flash fire FR test standard comparison

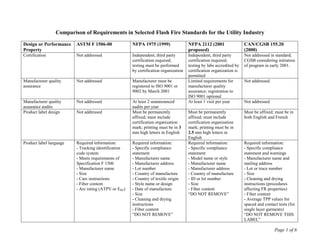

- 1. Comparison of Requirements in Selected Flash Fire Standards for the Utility Industry Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Certification Not addressed Independent, third party certification required; testing must be performed by certification organization Independent, third party certification required; testing by labs accredited by certification organization is permitted Not addressed in standard; CGSB considering initiation of program in early 2001. Manufacturer quality assurance Not addressed Manufacturer must be registered to ISO 9001 or 9002 by March 2001 Limited requirements for manufacturer quality assurance; registration to ISO 9001 optional Not addressed Manufacturer quality assurance audits Not addressed At least 2 unannounced audits per year At least 1 visit per year Not addressed Product label design Not addressed Must be permanently affixed; must include certification organization mark; printing must be in 3 mm high letters in English Must be permanently affixed; must include certification organization mark; printing must be in 2.5 mm high letters in English Must be affixed; must be in both English and French Product label language Required information: - Tracking identification code system - Meets requirements of Specification F 1506 - Manufacturer name - Size - Care instructions - Fiber content - Arc rating (ATPV or EBT) Required information: - Specific compliance statement - Manufacturer name - Manufacturer address - Lot number - Country of manufacture - Country of textile origin - Style name or design - Date of manufacture - Size - Cleaning and drying instructions - Fiber content “DO NOT REMOVE” Required information: - Specific compliance statement - Model name or style - Manufacturer name - Manufacturer address - Country of manufacture - ID or lot number - Size - Fiber content “DO NOT REMOVE” Required information: - Specific compliance statement and warnings - Manufacturer name and mailing address - Lot or trace number - Size - Cleaning and drying instructions (procedures affecting FR properties) - Fiber content - Average TPP values for spaced and contact tests (for single layer garments) “DO NOT REMOVE THIS LABEL” Page 1 of 6

- 2. Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Classification system Not addressed Not addressed Not addressed 1. Single layer garments (Type 1) 2. Multilayer garments (Type 2) 3. Disposable garments (Type 3) General requirement (design) Not addressed Not addressed Not addressed Design can neither adversely affect protective characteristics nor contribute to severity of burn injury to wearer. Materials of construction (design) Not addressed May be either flame- resistant fabrics or 100% cotton or wool Not addressed Not addressed Closure system (design) Not addressed Not addressed Not addressed Closure must be constructed to secure garment to provide protection consistent with standard Hardware finish (design) Not addressed Not addressed Must be free of rough spits, burrs, or sharp images Not addressed Metal components (design) Not addressed Not addressed Contact with body not permitted Contact with body not permitted Laundering procedure (preconditioning) AATCC 135 - 3, IV, Aiii (permanent press machine cycle, wash temperature at 49o C, tumble drying on permanent press setting) Multistage industrial laundering with break, carry-over, 3 rinse cycles, sour and extraction; drying with dryer temperature set at 82o C (without load) Multistage industrial laundering with break, carry-over, 3 rinse cycles, sour and extraction; drying with dryer temperature of 68o C (without load) CAN/CGSB-4.2 No. 48 Procedure III E (medium temperature 50o C, moderate mechanical action, synthetic detergent and tumble drying) Dry-cleaning procedure (preconditioning) ASTM D 2724, paragraph 6.1 AATCC 158 AATCC 158 CAN/CGSB-4.2 No. 30 Page 2 of 6

- 3. Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Flame resistance (fabrics) Testing per ASTM D 6413 before and after 25 cycles of laundering or dry-cleaning; Afterflame £ 2 sec. Char length £ 152 mm No melting and dripping Not addressed Testing per ASTM D 6413 before and after 100 cycles of laundering or dry- cleaning (applies to fabric and reflective tape); Afterflame £ 2 sec. Char length £ 100 mm No melting and dripping Testing per CAN/CGSB-4.2 No. 27.10 using edge ignition (fabric for Type 1 and 3, each layer for Type 2) before and after 50 cycles of laundering or 5 cycles of dry-cleaning; Afterflame £ 2 sec. Char length £ 100 mm No melting or dripping Flame resistance (primary closures) Not addressed Not addressed Not addressed Same as fabrics Heat resistance (fabrics) Not addressed Samples exposed to 260o C for 5 minutes in forced air convective oven; no melting, dripping, or separation permitted; applies to textiles and components, excluding interlinings, collar stays, elastic, and hook and pile fasteners, when not in direct contact with the wearer’s body. Samples exposed to 260o C for 5 minutes in forced air convective oven, before and after 3 cycles of laundering or dry-cleaning; no melting, dripping, or separation permitted. Applies to fabric, other textile materials, and reflective striping; exceptions include label and emblems, and interlinings, collar stays, elastics, closures, and hook and pile fasteners, when not in direct contact with the wearer’s body. Samples exposed to 260o C for 5 minutes in forced air convective oven; no melting, dripping, or separation permitted; applies to textile materials including visibility trim, reinforcements, wristlets, collar and closure systems, binding and hanger loops; excludes hook and pile fasteners, labels, interfacing and emblems, when not in direct contact with the wearer’s body. Heat resistance (hardware) Not addressed Not addressed Same as fabrics but must also remain functional Same as fabrics but must also remain functional Heat resistance (primary closures) Not addressed Not addressed Not addressed Same as fabrics Thermal shrinkage resistance Not addressed Same exposure as above; shrinkage £ 15% in any one Same exposure as above; shrinkage £ 10% in any one Same exposure as above; shrinkage £ 3% in any one Page 3 of 6

- 4. direction direction direction (10% knits) Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Thermal insulation – heat exposure Not addressed Not addressed TPP measured using procedures similar to NFPA 1971 in both spaced and contact sample configurations, before and after 3 cycles of laundering or dry-cleaning; Contact TPP ³ 3.0 Spaced TPP ³ 6.0 Samples tested before and after 3 cycles of laundering or dry-cleaning TPP measured using modified version of ASTM D 4108 in both spaced and contact sample configurations as received; Spaced TPP ³ 6.0 No requirement for contact TPP (report only); Samples tested as received (without preconditioning) Thermal insulation – electrical arc Testing per ASTM F 1959 on full garments; Afterflame £ 5 sec. Report of arc rating Not addressed Not addressed Not addressed Overall garment insulation Not addressed Not addressed Testing of material in standard coverall design per ASTM F 1930 for 3 sec exposure at 84 kW/m2 with 100% cotton underwear on manikin, after 1 cycles of laundering or dry-cleaning; percent total body burn £ 50% Not addressed Melting resistance (thread) Not addressed Testing per FTMS 191A,1534 at 260o C with no observed melting Testing per FTMS 191A,1534 at 260o C with no observed melting Testing per FTMS 191A,1534 at 260o C with no observed melting Breaking strength (woven fabrics) Testing per ASTM D 1682; criteria based on fabric weight: 3.0-5.9 oz/yd2 ³ 134 N 6.0-8.4 oz/yd2 ³ 179 N 8.5 oz/yd2 or higher ³ 223 N Not addressed Not addressed Not addressed Page 4 of 6

- 5. Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Burst strength (knit fabrics) Testing per ASTM D 3786; criteria based on fabric weight: 3.0-8.0 oz/yd2 ³ 179 N 8.1-16.0 oz/yd2 ³ 268 N Not addressed Not addressed Not addressed Tear resistance (woven fabrics) Testing per ASTM D 1424; criteria based on fabric weight: 3.0-5.9 oz/yd2 ³ 11 N 6.0-8.4 oz/yd2 ³ 18 N 8.5 oz/yd2 or higher ³ 22 N Not addressed Not addressed Not addressed Seam strength Not addressed Woven seam testing per ASTM D 1683; knit seam testing per ASTM D 3940; Class I major woven seam strength ³ 245 N; Class II major woven seam strength ³ 180 N; Class I and II major knit seam strength ³ 180 N; Not addressed Not addressed Seam slippage Testing per ASTM D 434; 6 mm allowed at force based on fabric weight: 3.0-5.9 oz/yd2 = 134 N 6.0-8.4 oz/yd2 = 179 N 8.5 oz/yd2 or higher = 223 N Not addressed Not addressed Not addressed Colorfastness – laundering Testing per AATCC 61, IIA; Class 3 Not addressed Not addressed Not addressed Colorfastness – dry-cleaning Testing per AATCC 132; Class 3 Not addressed Not addressed Not addressed Dimensional change Testing per AATCC 135 - 3, IV, Aiii (5 cycles) for laundering or AATCC 158; shrinkage £ 3% (does not Page 5 of 6

- 6. apply to knits) Design or Performance Property ASTM F 1506-00 NFPA 1975 (1999) NFPA 2112 (2001 proposed) CAN/CGSB 155.20 (2000) Label legibility Not addressed Examination of labels after 100 laundry or dry-cleaning cycles Examination of labels after 100 laundry or dry-cleaning cycles Examination of labels after 50 laundry cycles or 5 dry- cleaning cycles Personal Safety Products Department 3M Safety and Security Systems Division 3M Center, Building 225-4N-14 St. Paul, MN 55144-1000 800-328-7098 Ext. 2 Page 6 of 6