequently as the opportunities present themselves O Involve employees in the identification of waste, and implementation of improvements for significant and maintainable progression over the longer term. Bernard Lawlor