Process control of weaving

•Télécharger en tant que PPTX, PDF•

10 j'aime•5,396 vues

Signaler

Partager

Signaler

Partager

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (20)

4 Point Fabric Inspection System in Textile Industry

4 Point Fabric Inspection System in Textile Industry

En vedette

Textile Book on process control in spinningProcess control and yarn quality in spinning woodhead publishing-karthik

Process control and yarn quality in spinning woodhead publishing-karthikSVKMs, NMIMS, MPSTME, CTF, Shirpur, Dist. Dhule

Development Of Jacquard Design Through Computer Aided Design Cad WeavingDevelopment Of Jacquard Design Through Computer Aided Design Cad Weaving

Development Of Jacquard Design Through Computer Aided Design Cad WeavingWeMited Innovations Pvt. Ltd

En vedette (20)

BRANDING — Fashion Institute of Technology Denim Project Presentation — Feb 2...

BRANDING — Fashion Institute of Technology Denim Project Presentation — Feb 2...

Process control and yarn quality in spinning woodhead publishing-karthik

Process control and yarn quality in spinning woodhead publishing-karthik

Development Of Jacquard Design Through Computer Aided Design Cad Weaving

Development Of Jacquard Design Through Computer Aided Design Cad Weaving

Similaire à Process control of weaving

Mill Training.Industrial Attachment of Square Knit Fabrics Limited by Milon, Mamun ,Plabon ...

Industrial Attachment of Square Knit Fabrics Limited by Milon, Mamun ,Plabon ...Bangladesh University of Textiles (BUTEX)

This thesis deals with a major problem of production loss of a knitting industry. The knitting machine has to stop when defects occurred and then faults are corrected, which results in time loss and efficiency loss. Not only that the knitted fabric may be rejected if quality requirements are not met. An effective monitoring is required to avoid defects and to avoid productivity and quality losses. The study identifies two main categories of defects (average time required for correcting defects and machine down time) are responsible for reducing productivity. The thesis reflects that due to yarn breakage machine stopped for seen minutes per days, for maintaining machine stopped for two hours per month, for needle breakage six minutes per day and for technical problem machine stopped for several times.Efficiency losses calculation and identify causes of losses of circular knitt...

Efficiency losses calculation and identify causes of losses of circular knitt...Elias Khalil (ইলিয়াস খলিল)

Similaire à Process control of weaving (20)

Weft knitting machine & parameters of weft knitted fabric

Weft knitting machine & parameters of weft knitted fabric

function of card frame in process control in spinning.docx

function of card frame in process control in spinning.docx

Industrial Attachment of Square Knit Fabrics Limited by Milon, Mamun ,Plabon ...

Industrial Attachment of Square Knit Fabrics Limited by Milon, Mamun ,Plabon ...

Efficiency losses calculation and identify causes of losses of circular knitt...

Efficiency losses calculation and identify causes of losses of circular knitt...

Garment manufacturing process from fabric to poduct

Garment manufacturing process from fabric to poduct

Production Process of fully fashioned knitwear manufacturing.

Production Process of fully fashioned knitwear manufacturing.

Plus de Md. Mazadul Hasan Shishir

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of 65/35 In Using Two Bath Systemproject on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...Md. Mazadul Hasan Shishir

Plus de Md. Mazadul Hasan Shishir (20)

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

PROJECT : REACTION MECHANISM OF REACTIVE DYES IN ON CELLULOSE FIBER.

PROJECT : REACTION MECHANISM OF REACTIVE DYES IN ON CELLULOSE FIBER.

Industrial attachment of Olio apparels ltd (envoy group)

Industrial attachment of Olio apparels ltd (envoy group)

Industrial attachment of divine group of industries limited (dgi).

Industrial attachment of divine group of industries limited (dgi).

Dernier

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Dernier (20)

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Process control of weaving

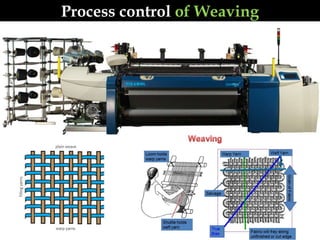

- 1. Process control of Weaving

- 2. Introduction : Process control is defined as a statistical & engineering tools or discipline that deals with architecture ( structure ) , mechanism and algorithm (sequence of finite instruction ) for controlling the output of a specific production process . Quality is formed during production process . So, if a production process is not controlled, the target production quality or reference parameter may not achieved INTRODUCTION

- 3. Process control is performed by six steps : 1. Step-1: Draw process flow chart showing real change in products geometry 2. Step-2 : Segregate or highlight the part of the flow chart where any change is taking place 3. Step-3 : Find the set points or control points value at each step 4. Step-4 : Determine which output variables have gone out of the range of standard / reference values beyond tolerance 5. Step- 5 : Identify cause which is responsible 6. Step-6 : Make recommendation as what to do PROCESS CONTROL

- 4. PROCESS FLOW CHART OF WEAVING

- 5. Fabric Sample :Denim Fabric Construction :( 73 × 43 / 15 × 10 ) × 55 Structure :Twill Interlacing Pattern :2/1 Yarn Type :Cotton Yarn GSM :230

- 6. Process Control of Warping Section

- 7. Input Variable of Warping Input Quantity Required Quantity Yarn Count 15 16 CV % 10 12 Strength / tenacity 11 13 Breaking elongation (%) 8 8.5 Minimum Staple length of Yarn 2.5 2.7 Contamination Moderate Moderate Yarn type Cotton Cotton Yarn hairiness Moderate Low Yarn micronaire value 3.5 4 Twist factor 4 4.5

- 8. Output Variable of Warping Output Quantity Required Quantity Process Control Yarn uniformity (CV % ) 10 12 Uniformity of warped yarn depends on the uniformity of the input raw yarn. By controlling the uniformity of raw yarn warped yarn uniformity also can be controlled Broken or loose ends 10 5 To reduce yarn breakage lower strength / tenacity yarn has to remove Density of package(yarn/inch) 132 130 To maintain the yarn density of warp beam perfect count of V – reed have to be used Beam barrel diameter ( inch) 12 13 To maintain the warp beam diameter , beam barrel diameter also have to control during selection of warp beam Width of warp beam 58 60 To produce the actual wide of the fabric the warp beam diameter also have to be perfect . It is control during selection of warp beam Coarse knots 10 5 To reduce coarse knot actual quantity & type of yarn twist have to be maintain

- 9. Process Control of Sizing Section

- 10. Output Variable of Sizing Output Quantity Required Quantity Process Control Count of sized yarn 8 10 To maintain sized yarn count proper amount of sizing percentage have to be maintained Uniformity of sized yarn Moderate Good Uniformity of sized yarn can be maintained by properly sizing Percent of size 3 1.5 Percent of size can be maintained by controlling the immersion roller Strength & uniformity of sized yarn 13 15 Strength & uniformity of sized yarn can be maintained by maintaining the proper sizing recipe & heat of drying chamber Unwindability Low Moderate Unwindability can be reduce by properly drying sized yarn Density of sized beam ( 73 75 Density of sized beam can be

- 11. Process Control of Drawing-in & trying Section

- 12. Output Variable of Drawing in & trying Output Quantity Required Quantity Process Control Cross ends 5 3 Cross ends can be reduce by carefully drawing - in Extra ends 10 5 Extra ends can be reduce by conforming sufficient yarn strength

- 13. Process Control of Looming Section

- 14. Output Variable of Warping Output Quantity Required Quantity Process Control Construction 73 × 43 / 15 × 10 75 × 45 / 16 × 12 Construction of the fabric can be maintained by using proper reed count &pattern card GSM 230 235 GSM of the fabric can be maintained by using proper fabric construction & yarn count Salvage Structure Plain Plain Salvage Structure can be maintained by using proper type of selvedge & the salvage forming pattern card Broken ends / picks 5 3 Broken ends / picks can be reduce by controlling the RPM of the loom Double ends / double picks 5 3 Double ends / double picks can reduce by carefully drawing – in

- 15. Output Variable of Warping Output Quantity Required Quantity Process Control End out / miss picks / knot 6 4 End out / miss picks / knot can be reduce by properly adjusting the ends / picks after broken Hole ( per lot ) 10 8 Holes in the fabrics can be removed by reducing the no. of naps in the yarn Reed streak 3 2 Reed streak can be removed by maintaining or replacing the reed Stop marks ( Per lot ) 8 5 Stop marks can be reduce by reducing the machine stoppage time during production Dirt amount Moderate Low Dirt amount can be reduce by controlling the dirt contamination & carefully handling the machine

- 16. Conclusion: By this experiment we have learn about process quality control of weaving section. Which has increased our practical knowledge about process quality control. It will be helpful for our future practical knowledge. CONCLUSION: