Coal mill assembly

•Télécharger en tant que DOCX, PDF•

0 j'aime•298 vues

The document provides instructions for refurbishing the rollers of a Coal Mill, type MPS 250BK. The rollers are removed from the mill and placed on a steel frame to act as a hanger. They are bolted to a support below the roller hub and pinned on the backside. Welding equipment is installed, including gearboxes for rotation and a welding torch above the rollers. The rollers are then hardfaced in sequence while being checked hourly to prevent overheating.

Signaler

Partager

Signaler

Partager

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (20)

Oscillating bearing unit for inking and dampening rollers

Oscillating bearing unit for inking and dampening rollers

Rod Head Assembly Modification | Customer Service Sales

Rod Head Assembly Modification | Customer Service Sales

En vedette

En vedette (10)

Exploration and production, Sigve Hamilton Aspelund

Exploration and production, Sigve Hamilton Aspelund

BAB IV PLTMH Nisam Antara Kabupaten Aceh Utara, Provinsi Aceh

BAB IV PLTMH Nisam Antara Kabupaten Aceh Utara, Provinsi Aceh

Coal mill assembly

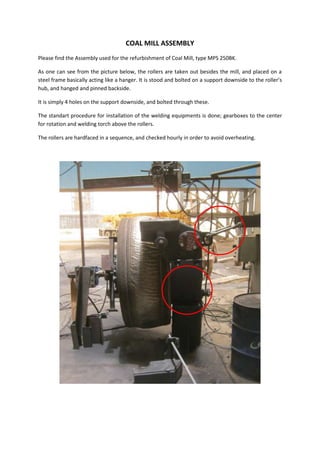

- 1. COAL MILL ASSEMBLY Please find the Assembly used for the refurbishment of Coal Mill, type MPS 250BK. As one can see from the picture below, the rollers are taken out besides the mill, and placed on a steel frame basically acting like a hanger. It is stood and bolted on a support downside to the roller’s hub, and hanged and pinned backside. It is simply 4 holes on the support downside, and bolted through these. The standart procedure for installation of the welding equipments is done; gearboxes to the center for rotation and welding torch above the rollers. The rollers are hardfaced in a sequence, and checked hourly in order to avoid overheating.

- 2. Please find another picture taken after installation is completed.