6-Sigma Lean 101

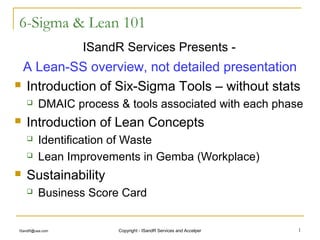

- 1. 6-Sigma & Lean 101 ISandR Services Presents - A Lean-SS overview, not detailed presentation Introduction of Six-Sigma Tools – without stats DMAIC process & tools associated with each phase Introduction of Lean Concepts Identification of Waste Lean Improvements in Gemba (Workplace) Sustainability Business Score Card ISandR@usa.com Copyright - ISandR Services and Accelper 1

- 2. 6-Sigma & Lean 101 Process Improvement – “Describe & Measure” “When you can measure what you are speaking about, and express it in numbers, you know something about it; but when you cannot measure it, when you cannot express it in numbers, your knowledge is of a meager and unsatisfactory kind….” William Thompson (Lord Kelvin), 1824-1907 “If you can't describe what you are doing as a process, you don't know what you're doing.” W. Edwards Deming, 1900-1993 ISandR@usa.com Copyright - ISandR Services and Accelper 2

- 3. 6-Sigma & Lean 101 The Average and the Standard Deviation are Most Important X = (∑ xi ) / n AVERAGE S= ∑ (x − X ) i 2 STANDARD n −1 DEVIATION These metrics are important, but we will keep this simple ISandR@usa.com Copyright - ISandR Services and Accelper 3

- 4. 6-Sigma & Lean 101 Process Improvement – “The Family Vacation” Example Start with the end in mind – THE GOAL Analogy of the family vacation Would you start with how to pack better? Where, What, Who - Destination, Activities, You &…? DEFINE Activities, Accommodations, Alt Options, Where is Start Route - how far/long, transport vehicle MEASURE Cost of alternatives ANALYZE What to take - backpacks or suitcase ANALYZE What can be done better from last time IMPROVE Stick to budget & plan CONTROL ISandR@usa.com Copyright - ISandR Services and Accelper 4

- 5. 6-Sigma & Lean 101 What is 6-Sigma? A Short History Improvement tools known for a LONG time Popularized by GE, Motorola, et al Collection of tools with standardize usage! About BEST in class About dramatic improvement – not stats ASQ – “80% of tools are not statistical” Process based on D M A I C - Define - Measure - Analyze - Improve - Control Presentation parallels book “Stat Free Six Sigma” – P. Gupta (Accelper) ISandR@usa.com Copyright - ISandR Services and Accelper 5

- 6. 6-Sigma & Lean 101 What is the Significance of the Words “6-Sigma”? What does “6-Sigma” imply? Process of 3 defective parts per million (3ppm) Depends on Customers specified limits (Upper & Lower Bound) Average in the process (Average or Mean) Variability in the process (Standard Deviation) Not all processes need to be 6-Sigma Capable A process that meets customer specifications by providing consistent accurate results with no variation - near zero defects ISandR@usa.com Copyright - ISandR Services and Accelper 6

- 7. 6-Sigma & Lean 101 What is 6-Sigma? Statistics Concepts, Without Statistics Examples Mean = X Low Hi Customer Production – Limit Limit specifies size & location LL and UL of hole in a part Distribution: Service - Gaussian Variation = 2 σ preparation of Random tabloid content Normal Error & distribution, early vs late Characterizing The Process The Process 6σ 1 sigma (σ) ½ width at ½ height Good Mean Good Variability Process Capability Good Capability Closest Limit – X CpK = [ Closest Limit – X ] 3σ “Higher ‘sigma’ is better to avoid quality escapes!” ISandR@usa.com Copyright - ISandR Services and Accelper 7

- 8. 6-Sigma & Lean 101 What Process Capability? mean LL HL variation This is previous slide Good Mean Poor Mean Poor Mean Good Variability Good Variability Poor Variability Good Capability Poor Capability Poor Capability ISandR@usa.com Copyright - ISandR Services and Accelper 8

- 9. 6-Sigma & Lean 101 What Makes 6-Sigma Work? When everyone understands the Cost of Poor Quality In / ext failures, inspection, testing, rework (calc $$s) Align VOC and biz needs for big improvements S M A R T goals Specific – why, what, when, who, where, finally how Measurable – which metrics: how much / many, B4 & after Attainable – have resources: attitudes, abilities, finances Realistic – challenging believable & achievable Timely* – reasonable duration to complete with urgency Visible with Executive Management Support Employees encouraged to take risks (Deming, “Drive out fear”) * Could be “Tangible” – can experience with senses makes it more realistic and measurable ISandR@usa.com Copyright - ISandR Services and Accelper 9

- 10. 6-Sigma & Lean 101 What makes 6-Sigma Work? Culture Change Response Curve The energy to overcome an existing culture, make improvements and sustain change takes effort, time and money The paths are different for each organization. Effort/Cost/Resistance A I Organization B M C D Organization A Present Time Future ISandR@usa.com Copyright - ISandR Services and Accelper 10

- 11. 6-Sigma & Lean 101 Customer Surveys – Voice Of the Customer (VOC) Research on customer satisfaction: Determine what is quality [“Q is what the customer says it is”] Find out what competitors are doing [better] Define quality performance measures to identify defects [Pareto] Identify factors to give a competitive edge [SWOT] Identify urgent problems [low hanging fruit 1st with best ROI] Use multiple instruments to ID customer satisfaction. The opportunity to collect misleading or useless information is possible with just one instrument. Surveys, Focus Group, Face-to-face, (Dis)satisfaction cards, Competitive Shopping - to gain information on - Stated Needs, Real Needs, Perceived Needs, Cultural/Unstated Needs, Unintended Needs (Distinguish: Wants, Needs, Dissatisfiers) ISandR@usa.com Copyright - ISandR Services and Accelper 11

- 12. 6-Sigma & Lean 101 Customer Surveys - VOC Customer Response to Survey HI MUST Improve Maintain Good Work Feature Importance Opportunity Being & Performance Lost Maintain Current Over-effort for little Status value LO Feature/Process Satisfaction HI What was expected and experienced, what was the level of satisfaction and importance ISandR@usa.com Copyright - ISandR Services and Accelper 12

- 13. 6-Sigma & Lean 101 How to look for and improve the PROBLEMS ISandR@usa.com Copyright - ISandR Services and Accelper 13

- 14. 6-Sigma & Lean 101 What is DMAIC? Define – “the charter”: why do this (ROI / VOC), which process (Pareto), achieve what, measure what (errors, FTT), which resources, who’s involved, how to accomplish (brainstorm / fishbone), what is goal, when complete, what’s not included, … Measure – specify info sources to measure, precision, frequency of measurement, instruments used to measure, … Analyze – examine patterns, correlate dependent & independent variables (SIPOC / histograms / scatter-plots), root-cause, failure influence (FMEA-SOD), … Improve – development of alternatives to reduce cost, variation, & waste or for faster delivery, … Control – sustaining gains from project and maintaining process control ISandR@usa.com Copyright - ISandR Services and Accelper 14

- 15. 6-Sigma & Lean 101 What are Tools Used with DMAIC? Define Measure Analyze Improve Phase Tools Brief Description D Project Priority Index PPI = (Benefit/Cost) X (Probability of Success/Time to complete in years) Time < .5 Estimated Savings/Cost > 2.0 Recommended PPI > 4.0 D Pareto A graphical tool to prioritize various defects to identify the most important one D Process Map A graphical description of activities and decision points D Kano's Analysis A graphical tool to identify customer critical requirements, including customers' `love to have' requirements D SIPOC An excellent tabular capture of most of the process constraints D CTQ Operational critical-to-quality characteristics related to the customer expectation D Project Charter Project plan with clearly-defined goals and milestones M Cost of Quality Breakdown of product or service cost related to appraisal, failures and prevention M DPU A product measurement, which is a ratio of the number of defects observed per unit verified M Yield The percent of process output with no error or defect. A DPMO A process measurement, which is the DPU normalized to the product or process complexity A Sigma Level A business measurement, estimated from DPMO, commonly used for benchmarking A Average Typical performance I Range Range of performance (maximum – minimum) “Stat Free Six Sigma”, Gupta ISandR@usa.com Copyright - ISandR Services and Accelper 15

- 16. 6-Sigma & Lean 101 What are Tools Used with DMAIC? Improve Control Phase Tools Brief Description I Standard Deviation More accurate estimate of performance range I Statistical Thinking Ability to distinguish assignable causes from random causes of variation I Root Cause Analysis Fishbone diagram consisting causes that produce effects - materials, machines, methods, man, nature, measurements I FMEA Failure Mode and Effects Analysis for anticipating problems I Scatter Plot Graphical display of relationship between output (dependent) and input (independent) variables I Visual Regression Analysis Estimate of relationship between input and output variables I Component Search To identify the defective part in an assembly by exchanging the questionable part between 'good' and 'bad' units I Comparative Tests - Improving Means Evaluating significance of shift or change in the process means I Comparative Tests - Improving Variance Ratio of variances between the current and reduced variances I Full Factorial Experiment Evaluating various combinations of multiple variables to determine the right combination for best performance. Total combinations = level to the power variables (Lv, e.g., 23 = 8) C Process Thinking (4P Model) A logical building block of the process management for achieving excellence. 4P => Prepare 4Ms, Perform Well, Perfect on target, Progress by reducing inconsistencies C Management Review A review meeting led by the leader to ensure targeted performance is achieved and to identify necessary actions to sustain improved performance C Control Chart Graphical tool to sustain normal (without known problems) behavior of the process C Scorecard Measure of business performance for identifying new opportunities “Stat Free Six Sigma”, Gupta ISandR@usa.com Copyright - ISandR Services and Accelper 16

- 17. 6-Sigma & Lean 101 Good Charter Components? Business need - cost reduction, margin increase, government compliance or increased customer satisfaction. Business advantage – ROI? - case should show the business need as dollars ($$s) to substantiate which project’s selection. High-level project scope – sponsor’s vision of the project. Critical to success factors – ID project, team, deliverables, schedule, what is needed for project success: scope, schedule, Constitution cost, or quality. Project constraints, risks and assumptions – document these conjectures; revisit during project to see if these remain true. Bill of Rights Authority of the project manager – what is the responsibility of Plans Change the project manager, to clarify their role assists with future decisions (controversial?) dealing with the stakeholders and organization. Signatures – demonstrates management importance & support Example of form to assist in addressing items to consider ISandR@usa.com Copyright - ISandR Services and Accelper 17

- 18. 6-Sigma & Lean 101 DMAIC Tools – PARETO Ranking of Issues Customer's Order Complaints * Late 192 Defective 44 Minitab Rude CS 37 No call back 23 Wrong Item 72 Incomplete 101 Refund late 17 Wrong Price 15 No Gift Card 3 Figure out cost/benefit Excel Missing item 2 Not New - Used 12 Never Received 7 ISandR@usa.com Copyright - ISandR Services and Accelper 18

- 19. 6-Sigma & Lean 101 Process Map (This is the “as is” also need the “proposed”) ORDER FULLFILLMENT SWIMLANE FLOWCHART CUSTOMER SERVICE ACCOUNTING WAREHOUSE Possibilities for improvement? ENGINEERING Loops and SHIPPING Many Crossings & RECEIVING Created with Visio ISandR@usa.com Copyright - ISandR Services and Accelper 19

- 20. 6-Sigma & Lean 101 What is SIPOC? Look for relationships so Input improves stability in Output Suppliers – individuals providing Suppliers Inputs Process Outputs Customers resources Paper Cliffnotes Bookclubs Graphics Figs & Photos DVDs & CDs Audio books Electronics Electronic Docs Abstracts Web Whit Papers Inputs – info, materials & Binders Album of Related work Libraries Services Authors Original Written Manuscript Exercises Consultants Training Process – value added Scholarly Educators & Researchers Instructional References Trainers Info transformation steps Editors Suggested Adds & Deletes Magazines Library Reference Docs Outputs – final product or service Process for Publishing and Distribution of Scholarly Research and Textbook Materials Customers – entity finding value Graphics Publisher First Authors submits Editor Process Approval Printing Shipment submit > figures > checks > > > Distributo > & Printing Promotio of Orders content and content r Orders in output photos Schedule n ISandR@usa.com Copyright - ISandR Services and Accelper 20

- 21. 6-Sigma & Lean 101 What is SWOT? Internal Characteristics to Business STRENGTH – list and find how to improve these WEAKNESSES – list and find how to minimize these External Characteristics to Business (in Industry or with the Competition) OPPORTUNITIES – what can you take advantage of THREATS – what should you avoid ISandR@usa.com Copyright - ISandR Services and Accelper 21

- 22. 6-Sigma & Lean 101 Cost of Quality The “cost of quality” isn’t the price of creating a quality product or service. It’s the cost of NOT creating a quality product or service. Prevention Costs - New product review, Quality planning, Supplier capability surveys, Process capability evaluations, Quality improvement team meetings, Quality improvement projects, Quality education and training, Appraisal Costs Inspection Costs - measuring, evaluating or auditing products or services to assure conformance to quality standards and performance requirements; Incoming and source inspection/test of purchased material; In-process and final inspection/test; Product, process or service audits; Calibration of measuring and test equipment; Associated supplies and materials; Failure Costs Internal Failure Costs - Failure costs occurring prior to delivery or shipment of the product, or the furnishing of a service, to the customer. Scrap, Rework, Re- inspection, Re-testing, Material review, Downgrading External Failure Costs - Failure costs occurring after delivery or shipment of the product -- and during or after furnishing of a service -- to the customer. Processing customer complaints, Customer returns, Warranty claims, Product recalls ISandR@usa.com Copyright - ISandR Services and Accelper 22

- 23. 6-Sigma & Lean 101 Brainstorming – Fishbone / Cause-Effect / Ishikawa This is a way of analyzing problem and get to the root cause The effect is usually negative - a problem The problem should be specific and clearly stated The ideas are generated by using brainstorming (vocal or silent) Keep the group to asking themselves “what would cause the problem?” Keep attention on the effect of the problem – not criticism or how to fix The goal is to find as many sources for variation as possible that cause the problem Measurements Machine Man PM vs AM Shift Temp RMAs Effect Season Storage Preparation Methods Mother Nature Materials ISandR@usa.com Copyright - ISandR Services and Accelper 23

- 24. 6-Sigma & Lean 101 FMEA – Failure Mode Effects Analysis Determine what can go wrong, the severity, and how to avoid it Risk Assessment should be a log controlled number for tracking the FMEA Number: This document Probabilitydesign responsibility: Which department or group is responsible for The of The part number, name, or other description Effect of Failure Occurrence this design? for FMEA preparation The person responsible Part Number & Function Severity The date the FMEAcomponent partand any necessary revision level The subsystem or was prepared number getting detailed analysis Potential Failure Ability toThe component function Detect mode The potential failure Risk Priority Number The potential effect of failure Cause of Failure The potential cause of failure What are the current controls in place to prevent Re-evaluation Corrective Actions & the cause from Control for Failure O is theoccurring? this failure mode will occur. This index is from 1 to 10 probability with 1 being virtually no chance and 10 being near certainty of occurrence. S is the severity of the effect of the failure on the rest of the system if the failure occurs. Values are from 1 to 10. A value of 1 means the user will be unlikely to notice with a 10 meaning that the safety of the user is in jeopardy. D is a measure of the effectiveness of the current controls to identify the potential weakness or failure prior to release to production. This index ranges from 1 to 10. A value of 1 means this will certainly be caught whereas a value of 10 indicates the design weakness would most certainly make it to final production without detection. RPN The Risk Priority Number is the product of the indices from the previous three columns. RPN = O•S•D The actions then are based upon what items either have the highest RPN and/or where the major safety issues are. There is a column for actions to be taken to reduce the risk, a column for the responsibility and finally a column for the revised RPN once corrective action is implemented. FMECA provides a disciplined approach for the engineering team to evaluate designs to ensure that all the possible failure modes have been taken into consideration. QCI – Indiana Quality Council ISandR@usa.com Copyright - ISandR Services and Accelper 24

- 25. 6-Sigma & Lean 101 Average, Standard Deviation, Max Value, Min Value in Data Sets Average Standard Maximum Minimum Deviation Active Cell ISandR@usa.com Copyright - ISandR Services and Accelper 25

- 26. 6-Sigma & Lean 101 Evaluating Data Quantify what you want to improve and make decisions based on the data. ISandR@usa.com Copyright - ISandR Services and Accelper 26

- 27. 6-Sigma & Lean 101 Comparative Tests - Improving Means & Variance - Visualization Use Methodsfor determining significant Make decisions Easier T-test to Visualize the Data to difference in Means MiddleF-test for determining significant difference in Variance Data Range 50% of MeanData 6 Sampl es - Compar i son of Means and Var i at i on 6 Sampl es - Compar i son of Means and Var i at i on 2.0 2.0 1.8 1.8 1.78123 1.68022 1.6 1.6 Dat a Dat a 1.52912 1.45738 1.47119 1.47366 1.4 1.4 1.2 1.2 1.0 1.0 sample1 sample2 sample3 sample4 sample5 sample6 sample1 sample2 sample3 sample4 sample5 sample6 Same Mean Diff Mean Same Mean Same Mean Diff Mean Same Mean Same Vari(1) Same Vari(2) Diff Vari(3) Same Vari Same Vari Diff Vari ISandR@usa.com Copyright - ISandR Services and Accelper 27

- 28. 6-Sigma & Lean 101 Yield - Efficiency of the Process %Yield most familiar for defect eval Units Pr oduced − DefectiveUnits %Yield = *100 Units Pr oduced 500 − 26 %Yield = *100 = 94.8% 500 DPU TheseTotalDefecformulas DefectsPerUnit = DPU = are tsObserved DPU = 53 with examples from = .106 Units Pr oduced 500 this table. Please Defect per Million Opportunities (DPMO) - the number of ways a defect can occur. If each item could at theseto fail (label, scratch, color, wrong info, performance,…) then look have 8 ways offline. DPU *1,000,000 0.106 *1,000,000 106,000 DPMO = = = = 13,250 # ofWayUnitCanBeDefective 8 8 Rolled Throughput Yield (RTY) What is overall Y1 x Y2 chainx Y4 yield in x Y3 of processes? Yield Yield Yield Yield Y1=0.90 Process 1 = .9 Y2=0.90 Process 2 = .9 Y3=0.90 Process 3 = .9 Y4=0.90 Process 4 = .9 (.90)x(.90)x(.90)x(.90)= Guess .656 65.6% ISandR@usa.com Copyright - ISandR Services and Accelper 28

- 29. 6-Sigma & Lean 101 Scatter Plot – Visualize Process Data & Look for Trends Y has equivalent response to X and Y has varying response to X and similar variation along response curve different variation along response curve 25 20 Dependent Variable Y y y=f(x) 15 10 x 5 0 0 5 10 15 20 25 Independent Variable X What is different about processes? ISandR@usa.com Copyright - ISandR Services and Accelper 29

- 30. 6-Sigma & Lean 101 Control/Run Chart - Variable & Attribute - Track/React to Trends Average & Range SPC Chart 31 UCL (3ϭ) 29 Continuous 27 Variable 25 Average Median & Range 23 Diameter& of Hole Average Range Average & Std Deviation 21 Short Run Charts You would look into why 19 these extremes happened LCL (3ϭ) Discrete 17 6 Attribute UCL Fraction Defective 4 P.O. with Errors Number Defective Range 2 Number of Defects Percent Defective 0 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 ISandR@usa.com Copyright - ISandR Services and Accelper 30

- 31. 6-Sigma & Lean 101 Objectives of Design of Experiments (DOE) DOE is a systematic approach to determine & optimize the response between process inputs & outputs (independent and dependent variables). S & H and Delivery Time PROCESS Part Size The objective - optimize S&H of different part sizes for best delivery time. DOE experiments do not change only one variable - variables can interact Consider the interaction of temperature and wind velocity in the wind chill factor; more wind makes it feel colder and an engine requires the right amount of both gasoline and air to get the maximum performance. The experiment that changes variables one-at-a-time (OAAT) requires more experiments and cannot evaluate interactions; it is inefficient at best. ISandR@usa.com Copyright - ISandR Services and Accelper 31

- 32. 6-Sigma & Lean 101 Two Factor DOE – Variable Influence INPUT RESULT P T Yield If you want to know the affects from two factors P1 T1 Y1 (i.e. temperature and pressure), then vary both T P1 T2 Y2 and P then record the results of the dependent P2 T1 Y3 variable (i.e. yield). P2 T2 Y4 Don’t just change one factor at a time. INPUT RESULT Introduce terms, select levels, run experiment. P T Yield 50 25 94 Change the pressure between 50 and 100 psi and 50 75 92 the temperature between 25 and 75 degrees F; record the yield results. 100 25 96 Calculate the mean yield for each factor level 100 75 88 Y@P1 = 93 Y@P2 = 92 Y@T1 = 95 Y@T2 = 90 This experiment is with 2 levels of P & T with a yield result… It could be Internal vs External S&H with big vs small parts and delivery time result 96 Plot the response. 94 From the main effects… pressure has lower 92 influence on the yield, while temperature has a 90 larger effect on the yield (more slope, more effect). 88 86 P1 P2 T1 T2 ISandR@usa.com Copyright - ISandR Services and Accelper 32

- 33. 6-Sigma & Lean 101 Two Factor DOE – Hi vs Lo Importance INPUT RESULT OK. Some of you are saying… Wait a second! P T Yield When P is changing so is T!? WHAT??????? P1 T1 Y1 EXAMPLE - Calculate the effect of P change. P1 T2 Y2 P2 T1 Y3 Yield at P1 = (Result Y1) + (Result Y2) P2 T2 Y4 Yield at P2 = (Result Y3) + (Result Y4) INPUT RESULT SUBSTITUTING VARIABLES PRODUCING THOSE YIELDS P T Yield Yield at P1 = (P1 + T1) + (P1 + T2) 50 25 94 Yield at P2 = (P2 + T1) + (P2 + T2) 50 75 92 REARRAGNING & REASSOCIATING 100 25 96 Yield at P1 = (P1 + P1 ) + (T1 + T2) 100 75 88 Yield at P2 = (P2 + P2 ) + (T2 + T2) SIMPLIFYING Yield at P1 = 2P1 + (T1 + T2) T1 & T2 contribute the This is what is important!!!! Yield at P2 = 2P2 + (T1 + T2) GRAPHICAL DEPICTION same amount to P1 or P2 2P1 or consider, the difference removes T effect 2P2 (Yield at P1) - (Yield at P2) = 2P1 - 2P2 T1+T2 T1+T2 Y@P1 Y@P2 ISandR@usa.com Copyright - ISandR Services and Accelper 33

- 34. 6-Sigma & Lean 101 More Factorial Experiment Designs – 3 & 4 Variables INPUT OUTPUT INPUT OUTPUT A B C D Result1 Result2 A B C Result1 Result2 A1 B1 C1 D1 R1 R2 A1 B1 C1 R1 R2 A1 B1 C1 D2 R1 R2 A1 B1 C2 R1 R2 A1 B1 C2 D1 R1 R2 A1 B2 C1 R1 R2 A1 B1 C2 D2 R1 R2 A1 B2 C2 R1 R2 A1 B2 C1 D1 R1 R2 A2 B1 C1 R1 R2 A1 B2 C1 D2 R1 R2 A2 B1 C2 R1 R2 A1 B2 C2 D1 R1 R2 A2 B2 C1 R1 R2 A1 B2 C2 D2 R1 R2 A2 B2 C2 R1 R2 A2 B1 C1 D1 R1 R2 Exercise for later – A2 B1 C1 D2 R1 R2 A2 B1 C2 D1 R1 R2 these are balanced experiments – equal number of each variable (A1, A2 B1 C2 D2 R1 R2 A2, B1, B2, C1, C2…), within all A2 B2 C1 D1 R1 R2 experiments that are also unique with A2 B2 C1 D2 R1 R2 respect to the arrangement of these A2 B2 C2 D1 R1 R2 variables – note: check out the colors. A2 B2 C2 D2 R1 R2 ISandR@usa.com Copyright - ISandR Services and Accelper 34

- 35. 6-Sigma & Lean 101 Lean Document the process Find the waste Make a plan to eliminate the waste ISandR@usa.com Copyright - ISandR Services and Accelper 35

- 36. 6-Sigma & Lean 101 What Are Key Concepts of Lean? Give customers what they want, when they want it, for what they want to pay, and without more inve$tment by your company Get the big picture of the process to Improve Quality Eliminate Waste - ID Value Added vs. Non-Value Added Activities Reduce Lead Time Reduce Total Costs ISandR@usa.com Copyright - ISandR Services and Accelper 36

- 37. 6-Sigma & Lean 101 Create a Value Stream Map – Present (Need Future State) This is the value stream item Description 14 process for theand Production 1 ID Customer, Supplier, entire 8 1 plant. You can also Interval 2 Customer Requirements per Time Production & Containment Requirements 1 1 make a value stream 3 4 Shipping 15 2 mapDelivery a sub-process. 5 for 5 4 EventuallyProcesses need to 6 Sequence of you 3 lookData specific toentire 7 at the each Sequence Communication Methods 11 8 processAttributes: times, Efficiency 6 9 Process to make sure 12 10 changesSymbol - not shift 10 Operator did number 7 waste or&problems to 11 Inventory Work in Process (WIP) 9 14 "Push" vs "Pull" Operations another process and 12 15 13 Other Info onlyWorking Hours Availability 14 created a “local You will probably do this with pencil & paper optimum”.Times 15 Cycle & Lead Example from - www.strategosinc.com ISandR@usa.com Copyright - ISandR Services and Accelper 37

- 38. 6-Sigma & Lean 101 How to Identify Waste – TIMWOOD or DOWNTIME Look for these forms of waste in the Value Stream Map TIMWOOD DOWNTIME Transportation Defects Inventory Over-production Motion Waiting Waiting Not Utilizing Employees* Over-processing Transportation Over-production Inventory Defects Motion Excess processing *skills, ideas, creativity ISandR@usa.com Copyright - ISandR Services and Accelper 38

- 39. 6-Sigma & Lean 101 How does 5S Help Eliminate Waste? Makes Waste Visible. 5 S - seiri, seiton, seiso, seiketsu and shitsuke Sort, separate needed from unneeded items & remove the latter Set-in-Order*/Straighten, arrange items for ease of use Shine/Scrub, means to cleanup Standardize/Systemize, disciplined structured routines Sustain/Self-Discipline, create a new habit * “6 S” adds Safety (part of Set-in-Order) – make safety equipment easy to use ISandR@usa.com Copyright - ISandR Services and Accelper 39

- 40. 6-Sigma & Lean 101 Relation of What We Learned wrt Process Improvement Other PI 6-Sigma Contributions There is more Lean ISandR@usa.com Copyright - ISandR Services and Accelper 40

- 41. 6-Sigma & Lean 101 Other Process Improvement Concepts/Tools ISandR@usa.com Copyright - ISandR Services and Accelper 41

- 42. 6-Sigma & Lean 101 What is 6-Sigma? Components of Sustained Profitable Growth Good Management Systems Business Innovation Scorecard Creating a culture 6-Sigma to sustain & create Lean new improvements ISandR@usa.com Copyright - ISandR Services and Accelper 42

- 43. 6-Sigma & Lean 101 How to Sustain Progress with Lean & 6-Sigma Keep employees motivated, customers happy, processes running smoothly, and the company making money LEAN is NOT MEAN ISandR@usa.com Copyright - ISandR Services and Accelper 43

- 44. 6-Sigma & Lean 101 What are Components of Sustained Profitable Growth Business Scorecard Customer Financials Vision & Strategy Employees Processes Management Provides Vision & Strategy so the Business Can: #1 Take Care of Customers (VOC), #2 Take Care of Employees (Training, Resources, Rewards) Employees Take Care of Processes (Process Control & Improvement) Processes Take Care of Finances (Efficient Value Added Processes = $$s) Finances Take Care of Stakeholders and Provide $$s for Growth and Improvements that add value for the customer ISandR@usa.com Copyright - ISandR Services and Accelper 44