Final draft GRADED UNIT REPORT 5THMAY (1) (1) (1) (Repaired) - for merge

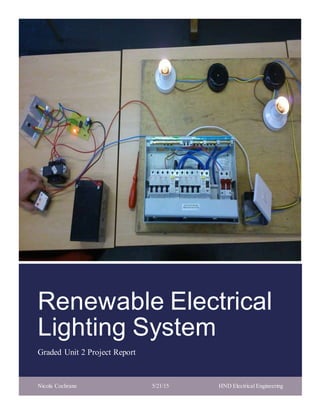

- 1. RENEWABLE ELECTRICAL LIGHTING SYSTEM NICOLA COCHRANE Renewable Electrical Lighting System Graded Unit 2 Project Report Nicola Cochrane 5/21/15 HND Electrical Engineering

- 2. Renewable Electrical Lighting System Nicola Cochrane 1 SUMMARY A renewable electrical lighting system is required for implementation in a small caravan or motor home. The renewable energy will be sourced through the application of a wind turbine and a PV cell which will operate to charge a 12V battery. The battery, which acts as an energy storage device, will drive a 230/240V AC, 50Hz lighting circuit. The system also incorporates a full wave bridge rectifier with regulator circuit, a DC to AC inverter circuit, a consumer unit, a two-way switch and a small lighting circuit consisting of two junction boxes and two light fittings.

- 3. Renewable Electrical Lighting System Nicola Cochrane 2 TABLE OF CONTENTS Summary .......................................................................................................1 Introduction ...................................................................................................5 Project Brief...................................................................................................6 Project Specification.......................................................................................7 Electrical Parameters...................................................................................7 Three Phase 12 V Wind Turbine Output Voltage .......................................7 12 V PV Cell Output Voltage...................................................................7 Full wave Bridge Rectifier with Regulator Circuit Input / Output Voltages..7 12 V Battery Input / Output Voltages........................................................7 DC to AC Inverter Circuit Input / Output Voltages ....................................7 DC to AC Inverter Circuit Frequency .......................................................7 230/240 V AC Lighting Circuit ................................................................7 Environmental Parameters...........................................................................8 Safety.....................................................................................................8 Waterproofing.........................................................................................8 Physical Characteristics...............................................................................8 Size ........................................................................................................8 Power Indicator.......................................................................................8 Battery Connections ................................................................................9 PV Cell...................................................................................................9 Wind Turbine..........................................................................................9 Project Objectives and Schedule ....................................................................10 Solution Analysis and Justification ................................................................12 Block Diagram .............................................................................................14 Technical Description ...................................................................................15 Three Phase to Single Phase Conversion ....................................................15 Power Rectification...................................................................................15 Voltage Regulation ...................................................................................15 Power Inversion........................................................................................15 Power Distribution....................................................................................15

- 4. Renewable Electrical Lighting System Nicola Cochrane 3 Wind Turbine ...........................................................................................16 Three Phase to Single Phase Conversion ....................................................16 PV Cell....................................................................................................16 Full Wave Bridge Rectifier Circuit w/ Regulator & Smoothing Capacitor.....17 Battery.....................................................................................................17 DC to AC Inverter....................................................................................17 Lighting Circuit ........................................................................................18 Implementation ............................................................................................19 Overcoming Problems...............................................................................19 Lighting Circuit ........................................................................................19 DC to AC Inverter Circuit .........................................................................20 Implementation Checklist..........................................................................21 Progress Reports...........................................................................................22 Verification Strategy.....................................................................................25 Full Wave Bridge Rectifier........................................................................25 Battery.....................................................................................................26 DC to AC Inverter....................................................................................26 Lighting Circuit ........................................................................................27 Costing ........................................................................................................28 Materials..................................................................................................28 Labour and Service ...................................................................................28 Safety..........................................................................................................29 Main Operational Safety Standards ............................................................29 Safety Devices..........................................................................................29 MCB....................................................................................................29 RCD.....................................................................................................30 Discussions and Conclusions .........................................................................31 Acknowledgements ......................................................................................32 References ...................................................................................................33 Appendices ..................................................................................................34 Appendix 1 – Three Phase to Single Phase Conversion................................35 Appendix 2 – Full Wave Bridge Rectifier Output Waveform .......................36

- 5. Renewable Electrical Lighting System Nicola Cochrane 4 Appendix 3 – Mosfet Output Waveform.....................................................37 Appendix 4.0 – Original DC to AC Inverter Schematic Including Mosfets (Designed on Express PCB).......................................................................38 Appendix 4.1 – Re-designed DC to AC Inverter Schematic Excluding Mosfets ................................................................................................................39 Appendix 5 – DC/AC Inverter – IC chip – Logic Table ...............................40

- 6. Renewable Electrical Lighting System Nicola Cochrane 5 INTRODUCTION My client Charlie Watson, a member of the Caravan Club, approached my employer, Green Electrical Installations requesting an electrical lighting system powered by renewable energy sources for a small caravan or motor home. Mr. Watson, who is in the early stages of retirement, is in the process of planning an extended caravan vacation. As an environmentalist who owns a completely passive, energy-efficient home, Mr. Watson is seeking to make adjustments to his motor home in order to reduce his carbon footprint further. My client has highlighted severalstipulations in relation to the design parameters of the installation; System must be efficient System must be safe Energy source must be renewable i.e. Wind or solar Installation must include a minimum of two luminaires with room for expansion

- 7. Renewable Electrical Lighting System Nicola Cochrane 6 PROJECT BRIEF In order to produce a safe and sustainable system, sufficient safety features, power rectification, voltage regulation and power inversion must be incorporated along with a storage device to ensure safe,efficient operation of the installation and security of supply. Renewable wind and solar energy are required to charge a 12 V battery which in turn must safely operate a lighting circuit, requiring a power input of around 230 V AC at 50 Hz. As project engineers, my colleague, Martin McNulty and I have been assigned and are responsible for the design, construction and testing of the renewable electrical lighting system as agreed with Mr. Watson. Mr. Watson is satisfied with our proposal and stipulated a budget of £2,000. The total cost of the project has come under budget at £1652.36, with materials priced at £ 552.76 and labor charged at £999.60, presenting a budget reduction of £347.64. My client requires the project to be completed by 05/06/15.

- 8. Renewable Electrical Lighting System Nicola Cochrane 7 PROJECT SPECIFICATION This specification details the main electrical and environmental parameters of the renewable electrical lighting system. All systemcomponents must ONLY be operated within the following specified parameters to ensure that the installation functions safely and without posing risk to systemusers. ELECTRICAL PARAMETERS Three Phase 12 V Wind Turbine Output Voltage The turbine output voltage will vary dependant on wind speed, ranging from 6 V – 15 V. However,under optimum operating conditions the turbine will emit 12 V AC (±5%). 12 V PV Cell Output Voltage The PV cell will have restricted operating times as due to its necessity for solar energy, the cell will only function during daylight hours, producing a constant 12 V DC output under normal operating conditions. Full wave Bridge Rectifier with Regulator Circuit Input / Output Voltages The full wave bridge rectifier circuit will require an input voltage range of between 10 V – 30 V AC in order to perform rectification and regulation to provide the desired output voltage of 12 V DC (±5%). The input voltage must not exceed 35 V as the regulator will cease to function correctly beyond this voltage. 12 V Battery Input / Output Voltages The battery will require a constant 12 V DC (±5%) input voltage to charge effectively and emit an output voltage of 12 V DC (±5%) under normal operating conditions. The output voltage may vary, outside of normal operating conditions, according to the charge level of the battery. DC to AC Inverter Circuit Input / Output Voltages The inverter circuit requires a minimum input voltage of 12 V DC (±5%) to function correctly and provide an output of 240 V AC (±5%). The input voltage must not fall below 10 V DC or exceed 14 V DC for full functionality of the circuit under normal operating conditions. DC to AC Inverter Circuit Frequency The inverter requires a frequency of 50 Hz to operate effectively under normal operating conditions. 230/240 V AC Lighting Circuit The lighting circuit requires a minimum input voltage of 230 V AC at a frequency of 50 Hz but can continue to operate efficiently, energising the 15 W light bulbs with an input of 240 V AC.

- 9. Renewable Electrical Lighting System Nicola Cochrane 8 ENVIRONMENTAL PARAMETERS Safety The consumer unit which hosts the live, neutral and earth connections for the lighting circuit is fitted with several safety features including supply switches, MCBs (miniature circuit breakers) and RCDs (residual current devices) all of which can operate to interrupt the circuit under fault conditions. These safety devices provide over current and earth leakage protection to system components and protection against electric shock to system users. Two switches are also incorporated in the system as safety features and are connected between the following system components to permit interruption of the circuit out with normal operating conditions or for maintenance purposes: - Full wave bridge rectifier circuit and battery - Battery and inverter circuit The system has been designed and constructed in accordance with all relevant safety standards of BS 7671: 2008. Waterproofing The wind turbine and PV cell are both designed specifically for use in external applications such as caravan installations, therefore hold certification indicating waterproof protection which can be identified on the label of each component. The PV cell selected for the system includes a protective enclosure which will be mounted internally and contain the 12 V battery, along with the switches and full wave bridge rectifier circuit. Mounting internally provides protection from bad weather conditions and permits ease of access. The container has a door that is key operated, which will help to minimise unwanted interference of the system in the event that someone unknown/unskilled attempts to access/alter it. The inverter circuit complete with heat sinks and transformer will be housed in a separate protective enclosure which also includes a key-operated door and will also be mounted internally for additional protection from severe weather conditions and to allow ease of access. PHYSICAL CHARACTERISTICS Size The protective PVC casing in which the full inverter circuit including the transformer will be housed, is 400 mm long, 300 mm wide with a depth of 200 mm. Power Indicator The inverter circuit includes a power indicator in the form of an LED (light emitting diode) which illuminates during operation and de-energises when the

- 10. Renewable Electrical Lighting System Nicola Cochrane 9 circuit is not conducting. The unit in which it is encased has a small window through which the power indicator can be visually identified. Battery Connections Battery connections are formed using crimpled ring terminals for secure connections. The cables are insulated and colour coded to avoid confusion, black for the anode and red for the cathode. PV Cell The PV cell itself will be mounted flat and externally on the roof of the caravan. Wind Turbine The turbine will also be mounted externally on the roof of the caravan by means of a nut and bolt. This is sufficient due to the small yet highly ergonomic proportions of the turbine.

- 11. Renewable Electrical Lighting System Nicola Cochrane 10 PROJECT OBJECTIVES AND SCHEDULE Locally accessible components and materials will be utilised to modify the researched inverter and rectifier circuits. Initial energy to operate the system must be renewable. The system is constructed to utilise renewable energy in order to provide 230-240 V AC at a frequency of 50 Hz when powered by a 12 V DC source. Each system component must be tested and improved until it satisfies the client’s requirements. All project operations must be conducted safely and in accordance with the IET Wiring Regulations BS7671, the Electricity at Work Act 1992, the Health and Safety at Work Act 1974 and all other relevant safety standards. The project must be completed and submitted to the client within the agreed timescale. The total project cost must exist within the client’s specified budget. The project must be completed in accordance with Electrical Engineering: Graded Unit 2. Graded Unit Code: DN3X 35. The final project submission must include a project report, a log book and a presentation, all of a very high standard to present to potential future employers.

- 12. Renewable Electrical Lighting System Nicola Cochrane 11

- 13. Renewable Electrical Lighting System Nicola Cochrane 12 SOLUTION ANALYSIS AND JUSTIFICATION The main parameters stipulated by my client are the utilization of renewable energy to produce 230 V AC at 50 Hz for operation of a lighting circuit. The system must be operable in remote settings, without dependence on a mains power supply and must function efficiently with appropriate safety features. The main system components have remained the same apart from a few additional electronic components and some minor changes to circuit designs and layouts. However there have been severaloptions to deliberate in regard to the energy source required to operate the system. Subsequently, a hydroelectric system was considered along with a windmill powered motor system that incorporated a dump or diversion load. The selected renewable system incorporating a wind turbine and PV cell was also considered. To ascertain which system would be selected for the application, the following parameters were identified, revised and explored in some detail with the client: Eco-friendly Efficiency Cost Suitable for implementation in a caravan Reliability Safety Discreet operation Aesthetically pleasing Portability Extensive discussion with the client revealed that the necessity for portability of the system is more important than initially discussed. The client has recently been approached by a fellow member of the Caravan Club with an exceptional financial offer for the purchase of his motor home. Although the client has postponed the possibility of the sale for one year, this deems the requirement of a portable system vital. Immediately, this eradicates the hydroelectric system from potential options as that would remain static in the site in which it would be erected. To determine which system adheres most appropriately to the specified parameters,a resolution table shall be constructed.

- 14. Renewable Electrical Lighting System Nicola Cochrane 13 Parameters Windmill Wind turbine & PV cell Eco-friendly 10 10 Efficient 5 8 Cost 7 8 Caravan suitability 8 10 Reliability 7 8 Safety 6 9 Discreet operation 7 9 Aesthetically pleasing 4 10 Portability 5 8 Total 59 80 The analysis clearly demonstrates that the combined system of a wind turbine and PV cell is favorable as it gains the greatest number of points. The table assists in determining a convenience factor which strongly supports the wind turbine and PV cell option due to high ratings for all parameters,especially portability, eco-friendliness and caravan suitability. Although the windmill powered system is eco-friendly, it does not hold enough merit for efficiency, safety and portability. This indicates potential power losses, a lack of safety features which could result in damage to equipment or harm to system users and an inability to relocate the system intact from one caravan to another. In terms of aesthetic value, the windmill would also be fairly obtrusive compared to the alternative system. The wind turbine and PV cell system has been selected as it matches the criteria set by the client more substantially than the other options.

- 15. Renewable Electrical Lighting System Nicola Cochrane 14 Wind Turbine BLOCK DIAGRAM PV Cell Full Wave Bridge Rectifier with Regulator Circuit Battery DC to AC Inverter Circuit Consumer Unit and Lighting Circuit

- 16. Renewable Electrical Lighting System Nicola Cochrane 15 TECHNICAL DESCRIPTION Please referto references [1-11] and appendices foradditional information. THREE PHASE TO SINGLE PHASE CONVERSION o The wind turbine is connected in star and provides a three phase output. The connections are rewired into a delta configuration and with the aid of a terminal slip, a capacitor is added across two phases to convert the output from three phase to single phase. POWER RECTIFICATION o The wind turbine provides an output of approximately 10-12 V AC. This passes through the full wave bridge rectifier chip which encases the 4 x diode bridge rectifier formation and produces a rough 10-12 V DC. o The added smoothing capacitor yields a higher output voltage and creates a more constant and consistent DC output voltage, also known as a ripple voltage. VOLTAGE REGULATION o The 7812 Regulator chip incorporated in the rectifier circuit regulates the voltage, providing the desired output of 12 V DC required to charge the battery. POWER INVERSION o The DC to AC inverter, designed on Express PCB software, will be powered by 12 V DC from the battery. The circuit utilizes an IC (Integrated Circuit) chip which acts as a controller, generating the duty cycle of the mosfet components which are attached to separate heat sinks. A step-up transformer completes this circuit, inverting the input voltage to around 230 V AC at 50 Hz. POWER DISTRIBUTION o The consumer unit will safely distribute around 230 V AC at 50 Hz to each lamp.

- 17. Renewable Electrical Lighting System Nicola Cochrane 16 WIND TURBINE [1] Wasser Generator Wind Turbine. Manufactured by Ista Breeze. Model – i-500G Rated Output – 400 W Peak Output – 500 W Rated Voltage – 12 V AC Rated Charging Current – DC 41.7 A Operating Temperature Range (℃) – From -40° to 60° Over speed Control – Electromagnetic brake with Controller Generator type – Brushless 3-phase PMA with high performance Neodymium Magnets Weight – 2kg Product Life – 15 years Warranty – 2 years THREE PHASE TO SINGLE PHASE CONVERSION (Appendix 1) Capacitor - 10𝜇F Terminal slip PV CELL [2] 10 W Solar System. Manufactured by Connexa. Rated Output – 10 W

- 18. Renewable Electrical Lighting System Nicola Cochrane 17 Rated Voltage – 12 V DC 25 years limited power output warranty Cells are laminated with TPT and EVA ensuring longer life and maximum performance Battery included High transparent low-iron, tempered glass Heavy-duty anodized frames Outstanding low-light performance Rugged design to withstand high wind pressure,hail and snow FULL WAVE BRIDGE RECTIFIER CIRCUIT W/REGULATOR & SMOOTHING CAPACITOR Vero board Bridge Rectifier Chip – KBP2008G [5] Regulator Chip – 7812 [7] Smoothing Capacitor – 100𝜇F BATTERY [6] Included in the solar system. 12 V DC,18 A DC TO AC INVERTER (Refer to Appendix 4 for original and re-designed schematics.) PCB IC Chip: CD 4047 [9] Capacitors: 2200 𝜇𝐹, 0.1 𝜇𝐹 Resistors: 33 kΩ, 330 Ω, 1 kΩ, 2 x 220 Ω Potentiometer: 100 kΩ Diodes: IN4007, LED Mosfets: 2 x IRF540 [8]

- 19. Renewable Electrical Lighting System Nicola Cochrane 18 Transformer: Step-up, turns ratio - 1:20 Flying leads Fixing pins Heat sinks: MDF, 2 x aluminium plates. LIGHTING CIRCUIT Consumer unit: Wylex - 230 V AC 50Hz [3] Two-way switch 2 x Light fittings [4] 2 x 15 W light bulbs 2 x junction boxes [10] Twin and earth cable

- 20. Renewable Electrical Lighting System Nicola Cochrane 19 IMPLEMENTATION In order to ensure efficient operation of the project in all stages,my colleague and I demonstrated our organizational skills by dividing the tasks equally between us both. On encountering a problem we worked as a team to carry out research from a range of sources including books, websites, research papers and advice from other engineers, enabling us to resolve issues competently and rapidly. We implemented the knowledge gained from research by developing our project. My colleague and I have maintained a high level of communication with each other and the client throughout the duration of the project by arranging and attending regular meetings. This has enabled us to discuss the project development and also the problems we have encountered in order to fully agree, with the client, on each of the steps taken to resolve them. We have remained focused on the projects objectives, taking into account any suggestions or alterations proposed by the client. The following table highlights how the main tasks were distributed between both my colleague and I; Component Nicola Cochrane Martin McNulty Lighting circuit Design/Construction Construction Rectifier/Regulator Design Construction PCB (1st attempt) Construction Design PCB (2nd attempt) Construction Design PCB (3rd attempt) Construction Design/Construction All minor electronic and electrical components required for construction of the project were made readily available to us in the Green Electrical Installations workshop. The heat sinks were hand-crafted using recycled materials. OVERCOMING PROBLEMS We encountered a variety of problems throughout the construction phase of the project. Each issue we tackled assisted us in establishing an understanding of unfamiliar components and a greater understanding of other known topics. LIGHTING CIRCUIT The first issue we encountered was unwanted power reduction in the lighting circuit. We recognized there was a problem as during testing, the light bulbs were not illuminating fully. After researching lighting circuits we understood that the reason for this was due to the fact that we had connected the circuit in series. Series lighting circuits distribute power by dividing the power equally by the number of luminaires; therefore the more luminaires present in the circuit, the dimmer the illumination from each lamp will be. To rectify this issue we re-

- 21. Renewable Electrical Lighting System Nicola Cochrane 20 connected the lighting circuit in parallel which eradicated the unwanted power reduction and allowed maximum power to flow to each luminaire. DC TO AC INVERTER CIRCUIT There were severalproblems with this circuit due to our unfamiliarity of several of the electronic components. Our initial problem arose from the wrong pin configuration of the IC CD4047 chip on the originally designed PCB. Having constructed the circuit and soldered the components, we began testing with a logic probe. The logic probe identified an issue with the pin configuration as we were not achieving the results expected for each individual pin. To overcome this problem, we researched the CD4047 pin configuration on a variety of websites to ensure accuracy then my colleague re-designed the PCB. Secondly, after I started to solder the components into the re-designed PCB,we were advised by an electronics engineer to create heat sinks for the mosfet components to allow for heat dissipation. The heat sinks could not be attached to the mosfets whilst connected to the PCB as we had not factored this possibility into the design process,so there was not sufficient space to do so. We managed to resolve this problem by constructing separate heat sinks from MDF and two aluminium plates, creating a larger surface area for heat dissipation. Aluminium was selected for its low resistivity and high dissipation values. We then excluded the mosfets from the third and final PCB design. Our final issue with the DC to AC inverter circuit occurred post construction and soldering of the circuit. Upon testing the output voltage, frequency and waveform of the circuit with an oscilloscope, we identified that the frequency was extremely high, around 1.2 kHz and the voltage was exceptionally low at approximately 500 mV. Such a high frequency would create harmonics through the transformer when on load which is highly undesirable. We determined that the 390 kΩ resistor was the cause of such a high frequency, so we replaced this with a decade resistor in order to vary the resistance and achieve the desired frequency of 50 Hz at around 12 V AC (prior to connection of the transformer). From this, we were able to distinguish that the resistance required in place of the 390 kΩ resistor was 33 kΩ. We then replaced the decade resistor with a 33 kΩ resistor and tested the outputs again with an oscilloscope. Fortunately we achieved the ideal results.

- 22. Renewable Electrical Lighting System Nicola Cochrane 21 IMPLEMENTATION CHECKLIST 1 Reports and discussions with the client are clear and well informed. 2 Progress reports identify completed tasks,progress made and goals for future work. 3 Effective action is taken when feedback is received from the client. 4 Additional expertise is identified and acquired when necessary. 5 Adjustments are made to the schedule when appropriate and with the agreement of the client. 6 Clear documents including the log book are maintained.

- 23. Renewable Electrical Lighting System Nicola Cochrane 22 PROGRESS REPORTS

- 24. Renewable Electrical Lighting System Nicola Cochrane 23 PROJECT ENGINEER: Nicola Cochrane Project Supervisor: Charlie Watson PROJECT TITLE Renewable Electrical Lighting System. Date 05/05/15 No. Item Checked 1 Progress to Date: Full system construction is complete along with testing. First half of report is also complete. 2 Actions since last Report: Altered the time constant by changing the value of resistor in order to achieve a frequency of 50Hz. Removed MOSFETS from PCB and connected to heat sinks. Simulating Turbine. 3 Problems Overcome and Outstanding: Frequency out from the MOSFETS was too high but the problem was overcome. Addition of switches for safety 4 Next Actions and Goals: Complete report and presentation. 5 Log Book up to Date: Yes 6 Current Documentation Provided: Log Book 7 Supervisor’s Comments:

- 25. Renewable Electrical Lighting System Nicola Cochrane 24 PROJECT ENGINEER: Nicola Cochrane Project Supervisor: Charlie Watson PROJECT TITLE Renewable Electrical Lighting System. Date 20/01/15 No. Item Checked 1 Progress to Date: Selected project, researched circuits, built full bridge wave rectifier circuit with smoothing capacitor and regulator, started construction on lighting circuit, altered DC to AC inverter circuit. 2 Actions since last Report: N/A 3 Problems Overcome and Outstanding: Initially connected lighting circuit in series but power to the lights was reduced so rearranged and connected in parallel, to avoid this problem. 4 Next Actions and Goals: Finish constructing lighting circuit, order parts for the inverter and design the wind turbine. 5 Log Book up to Date: Yes 6 Current Documentation Provided: Log Book 7 Supervisor’s Comments:

- 26. Renewable Electrical Lighting System Nicola Cochrane 25 VERIFICATION STRATEGY Testing and evaluation are vital aspects of every engineering project. These processes are consistent throughout the development of the project as every stage must be compared with and adhere to the project objectives and the customer’s specifications. The verification strategies and results of each component of the project were as follows: Methods of testing included: Visual inspections of each circuit at every stage of construction. A multimeter was utilized for testing continuity and output voltages. An oscilloscope was used to verify the output waveforms and frequency of the circuits. A logic probe was utilized to test the IC chip. FULL WAVE BRIDGE RECTIFIER Results for each test were as follows: o Visual inspections – Ensured that components were positioned correctly and soldered to a good standard, allowing for full functionality and safe operation of the circuit. o Continuity tests were performed prior to any testing which involved the multimeter. All continuity tests were successfulas the multimeter measured 0Ω of resistance each time. o Rectifier/Regulator Output Voltage – 12.25 VDC: This demonstrates that the circuit is operating correctly as 12 V AC is flowing into the circuit, there is a 1.4 Voltage drop across the rectifier as each diode has a volt drop of 0.7 V and two diodes operate at any one time. This brings the voltage to around 10.6 V DC (±5%) which then passes through the smoothing capacitor yielding a higher output voltage and finally through the regulator which emits a constant DC voltage of 12 V (±2.5%). o Rectifier output waveform:As expected: [11] (Appendix 2)

- 27. Renewable Electrical Lighting System Nicola Cochrane 26 o Regulator output waveform: As expected:Constant 12 V DC output. BATTERY The output voltage of the battery was tested with a multimeter: Output voltage – 12.53 VDC:This demonstrates that the battery is fully charged and is operating correctly. DC TO AC INVERTER Results for each test were as follows: o Visual inspections – Ensured that components were positioned correctly and soldered to a good standard, allowing for full functionality and safe operation of the circuit. o Continuity tests were performed prior to any testing which involved the multimeter. All continuity tests were successful as the multimeter measured 0Ω of resistance each time. o Logic probe test results table for IC CD4047: (Appendix 5) Results were as expected. o Dummy load – Prior to connection of the center-tapped transformer, the inverter was tested by connecting a dummy load consisting of two 330Ω resistors in series across the output. The resultant output was around 13.85 V as expected. This enabled us to verify that the circuit was operating safely. Please refer to Appendix 3 for mosfet output waveform.

- 28. Renewable Electrical Lighting System Nicola Cochrane 27 Figure 1.0 – Inverter testing with dummy load o Inverter Input / Output Voltages: Input voltage – 12.24 VDC Output voltage – 168 Vrms AC The output voltage measurement was taken from the live and neutral of the consumer unit. In order to calculate the peak voltage (Vp) the rms voltage must be multiplied by √2 as follows: Vp = 168 x √2 = 238 Vp AC Since the voltage required to operate the lighting circuit is 230-240 Vp AC, 238 V AC is ideal and as expected. LIGHTING CIRCUIT Test results were as follows: o Visual inspections – Ensured that components were wired correctly and corresponding safety devices were positioned appropriately, allowing full functionality and safe operation of the circuit. o Continuity tests were performed prior to any testing which involved the multimeter. All continuity tests were successfulas the multimeter measured 0Ω of resistance each time. o Live to Neutral – 170.8 VAC – 240 Vp AC As expected. o Live to Earth – 0 V – As expected. The circuit is operating safely. o Neutral to Earth – 0V – As expected. The circuit is operating safely.

- 29. Renewable Electrical Lighting System Nicola Cochrane 28 COSTING The overall charge for the installation will be calculated and invoiced to the client on completion of the project. The costs involved in manufacturing the prototype can be divided into two main parts: Materials Labour and service MATERIALS Green Electrical Installations are happy to subsidize the cost of minor components as an incentive for our new client to approach us in the future with any further renewable concepts. The following table lists the price of each component and the total cost of materials that will be charged to the client: Component Price Wind Turbine £98.50 PV Cell £445.50 Rectifier £1.99 Regulator £0.36 IC CD4047 £0.53 Mosfets £1.35 Lamps £3.48 Junction boxes £1.05 TOTAL £552.76 LABOUR AND SERVICE These costs will be broken down into two parts,company cost and physical labour charge. Green Electrical Installations will charge a service cost of £100 due to the necessity for a prototype to be created prior to production of the finalized system. This installation required additional time and attention compared to our pre- fabricated systems which validates the service cost. My colleague and I are paid an hourly rate of £14.28 and spent 35 hours each working on the installation. The total cost of labour is calculated as £999.60. This brings the overall cost of the project to a total of £1652.36, which has been agreed fully with the project supervisor and the client.

- 30. Renewable Electrical Lighting System Nicola Cochrane 29 SAFETY As an employer, Green Electrical Installations are fully liable for ensuring that all employees operate within the boundaries of current safety legislation and adhere fully to all IET Wiring Regulations. MAIN OPERATIONAL SAFETY STANDARDS Throughout the construction phase of the project, my colleague and I abided strictly by the following fundamental safety standards: Goggles must be worn during participation in any drilling/soldering activities and also when operating in close vicinity of such activities. Earth wrist strap must be worn when handling components. Power supply to workshops and labs must be switched off if unattended. All components must be tested prior to implementation. All circuits must be tested individually and appropriately post construction. Circuits must not be energized until testing is complete and satisfactory. Battery must remain isolated until testing and full system constructions are complete. The project supervisor signed off every stage of construction to verify that each one was conducted safely and suitably. SAFETY DEVICES The consumer unit incorporates two different safety features which are detailed below. MCB An MCB (Miniature Circuit Breaker) is an electromechanical device that operates to protect the circuit and equipment from overload and fault conditions. Figure 1.1 - MCB The thermal operation of an MCB is achieved with a bimetallic strip in the event that over current flows through the MCB, the bimetallic strip is heated and deflects by bending. The deflection of the bimetallic strip releases a mechanical

- 31. Renewable Electrical Lighting System Nicola Cochrane 30 latch. As the latch is attached with an operating mechanism, it opens the MCB contacts. However,if a short circuit occurs, there will be a sudden increase of current which causes electromechanicaldisplacement of the plunger associated with the solenoid part of the MCB. The plunger strikes the trip level, resulting in the release of the latch which again opens the contacts. RCD A residual current device is an electrical wiring device that operates to provide protection to system users from electric shock. These devices can also be used as a form of system protection against excessive heat. Figure 1.2 – RCD schematic These devices operate by detecting and interrupting earth fault currents that equate to 50% or more of the rated tripping current. The key component in these devices is a current transformer upon which the live and neutral conductors are wound in opposite directions. There is a third winding on the transformer which acts as a detector or search coil. If no fault current flows then the live and neutral conductors will carry the same currents. Therefore there will be no resulting flux in the current transformer for the detecting coil to generate a current. When a fault current flows, a potential difference will exist between the live and neutral conductors. This will generate a resultant flux which will induce a current in the search coil. This, in turn, operates a relay or trip coil which opens the main RCD contacts.

- 32. Renewable Electrical Lighting System Nicola Cochrane 31 DISCUSSIONS AND CONCLUSIONS The design process of the prototype broadened my understanding of design software and my ability to simulate electronic circuits. I was also introduced to severalelectronic components that I was previously unfamiliar with and gained skills in implementing electronic circuits from schematic diagrams. I gained a lot of valuable practical experience throughout the construction phase of the system. This included installation of a small domestic lighting circuit, constructing and soldering electronic and electrical components and fault finding techniques, of which my knowledge has vastly increased. The use of a log book to retain ideas, make notes and document results proved to be an important reference guide. My initial attempt at soldering left a lot to be desired. To improve my soldering skills I approached the college technician for advice and was directed in how to progress. Thereafter,I practiced soldering simple circuits onto vero board including a relay and my technique improved substantially in a short period of time. I was then a lot more confident in my approach to solder and continued to complete the electronic circuits without any difficulties. I am now considering purchasing my own soldering equipment to practice as a hobby. Due to my unfamiliarity of certain components, I found electronics and fault finding to be the most challenging aspects of the project as a whole. I found it difficult to understand the operation of certain electronic components and therefore, how to rectify faults from these components. However,with research and good advice and direction from my lecturer, Charlie Watson, I was able to gain a better knowledge and understanding of said components and how to detect faults. From this experience I have achieved a greater ability to find and fix faults using equipment such as logic probes. Overall, I thoroughly enjoyed the project and I am satisfied that Martin McNulty and I have successfully designed, constructed and tested a fully operational system which adheres to the project objectives and specification. We implemented our collective knowledge from modules such as; Electrical installation design, DC/AC principles, Application of power electronics, Energy overview, Digital electronics as well as the practical experience we gained in completing an SVQ level 2 in Performing Engineering Operations last year, to aid us throughout the whole process. The knowledge and skills I have gained, both practically and theoretically, are vital to my progression into University and ultimately into the engineering industry on completion of my studies. I now have the confidence in myself as an engineering student that I lacked prior to commencement of the project. This has reaffirmed my passion for engineering and my motivation to succeed as an engineer in the near future.

- 33. Renewable Electrical Lighting System Nicola Cochrane 32 ACKNOWLEDGEMENTS First and foremost I would like to thank my colleague, Martin McNulty for his collaboration and support throughout the project. I would also like to thank the all talented Charlie Watson. As client, lecturer, and project supervisor, Mr. Watson had several roles in our project and fulfilled each one expertly. Thanks for your guidance, confidence and perseverance Charlie. Thank you to Gary Murray, the college technician, for all of his advice and assistance throughout the difficult stages of the build and also for my new and vastly improved soldering technique. I would also like to thank Stuart Logan for his recommendations and reassurance at severalpoints throughout the project completion. Finally, thank you to all of the lecturers who have contributed to my progression through the HNC and HND in Electrical Engineering. The knowledge and skills I have gained with your assistance have enabled me to produce a successfulgraded unit project.

- 34. Renewable Electrical Lighting System Nicola Cochrane 33 REFERENCES [1] Wind Turbine: http://www.istapower.net/en/home/12-wassergenerator-windturbine- istabreeze.html [2] PV Cell: http://www.cannonwater.net/Solar_Power_System_10watt.aspx [3] Consumer Unit: http://uk.rs- online.com/web/p/product/569603/?grossPrice=Y&cm_mmc=UK%7CShopping- _-Google+PLA-_-Wylex%7CConsumer+Units-_- 569603&kpid=&kpid=569603&istCompanyId=f7e7b05b-2daf-4c0e-8825- 3633baf8113b&istItemId=xwimtxtww&istBid=tzit&gclid=CKGmj9r3ncUCFQz HtAodpWwA4w [4] Light fittings: http://www.diy.com/departments/crabtree-gloss-urea-batten-lamp- holder/241874_BQ.prd [5] Rectifier: http://html.alldatasheet.com/html- pdf/625893/JUXING/KBP2008G/217/1/KBP2008G.html [6] 12V Battery: http://www.slingsby.com/Workshop-Maintenance987/Power- supply924/Batteries641/Rechargable-sealed-lead-acid- batteries_386639.htm?gclid=CMjn5fT5ncUCFQcTwwodmL0ARA [7] Regulator: http://www.hobbytronics.co.uk/voltage-regulator-l7812 [8] Mosfets: http://www.irf.com/product-info/datasheets/data/irf540n.pdf [9] IC CD4047: http://uk.farnell.com/texas-instruments/cd4047be/ic-4000-cmos-4047-dip14- 18v/dp/1106105 [10] Junction boxes: http://www.diy.com/departments/marbo-20a-4-terminal-black-junction- box/213554_BQ.prd [11] Rectifier waveform: https://www.sonoma.edu/users/m/marivani/es231/units/experiment_05.shtml

- 35. Renewable Electrical Lighting System Nicola Cochrane 34 APPENDICES

- 36. Renewable Electrical Lighting System Nicola Cochrane 35 APPENDIX 1 – THREE PHASE TO SINGLE PHASE CONVERSION Figure 1.0 – Configuration from Star to Delta Fig 1.1 – Re-wiring Star to delta Fig 1.1 demonstrates how the star connections will be re-configured to a delta formation. The delta configuration will continue to emit a three phase output. In order to convert the output to single phase, a capacitor will be connected across two of the three phases. This a better alternative to removing a phase as it ensures prevention of power loss to the load. Great care must be taken in the selection of a suitably rated capacitor, failure to do so may result in thermal damage of the windings or in extreme cases,fire. The capacitor will be connected to complete the three phase to single phase conversion with the aid of a terminal block as demonstrated below: Three phase in Single phase out Capacitor connection

- 37. Renewable Electrical Lighting System Nicola Cochrane 36 APPENDIX 2 – FULL WAVE BRIDGE RECTIFIER OUTPUT WAVEFORM This variation of the output voltage is called a Ripple. This particular ripple is ideal as it flows smoothly without excessive variation. The ripple varies depending on the load and also the value of capacitor used for smoothing purposes. If the circuit is under heavy load and the load is demanding a large current, the ripple will vary more, creating an excessive ripple effect. The same excessive ripple will also occur if the value of capacitor is too small.

- 38. Renewable Electrical Lighting System Nicola Cochrane 37 APPENDIX 3 – MOSFET OUTPUT WAVEFORM The above waveform was measured from the output of the Metal-oxide- semiconductor field-effect transistors, commonly known as mosfets during operation of the system. The waveform demonstrates emission of an AC supply from these voltage controlled switches. The square wave represents the on and off switching periods according to the duty cycle set by the controller (IC chip) in order to obtain the desired output voltage. The slightly sloping tops and bottoms rare caused by low primary inductance, however this is not an issue as the slopes are less than a few volts.

- 39. Renewable Electrical Lighting System Nicola Cochrane 38 APPENDIX 4.0 – ORIGINAL DC TO AC INVERTER SCHEMATIC INCLUDING MOSFETS (DESIGNED ON EXPRESS PCB)

- 40. Renewable Electrical Lighting System Nicola Cochrane 39 APPENDIX 4.1 – RE-DESIGNED DC TO AC INVERTER SCHEMATIC EXCLUDING MOSFETS

- 41. Renewable Electrical Lighting System Nicola Cochrane 40 APPENDIX 5 – DC/AC INVERTER – IC CHIP – LOGIC TABLE Pin Logic 1 Pulsating 2 Pulsating 3 Pulsating 4 Pulsating 5 Pulsating 6 Pulsating 7 Lo 8 Lo 9 Lo 10 Pulsating 11 Pulsating 12 Lo 13 N/A (No connection) 14 Pulsating