Energy saving, pulsation-free and smooth pumping of viscous liquids and solids

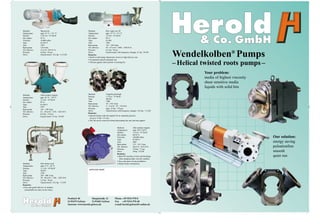

- 1. Medium: Massecuite Medium: Raw sugar run off Temperature: appr. 55 °C / 131 °F Temperature: appr. 55 °C / 131 °F Density: 1,45 t/m3 / 91 lbs/ft3 Density: 1,4 t/m3 / 87 lbs/ft3 Dry matter: 91 % Dry matter: 84 % Viscosity: 10.000 mPas Type: 01.050 Type: 01.035 V Year: 1993 Year: 1997 Rpm pump: 110 – 250 l/min Rpm pump: 145 l/min Vol. delivery: 30 – 67 m3/h / 1060 – 2366 ft3/h Vol. delivery: 27 m3/h / 954 ft.3/h Pressure: 6,5 bar / 92 psi Pressure: Drive: 6,0 bar / 85 psi Geared motor: 18,5 hp / 13,5 kW Drive: Remarks: Geared motor with frequency changer: 41 hp / 30 kW • Small overall pump dimensions, however high delivery rate. • Exceptional smooth and quiet run. Wendelkolben® Pumps • Tolerant against short periods of running dry. – Helical twisted roots pumps – Your problem: media of highest viscosity shear sensitive media liquids with solid bits Medium: After product magma Medium: Gingerbread dough Temperature: appr. 65 °C / 149 °F Density: 1,2 t/m3 / 75 lbs/ft3 Density: 1,4 t/m3 / 87 lbs/ft3 Type: 06.010 Dry matter: 95 % Year: 1996 Type: 01.050 V Rpm pump: 30 - 150 1/min Year: 1997 Vol. delivery: 2 – 9 m3/h / 70 – 318 ft3/h Rpm pump: 110 – 160 l/min Pressure: appr. 12 bar / 170 psi Vol. delivery: 32 – 46 m3/h / 1130 – 1625 ft3/h Drive: Geared motor with frequency changer: 10,5 hp / 7,5 kW Pressure: 8,0 bar / 118 psi Remarks: Drive: Geared motor: 41 hp / 30 kW • Special design with end support for an operating pressure of up to 15 bar / 213 psi. • The lid can be removed without demounting the seal and end support. Medium: After product magma Temperature: appr. 50°C/122°F Density: 1,4 t/m3 / 87 lbs/ft3 Dry matter: 89-92 % Viscosity: 320.000 mPas Our solution: Type: 01.050 V Year: 2001 energy saving Rpm pump: 133 - 145 1/min Vol. delivery: 40 m3/h / 1413 ft3/h pulsationfree Pressure: 5,0 bar / 71 psi Drive: 30 hp / 22 kW smooth Remarks: • Ideal 90° position of inlet and discharge quiet run when pumping high viscosity medium. • Easy and space saving installation Medium: Soft cheese-curd • Sturdy frame construction Temperature: appr. 8 °C / 46 °F Density: 1,1 t/m3 / 69 lbs/ft3 authorized dealer Type: 06.035 Year: 1993 Rpm pump: 264 - 400 1/min Vol. delivery: 50 – 80 m3/h / 1766 – 2825 ft3/h Pressure: 2,5 bar / 36 psi Drive: Geared motor: 10,5 hp / 7,5 kW Remarks: • Easy and gentle delivery of medium (remarkable less fines in the whey). Postfach 40 Hauptstraße 12 Phone +49 9254 970-0 D-95479 Gefrees D-95482 Gefrees Fax +49 9254 970-40 Internet: www.herold-gefrees.de e-mail herold.gefrees@t-online.de

- 2. Wendelkolben® Pumps – helical twisted roots pumps – Both of the sectional drawings show the elementary and rugged were developed by Herold & Co. GmbH, Gefrees, construction of the Wendelkolben® Pump - helical twisted roots pump. Germany, and are patented The Wendelkolben® Pumps, developed and patented by Herold & Co. GmbH, produce a pulsation free flow, as both end faces of each Wendelkolben® -rotor are helical twisted against each other by 90°. They rotate with microscopic clearance and are synchronized by ground, surface hardened helical timing gears. The advantages of those helical twisted Wendelkolben® -rotors: • continuous flow with absolute equal volume • pulsation free pumping principle • smooth and gentle treatment of the medium to be pumped • exceptional low noise level • tremendous reduction in power consumption Model number 0.1 with mechanical seals and quench Schematic of the pumping principle 1. Due to rotation of the helical twisted rotors a vacuum is created, which draws the liquids without interruption into the pumping chamber. 2. By further rotation the liquids are locked in between the rotors and the rotor housing, 3. transported 4. and discharged without pulsation. When changing the direction of rotation the flow is reversed. Dental paste Canned mushrooms Model number 0.6 with mechanical seals The pulsation-free flow is achieved through the patented shape of the suction and discharge end of the pumphousing. The displacement chamber`s sealing line has a configuration resembling two triangles which are oppositely positioned, standing 180° to each other. This positioning is vital in achieving the pulsation-free flow.

- 3. 400 Applications .003/.005 .010/.014/.028/.035 Sugar and starch industry .050 White sugar, raw sugar, after product, crystal suspensions, sucrose solutions, massecuites, molasses, thick juices, 300 .075/.100 dextrose anhydride, dextrose monohydrate Pulp and paper industry rpm 200 Pulp, starch, coating Bake, pastry and pie products 100 Yeast, leaven and biscuit dough, edible fat and oil, chocolate and sugar-icing, fruit, truffle and nut fillings, honey, syrup and cream, noodle and spaghetti dough, gingerbread dough and other such dough Sweets and candies 0 Jelly, gelatine, ice cream, chocolate, cacao butter, peanut butter, butter fat, starch gum 1.000 5.000 10.000 20.000 40.000 60.000 80.000 100.000 150.000 200.000 250.000 Viscosity in mPas / cP Milk and cheese products Cream, soft cheese-curd, butter milk, yogurt, curd, ice cream, butter, spreaded cheese, soft cheese, raclette cheese, Maximum rpm in relation to viscosity of the media. processed cheese, cottage cheese, whey curd Liquor and beverage industry Mash, yeast, condiments, fruit purees, fruit juice concentrates Type Vol. delivery m3/h Pressure Rpm max. Flange Meat and sausage products min. max. max. bar 1/min ID in mm inch Fats, meat salad, boiled sausage, raw sausage, pasty, pâte, liver sausage, spread sausage with and without solid bits 01.003 1 7 9 400 50 1.97 01.003 V 1 7 9 400 80/45° 3.15/45° Canned food 01.005 2 12 9 400 50 1.97 Ketchup, tomato paste, mustard, emulsified cream and gravy, marinade, salad dressing, jelly, jam, marmelade, plum-jam, 01.005 V 2 12 9 400 80/45° 3.15/45° 01.010 4 24 8 400 100 3.94 desserts, stewed fruit, pulp, syrup, soup, pap, stew, baby food, mash, pudding, mushrooms, cranberries, sauerkraut, red 01.010 V 4 24 8 400 150/45° 5.91/45° cabbage and other processed fruits and vegetables. 01.014 6 34 7 400 100 3.94 01.014 V 6 34 7 400 150/45° 5.91/45° 01.028 12 68 8 400 125 4.92 01.028 V 12 68 8 400 200/45° 7.87/45° 01.035 15 84 7 400 125 4.92 01.035 V 15 84 7 400 200/45° 7.87/45° 01.050 18 105 8 350 150 5.91 How do Wendelkolben® Pumps compare to other pumps? 01.050 V 18 105 8 350 250/45° 9.84/45° Here’s what our customer say … 01.075 27 135 7 300 200 7.87 01.075 V 27 135 7 300 300/45° 11.81/45° 01.100 36 180 6 300 200 7.87 Sugar and starch industry 01.100 V 36 180 6 300 300/45° 11.81/45° When pumping media of highest viscosity, such as after product, raw sugar, white sugar and sugar solution, there was no ^ ^ ^ ^ damage of the sugar crystal structure. There was no impurity of the medium by foreign matters, as Wendelkolben® rotors 1m3 (1000 l) = 264 US gal = 220 Imp gal = 35.31 ft3 1 bar = 14.2 psi and pump housing are made of extremely wear-resistant material. The one-sided bearing support makes for very All parts which are in touch with the media are in ni-resist or stainless steel. maintenance, plus, for intermittent operation, the pump housing has connectors for steam cleaning. Size code: Example 01.005 = 0,5 liter / 0.13 US gal / 0.11 Imp gal / vol. delivery / rpm 01.100 = 10,0 liter / 2.64 US gal / 2.20 Imp gal / vol. delivery / rpm Cheese and dairy industry 06.028 = 2,8 liter / 0.74 US gal / 0.62 Imp gal / vol. delivery / rpm Wendelkolben® Pumps gave no visual dust effect and change of consistency even when pumping soft cheese curd. We saw totally germ-free delivery of cottage cheese due to the sterile axial seal ring, which was developed and patented by Herold. And we saw no effervescence when pumping cream and skimmed cream. We can pump, portion and bag soft cheese with only one Wendelkolben® Pump. Type Vol. delivery m3/h Pressure Rpm max. Milkpipe thread min. max. max. bar 1/min ID in mm inch Chocolates 06.003 1 7 9 400 50 1.97 Wendelkolben® Pumps pump a constant volume of chocolates with solid bits, such as raisin-nut-chocolate mixtures, with 06.003 V 1 7 9 400 80/45° 3.15/45° showing no visual signs of being crushed or separated after the pumping process. 06.005 2 12 9 400 50 1.97 06.005 V 2 12 9 400 80/45° 3.15/45° Bake, pastry and pie production 06.010 4 24 8 400 80 1.97 With additional counter bearings mounted in the lid of the pump housing, a constant pressure of 15 bar (213 psi) can be 06.014 6 34 7 400 80 1.97 06.028 12 68 8 400 100 3.94 kept when pumping heavy dough and gingerbread with a high amount of solid bits. 06.035 15 84 7 400 100 3.94 Canned food industry We pump cooked sauerkraut and red cabbage with up to 80% dry matter content and a temperature of 95 °C (203 °F) over All parts which are in touch with the media are in stainless steel. a longer pipeline system directly into the can, without volume deviation or clogging. They deliver shear-sensitive products, such as mushrooms, cranberries and other fruits without any visual damage. Drive housing in grey cast. Wendelkolben® pumps give operators the chance to keep up with the always-increasing demand for higher quality product Extras on request. while achieving a higher output with less energy consumption, (i.e. optimizing the production process).

- 4. Outstanding features of the Wendelkolben®pumps: Advantages of the Wendelkolben® helical twisted rotors: Seals • revolving rotors do not touch each other or casing • pulsation-free operation • minimum wear • gentle positive displacement of medium • tolerant of short periods of running dry • continuous flow Axial seal ring in standard design • option of switching pumping direction • reduced power consumption • volumetric delivery directly proportional to rpm • no vibrations on pipeline system This mechanical seal is strainfree, independent of the • continuous flow • minimum noise level direction of rotation, and has enclosed spring suspension. On • wide range of applications our standard version the O-rings are made of Viton and the Design advantages: • pumps media of highest viscosity fitting mechanical seals are made of silicone carbide. A • sturdy, yet rugged construction • pumps liquids mixed with solids quench system with zero pressure can be ordered as an • easy cleaning • gentle mixing effect on medium accessory. • designed for ease of inspection and maintenance • high efficiency • various design seals available • modular construction • if required, construction can be altered to provide a higher pressure and/or a higher temperature Mechanical hard metal seals with quench For the sugar industry special mechanical seals were developed which are strainfree, independent of direction of • In comparison to almost all ordinary positive displacement pumps, which have a “portion-wise“ pumping action at rotation, and are spring-suspended outside of the medium. the suction and discharge end, the two counter-turning Wendelkolben® -helical twisted rotors- create a pulsation-free, On our standard version the O-rings are made of Viton and absolutely smooth and continuous flow of medium. the fitting mechanical seals are made of tungsten carbide. The mechanical seals are lubricated and cooled by a quench • The Wendelkolben® -helical twisted rotors- improve the quality of the pumping process. The gentle way of transport- system at zero pressure. The secondary seal is also a mecha- ing a medium is ideal for its homogeneity. It creates a very good, but at the same time very gentle and continuous, nical seal. mixing effect. Due to its maximized delivery surface and displacement volume, sugar crystals will not get triturated. Even media of highest viscosity can be pumped without problems. Another notable result of the configuration of the rotors is the tremendous reduction in power consumption. • The revolving Wendelkolben® -helical twisted rotors- do not touch each other or the pump housing. The material of the Axial seal ring for sterile processing rotors and the pump housing have a high degree of hardness. This is a guarantee for the purity of the medium to be pumped, as no foreign matter gets mixed in between sugar crystals or other such media. This mechanical seal, developed and patented by Herold, is strainfree, independent of direction of rotation, and is spring • The exceptionally quiet run and pulsation-free operation increases the service life of the pumps, drive units, valves suspended outside of the medium. There is no gap around and seals. It also reduces the load on the complete pipeline system and its mounting brackets. Roaring sounds are the mechanical seal or the O-ring. This design is ideal for eliminated. sterile processing. A quench system with zero pressure can be ordered as an accessory. • The pumps are designed for ease of inspection. In the case of a power failure causing the pumped medium to solidify, the Wendelkolben pumps® -helical twisted roots pumps- can be cleared and returned to operation in shortest time. The lid of the pump housing can be removed and even the pump housing can be taken off completely, providing easy access for cleaning, without demounting the gear box, drive unit or pipes. Stuffing box A lantern ring, fitted in between four packing rings, provides flushing and lubrication to the stuffing box. State of the art Components packing material is used to produce even pressure around the circumference of the shaft, minimizing wear. For most appli- Materials in contact with the medium Installation Adapters cations the stuffing box can be connected to an external Ni-resist Standard: horizontal Flange quench system. When pumping abrasives or crystalline pro- Stainless steel On request: vertical Milkpipe thread ducts as found in the paper and sugar industries the lantern 45° up or 45° down ring should be pressurized slightly above pump discharge 90° up or 90° down pressure. Finish O-rings Accessory Painted NBR Quench-tank Viton Heating/Cooling plate Elastomer seal ring EPDM Basic frame (other materials on request) Height adjustable frame The seal ring is made of PTFE and has three sealing lips. It Portable frame is a very space-saving design. Due to its reinforced lip design Sizes Drive 45° frame and the ceramic coated running surface, its application is 9 sizes Three-phase-geared motor Current reverser very versatile. Pressure up to 9 bar/128 psi Mechanical variable speed geared motor product (higher pressure on request) Standard clutch Optional is a single O-ring seal or a twin O-ring seal with Vol. delivery up to 180 m3/h Safety clutch quench liquid flushing chamber. Rpm up to 400 l/min Timing-belt-drive atmosphere