Mud thinner

- 1. 1 Drilling Engineering TITLE: Mud Thinner Author name: Mahmood Abdul-Jabbar hebah

- 2. 2 Acknowledgement “I would like to express my deepest appreciation to all those who provided me the possibility to complete this experiment. I would also like to show my deepest gratitude to my lecturer, Dr. Mahmood for giving me a good guideline for this experiment throughout numerous consultations. Moreover, I would like to appreciate the crucial role of the staff of APU University who gave the permission to use all equipment and necessary materials to complete the laboratory, and also a special thanks goes to my group who did well in the lab to success in this experiment. Last but not least, many thanks go to the head of the APU University whose have invested his full effort in guiding the students to achieving their goals.”

- 3. 3 Contents ABSTRACT...........................................................................................................................5 Introduction............................................................................................................................6 Objective ................................................................................................................................7 Theory and Literature Review................................................................................................8 Inorganic complex phosphate.................................................................................................8 Organic thinners are divided into three groups:.....................................................................8 Procedures ..............................................................................................................................9 Apparatuses ..........................................................................................................................10 Materials used ......................................................................................................................13 Results ..................................................................................................................................14 The advantage and disadvantage of mud thinner.................................................................16 Discussion ............................................................................................................................16 9.0 Conclusion......................................................................................................................18 10.0 Errors.........................................................................................................................19 11.0 Suggestions................................................................................................................19 Reference..............................................................................................................................20

- 4. 4 List of Figures Figure 1 Mud mixer .................................................................................................................10 Figure 2 Weighing balance ......................................................................................................10 Figure 3 Mud Balance..............................................................................................................11 Figure 4 Rheometer..................................................................................................................11 Figure 5 Thermometer .............................................................................................................11 Figure 6 Filter Press .................................................................................................................12 Figure 7 Graduated Cylinder....................................................................................................12 Figure 8 pH scale .....................................................................................................................12 Figure 9 Aging Cell .................................................................................................................13 Figure 10 Vernier Caliper ........................................................................................................13 Figure 11 Filtrate volume vs Time...........................................................................................17 List od Tables Table 1 parameters needed for preparing the amount of barite ...............................................14 Table 2 results ..........................................................................................................................15

- 5. 5 ABSTRACT “This experiment examined the effect of mud thinner on drilling fluid density and viscosity. The function of mud thinner is to control and reduce the apparent density of the mud by calculate the amount of water that needed to decrease the density. The experiment was conducted by using one basic mud as the comparison for second experiment that has 10.7ppg mud density, then it uses mud thinner to achieve the exact mud density that required in this experiment which is 10.2ppg. Also, this experiment was undertaken with the purpose of decrease the density of the drilling fluid as well as to measure the properties of the drilling fluids and compare it with the last experiment. In general, to proceed with the experiment in order to achieve the goals mentioned, a range of instruments were selected such Mud mixer, Mud balance, Thermometer, Remoter, Filter press, Graduated cylinder, pH meter / pH paper, Aging cell, Rotating oven and litter cup, Viscometer and Venire calliper. All these materials were used in order to understand the reasons why the mud varies and to know with precision the different properties that the fluids have. overall, at this experiment was conducted by using Bentonite, Barite and soda ash mixed with water to control the density of the mud.”

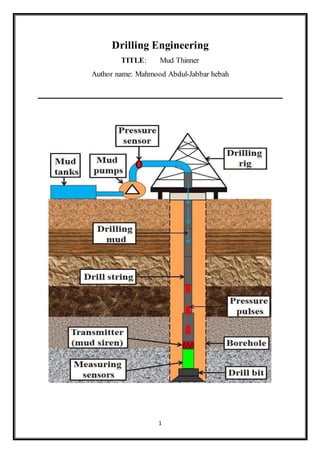

- 6. 6 Introduction “Additives that may simultaneously modify viscosity, control filtration properties, stabilize shales and create or prevent clay flocculation. Thinners: Mud thinners or dispersants reduce viscosity by breaking the attachment of clay plates through the edges and faces. The thinners absorb to the clay plates, thus disturbing attractive forces between the sheets. Thinners are added to a mud to reduce viscosity, gel strength and yield point. Thinner can be classified as organic materials or as inorganic complex phosphates.” “In geotechnical engineering, drilling fluid is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water well. Liquid drilling fluid is often called drilling mud. The three main categories of drilling fluids are water-based muds (which can be dispersed and non- dispersed), non-aqueous muds, usually called oil-based mud, and gaseous drilling fluid, in which a wide range of gases can be used.” “The main functions of drilling fluids include providing hydrostatic pressure to prevent formation fluids from entering into the well bore, keeping the drill bit cool and clean during drilling, carrying out drill cuttings, and suspending the drill cutting while drilling is paused and when the drilling assembly is brought in and out of the hole. The drilling fluid used for a particular job is selected to avoid formation damage and to limit corrosion. (Global driling fluid and chemicals LTD, n.d.).” “In order to ensure smooth drilling operations and to compensate for the natural and progressive contamination of the mud, it is also standard practice to introduce additives, of which so-called thinners are examples. The particular function of a thinner is to control the rheological properties of the mud and, in this way, to maintain normal mud flow without excessive power consumption.” “Chemically, thinners can vary widely. The mud thinner can be divided into two categories namely inorganic complex phosphate and organic thinner. The normally used inorganic complex phosphates are sodium acid pyrophosphate (SAPP), sodium hexanetaphosphate (Calgon), sodium tetraphosphate (BARAFOS), and tetra sodium phosphate (TSPP). While for organic thinners are divided into three groups which are Lignin (example: CARBONOX and CC-16 or alkaline + lignite), Tannin (example: quebracho and TANNEX or quebracho + lignite), and Lignosulfonate (example: LIGNOX or calcium lignosulfonate and Q-BROXIN or ferrochrome lignosulfonate).”

- 7. 7 “But two of the common types is a complex mixture marketed under the common name “Lignite”. The active components in this type of thinner are known as humic acids. Since these materials occur in naturally weathered, or artificially oxidized, coals – from which they can, if desired, be extracted with aqueous alkali solutions – and since several Alberta coals are known to be particularly rich in humid acids, it was thought pertinent to explore the direct use of such coals as thinners. The investigations reported in the following pages accordingly deal with attempts to survey and characterize some potentially suitable coals and to compare them with two well- established, commercially marketed lignite thinners. It might, in this connection, be observed that as much as 500 tons per years of these lignite have been imported into Alberta for use in oil –exploration pogroms, and that material sold at approximately 10 cents per pound. When bentonite mining and purification was started in Alberta, lignite importation is believed to be still fairly substantial.” Objective “The objective of this experiment is to study the effect of mud thinner on mud viscosity, by adding a limited amount of water to decrease the muds density, and this procedure is called mud thinner. And to understand the function and types of mud thinner.”

- 8. 8 Theory and Literature Review “The viscosity of the muds must be control at certain level to make sure that mud can work at it top performance. Too high viscosity can reduce the hydraulic efficiency, increase the pressure wave and increase the swabbing effect. If viscosity is too low, it can reduce the hole cleaning efficiency. Mud viscosity is the function of:” a. “Base fluid viscosity” b. “Measurement and volume of particles” c. “Force between particles” “Viscosity measurement which accounts for these three factors at certain flow condition is called apparent viscosity measurement. The measurement can be done using marsh funnel or electronic rheometer. Normally the solid material is needed to increase the plastic viscosity. To decrease the viscosity, remove solid material or add water to the mud.” “The value of yield point is defined by the forces between solid particles within the mud. If the reactive material like bentonite is added, the value of yield point also increases. The value of yield point can be decreased by adding mud thinner. Mud thinner can be used to reduce the yield point value and apparent viscosity of the mud by reducing the forces between particles. At the same time, the value of gel strength also reduced by adding mud thinner. As a conclusion, the mud thinner is used to control the apparent viscosity of the mud without using too much of water. There are too many materials can be used as a mud thinner. The mud thinner can be divided into two categories namely:” Inorganic complex phosphate “Normally used inorganic complex phosphates are:” a. “Sodium acid pyrophosphate (SAPP)” b. “Sodium hexanetaphosphate (Calgon)” c. “Sodium tetraphosphate (BARAFOS)” d. “Tetra sodium phosphate (TSPP)” e. “Organic thinner” Organic thinners are divided into three groups: a. “Lignin, example CARBONOX (lignite) and CC-16 (alkaline + lignite)” b. “Tannin, example quebracho and TANNEX (quebracho + lignite)”

- 9. 9 c. “Lignosulfonate, example LIGNOX (calcium lignosulfonate) and Q-BROXIN (ferrochrome lignosulfonate).” Procedures 1.1 “Bentonite of 15g, 0.2g soda ash and 134.3 of barite was measured by using the weight balance.” 1.2 “Water of 350 ml was measured and calculated the amount of water that can be added to decrease the density to be 10.2ppg by using a measuring cylinder.” 1.3 “Mixed 350 ml of water with soda ash for 5 seconds in mud mixer.” 1.4 “The 15g of bentonite and 134.3g of barite have been mixed with 350 ml of water for 3 minutes after 3 minutes we added 94 ml of water and continued mixing for 15 minutes by using mud mixer. 4.5The temperature of the mud was measured by using thermometer to be 30.1°C.” 1.5 “The density of the mud was measured by using mud balance to be 10.2 ppg.” 1.6 “The Ph of the mud was obtained by using PH paper to be 8.” 1.7 “The viscometer supplied should have 6 speed settings: 3rpm, 6 rpm, 100rpm, 200rpm, 300rpm, and 600rpm. There is a diagram on how to operate each rpm mode in combination with 3 gear settings and 2 speed settings.” 1.8 “The viscometer was switched on and measured the viscosity of the mud in different speed rpm and the process has repeated till all the rpm settings are done.” 1.9 “Once the readings have been obtained, a gel strength test is to be done.” 1.10 “The viscometer was turned off for 10 seconds and the reading was obtained.” 1.11 “The viscometer was turned on in 3 rpm and the reading was taken to be 5.5. After that the viscometer turned off for 10 minutes and the reading was obtained.” 1.12 “The viscometer was turned on in 600 rpm for 10 seconds then turned off for 10 seconds and the reading was taken to be 6.” 1.13 “After the gel strength readings were obtained, the mud was put into the mud cell, and fixed it into the base with strong Tighten screw and make sure all valves are closed.” 1.14 “Injected nitrogen gas to the filter press at high pressure and the volume was measured in each step started from 5 minutes till 30 minutes.” 1.15 “The mud thickness was measured by using Vernier caliper.”

- 10. 10 Apparatuses Figure 2 Weighing balance Figure 1 Mud mixer

- 11. 11 Figure 3 Mud Balance Figure 4 Rheometer Figure 5 Thermometer

- 12. 12 Figure 6 Filter Press Figure 7 Graduated Cylinder Figure 8 pH scale

- 13. 13 Figure 9 Aging Cell Figure 10 Vernier Caliper Materials used a. Bentonite b. Soda ash c. Water d. Barite

- 14. 14 Results “The viscosity of the muds must be control at certain level to make sure that mud can work at it top performance. Too high viscosity can reduce the hydraulic efficiency, increase the pressure wave and increase the swabbing effect. If viscosity is too low, it can reduce the hole cleaning efficiency. Mud viscosity is the function of:” Table 1 parameters needed for preparing the amount of barite “In order to calculate the proper amount of water needed to decrease the density to 8.65ppg a certain equation was given,” “The amount of water needed to decrease the density = 547 350 = 197ml” “The equation needed to calculate the plastic viscosity,” Plastic viscosity (cp)= [600 rpm reading] – [300 rpm reading] “The equation needed to calculate the Apparent viscosity,” Apparent viscosity (cp) = [600 rpm reading] / 2 “The equation needed to calculate the Yield Point,” Yield Point (Ib/1002) = [300rpm reading] – Plastic viscosity

- 15. 15 Table 2 results No. Apparatus Property Result 1 Thermometer Temperature (°C) 30.3 °C 2 Mud Balance Density (ppg) 8.75 ppg 3 pH Meter / pH Paper pH Value 8 4 Rotational Viscometer Rheology (cP) 3 rpm 4 cP 6 rpm 4 cP 100 rpm 6 cP 200 rpm 8 cP 300 rpm 10 cP 600 rpm 15 cP Plastic Viscosity (cP) Plastic viscosity (cp)= [600 rpm reading] – [300 rpm reading] 15 – 10 = 5 cP Apparent Viscosity (cP) Apparent viscosity (cp) = [600 rpm reading] / 2 15 ÷ 2 = 7.5 cP Yield Point (lb/100 ft2) Yield Point (Ib/1002) = [300rpm reading] – Plastic viscosity 10 – 5 = 5 lb/100 ft2 Gel Strength (lb/100 ft2) 3(10 sec) 4 lb/100 ft2 3 (10 min) 4 lb/100 ft2 5 LPLT Filter Press Filtrate Volume (cc) 5 min 5 (cc) 10 min 7 (cc) 15 min 9 (cc) 20 min 14 (cc) 25 min 17.5 (cc) 30 min 19.5 (cc) 6 Vernier Caliper Mud cake Thickness (mm) 1.65 mm

- 16. 16 The advantage and disadvantage of mud thinner “Reduces viscosity and gel strengths. Also extends the temperature limitation of water base fluids as well as to Improves filter cake by reducing its permeability. However, the disadvantages or the limitation of using mud thinner is decrease the mud weight can decrease the overall pressure exerted against the formation pressure. Also Mud thinner does not allow excessive waste clay material to be flocculated and cannot be removed.” Discussion “The density of a simple drilling fluid that consists of 15 g of bentonite and 134.3 g of barite by adding water as thinner additive as well as to understand the characteristic and properties of drilling fluid in term of adding water to modify the thickness of the mud. Ph scale showed a less alkaline than experiment (2) with 2 grades from 11 to 8 and that because the water is neutral liquid that minimize the alkalinity of the mud. The density indicated to an decrease from 9.15 ppg to 8.75 ppg. The dilution has effected the viscosity of the mud and that it decreases due to the increase in the volume of water in the mud. Density is defined as the weight per unit volume of drilling fluid the increase of the volume of the water mixed with the mud caused the decreased in the density of the md, Plastic viscosity, apparent viscosity and yield point show an obvious decreased to 5 cp , 7.5 cp and 5 lb/100 ft2 for plastic viscosity , apparent viscosity and yield point respectively. The decrease on the concentration of the mud ingredients decreases the viscosity and the yield point. Gel strength also got effected by the dilution and decreased to 4 lb/100 ft2 in 3 sec and 4 lb/100 ft2 in 10 mins. The gel strength that is showed in table (2) indicates that the dilution was the reason decreased the gel strength in experiment 3 for. The filtrate mud declared a high mud filtrate comparing to experiment 2 in the first 5 mins in experiment that in 5 mins the obtained filtrate mud was 3cc in experiment (2) and 5cc in experiment 3. Mud thickness obtained in the experiment (3) was 1.65mm.”

- 17. 17 Figure 11 Filtrate volume vs Time “Mud filter cake is a layer formed by solid particles in drilling mud against porous zones due to differential pressure between hydrostatic pressure and formation pressure. For the drilling operation, it is preferred to have a filter cake that is impermeable and thin. Practically, the filter cake from API or HTHP fluid loss test should be less than or equal to 1/16 inch. If drilling fluid is not in a good shape, which results in a thick filter cake in the wellbore, it will lead to a stuck pipe situation and high torque/drag (drillingformulas, 2016). The obtained mud cake thickness was 1.65mm which consider to be a good shape that will not cause any sticking pipes or high torque situations. On the other hand, filtration process of drilling mud takes place as the drilling operation in carried out under a certain condition called overbalanced conditions, which means that the pressure of drilling mud injected is higher than the pressure of the formations. Due to this differential in pressure, drilling fluids will tend to be invaded into the porous part of the formation; where by the smaller particles of the drilling fluid will invade further into the formation, while the larger particles will accumulate at front surface of the pore size, creating a layer of mud cake.” 0 5 10 15 20 25 0 5 10 15 20 25 30 35 Filtrate Volume (cc) Time (mins) LPLT FilterPress

- 18. 18 Conclusion “In this experiment, the density of a simple drilling fluid was decreased by adding extra amount of water that mixed with bentonite and barite. The dilution worked on changing the physical properties of the mud. The density decreased from 9.15 to 8,75 ppg is a change of 4.67%The viscosity showed a clear indication of decreasing of yield point by 37.5 %, 54.69% and 60.42% for plastic viscosity, apparent viscosity and yield point respectively. The obtained mud filtrate after 30 minutes was higher than the mud filtrate in experiment (2) and it changed by 28.75% Therefore the mud thickness measured by using the Vernier caliper was obtained to be 1.65mm experiment (3). Mud thickness of 1.65mm is a good shape of mud in the scale of API or HTHP fluid loss test that declare the safety and effectiveness of using the mud to avoid any stuck piping, causing mud cake and other problems. The experiment was successfully done, and it has achieved the aim of it as well as we learn how to deal with drilling fluid to reduce its density.”

- 19. 19 Errors “Human error occurred in the experiment that effected the main objective of the series of experiment to compare experiment with the coming after experiments that 40g of bentonite, 20 soda ash and 300 ml of water. On other hand the in this experiment 15g of bentonite, 0.2 soda ash and 350ml of water. The change of amounts used affected the results of experiment two.” Suggestions “Drilling fluid has good fluid loss property, it will show a thin and impermeable mud cake. because at the surface condition the test demonstrates very good fluid loss and a very thin filter cake. When the drilling mud is in a downhole condition, wellbore temperature and pressure can dramatically change drilling fluid properties. The best way to test the fluid loss is to simulate wellbore condition at high pressure high temperature in order to see what the fluid loss property will be.” “Since this experiment is based on the bentonite density in the first experiment which was 9.15 ppg at 35.5 degree Celsius, the change in temperature should considered due to its ability to affect density.”

- 20. 20 Reference A. Drillingformulas, 2016. drillingformulas. [Online] Available at: http://www.drillingformulas.com/mud-filter-cake/ [Accessed 25 2 2021]. B. Energy-resources, n.d. energy-resources. [Online] Available at: https://energy resources. basf.com/global/en/oilfield- solutions/applications/drilling/thinners.html [Accessed 25 2 2021]. C. Global driling fluid and chemicals LTD, n.d. Global driling fluid and chemicals LTD. [Online] Available at: http://www.oil-drilling-fluids.com/k2/oil-based-mud-additives- obm/obm-mud- thinner [Accessed 25 2 2021]. D. Oilfield Glossary, n.d. Oilfield Glossary. [Online] Available https://www.glossary.oilfield.slb.com/en/Terms/a/apparent_viscosity.aspx [Accessed 25 2 2021]. E. Philips, A., 2016. drillingformulas. [Online] Available at: http://www.drillingformulas.com/yield-point-yp-of-drilling-fluids/ [Accessed 25 2 2021].