MATERIAL STANDARDS

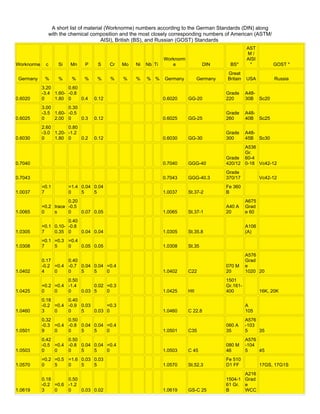

- 1. A short list of material (Worknorme) numbers according to the German Standards (DIN) along with the chemical composition and the most closely corresponding numbers of American (ASTM/ AISI), British (BS), and Russian (GOST) Standards AST M/ Worknorm AISI Worknorme c Si Mn P S Cr Mo Ni Nb Ti e DIN BS* * GOST * Great Germany % % % % % % % % % % Germany Germany Britain USA Russia 3.20 0.60 -3.4 1.60- -0.8 Grade A48- 0.6020 0 1.80 0 0.4 0.12 0.6020 GG-20 220 30B Sc20 3.00 0.30 -3.5 1.60- -0.5 Grade A48- 0.6025 0 2.00 0 0.3 0.12 0.6025 GG-25 260 40B Sc25 2.60 0.80 -3.0 1.20- -1.2 Grade A48- 0.6030 0 1.80 0 0.2 0.12 0.6030 GG-30 300 45B Sc30 A536 Gr. Grade 60-4 0.7040 0.7040 GGG-40 420/12 0-18 Vc42-12 Grade 0.7043 0.7043 GGG-40.3 370/17 Vc42-12 =0.1 =1.4 0.04 0.04 Fe 360 1.0037 7 0 5 5 1.0037 St.37-2 B 0.20 A675 =0.2 trace -0.5 A40 A Grad 1.0065 0 s 0 0.07 0.05 1.0065 St.37-1 20 e 60 0.40 =0.1 0.10- -0.8 A106 1.0305 7 0.35 0 0.04 0.04 1.0305 St.35.8 (A) =0.1 =0.3 =0.4 1.0308 7 5 0 0.05 0.05 1.0308 St.35 A576 0.17 0.40 Grad -0.2 =0.4 -0.7 0.04 0.04 =0.4 070 M e 1.0402 4 0 0 5 5 0 1.0402 C22 20 1020 20 0.50 1501 =0.2 =0.4 -1.4 0.02 =0.3 Gr.161- 1.0425 0 0 0 0.03 5 0 1.0425 HII 400 16K, 20K 0.18 0.40 -0.2 =0.4 -0.9 0.03 =0.3 A 1.0460 3 0 0 5 0.03 0 1.0460 C 22.8 105 0.32 0.50 A576 -0.3 =0.4 -0.8 0.04 0.04 =0.4 060 A -103 1.0501 9 0 0 5 5 0 1.0501 C35 35 5 35 0.42 0.50 A576 -0.5 =0.4 -0.8 0.04 0.04 =0.4 080 M -104 1.0503 0 0 0 5 5 0 1.0503 C 45 46 5 45 =0.2 =0.5 =1.6 0.03 0.03 Fe 510 1.0570 0 5 0 5 5 1.0570 St.52.3 D1 FF 17GS, 17G1S A216 0.18 0.50 1504-1 Grad -0.2 =0.6 -1.2 61 Gr. e 1.0619 3 0 0 0.03 0.02 1.0619 GS-C 25 B WCC

- 2. A216 0.18 0.50 1504-1 Grad -0.2 =0.6 -1.2 61 Gr. e 1.0619.01 3 0 0 0.03 0.02 1.0619.01 GS-C 25N B WCC 0.60 0.18 =0.1 =0.0 -1.2 -0.2 AISI 1.0711 3 5 0 0.1 5 1.0711 9S20 1212 0.90 0.27 =0.1 =0.0 -1.3 -0.3 12L 1.0718 4 5 0 0.1 3 1.0718 9SMnPb 28K 13 0.17 0.30 -0.2 =0.4 -0.7 0.03 0.03 =0.4 055 M 1020; 1.1151 4 0 0 5 5 0 1.1151 Ck 22 15 1023 20 A352 0.20 0.50 Grad -0.2 0.30- -0.8 =0.3 e 1.1156 8 0.50 0 0.03 0.03 0 1.1156 GS-Ck24 LCB 0.32 0.50 -0.3 =0.4 -0.8 0.03 0.03 =0.4 080 A 1035, 1.1181 9 0 0 5 5 0 1.1181 Ck 35 35 1038 35 0.52 0.60 2 C 55/ -0.6 =0.4 -0.9 0.03 0.03 =0.4 XC 55 1.1203 0 0 0 5 5 0 1.1203 Ck 55 H1 1055 55 4.00 20.0 3.00 15.0 =0.0 =1.0 -6.0 0.02 -21. -3.5 -17. X4CrNiMnMoN1 1.3964 3 0 0 5 0.01 5 0 0 1.3964 9 16 5 AISI 12.0 403, =0.0 =1.0 =1.0 0.04 -14. 403 S 410S 1.4000 8 0 0 5 0.03 0 1.4000 X6Cr13 17 , 42 O8Ch13 AISI 13.0 403, =0.0 =1.0 =1.0 0.04 -15. 403 S 410S 1.4001 8 0 0 5 0.03 0 1.4001 X7Cr14 17 , 42 O8Ch13 0.08 12.0 -0.1 =1.0 =1.0 -14. =1.0 410 S AISI 1.4006 2 0 0 0.04 0.03 0 0 1.4006 X10Cr13 21 410 12Ch13 16.0 =0.1 =1.0 =1.0 -18. =0.5 430 S AISI 1.4016 0 0 0 0.04 0.03 0 0 1.4016 X6Cr17 15 430 12Ch17 0.17 12.0 -0.2 =1.0 =1.0 0.04 -14. 420 S AISI 1.4021 5 0 0 5 0.03 0 1.4021 X20Cr13 37 420 20Ch13 0.12 12.0 -0.1 =1.0 =1.0 0.04 -14. 420 S 1.4024 7 0 0 5 0.03 0 1.4024 X15Cr13 29 0.42 12.5 -0.5 =1.0 =1.0 0.04 -14. 420 S 1.4034 0 0 0 5 0.03 5 1.4034 X46Cr13 45 40Ch13 0.14 15.5 1.50 -0.2 =1.0 =1.0 0.04 -17. -2.5 431 S AISI 1.4057 3 0 0 5 0.03 5 0 1.4057 X20CrNi17 2 29 431 20Ch17N2 0.10 0.15 15.5 0.20 -0.1 =1.0 =1.5 -0.3 -17. -0.6 AISI 1.4104 7 0 0 0.06 5 5 0 1.4104 X12CrMoS17 430F 1.4110 0.48 =1.0 =1.0 0.04 0.01 13.0 050- 1.4110 X55CrMo14 -0.6 0 0 5 -15. 0.80

- 3. 0 0 0.12 12.0 1.00 -0.1 =1.0 =1.0 -14. -1.3 1.4119 7 0 0 0.03 0.03 0 0 1.4119 X15CrMo13 0.33 15.5 0.80 -0.4 =1.0 =1.0 0.01 -17. -1.3 =1.0 X35CrMo17 1.4122 5 0 0 0.04 5 5 0 0 1.4122 X39CrMo17-1 0.50 27.0 2.00 -0.9 =2.0 =1.0 0.04 -30. -2.5 1.4136 0 0 0 5 0.03 0 0 1.4136 G-X70CrMo29 2 17.0 8.00 =0.1 =1.0 =2.0 0.04 -19. -10. 302 S AISI 1.4300 2 0 0 5 0.03 0 0 1.4300 X12CrNi18 8 25 302 12Ch18N9 17.0 8.50 =0.0 =1.0 =2.0 0.04 -19. -10. 304 S AISI 1.4301 7 0 0 5 0.03 0 5 1.4301 X5CrNi18 10 17 304 08Ch18N10 0.15 17.0 8.00 =0.1 =1.0 =2.0 -0.3 -19. -10. 303 S AISI 1.4305 2 0 0 0.06 5 0 0 1.4305 X10CrNiS18 9 22/31 303 AST 17.0 8.00 M =0.0 =1.5 =1.5 0.03 -20. -12. 304/30 A351 1.4306 3 0 0 5 0.02 0 0 1.4306 G-X2CrNi18 9 5 S 11 CF-3 03Ch18N11 AST 18.0 8.00 M =0.0 =1.5 =1.5 -20. =0.5 -11. 304 C A351 1.4308 7 0 0 0.04 0.03 0 0 0 1.4308 G-X6CrNi18 9 15 CF-8 07Ch18N9L 16.0 6.00 =0.1 =1.5 =2.0 0.04 0.01 -18. =0.8 -9.0 301 S AISI 1.4310 2 0 0 5 5 0 0 0 1.4310 X12CrNi17 7 21/22 301 17.0 8.00 =0.1 =2.0 =1.5 0.04 -19. -10. 302 C 1.4312 2 0 0 5 0.03 5 0 1.4312 G-X10CrNi18 8 25 10Ch18N9L 16.5 2.00 10.5 316 S =0.0 =1.0 =2.0 0.04 -18. -2.5 -13. X5CrNiMo17 12 13/17/1 AISI 1.4401 7 0 0 5 0.03 5 0 5 1.4401 2 9 316 AST MA 17.0 2.00 9.00 316 S 351 =0.0 =1.5 =1.5 0.03 -20. -3.0 -13. G-X2CrNiMo18 11/13/1 CF-3 1.4404 3 0 0 5 0.02 0 0 0 1.4404 10 4 M AST MA 18.0 2.00 9.00 351 =0.0 =1.5 =1.5 -20. -2.5 -12. G-X6CrNiMo18 316 C CF-8 1.4408 7 0 0 0.04 0.03 0 0 0 1.4408 10 16 M 07Ch18N10G2SM2L 17.0 2.00 9.00 =0.1 =2.0 =1.5 0.04 -19. -2.5 -11. G-X10CrNiMo18 1.4410 2 0 0 5 0.03 5 0 0 1.4410 9 16.5 2.50 12.5 316 S =0.0 =1.0 =2.0 0.04 -18. -3.0 -15. X2CrNiMo18 14 11/13/1 AISI 1.4435 3 0 0 5 0.03 5 0 0 1.4435 3 4 316L 03Ch17N14M3 ASTM Worknorm / AISI Worknorme C Si Mn P S Cr Mo Ni Nb Ti e DIN BS* * GOST * Great Germany % % % =% =% % % % % % Germany Germany Britain USA Russia

- 4. 16.5 11.0 =1.0 =2.0 0.04 0.02 -18. 2.50- -14. X5CrNiMo17 13 316 S AISI 1.4436 =0.07 0 0 5 5 5 3.00 0 1.4436 3 19/31 316 16.7 =1.4 =1.4 -18. 0.35- 1.4502 =0.09 0 0 0.03 0.02 3 0.65 1.4502 X8CrTi18 0.15 17.5 0.30 =0.03 =1.0 =0.5 -0.3 -19. 2.00- -0.8 1.4523 0 0 0 0.04 5 0 2.50 5 1.4523 X8CrMoTi17 17.0 >(5xC =1.0 =2.0 0.04 -19. 9.00- ) 321 S AISI 1.4541 =0.80 0 0 5 0.03 0 12.0 =0.80 1.4541 X6CrNiTi18 10 31/51 321 06Ch18N10T 16.5 10.5 =1.0 =2.0 0.04 -18. 2.00- -13. >5xC X6CrNiMoTi17 320 S AISI 10Ch17N13M2 1.4571 =0.80 0 0 5 0.03 5 2.50 5 =0.80 1.4571 12 2 18/31 316Ti T 16.5 10.5 =1.0 =2.0 0.04 -18. 2.00- -13. >5xC X10CrNiMoTi18 320 S AISI 10Ch17N13M2 1.4571 =0.80 0 0 5 0.03 5 2.50 5 =0.80 1.4571 10 18/31 316Ti T 16.5 12.0 =1.0 =2.0 0.04 -18. 2.00- -14. X10CrNiMoTi18 320 S AISI 10Ch17N13M3 1.4573 =0.10 0 0 5 0.03 5 2.50 5 >5xC 1.4573 12 33 316Ti T 18.2 10.2 =1.4 =1.9 0.02 0.01 -19. 2.50- -12. >(12xC)=1.1 X5CrNiMoNb19 1.4576 =0.06 0 0 5 5 8 3.00 8 5 1.4576 12 16.5 11.0 G- AISI =1.0 =2.0 0.04 -18. 2.00- -14. X10CrNiMoNb1 318 S 316C 08Ch16N13M2 1.4580 =0.08 0 0 5 0.03 5 2.50 0 >8xC 1.4580 8 10 17 b B 18.0 9.00 G- =1.5 =1.5 -20. 2.00- -12. >8x X5CrNiMoNb18 318 C 1.4581 =0.07 0 0 0.04 0.03 0 2.50 0 C=1.00 1.4581 10 17 18.0 9.00 =2.0 =1.5 0.03 0.01 -20. =0.5 -11. 1.6902 =0.07 0 0 5 5 0 0 0 1.6902 G-X6CrNi18 10 0.50 0.51-0 1.20- 0.50- -0.8 1.7102 .59 1.60 0.80 0.03 0.03 0 1.7102 54SiCr6 A182 0.70 Grade 0.08-0 =0.3 0.40- 0.02 -1.1 0.40- 1501-6 F11/1 1.7335 .18 5 1.00 0.03 5 5 0.60 1.7335 13CrMo4-4 20/621 2 12ChM; 15ChM 1.00 A217 0.15-0 =0.6 0.50- -1.5 0.45- Grade 1.7357 .20 0 1.00 0.02 0.02 0 0.65 1.7357 GS-17CrMo5-5 WC6 2.00 A182 0.08-0 0.30- 0.40- -2.5 0.90- 1501-6 Grade 1.7380 .15 0.50 0.70 0.04 0.04 0 1.10 1.7380 10CrMo9 10 22/515 F22 12Ch8 0.90 0.47-0 =0.4 0.70- 0.03 0.03 -1.2 735, H 1.8159 .55 0 1.10 5 5 0 1.8159 50CrV4 51 6150 50ChFA Worknorm ASTM Worknorme Mn P Si Ni Cu Sn Zn Pb Al Fe e DIN BS* / AISI* GOST* Great Britai Russi Germany % % % % % % % % % % Germany Germany n USA a not not available 65 0.8 30.7 2 1.5 available SoMs 2065

- 5. 69.0 =0.0 -71. =0.0 =0.0 =0.0 =0.0 2.0265 5 0 5 rem 5 2 5 2.0265 CuZn30 62.0 0.10 =0.1 =0.3 -64. =0.1 -0.7 =0.0 =0.2 2.0332 0 0 0 0 rem 0 5 0 2.0332 CuZn37Pb0.5 59.0 0.50 0.20 =0.1 =0.0 -63. =0.7 -2.5 -0.8 =0.5 2.0340.05 0 5 0 0 rem 0 0 0 2.0340.05 G-CuZn37Pb 58.5 1.50 2874 B124 =0.1 =0.3 -59. =0.2 -2.5 =0.1 =0.4 CZ12 C3770 2.0380 0 0 8 0 rem 0 0 0 2.0380 CuZn39Pb2 1 0 57.5 2.50 2874 B124 =0.2 =0.4 -59. =0.3 -3.3 =0.1 =0.4 CZ12 C3770 2.0401 0 0 0 0 rem 0 0 0 2.0401 CuZn39Pb3 1 0 57.5 1.50 2872 B124 =0.2 =0.4 -59. =0.3 -2.5 =0.1 =0.4 CZ12 C3770 2.0402 0 0 0 0 rem 0 0 0 2.0402 CuZn40Pb2 2 0 56.0 1.50 2872 B124 =0.2 =0.4 -58. =0.3 -2.5 =0.1 =0.4 CZ12 C3770 2.0406 0 0 0 0 rem 0 0 0 2.0406 CuZn41Pb2 3 0 1.50 2.00 58.0 -2.5 =0.1 -3.0 -61. =0.5 =0.8 0.30 =0.5 2.0540 0 0 0 0 0 rem 0 -1.5 0 2.0540 CuZn35Ni 3.00 79.5 8.50 2.50 2872 B150 =1.5 -6.0 -85. -10. -5.3 Ca10 C6300 2.0966 0 0 0 5 0 2.0966 CuAl10Ni 4 0 4.00 8.50 3.50 B148 =2.5 -6.5 >76. -11. -5.5 1400 C9550 2.0975.01 0 0 0 0 0 2.0975.01 G-CuAl10Ni AB2 0 0.01 7.50 2872 B103 -0.4 =0.3 -9.0 =0.3 =0.0 =0.1 Pb10 C5210 2.1030 0 0 rem 0 0 5 0 2.1030 CuSn8 4 0 88.0 9.00 =0.2 -90. -11. =0.5 =1.0 =0.2 1400 2.1050.01 0 0 0 0 0 0 2.1050.01 G-CuSn10 Pb4 86.0 9.00 1.00 G- B584 =0.0 -89. -11. -3.0 =1.5 =0.2 CuSn10Zn(Rg 1400 C9050 2.1086.01 5 0 0 0 0 5 2.1086.01 10) G1 0 81.0 6.00 3.00 5.00 G- B584 =0.0 -85. -8.0 -5.0 -7.0 =0.2 CuSn7ZnPb(R 1400 C9320 2.1090.01 5 0 0 0 0 5 2.1090.01 g 7) LPB1 0 84.0 4.00 4.00 4.00 G- B62 =0.0 -86. -6.0 -6.0 -6.0 =0.3 CuSn5ZnPb(R 1400 C8360 2.1096.01 5 0 0 0 0 0 2.1096.01 g 5) LG2 0 0.10 10.5 -0.5 -13. =0.2 =1.0 =0.1 =0.5 =0.2 =0.8 3.2523 0 5 0 0 0 0 0 rem 0 3.2523 GB-AlSi12(Cu) 10.5 =0.4 -13. =0.0 =0.1 =0.5 3.2581 0 5 5 0 rem 0 3.2581 G-AlSi12 * equivalent materials to DIN to be used for guidance only