Introduction to Mass Transfer Operations (2 of 5)

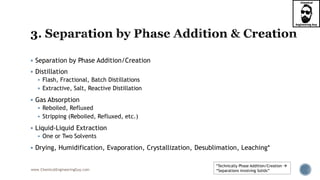

- 1. www.ChemicalEngineeringGuy.com ▪ Separation by Phase Addition/Creation ▪ Distillation ▪ Flash, Fractional, Batch Distillations ▪ Extractive, Salt, Reactive Distillation ▪ Gas Absorption ▪ Reboiled, Refluxed ▪ Stripping (Reboiled, Refluxed, etc.) ▪ Liquid-Liquid Extraction ▪ One or Two Solvents ▪ Drying, Humidification, Evaporation, Crystallization, Desublimation, Leaching* *Technically Phase Addition/Creation → “Separations involving Solids”

- 2. www.ChemicalEngineeringGuy.com ▪ We use both (Creation & Addition) since they are pretty similar and in some case they act both at the same time: ▪ Distillation vs. Gas Absorption ▪ Extractive distillation

- 3. www.ChemicalEngineeringGuy.com ▪ If the feed is a single-phase solution, a second separable phase must be developed before separation of the species can be achieved. ▪ The second phase is created by: ▪ an energy separating agent (ESA) and/or ▪ added as a mass-separating agent (MSA) Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 4. www.ChemicalEngineeringGuy.com ▪ An ESA involves: ▪ heat transfer or ▪ transfer of shaft work to/from the mixture. ▪ An example of shaft work: ▪ Creation of vapor from a liquid phase by reducing the pressure. ▪ An MSA may be partially immiscible with one or more mixture components ▪ It is frequently the constituent of highest concentration in the added phase. ▪ Alternatively, the MSA may be miscible with a liquid feed mixture ▪ BUT may selectively alter partitioning of species between liquid and vapor phases. ▪ This facilitates a separation when used in conjunction with an ESA ▪ E.g. extractive distillation

- 5. www.ChemicalEngineeringGuy.com ▪ Disadvantages of using an MSA: ▪ need for an additional separator to recover the MSA for recycle ▪ need for MSA makeup ▪ possible MSA product contamination ▪ more difficult design procedures. ▪ When immiscible fluid phases are contacted: ▪ intimate mixing is used to enhance mass-transfer rates so that the maximum degree-of- partitioning of species can be approached rapidly. ▪ After phase contact: ▪ the phases are separated by employing gravity and/or an enhanced technique such as centrifugal force. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 6. www.ChemicalEngineeringGuy.com ▪ The most common separation operations based on interphase mass transfer between two phases. ▪ Commonly, one of which will be created by an ESA or added as an MSA.

- 7. www.ChemicalEngineeringGuy.com ▪ Overview, Calculations, Process, Equipment ▪ Flash Distillation ▪ Fractional Distillation ▪ Batch Distillation ▪ Azeotropic Distillation ▪ Extractive Distillation ▪ Pressure-Swing Distillation ▪ Steam Distillation ▪ Vacuum Distillation

- 8. www.ChemicalEngineeringGuy.com ▪ Partial condensation/vaporization and Flash vaporization. ▪ Exploiting Partial Pressures and Volatilities: ▪ When the feed mixture includes species that differ widely in volatility, expressed as vapor–liquid equilibrium ratios (K- values)— partial condensation or partial vaporization - may be adequate to achieve the desired separation. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 9. www.ChemicalEngineeringGuy.com ▪ Two phases are created when a vapor feed is partially condensed by: ▪ removing heat, and a liquid feed is partially vaporized by adding heat.

- 10. www.ChemicalEngineeringGuy.com ▪ Alternatively: ▪ A partial vaporization can be initiated by flash vaporization Operation ▪ By reducing the feed pressure with a valve or turbine.

- 11. www.ChemicalEngineeringGuy.com ▪ In both operations: ▪ After partitioning of species has occurred by interphase mass transfer, the resulting vapor phase is enriched with respect to the species that are more easily vaporized ▪ While the liquid phase is enriched with respect to the less-volatile species. ▪ The two phases are then separated by gravity (Vapor on Top as Distillate, Liquid on Bottoms) Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 12. www.ChemicalEngineeringGuy.com ▪ Typical Calculations: ▪ Inlet Feed Composition ▪ Material balance in Vapor/Liquid ▪ Energy requirements for isothermal operation ▪ The Drum: ▪ Drum Size (Diameter & Height) ▪ Dimensions (inside) ▪ Demister sizing / placing

- 13. www.ChemicalEngineeringGuy.com ▪ One of the most widely uses of flashing is in the petroleum refining: ▪ Rough separation of: ▪ Gases vs. Liquids is required prior distillation. ▪ Another application is in the Amine Treating Process: ▪ Removal of Vent gases Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 14. www.ChemicalEngineeringGuy.com ▪ Flash Drums ▪ Horizontal / Vertical

- 15. www.ChemicalEngineeringGuy.com ▪ Often, the degree of separation achieved by a single contact of two phases is inadequate ▪ It may be to the volatility differences among species not being sufficiently large. ▪ In that case, fractional distillation is a good fit! ▪ It is the most widely utilized industrial separation method

- 16. www.ChemicalEngineeringGuy.com ▪ Distillation involves multiple contacts between counter- currently flowing: ▪ liquid phase (goes downwards, due to gravity) ▪ vapor phase (goes upwards, due to gravity) ▪ Each contact, called a stage, consists of mixing the phases ▪ This promotes rapid partitioning of species by mass transfer ▪ It is then followed by phase separation. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 17. www.ChemicalEngineeringGuy.com ▪ The contacts are often made on horizontal trays arranged in a column ▪ Vapor, flowing up the column, is increasingly enriched with respect to the more-volatile species ▪ Liquid flowing down the column is increasingly enriched with respect to the less-volatile species.

- 18. www.ChemicalEngineeringGuy.com ▪ Feed to the column enters on a tray somewhere between the top and bottom trays. ▪ The portion of the column above the feed entry is the enriching or rectification section, and that portion below is the stripping section ▪ Vapor feed starts up the column; feed liquid starts down. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 19. www.ChemicalEngineeringGuy.com ▪ Liquid is required for making contacts with vapor above the feed tray ▪ Vapor is required for making contacts with liquid below the feed tray. ▪ Commonly: ▪ At the top of the column, vapor is condensed to provide down-flowing liquid called reflux. ▪ Similarly, liquid at the bottom of the column passes through a reboiler, where it is heated to provide up- flowing vapor called boilup.

- 20. www.ChemicalEngineeringGuy.com ▪ Typical objectives: ▪ Use a Murphree vapor-stage efficiency to determine the number of actual stages (plates) from the number of equilibrium stages. ▪ Extend the McCabe–Thiele method to: ▪ multiple feeds ▪ Sidestreams ▪ open steam (in place of a reboiler). ▪ Estimate overall stage efficiency for binary distillation from correlations & laboratory column data.

- 21. www.ChemicalEngineeringGuy.com ▪ 1. Feed flow rate, composition, temperature, pressure, and phase condition 2. Desired degree of component separation ▪ 3. Operating pressure (which must be below the critical pressure of the mixture) ▪ 4. Pressure drop, particularly for vacuum operation ▪ 5. Minimum reflux ratio and actual reflux ratio ▪ 6. Minimum number of equilibrium stages and actual number of equilibrium stages (stage efficiency) ▪ 7. Type of condenser (total, partial, or mixed) ▪ 8. Degrees of liquid reflux subcooling Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 22. www.ChemicalEngineeringGuy.com ▪ 9. Type of reboiler (partial or total) ▪ 10. Type of trays or packing ▪ 11. Column height ▪ 12. Feed-entry stage ▪ 13. Column diameter ▪ 14. Column internals, and materials of construction ▪ 15. Heat lability and chemical reactivity of feed components

- 23. www.ChemicalEngineeringGuy.com ▪ Fractional Distillations in the industry:

- 24. www.ChemicalEngineeringGuy.com ▪ Most common types of Distillations are: ▪ Petrochemicals, separation of liq-vap ▪ Petroleum Refining Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 26. www.ChemicalEngineeringGuy.com ▪ As the name implies, is a Distillation. ▪ Batch refers to the concept of non-continuous “batch” operation. ▪ Composition, flow rates, heat rates, temperature and many other variables WILL change with respect to time. ▪ A familiar example of a batch distillation is the laboratory distillation shown next. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 27. www.ChemicalEngineeringGuy.com ▪ The liquid mixture is charged to a still-pot and heated to boiling. ▪ The vapor formed is continuously removed and condensed to produce a distillate. ▪ The compositions of the initial charge and distillate change with time; there is no steady state. ▪ The still temperature increases and the amount of lower- boiling components in the still pot decreases as distillation proceeds.

- 28. www.ChemicalEngineeringGuy.com ▪ Batch operations can be used to advantage when: ▪ The capacity of a facility is too small to permit continuous operation at a practical rate. ▪ Seasonal or customer demands require distillation in one unit of different feedstocks to produce different products. ▪ Several new products are to be produced with one distillation unit for evaluation by potential buyers. ▪ Upstream process operations are batchwise and the compositions of feedstocks for distillation vary with time or from batch to batch. ▪ The feed contains solids or materials that form solids, tars, or resin that can plug or foul a continuous distillation column. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 29. www.ChemicalEngineeringGuy.com ▪ Time is king! ▪ Batch Operations: ▪ No Reflux (Simple) ▪ With Reflux ▪ Continuous Reflux, changing Composition of Distillate ▪ Continuous Distillate composition, changing Reflux ▪ Operation Line vs. Equilibrium Lines ▪ Number of Stages ▪ Sizing, Pressure Drops ▪ Pot Size / Equipment ▪ Reservoir, Reflux control

- 30. www.ChemicalEngineeringGuy.com ▪ Application of Rayleigh equation for a simple batch distillation for differential distillation (1 stage) ▪ Calculations as a function of time: ▪ batch-still temperature, residue composition, instantaneous comps, average distillate composition ▪ Apply the by modified McCabe–Thiele methods, residue and distillate compositions for binary batch rectification under conditions of equilibrium stages ▪ Application of: ▪ shortcut and rigorous equilibrium-stage methods Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 31. www.ChemicalEngineeringGuy.com ▪ Type of Operations: ▪ Batch Stripper ▪ Middle Vessel Column ▪ Batch Rectifier

- 32. www.ChemicalEngineeringGuy.com ▪ Pharma Industry ▪ Breweries ▪ Small Plants

- 34. www.ChemicalEngineeringGuy.com ▪ Steam distillation refers to a process in which live steam is in direct contact with the distilling system in either batch or continuous operation. ▪ The basis of steam distillation rest on the fact that water forms immiscible mixtures with most organic substances ▪ These mixtures will boil at a temperature below that of either water or the other materials.

- 35. www.ChemicalEngineeringGuy.com ▪ This is a very desirable feature, especially if the organic compound has a high boiling point at which it may be unstable or decompose. ▪ As long as liquid water is present, the high boiling component will vapourise at a temperature well below its normal boiling point. ▪ Steam is widely used because of its energy level, cheapness, and availability. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 36. www.ChemicalEngineeringGuy.com ▪ Steam distillation is commonly used in the following situations (1/2) ▪ To separate relatively small amounts of volatile impurity from a large amount of material ▪ To separate appreciable quantities of higher-boiling materials ▪ To recover high-boiling materials from small amounts of impurity which have a higher boiling point

- 37. www.ChemicalEngineeringGuy.com ▪ Steam distillation is commonly used in the following situations (2/2) ▪ Where the material to be distilled is thermally unstable or reacts with other components associated with it at the boiling temperature ▪ Where the material cannot be distilled by indirect heating even under low pressure because of the high boiling temperature ▪ Where direct-fired heaters cannot be used because of fire hazards Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 38. www.ChemicalEngineeringGuy.com ▪ Typically, you will focus on: ▪ Distillation Column ▪ Extraction ▪ Retention of organic-aqueous layer

- 39. www.ChemicalEngineeringGuy.com ▪ Typical crude distillation unit with steam strippers for its side-draw products: ▪ Kerosene & gas oil. ▪ Steam distillation is most commonly employed in petroleum refining operation, usually in combination with vacuum distillation. ▪ Essential Oils Extraction ▪ Typically performed via batch (non-copntinuous)

- 40. www.ChemicalEngineeringGuy.com ▪ Steam distillation of stearic acid. ▪ Stearic acid is steam distilled at 200°C in a direct-fired still. ▪ Steam is introduced into the molten acid in small bubbles, and the acid in the vapor leaving the still has a partial pressure equal to 70% of the vapor pressure of pure stearic acid at 200°C. ▪ Plot the kg acid distilled per kg steam added as a function of total pressure from 101.3 kPa to 3.3 kPa at 200°C. ▪ The vapor pressure of stearic acid at 200°C is 0.40 kPa. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 41. www.ChemicalEngineeringGuy.com ▪ This method of distillation is very much similar to conventional distillation ▪ Main exception is that it operates at very low (near vacuum) pressure.

- 42. www.ChemicalEngineeringGuy.com ▪ This method of distillation allows the mixture to boil at a lower temperature ▪ This avoids the thermal degradation problem ▪ To handle the larger volume of vapours that result from distillation at reduced pressure, a vacuum distillation column usually have fairly large diameter and tray spacings. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 43. www.ChemicalEngineeringGuy.com ▪ Pretty similar as any Distillation Tower. ▪ Pressure Controllers is an issue

- 45. www.ChemicalEngineeringGuy.com ▪ An example flowsheet for a crude distillation column (using steam distillation) & the vacuum distillation column is shown in the below. ▪ The most common type of unit: ▪ VDU (pink) ▪ Vacuum Distillation Unit ▪ After Atmospheric (cheaper) distillation is performed ▪ VDU is further used

- 46. www.ChemicalEngineeringGuy.com ▪ Separates a mixture that forms a pressure-sensitive azeotrope ▪ It uses two columns in sequence at different pressures. ▪ In this case, separation can be achieved without using an additional entrainer (MSA) ▪ For example: ▪ Ethanol-Water mixture ▪ Azeotropic composition 89.4 mole% at 101.325 kPa ▪ Azeotropes does not form at P < 9.2 kPa. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 47. www.ChemicalEngineeringGuy.com ▪ Consider the case of a minimum-boiling azeotrope: ▪ with T-x-y curves at P2 ▪ As the pressure is reduced to P1: ▪ the azeotropic concentration moves toward a smaller percentage of A (xP2 to xP1).

- 48. www.ChemicalEngineeringGuy.com ▪ The set-up for a pressure-swing distillation will be then: ▪ Column 1, at P1 ▪ Column 2, at P2

- 49. www.ChemicalEngineeringGuy.com ▪ Typical calculations are similar as in Distillation ▪ Plus: Pressure changer

- 50. www.ChemicalEngineeringGuy.com ▪ Planning and Sequencing are an important factor here. ▪ Correct displacement of the azeotrope is required Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 52. www.ChemicalEngineeringGuy.com ▪ Separation of a mixture of 5% water with 95% tetrahydrofuran. ▪ This azeotrope can be economically separated using a pressure swing distillation system. ▪ The “swing” in this case between 1 atm and 8 atm.

- 53. www.ChemicalEngineeringGuy.com ▪ Recall from previous lecture that: ▪ an azeotrope is a special class of liquid mixture that boils at a constant temperature at a certain composition. ▪ It behaves as if it were one component with one constant boiling point. ▪ Such mixture cannot be separated using conventional distillation methods. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 54. www.ChemicalEngineeringGuy.com ▪ The problem: ▪ A temperature is reached at which the compositions of the vapour phase and liquid phase become the same. ▪ The compositions of the liquid and vapour remain the same until all of the liquid is eventually vapourised.

- 55. www.ChemicalEngineeringGuy.com ▪ Separation of Azeotropic Mixtures can be broadly classified into the following methods: ▪ changing system pressure (Pressure-Swing Distillation) ▪ by addition of an entrainer ▪ Azeotropic Distillation ▪ NOT → Extractive Distillation ▪ by combination with other processes (Hybrid systems) Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 56. www.ChemicalEngineeringGuy.com ▪ Main focus: ▪ Separation of Binary Azeotropes by Addition of Entrainer ▪ A new component (called the entrainer) is added to the original feed mixture ▪ This form (or nearly form) an azeotrope with one (or more) of the feed components. ▪ The azeotrope is then removed as either the distillate or the bottoms.

- 57. www.ChemicalEngineeringGuy.com ▪ Azeotropic distillation also refers to those processes in which a new component is added to an original feed mixture ▪ This will break an azeotrope that otherwise would be formed by the feed components. ▪ Thus, the purpose of deliberately adding the entrainer is: ▪ Either: ▪ to separate one component of a closely boiling pair ▪ Or: ▪ to separate one component of an azeotrope. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 58. www.ChemicalEngineeringGuy.com ▪ To illustrate the basic concepts consider the following set- up: ▪ Separation of a mixture A-B that forms minimum-boiling azeotrope (MinBA) ▪ The entrainer “E” is either: ▪ A medium boiler ▪ i.e. its boiling point in intermediate between components A and B ▪ or is a low boiler ▪ that can form an intermediate boiling maximum azeotrope with A. *This is the main difference between Extractive distillation Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 59. www.ChemicalEngineeringGuy.com ▪ The FEED (A and B) is mixed with the entrainer E (recycled/recovered from C2) before entering column C1 ▪ Component B (which is essentially free of the azeotrope A-E) is removed from the bottom of column C1 ▪ The overhead vapour from C1 is fed to column C2.

- 60. www.ChemicalEngineeringGuy.com ▪ Component A is removed as overhead product and entrainer E as the bottoms product. ▪ The entrainer is recycled back to column C1. ▪ This assume 100% removal of Entrainer “E” in C2.

- 61. www.ChemicalEngineeringGuy.com ▪ Alternatively, component A can be separated first as overhead from column C1. ▪ Column C2 then splits the bottoms from C1 into: ▪ the entrainer E (as overhead product) ▪ component B (as bottoms product). ▪ For a maximum-boiling azeotrope: ▪ the entrainer should either be a medium boiler ▪ or a high boiler that forms an intermediate-boiling azeotrope with component B. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 62. www.ChemicalEngineeringGuy.com ▪ The problem of such processes lies in the existence of an appropriate entrainer. ▪ The probability of azeotrope formation increases with decreasing boiling point differences of A and B ▪ Most azeotropic mixtures to be separated by distillation are close boiling ones. ▪ In many cases it may be difficult or even impossible to find a substance that boils between AND does not form new azeotropes.

- 63. www.ChemicalEngineeringGuy.com ▪ But even if such an entrainer exists: ▪ the process might be uneconomical because of the small boiling point difference in the system. ▪ The entire process has to be performed in the boiling point range of the A-B mixture. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 64. www.ChemicalEngineeringGuy.com ▪ The system acetone-heptane-benzene is one of the few examples in which the process works economically. ▪ Example: ▪ Acetone-Heptane + benzene as the entrainer. ▪ The respective boiling points are: ▪ A - acetone (56.2°C) ▪ B - heptane (98.4°C) ▪ E - benzene (80.1°C) ▪ A-B Minimum-boiling azeotrope (55.6°C).

- 66. www.ChemicalEngineeringGuy.com ▪ When the volatility difference between two species to be separated is so small as to necessitate more than about 100 trays ▪ Consider Extractive Distillation ▪ Here, a miscible MSA, acting as a solvent, increases the volatility difference among species in the feed ▪ This reducing the number of trays Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 67. www.ChemicalEngineeringGuy.com ▪ The boiling point of the solvent is generally: ▪ much higher than the boiling points of the feed mixture that formation of new azeotropes is impossible. ▪ The high boiling point will also ensure that the solvent: ▪ will not vapourise in the distillation process. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 68. www.ChemicalEngineeringGuy.com ▪ Generally: ▪ the MSA is the least volatile species and is introduced near the top of the column. ▪ Reflux to the top tray minimizes MSA content in the top product. ▪ A subsequent operation, usually distillation ▪ is used to recover the MSA for recycling.

- 69. www.ChemicalEngineeringGuy.com ▪ Typically, Requires 2 Equipment: ▪ Extractive Distillation Column ▪ Entertainer/MSA Separation Column ▪ Aka Solvent Recovery Column ▪ Calculations are pretty similar to those in Fractional Distillation ▪ Ternary Diagrams might be required for Extraction ▪ Solvent Selection ▪ Volatility Change Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 70. www.ChemicalEngineeringGuy.com ▪ Petrochemical Applications: ▪ Separation of acetone & alcohol ▪ Separation of Toluene & i-Octane

- 71. www.ChemicalEngineeringGuy.com ▪ In general, Distillation Columns ▪ Trayed Columns

- 72. www.ChemicalEngineeringGuy.com ▪ A classic example to be cited here is the separation of an azeotropic mixture of benzene and cyclohexane ▪ Here: ▪ Aniline is one suitable solvent (MSA)

- 73. www.ChemicalEngineeringGuy.com ▪ Salt Distillation: ▪ A variation of extractive distillation in which a of the key components is altered by adding to the top reflux a soluble, nonvolatile ionic salt ▪ This material stays in the liquid phase as it passes down the column.

- 74. www.ChemicalEngineeringGuy.com ▪ Quick Answer: ▪ In azeotropic distillation → ▪ the formation of an azeotrope is required to separate the components of a mixture ▪ In Extractive distillation → ▪ no azeotrope formation takes place.

- 75. www.ChemicalEngineeringGuy.com ▪ Point 1: ▪ In azeotropic distillation (AC) the third component added is referred as entrainer ▪ In extractive distillation (EC) third component added is referred as solvent. ▪ Point 2: ▪ Azeotropic Distillation: ▪ The third component added in AC forms low boiling azeotrope ▪ Extractive Distillation: ▪ The third component added has low volatility (high boiling point)

- 76. www.ChemicalEngineeringGuy.com ▪ The main difference between the two is in the process of separating the mixture. ▪ Azeotropic distillation: ▪ It will forms an azeotrope right after combining the separation solvent. ▪ This azeotrope can be a complicated way of separating the mixture because it cannot be easily changed by just a simple distillation. ▪ Extractive distillation ▪ A specific separation solvent is used in every mixture that should not form an azeotrope. ▪ Typically, extractive distillation is a better and easier method than the azeotropic distillation. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 77. www.ChemicalEngineeringGuy.com ▪ Many of the entrainers used in azeotropic distillation are carcinogens/hazardous pollutants. ▪ For this case, let us select the ethanol-water system ▪ Here, benzene is the entrainer. ▪ In Azeotropic Distillation: ▪ Ethanol is removed as the bottoms product from the column. ▪ BUT: ▪ Benzene is too hazardous for various reasons ranging from workplace to product to environmental safety.

- 78. www.ChemicalEngineeringGuy.com ▪ An alternative to recover ethanol is to use ▪ Extractive distillation. ▪ The solvent used is: ▪ Propylene Glycol ▪ Recall also that: ▪ Water-ethanol forms a minimum-boiling azeotrope ▪ 89.4 mole% (96 wt%) ethanol

- 79. www.ChemicalEngineeringGuy.com ▪ For Water – Ethanol Separation, let us use: ▪ Propylene glycol: ▪ It meets all the requirements of an ideal extractive solvent: ▪ It is miscible with water at all concentrations ▪ It has a higher boiling point than water (will remain liquid) ▪ 187°C at 1 atm ▪ It does not form an azeotrope with water ▪ It has a molecular affinity for water ▪ Hydroxyl -OH group forms a weak bond with water molecule ▪ Great for Extraction! ▪ It is a relatively safe workplace material Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 80. www.ChemicalEngineeringGuy.com ▪ The first column: ▪ is the ordinary azeotropic distillation ▪ Top: ethanol-water azeotrope ▪ Bottoms: nearly pure water

- 81. www.ChemicalEngineeringGuy.com ▪ The second column: ▪ Is an extractive distillation ▪ Propylene glycol is added ▪ Separations: ▪ Top, Middle, Bottoms

- 82. www.ChemicalEngineeringGuy.com ▪ Top ▪ Ethanol is the Distillate

- 83. www.ChemicalEngineeringGuy.com ▪ Middle ▪ Rectifying section ▪ Ethanol is purified by the removal of water. ▪ Bonding of the water molecules with glycol raises ethanol's relative volatility with respect to water ▪ This facilitates separation. ▪ The top section reduces the concentration of propylene glycol in the ethanol distillate to negligible level. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 84. www.ChemicalEngineeringGuy.com ▪ Bottom ▪ Here is the striping section - ethanol from water. ▪ These are sent to the third column.

- 85. www.ChemicalEngineeringGuy.com ▪ The Third Column: ▪ A glycol stripper, where the glycol is recovered. ▪ The propylene glycol leaves the stripper as a bottoms product ▪ It is is recycled back to the extraction column as the source of solvent. ▪ The overhead from the glycol stripper: ▪ Contains mainly water & some ethanol ▪ is sent back to the first column ▪ It is combined with fresh feed.

- 86. www.ChemicalEngineeringGuy.com ▪ This technique embodies simultaneous: ▪ Reaction ▪ Separation. ▪ Catalysts are enclosed in special packing inside a distillation column. ▪ This method uses distillation to remove products as they are formed ▪ This maximizes a shift to the chemical equilibrium of a reaction toward 100% conversion.

- 87. www.ChemicalEngineeringGuy.com ▪ In reactive distillation: ▪ one or more feeds can be used ▪ the reactive zone can be anywhere in the column ▪ Optimizing the the product ▪ Reactive distillation is used mainly for: ▪ Etherification ▪ Esterification ▪ It has also been successfully applied to: ▪ Alkylation ▪ Nitration reactions. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 88. www.ChemicalEngineeringGuy.com ▪ An example is the production of MTBE: ▪ methyl-tert-butyl-ether (MTBE) ▪ an octane booster for gasoline. ▪ The set-up is shown the Figure below. ▪ Reactive D – MTBE ▪ The pre-reactor provides a reaction equilibrium of over 90% MTBE ▪ The reactive distillation pushes the reaction another 5-10% ▪ This gets almost total conversion of the reactants.

- 89. www.ChemicalEngineeringGuy.com ▪ In the reactive zone, bales containing beads of catalyst resins are stacked on top each other, as shown in the Figure below. ▪ Reactive D – Catalyst ▪ The advantage of reactive distillation is: ▪ the elimination of complicated product recovery ▪ The separation and recycling of unconverted reactants, ▪ All these lead to savings in equipment and energy costs. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 90. www.ChemicalEngineeringGuy.com ▪ Check out this Lecture on MTBE: ▪ Important Facts ▪ Raw Materials ▪ Production ▪ Process https://www.youtube.com/watch?v=MSbEnBMmZkM

- 91. www.ChemicalEngineeringGuy.com ▪ Exploiting Solubility of Gases in liquids/gases ▪ Several Gas-Liquid Operations ▪ They Requires MSA! ▪ Examples: ▪ Gas Absorption ▪ Stripping aka Gas Desorbption ▪ Refluxed Absorption/ Stripping ▪ Reboiled Absorption/ Stripping ▪ Refluxed & Reboiled Absorption/ Stripping Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 92. www.ChemicalEngineeringGuy.com ▪ If you are not sure about the difference between a Gas and a Vapor, check this video! ▪ In Gas Absorption, we use… GASES ▪ In Distillation & Evaporation we use VAPORS! https://www.youtube.com/watch?v=fqXXe9wnVFQ

- 93. www.ChemicalEngineeringGuy.com ▪ Absorption is used to: ▪ separate gas mixtures ▪ remove impurities ▪ Contaminants ▪ Pollutants ▪ catalyst poisons from a gas ▪ recover valuable chemicals.

- 94. www.ChemicalEngineeringGuy.com ▪ If the feed is vapor and the stripping section of the column is not needed ▪ The operation is referred to as absorption ▪ Similar to the “enriching section” of distillation ▪ Absorbers generally do not require an ESA ▪ They are frequently conducted at ambient temperature and elevated pressure. ▪ Liquid Absorbent (MSA) is required ▪ Species transferred to the liquid absorbent are called solutes or absorbate. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 95. www.ChemicalEngineeringGuy.com ▪ Species in the feed vapor dissolve in the absorbent to extents depending on their solubilities. ▪ We are exploiting Solubility rather than Volatility ▪ The idea is to “clean” or “remove” gases from the inlet feed. ▪ Those gases will be dissolved in the MSA (Liquid) ▪ Most typical Operation: ▪ High Pressure ▪ Low Temperature ▪ Counter-Current Flow

- 96. www.ChemicalEngineeringGuy.com ▪ Types of “Absorptions” ▪ physical absorption ▪ chemical absorption ▪ stripping ▪ Calculate the minimum MSA flow rate to achieve a specified key- component recovery. ▪ Packing Selection or Tray Selection ▪ Column Height + Diameter ▪ Material Balances of inlet/outlet Gases and Liquid Streams ▪ Derive the operating-line equation based on the equilibrium-line

- 97. www.ChemicalEngineeringGuy.com ▪ Determine the required number of equilibrium stages ▪ Total Stages/Trays ▪ Total Packing Height (HTU/NTU Model) ▪ Define overall stage efficiency ▪ Efficiencies are low for absorbers ▪ Efficiencies moderate for strippers. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 98. www.ChemicalEngineeringGuy.com ▪ Typical mechanisms of flooding in trayed column ▪ Calcualtions of the loading point and flooding point in a packed column. ▪ Pressure drop in a trayed column.

- 99. www.ChemicalEngineeringGuy.com ▪ Typically, the tray efficiency are calculated from correlations of mass-transfer coefficients using two-film theory. ▪ For a packed column: ▪ The Concept of Height equivalent to a theoretical (equilibrium) stage or plate (HETP or HETS) is the main goal. ▪ It is require for the number of: ▪ height of a transfer unit, HTU ▪ number of transfer units, NTU. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 103. www.ChemicalEngineeringGuy.com ▪ Stack Gas “Cleaning” ▪ Typically, industries will remove pollutants before sending the off-gases to the atmosphere ▪ This reduces pollution to the surroundings ▪ CO2, CO, NOx, SOx and even ashes are recovered here

- 104. www.ChemicalEngineeringGuy.com ▪ Stripping aka Gas desorption is the inverse of absorption is ▪ Here, ▪ Liquid mixtures are separated, at elevated temperature and ambient pressure ▪ This is done by contacting the feed with a vapor. ▪ Here, the vapor is acting as the stripping agent (MSA) ▪ This MSA eliminates the need to re-boil the liquid at the bottom of the column ▪ This may be important if the liquid is not thermally stable. ▪ Applications “Cleaning” Liquids Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 105. www.ChemicalEngineeringGuy.com ▪ Strippers are best operated at low pressure and high temperature ▪ Still, solubility of gases is considered ▪ Low Pressure → Favors solubility in gases ▪ Strippers are frequently coupled with absorbers to permit regeneration and recycle of the absorbent ▪ Typically: ▪ If water is used as the absorbent, it is common to separate the absorbent from the solute by distillation rather than by stripping

- 106. www.ChemicalEngineeringGuy.com ▪ Most calculations are similar to those of Gas Absorption ▪ The reverse must be designed ▪ Solvent Selection is of vital importance ▪ Gas/Vapor MSA is also of vital importance for the selectivity ▪ Packed Columns are typically preferred Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 109. www.ChemicalEngineeringGuy.com ▪ Air stripping is: ▪ transferring of volatile components of a liquid into an air stream. ▪ Typical materials stripped: ▪ BTEX compounds (benzene, toluene, ethylbenzene, and xylene found in gasoline) ▪ Solvents (trichloroethylene and tetrachloroethylene) ▪ Ammonia https://en.wikipedia.org/wiki/Air_stripping

- 110. www.ChemicalEngineeringGuy.com ▪ Stripping is commonly used in industrial applications to remove harmful contaminants from waste streams. ▪ The Feed is mixed with water to make a slurry and then stripped with steam. ▪ This process is able to decontaminate soils almost completely. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 111. www.ChemicalEngineeringGuy.com ▪ Steam is also frequently used as a stripping agent for water treatment. ▪ VOC - Volatile organic compounds - are partially soluble in water ▪ Because of environmental considerations and regulations, these contaminants must be removed from groundwater, surface water, and wastewater. ▪ These compounds can be present because of industrial, agricultural, and commercial activity.

- 112. www.ChemicalEngineeringGuy.com ▪ Check this Article! ▪ Directly from Rashig! ▪ YES the packings! http://www.raschig.de/editor/assets/RaschigRings/Literature%20- %20Literature/Literature%20-%20Air%20Stripping%20of%20VOC's%20from%20Water.pdf

- 113. www.ChemicalEngineeringGuy.com ▪ Mostly applied for Rectifiers ▪ If it is difficult to condense the vapor leaving the top of a distillation column: ▪ A liquid MSA called an absorbent will be fed to the top tray in place of reflux. ▪ The resulting operation is called reboiled absorption ▪ Main Product: ▪ “Clean” Vapor Stream ▪ Liquid contains mostly MSA + Impurities ▪ In reboiled absorbers: ▪ partial stripping of the lighter components is performed ▪ This occurs in the lower part of the equipment.

- 114. www.ChemicalEngineeringGuy.com ▪ The Addition of a Reflux (Condenser) to a Stripper will convert it to a Refluxed Stripper ▪ Typically Common when Impurities and/or MSA Recovery is important ▪ Main Product: ▪ Liquid ▪ By-Products: ▪ Impurities from feed, either condensed as Liquid or left as vapors/gases ▪ MSA Recovery ▪ Examples: ▪ Steam Distillation ▪ Air Stripping Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 115. www.ChemicalEngineeringGuy.com ▪ In these case: ▪ Several “Liquid” Products: ▪ Steam Addition as MSA inlet ▪ Sour Water as MSA outlet ▪ Gas Stream as impurities

- 116. www.ChemicalEngineeringGuy.com ▪ The column contains only a reboiler & the feed as a liquid. ▪ Two product lines: ▪ Vapor – Stack ▪ Liquid – Clean Main Product ▪ If the bottoms product from a stripper are thermally stable ▪ This requires ESA (Enery Separating Agent) in the Reboiler ▪ Common Example is the Recovery of Amine Absorbent

- 117. www.ChemicalEngineeringGuy.com ▪ Check this lecture: ▪ Identify: ▪ Gas Absorption ▪ Stripping ▪ Reflux ▪ Reboiling https://www.youtube.com/watch?v=LaQ26JEFuec Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 118. www.ChemicalEngineeringGuy.com ▪ Gas-Liquid and/or Vapor-Liquid Operations are very common in the Industry ▪ (a) Flash vaporization or partial condensation. ▪ (b) Absorption* ▪ (c) Rectifier ▪ (d) Stripping* ▪ (e) Reboiled stripping. * Main Interest of this Section

- 119. www.ChemicalEngineeringGuy.com ▪ (f) Reboiled absorption* ▪ (g) Refluxed stripping* ▪ (h) Extractive distillation ▪ (i) Azeotropic distillation * Main Interest of this Section

- 120. www.ChemicalEngineeringGuy.com ▪ If you are interested on: ▪ Vapor-Liquid & Gas-Liquid Operations ▪ Check this Course out! ▪ Basic Principles for Mass Transfer ▪ Unit Operations involved: ▪ Flashing ▪ Distillation ▪ Absorption ▪ Strippers ▪ Scrubbers https://courses.chemicalengineeringguy.com/p/mass-transfer-principles-for-vapor-liquid-unit-operations Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 121. www.ChemicalEngineeringGuy.com ▪ Extraction Overview ▪ Liquid-Liquid Extraction: ▪ 1-Solvent Extraction ▪ 2-Solvent Extraction

- 122. www.ChemicalEngineeringGuy.com ▪ In liquid–liquid extraction (aka solvent extraction or extraction) ▪ a liquid feed of two or more components is contacted with a second liquid phase, called the solvent ▪ The solvent is immiscible or only partly miscible with one or more feed components ▪ It will completely or partially miscible with one or more of the other feed components. ▪ Thus, the solvent partially dissolves certain species of the liquid feed, effecting at least a partial separation of the feed components. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 123. www.ChemicalEngineeringGuy.com ▪ The solvent may be a pure compound or a mixture. ▪ If the feed is: ▪ aqueous solution, an organic solvent is used ▪ if organic, the solvent is often water.

- 124. www.ChemicalEngineeringGuy.com ▪ Liquid–liquid extraction with one or two solvents: ▪ can be used when distillation is impractical ▪ especially when the mixture to be separated is temperature sensitive. ▪ A solvent selectively dissolves only one or a fraction of the components in the feed.

- 125. www.ChemicalEngineeringGuy.com ▪ In a two-solvent extraction: ▪ each has its specific selectivity for the feed components. ▪ Several counter-currently arranged stages may be necessary. ▪ As with extractive distillation: ▪ additional operations are required to recover solvent from the streams leaving the extraction operation.

- 126. www.ChemicalEngineeringGuy.com ▪ The raffinate: ▪ is the liquid stream which remains after solutes from the original liquid are removed through contact with an immiscible liquid. ▪ Raffinating (metallurgy): ▪ refers to a process in which impurities are removed from liquid material. ▪ Extract: ▪ Material containing most of the solute and the solvent

- 127. www.ChemicalEngineeringGuy.com ▪ Supercritical-fluid extraction ▪ If the extraction temperature and pressure are only slightly above the critical point of the solvent ▪ In this region: ▪ solute solubility in the supercritical fluid can change drastically with small changes in temperature and pressure. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 128. www.ChemicalEngineeringGuy.com ▪ Following extraction: ▪ the pressure of the solvent rich product is reduced to release the solvent, which is recycled. ▪ For the processing of foodstuffs: ▪ the supercritical fluid is an inert substance, with CO2 preferred because it does not contaminate the product.

- 129. www.ChemicalEngineeringGuy.com ▪ Solid–liquid extraction (also called leaching) involves recovery of substances from a solid by contact with a liquid solvent ▪ such as the recovery of oil from seeds by an organic solvent ▪ Liquid–liquid extraction has grown in importance since then because of the demand for: ▪ temperature-sensitive products ▪ higher-purity requirements ▪ better equipment ▪ availability of solvents with higher selectivity

- 130. www.ChemicalEngineeringGuy.com ▪ The simplest liquid–liquid extraction: ▪ Involves only a ternary system consisting of two miscible feed components: ▪ the carrier, C ▪ the solute, A + plus solvent, S, a pure compound. ▪ Components C and S are at most only partially soluble, but solute A is completely or partially soluble in S. Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 131. www.ChemicalEngineeringGuy.com ▪ During extraction: ▪ mass transfer of A from the feed to the solvent occurs ▪ with less transfer of C to the solvent, or S to the feed. ▪ Nearly complete transfer of A to the solvent is seldom achieved in just one stage. ▪ In practice: ▪ a number of stages are used in one-section or two-section countercurrent cascades.

- 132. www.ChemicalEngineeringGuy.com ▪ Important to know when Extraction is recommended: ▪ Ensure that Liquid Extraction is preferred to distillation ▪ Selection of a solvent using group-interaction rules ▪ Define the distribution coefficient of the ternary system ▪ Identification of its relationship to activity coefficients and selectivity of a solute between carrier and solvent. ▪ Distinguish & Apply the required ternary mixtures: ▪ Type I → One immiscible pair ▪ Type II → Two immiscible pairs

- 133. www.ChemicalEngineeringGuy.com ▪ Application of the Hunter and Nash method ▪ Use of the ternary diagram (triangular diagram) ▪ Calculations on: ▪ minimum solvent requirement ▪ equilibrium stages ▪ Cascade operation

- 134. www.ChemicalEngineeringGuy.com ▪ Design a cascade of mixer-settler units based on mass-transfer considerations. ▪ Size a multi-compartment extraction column ▪ Effects of axial dispersion. ▪ Determine effects on the system: ▪ pH, temperature, salt Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website:

- 136. www.ChemicalEngineeringGuy.com ▪ Typical Cases: ▪ Solvent Recovery ▪ Aromatics Removal

- 137. www.ChemicalEngineeringGuy.com ▪ Acetic Acid Production ▪ Requires Extraction of acetic acid from feed (aqueous) ▪ Solvents ▪ MTBE, Et.Ac. i-Propyl Ac. ▪ Raffinate ▪ Goes to Stripping Column ▪ Separates the water and acetic acid leftover ▪ Extract ▪ Goes to Solvent Recovery ▪ Separates acetic acid and solvent Do you need the Full Version? Contact me if needed! Contact@ChemicalEngineeringGuy.com https://courses.chemicalengineeringguy.com/courses You can also check out more content here: My Youtube Channel → My Fan Page → The LinkedIn→ My website: