Note of Quality and Change Management MGMT 5212

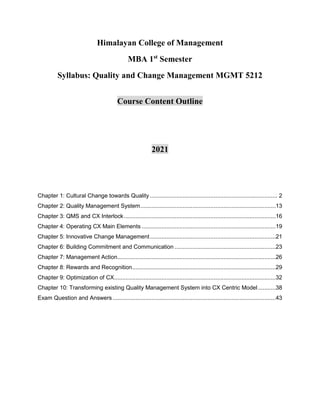

- 1. Himalayan College of Management MBA 1st Semester Syllabus: Quality and Change Management MGMT 5212 Course Content Outline 2021 Chapter 1: Cultural Change towards Quality .............................................................................. 2 Chapter 2: Quality Management System...................................................................................13 Chapter 3: QMS and CX Interlock.............................................................................................16 Chapter 4: Operating CX Main Elements ..................................................................................19 Chapter 5: Innovative Change Management.............................................................................21 Chapter 6: Building Commitment and Communication ..............................................................23 Chapter 7: Management Action.................................................................................................26 Chapter 8: Rewards and Recognition........................................................................................29 Chapter 9: Optimization of CX...................................................................................................32 Chapter 10: Transforming existing Quality Management System into CX Centric Model...........38 Exam Question and Answers....................................................................................................43

- 2. Chapter 1: Cultural Change towards Quality Quality Management Quality management is the act of overseeing all activities and tasks that must be accomplished to maintain a desired level of excellence. This includes the determination of a quality policy, creating and implementing quality planning and assurance, and quality control and quality improvement. Change Management Change management is a systematic approach to dealing with the transition or transformation of an organization's goals, processes or technologies. The purpose of change management is to implement strategies for effecting change, controlling change and helping people to adapt to change. This includes preparing and supporting employees, establishing the necessary steps for change, and monitoring pre- and post-change activities to ensure successful implementation Quality culture “An organizational value system that results in an environment that is conducive to the establishment and continual improvement of Quality” A significant advantage of a world-class quality culture is an engaged employee base, and an engaged employee delivers high productivity and results. To develop a world-class quality culture, organizations have to ensure that core values are implemented and lived by all. Gurus contribution to Quality Culture DR. W. EDWARDS DEMING Background ● Dr. William Edwards Deming (October 14, 1900 – December 20, 1993) was an American engineer, statistician, professor, author, lecturer, and management consultant. ● W. Edwards Deming worked as a statistician and researcher during World War II, and in the 1950s, he led efforts to bring statistical thinking and quality control methods to improve business, beginning with the manufacturing industry. Deming’s contributions

- 3. include developing a system of Statistical Quality Control (SQC) and championing the importance of quality in product and production through his philosophies and principles. ● Deming’s Theory is explained via four main parts and 14 principles called the 14 points for total quality management. ● He also popularized the Plan-Do-Check-Act cycle (PDCA), sometimes called the Deming Cycle. DEMING’S THEORY: 14 POINTS FOR MANAGEMENT ● Create constancy of purpose for improving products and services. ● Adopt the new philosophy. ● Cease dependence on inspection to achieve quality. ● End the practice of awarding business on price alone; instead, minimize total cost by working with a single supplier. ● Improve constantly and forever every process for planning, production and service. ● Institute training on the job. ● Adopt and institute leadership. ● Drive out fear. ● Break down barriers between staff areas. ● Eliminate slogans, exhortations and targets for the workforce. ● Eliminate numerical quotas for the workforce and numerical goals for management. ● Remove barriers that rob people of pride of workmanship, and eliminate the annual rating or merit system. ● Institute a vigorous program of education and self-improvement for everyone. ● Put everybody in the company to work accomplishing the transformation.

- 4. Plan-Do-Check-Act (PDCA Cycle) The PDCA cycle is a method for making changes to work processes and improving standards. During the 4 phases of the cycle, people do the following: 1. Plan: Assess the current state and look for improvements. If a problem exists, examine it in detail. Develop possible solutions and means of execution. In this phase, gather as much information as possible to make informed decisions about how to proceed. 2. Do: Try out the plans, making sure everyone involved understands the changes. This implementation phase is key to getting accurate results. 3. Check: Follow up to see how effective the changes are. Spend some time comparing the new state to how things were previously 4. Act: If the changes work, continue using them and make them the new standard. This will be the new point of reference for future PDCA efforts. DR. JOSEPH JURAN Background PHILIP CROSBY Background ● Born in Wheeling, West Virginia, United States on June 18, 1926 ● Was a businessman and author and also recognized as an influential quality guru ● Studied pediatrics in his early years and obtained his degree from Case Western Reserve University ● Start work by working in a manufacturing plant as an assembly worker ● During this period, in 1979, he published ‘ a book Quality is Free: The Art of Making Quality Certain,’ in which he presents a case study showing how the ITT Corporation saved million dollars by applying his quality concepts ● Book is translated into more than 15 languages, and more than 2.5 million copies have been sold. ● Establish his own company, the Philip Crosby Associates (PCA) in Florida. ● PCA is a quality management consulting firm that focuses on areas including quality management, process reengineering, managerial skill development, and process management. ● In 1997, Philip Crosby also established Philip Crosby Associates II, a teaching center in the field of quality control ● Best known for the quality management concepts Quality is Free, Zero Defects, and the Four Absolutes of Quality ● Several books such as ‘Quality is Free: The Art of Making Quality Certain ' and ‘Quality Without Tears: The Art of Hassle-Free Management.’ ● Died in Asheville, North Carolina, United States on August 18, 2001

- 5. Contributions 1. The major contribution made by Crosby is indicated by the fact that his phrases ‘zero defects’ , ‘getting it right first time’ and ‘conformance to requirements’ have now entered not only the vocabulary of quality itself, but also the general vocabulary of management. 2. Crosby devised the principle of “ doing it right for the first time “ (DIRFT). He also included 4 major principles: - The definition of quality is conformance to product and customers requirement. -Prevention is the system of quality. -Zero Defects should be the performance standard. -Quality measurements are the price of non-conformance. He believed that establishment of good quality management principles in an organisation will have more savings returns than what the organisation pays for the cost of the quality system. Crosby stated that since “quality is free” it is less expensive to do it right the first time rather than paying for repairs and reworks. Crosby’s zero defects theory states that there is no existence of waste in a project. Waste refers to anything that is unproductive i.e. processes, tools and employees etc. Anything that is not adding any value to a project should be eliminated. Eliminating waste leads to process improvement and consequently lowers costs. The zero defects theory is the concept of doing it right the first time to avoid cost and time spent later in the process of project management. According to him, the 4 absolutes of quality management are: -Quality is conformance to requirements. -Quality prevention is preferable to quality inspection. -Zero defects is the quality performance standard. -Quality is measured in monetary terms-the price of non-conformance. Crosby gave 14 steps for quality improvement. They are as follows: Management commitment - Make it clear that management is committed to quality. Quality improvement teams- Form quality improvement teams with senior representatives from each department. Measure processes- Measure processes to determine where current and potential quality problems lie. Cost of quality- Evaluate the cost of quality and explain its use as a management tool. Quality awareness- Raise the quality awareness and personal concern of all employees. Correct problems- Take actions to correct problems identified through previous steps. Monitor progress- Establish progress monitoring for the improvement process. Train supervisors- Train supervisors to actively carry out their part of the quality improvement program. Zero defects day- Hold a zero defects day to reaffirm management commitment. Establish improvement goals- Encourage individuals to establish improvement goals for themselves and their group. Remove fear- Encourage employees to tell management about obstacles to improving quality.

- 6. Recognize- Recognize and appreciate those who participate. Quality councils- Establish quality councils to communicate on a regular basis. Repeat the cycle- Do it all over again to emphasize that the quality improvement process never ends. Philip Crosby’s ideas on quality came from his vast experience of working with an assembly line. His main focus was on zero defects which ultimately led to the adoption of this concept by the modern Six Sigma Quality movement. Mr. Crosby explained the ideas that zero defects is not a phenomenon that originated on the assembly line. He defined quality as a conformity to a set of specifications defined by the management rather than a vague concept of “goodness”. However, these specifications are set according to the needs and wants of the customer rather than being arbitrarily defined. ARMAND V. FEIGENBAUM Background DR. H. JAMES HARRINGTON Background DR. WALTER A. SHEWHART Background ● Walter Andrew Shewhart (pronounced like "shoe-heart", March 18, 1891 – March 11, 1967) was an American physicist, engineer and statistician, ● sometimes known as the father of statistical quality control and also related to the Shewhart cycle. ● Shewhart was also awarded his doctorate in physics from the University of California, Berkeley in 1917. ● Mr.Shewhart is also known as a Pioneer and Visionary of modern quality control. ● Mr. Shewhart laid the first seed of the quality movement with his book “Economic Control of Quality of Manufactured Product”. ● His books were used by the Japanese after World War II.with aid of visiting consultants, to help shape modern quality practice in Japan. Involved Organization and Progress ● In 1918, Mr. Shewhart joined Western Electric Company Inspection Engineering Company inspection Engineering department. On that time Industry quality was limited to inspecting finished product and remogram, and the short text which preceded and

- 7. followed it, set forth all of the essential principles and considerations which are involved in what we know today as process quality control.ving defective items but later Mr. Shewhart prepared a memorandum only a page in length for which the page was given over a simple diagram which would recognized today as a systematic control chart. ● Most of Shewhart's professional career was spent as an engineer at Western Electric from 1918 to 1924, and at Bell Telephone Laboratories, where he served in several capacities as a member of the technical staff from 1925 until his retirement in 1956. ● That diagram, and the short text which preceded and followed it, set forth all of the essential principles and considerations which are involved in what we know today as process quality control. Shewhart’s Contributions ● Process Improvement Reducing variation ○ Simple schematic control chart ○ No two products will ever be the same two classes of variation, namely special- cause’ and common-cause’ ● Deming Wheel Cycle and Six Sigma ○ PDCA or plan-do-check-act, ○ DMAIC or define-measure-analyze-improve-control ○ The more iterations a product is subjected to, the better the end output. Shewhart is best known for his simple schematic control chart which changed the manufacturing industry forever. This chart outlined principles essential to modern process quality control. These are followed to this day with certain improvements as production processes became more complicated. A key thing to remember in any process is that no two products will ever be the same. Reducing these variations to improve quality has always been one of the manufacturing industry’s greatest challenges. Shewhart's acknowledgment of two classes of variation, namely special- cause’ and common-cause’ led him to improve his control chart mentioned above. He proposed variables which would reduce common-cause’ variations. According to him, to distinguish between the two, every manufacturing process would need to be brought under statistical control. This and other principles of Shewhart helped pave the way for modern analysis of manufacturing processes. Contribution Business dictated a need to reduce the frequency of failures and repairs to their amplifiers, connectors and other equipment that were buried underground. Bell Telephone had already realized that reducing variation in manufacturing processes would have a positive impact on repair costs. At the same time the company determined that continual adjustments in process parameters reacting to non-conformances resulted in increased variation and a degradation of quality.

- 8. Bell Telephone’s discoveries in product variation resulted in the institution of an inspection program, ensuring specification and quality standards to avoid sending defective products to customers. Even though this program was somewhat effective, it was very costly to deal with inspecting and sorting of finished goods. By 1924, Shewhart determined the problem of variability in terms of assignable cause and chance cause (Deming referred to this as common cause). On May 16, 1924, Shewhart prepared a memorandum of less than one page in length and forwarded it to his manager, George Edwards. About 1/3 of the page was devoted to a simple diagram that we would today recognize as a control chart. This memorandum set forth the essential principles and considerations that became known as process quality control. Shewhart’s principle was that bringing a process into a state of statistical control would allow the distinction between assignable and chance to cause variations. By keeping the process in control, it would be possible to predict future output and to economically manage processes. This was the birth of the modern scientific study of process control. DR. KAORU ISHIKAWA Background ● Born in Tokyo on July 13, 1915 ● Kaoru Ishikawa was a Japanese professor, advisor and motivator with respect to the innovative developments within the field of quality management ● graduated from TATIUC. ● He worked as a naval technical officer and later worked at the Nissan Liquid Fuel Company too. ● Ishikawa joined the (JUSE) quality control research group ● He mobilized large groups of people towards a specific common goal that was largely responsible for Japan's quality-improvement initiatives. ● Key figure in the development of quality initiatives in Japan, particularly the quality circle. ● Known for the Ishikawa cause and effect diagram (also known as fishbone diagram) often used in the analysis of industrial processes. ● Died on April 16, 1989

- 9. ● ● Fishbone Diagram (Cause & Effect Diagram) ● Named owing to its shape ● One of the seven basic Quality Control tools (Cause and effect diagram, Check sheet, Control chart, Histogram, Pareto chart, Scatter diagram and Flow Chart) ● Objective ● The removal of waste so as to identify the areas for improvement ● Clusters the roadblocks together to identify which factors have the greatest impact ● Commonly used in product design and prevention of quality defects to reveal the factors causing the overall effect.

- 10. Implementation of Quality Circles 1. Formal groups of people trained by specialists in human factors and skills of problem identification, data gathering, and analysis and generation of solutions 2. Concept was first launched in Nippon Wireless and Telegraph Company in the year 1962 3. The idea of Quality Circles was described by Edward Deming in 1950 and was later expanded by Ishikawa 4. Objectives 5. Improvement in Occupational health and safety 6. Product design 7. Manufacturing processes 8. Overall culture of the organization Emphasis on Internal Customer ● Suggested that over-reliance on specialists would limit the scope of improvement for all the employees ● Overall participation was required from workers at all the levels of the organization ● Every area has the potential for contributing to the overall quality ● All areas should embed statistical techniques in the internal and external audit programme ● Including internal quality control company should also focus on: ● The quality of management ● Human aspects ● After sales service ● Sensitive customer care DR. GENICHI TAGUCHI Background ● born in Tokamachi, Japan on January 1, 1924. ● was an engineer and statistician ● developed a methodology for applying statistics to improve the quality of manufactured products ● was recruited and taken to the Department of Astronomy of the Navigation Institute of the Imperial Japanese Navy in 1942. ● spent 12 years creating methods to improve the quality and reliability of the Electrical Communications Laboratory. ● was also a consultant to Toyota.

- 11. ● finished his doctorate at the University of Kyushu in 1962 ● his methodology was growing little by little, as well as in other important companies such as the Ford Motor Company, Boeing, Xerox and ITT Corporation ● 1982, was an advisor to the Japanese Standards Institute and executive director of the Suppliers Institute of America, an international consulting organization. ● died on June 2, 2012, at the age of 88 years. Contributions Among the contributions of Taguchi, his contribution to industrial statistics stands out. The Japanese suggested that it is cheaper to redesign the manufacturing processes and products than to perform quality improvement actions after an audit. Based on this concept, Genichi Taguchi created his own philosophy of quality in which he proposed: Loss function: Quality must be defined in monetary form through the loss function, in which the greater the variation of a specification with respect to the nominal value, the greater the monetary loss transferred to the consumer. Continuous improvement: The continuous improvement of the productive process and the reduction of variability are essential to survive at present. Variability: Can be quantified in monetary terms, the variability of the operation of the product causes a loss to the user. Product design: Quality is generated and the final cost of the product is determined. Optimization of product design: A product can be designed based on the non-linear part of its response, in order to reduce its variability. Optimization of the process design: Variability is reduced by means of the design of experiments, by selecting the optimal levels of the variables involved in the manufacture of the product. Quality Engineering: Divided into line and offline engineering. Taguchi also raised the concept of robust quality, which was oriented to the design of the product in a uniform way even if it was manufactured in unfavorable conditions. Customer Experience Customer experience is your customers’ holistic perception of their experience with your business or brand. CX is the result of every interaction a customer has with your business Customer experience (CX) is everything related to a business that affects a customer’s perception and feelings about it.

- 12. Importance of Customer Experience ● It's easier to retain customers than get new ones ● Happy customers are your best brand promoters ● CX gives you a competitive advantage ● Delighted customers buy more and refer more ● Bad CX spreads fast especially in the world of social media ● CX decides customers perception of the brand ● A delighted customer is a loyal customer ● Positive customer feedback helps in the future developments CX Life Cycle

- 13. Chapter 2: Quality Management System A quality management system (QMS) is defined as a formalized system that documents processes, procedures, and responsibilities for achieving quality policies and objectives. A QMS helps coordinate and direct an organization’s activities to meet customer and regulatory requirements and improve its effectiveness and efficiency on a continuous basis. A QMS is built for ISO Registration to satisfy customer requirement or to produce better products Importance of QMS ● Meeting the customer’s requirements ● Meeting the organization's requirements ● Defining, improving and controlling process ● Reduce waste ● Preventing mistakes ● Facilitating and identifying training opportunities ● Engaging staff ● Setting organization wide direction ● Communicating a readiness to produce consistent results QMS Principles 1. Customer Focus 2. Leadership 3. Engagement of People 4. Process Approach 5. Improvement 6. Evidence- Based decision making 7. Relationship Management Customer Focus It provides an opportunity to understand the current and future needs of the customers and retain their confidence. ● Understand the needs of existing and future customers ● Align organizational objectives with customer needs and expectations ● Meet customer requirements ● Measure customer satisfaction ● Manage customer relationships ● Aim to exceed customer expectations

- 14. ● Learn more about the customer experience and customer satisfaction Leadership Leaders can create an environment that empowers the people to engage with the organization and help it to achieve its quality objectives ● Establish a vision and direction for the organization ● Set challenging goals ● Model organizational values ● Establish trust ● Equip and empower employees ● Recognize employee contributions ● Learn more about leadership Engagement of People Involvement of organizational members at various stages can enhance the capability to deliver higher values so that the organization can achieve its quality objectives ● Ensure that people’s abilities are used and valued ● Make people accountable ● Enable participation in continual improvement ● Evaluate individual performance ● Enable learning and knowledge sharing ● Enable open discussion of problems and constraints ● Learn more about employee involvement Process Approach Quality Management is an interrelated process which helps to understand the results and boost the organization’s performance ● Manage activities as processes ● Measure the capability of activities ● Identify linkages between activities ● Prioritize improvement opportunities ● Deploy resources effectively ● Learn more about a process view of work and see process analysis tools Improvement Continuous improvement is essential to create new opportunities and enhance the current level of performance ● Improve organizational performance and capabilities

- 15. ● Align improvement activities ● Empower people to make improvements ● Measure improvement consistently ● Celebrate improvements ● Learn more about approaches to continual improvement Evidence Based Decision Making Decision making can be a complex process which always involves some uncertainty Facts, pieces of evidence and data analysis results help to make effective business decisions ● Ensure the accessibility of accurate and reliable data ● Use appropriate methods to analyze data ● Make decisions based on analysis ● Balance data analysis with practical experience ● See tools for decision making Relationship Management Maintain the success of the organization by managing the relationships with its interested parties to enhance the performance ● Identify and select suppliers to manage costs, optimize resources, and create value ● Establish relationships considering both the short and long term ● Share expertise, resources, information, and plans with partners ● Collaborate on improvement and development activities ● Recognize supplier successes ● Learn more about supplier quality and see resources related to managing the supply chain

- 16. Chapter 3: QMS and CX Interlock In many organizations the QMS and customer experience are addressed by two separate groups in separate silos. Since there is a very strong relationship between the two, we will first walk you through the dynamics of the silo mentality and then delve further into the merger of the QMS and customer experience. The interconnections Purpose of Intersection Silo behaviour ● Portrays a mind-set where a certain functional division, ● business entity or an individual refuses to collaborate with others in sharing information ● establishing teams where there is an exchange of ideas and constant feedback from colleagues. With a silo mentality, individuals also refuse to share knowledge with others. Damage From Silo Mentality Much evidence indicates that a large cost is associated with the silo mentality. In addition there are multiple negative effects: ● Example: one functional unite decided to go ahead and embark upon a ● new project without involving anyone else. ● When two departments literally work on the same project without ● communicating with each other and with sharing the data, then the synergy of the organization suffers, too. ● Situations where two or three individuals who think alike and have similar goals feel they are not being listened to and decide to go on their own. ● Breaking The Silo Barrier ● On the surface it may appear silo behavior is hard to address. ● There are simple and proven approaches that have worked well over the years in many organizations across the globe: ● To address the culture of silos by ensuring the staff understands that they will be held accountable not only for their own work but also for the overall success of the department. ● Constantly encouraged to share their knowledge with peers ● The exchange of ideas between employees assists in out of box thinking, leading to new ideas and solutions.

- 17. Breaking The Silo Barrier ● In organizations where QMS and CX are addressed by separate managers, with each manager having his or her own goals, metrics and incentives. ● Now we will dive deep into details of the silo activities of QMS and CX and the reasons for integrating them together into one, where the customer experience is viewed as a result of the QMS. ● In general terms, quality is described as meeting customer requirements and exceeding customer expectations. ● The technology advantage has narrowed and quality has become a source of competitive advantage where consumers rank quality and reliability of the solution as the number one success factor, followed by customer support and innovation. Exceptional Customer satisfaction Quality Goal Quality Essentials Strategic integration of quality and customer experience Knowledge Management Teamwork These are essential ingredients for achieving results from the implementation of a holistic QMS, with the quality management principles as the foundation. Foundation Customer Focus Process Approach Quality • Leadership • Improvement Principles les J . Engagement of People Evidenced-based decision making • Relationship Management 4.1 Mutual quality goal and essentials

- 18. Services Policies Products Figure 4.2 reflects the seven components of quality ecosystem that have direct impact on CX and suggests the need for close and careful integration between the components of the ecosystem. Customer Experience Quality Standards Processes Improvement Sustainability The QMS can work harmoniously and effectively if activities related to each of the components are carried out with leaders as sponsors, enabling individuals and making unwavering Quality and CX Understanding customer expectations is a prerequisite for improving quality to achieve full satisfaction, which affects customer experience! The relationship between quality and customer experience overlaps. Overlapping relationship: ● If the quality of the products or services is poor ● If the organization does not follow any industry or regulatory standards. ● If the quality of policies and processes is not up to par and they are way ● difficult to comprehend ● Due to continually exceeding customer expectations, sustainability of implemented improvement programs is vital Strategy to use ISO9001 QMS in addressing CX By the time the customer identifies the need, the product and/or service is already developed and all the requirements of various clauses in ISO 9001 must have been followed during the development cycle of the solution In some cases, there are multiple ISO 9001:2015 clauses that address a particular phase of the lifecycle due to the correlation, interrelationship, and dependencies between these phases and the activities that are performed within them.

- 19. The importance of main clauses of ISO 9001 such as leadership, planning, support, operation and performance evaluation are necessary for positive CS and apply to each phase of the life cycle. The interdependencies warrant cross-functional individuals to collaborate with each other for a solution realization process. Appropriate established metrics for the analysis of all processes working together as an overall QMS will act as a barometer of how effective the QMS is and will provide a reliable indication of the state of CX. Cross functional barriers feedback loop Chapter 4: Operating CX Main Elements It's not the strongest species that survive, nor the most intelligent, but the most responsive to change. Charles Darwin Role of Leaders 1. Ensure a strong foundation is laid for future CX improvement. 2. Effective leaders listen to employees and customers 3. Embraces employee motivation 4. Delegating employees 5. Built organization’s quality culture Customer knowledge Customer knowledge refers to understanding your customers, their needs, wants and aims. It is essential if a business is to align its processes, products and services to build real customer relationships.

- 20. Change management Change management is a systematic approach to dealing with the transition or transformation of an organization's goals, processes or technologies. The purpose of change management is to implement strategies for effecting change, controlling change and helping people to adapt to change. This includes preparing and supporting employees, establishing the necessary steps for change, and monitoring pre- and post-change activities to ensure successful implementation. Change management discipline Change management resistance The biggest challenge to any change comes through resistance to change. Change disturbs existing equilibrium, existing procedures, power structures etc within the system or organization, which may not be liked by many persons, thus leading to resistance to change. 1. The resistance to change could be a. Overt or Immediate resistances to change b. Implicit or Deferred resistances to change 2. Resistance to change can come from employees as well as employers or management. 3. Resistance to change can occur at any level i.e. individual level, and organization level. Introduction to innovative change management (ICM) Innovative Change Management (ICM) represents the accumulated wisdom and knowledge of one of the world’s foremost performance improvement specialists. It includes a clear and thorough explanation of the necessary critical tools for creating a system that results in a much higher percentage of your initiatives progressing to successful projects. Studies conducted by organizations such as Gartner, Ernst & Young, and Harrington Management Systems indicate that on average less than 25% of the innovative projects achieve sustained success. The American Productivity Quality Center's 2018 survey report pointed out that 88% of the organizations felt that process management discipline must be changed and 53.8% felt they must create a continuous improvement culture. Through the effective use of the ICM methodology, you can turn thousands of lost employee hours into millions of dollars in increased profit.

- 21. Chapter 5: Innovative Change Management Our environment is changing, our culture is changing, and the way we work is changing. Everyone in the management supports change. They want to see others change, but when it comes to the managers themselves changing, they are reluctant to move away from their past experience that has proven to be successful for them. The internet allows people to shop internationally, making it easy for them to get the best quality, reliability, and price the world can offer. The outside dynamics, technologies, strategies, and plans continuously change leaving us with only three options: 1. We can fight it and delay it, but we will change eventually. 2. We can ignore it and hope it will go away, but it will not, and we will be overcome by it. 3. We can embrace it, look forward to it, and thus find our assignment much more interesting, controllable, and enjoyable Importance 1. Change is a perceived departure from what was 2. Culture are the beliefs, behaviors, and assumptions shared by individuals within the organizations 3. Culture change management (CCM) focuses on the human side of change as it affects employees in their day-to-day work activities by creating a resilient culture, 4. ICM is a disciplined framework for driving business results by changing behaviors, 5. PCM is the application of change management (CM) methodologies to an individual project to increase its probability of being successful. Types of ICM Although many consultants and authorities have different views about how an ICM system should be put in place and operate, all of these views fall into two general categories of ICM: 1. PCM - Project Change Management Advantages: Most experts have developed process that support the PCM approach ● Unique to the individual project ● The needs and objectives of the specific project. ● Address the activities and people who are directly impacted by the project. ● Minimize the time required to recover on the employees during the change period. 2. CCM - Culture Change Management Advantages

- 22. The CCM approach address the total change needs of the organization ● Builds a common understanding and approach to the ever-changing environment ● Implemented in parallel with PCM ● Directed at building the foundation that allows individual changes to be absorbed into the organization Implementing PCM Over time everything changes-- even out underwear style has gone through a cycle. We recommend that an organization starts its ICM activities using the PCM methodology. This allows the organization to develop skills and confidence in their ability to manage resistance to change and to prepare employees for living in a new changed environment. PCM cycle Six phases that a make up a PCM project: 1. Phase 1: Cultural or project assessment 2. Phase 2: Inclusion of CM in the organization’s vision, values, and objectives 3. Phase 3: Development of a PCM plan and combination of that with the project plan 4. Phase 4: Pre-implementation activities 5. Phase 5: Implementation activities 6. Phase 6: Measurement of results The AS/IS Environment Innovation Areas In analyzing innovation activities, we find that there are five major innovation areas that are used in most projects: 1. Management 2. Products 3. Processes 4. Marketing and sales 5. Support services

- 23. Chapter 6: Building Commitment and Communication Building commitment within all of the project's stakeholders is essential. The commitment process is made up of three phases: 1. Phase 1: Preparation a. Stage 1: Contact b. Stage 2: Awareness 2. Phase 2: Acceptance a. Stage 3: Understanding b. Stage 4: Positive Perception 3. Phase 3: Commitment a. Stage 5: Installation b. Stage 6: Adoption c. Stage 7: Institutionalization Institutional and Internalized communication Institutionalized Commitment ● Not all changes require the people who are affected by the change to believe in the change. ● They may only be required to comply with the change. ● Forced on the target may be accepted by the targets because they wish to comply with the organization's activities. ● Motivates the targets to comply by rewarding those who comply and punishing the individuals who do not comply. Internalized commitment ● Target-sometimes called “impacted employee” ● The target is the individual or group affected by the change. ● Internalized commitment occurs when the targets believe the change reflects their personal beliefs, needs, and wants, as well as those of the organization.

- 24. Communication Change is happening through the organization, Management should focus on developing an attitude within the organization. Make the most of every idea that is implemented by sharing it with the rest of the organization Focus on the excitement of change, rather than on the problems related to change. Focus your communication on what individuals have done. Use regular town meetings to talk about the changes Use Poster campaigns to give credit to individuals active in the change process. 5-way communication, downside of improvement 1. Upward 2. Downward 3. Horizontal 4. Customer 5. Supplier The five way or star communication process is a key part of a participative team environment that is based on a strong supplier-customer re;ationship, The complex organizational environment makes this five way communication system an essential part of an effective operation. Management’s Responsibility is to provide the communication process media. Today, technology and personal initiative can easily take care of the communication problem if they are both used correctly. The Downside to Improvements (LayOffs)

- 25. In reality, the market is constant and productivity improves, someone, somewhere, has to be put out of a job. Most of the organization improves to stay in business. As a result, improvements in productivity and quality often allow the organization to operate with fewer and fewer people because the market has not expanded fast enough to consume the additional output. At this very early stage of implementing an improvement methodology, management needs to step up to the reality that as performance improves, jobs probably will be eliminated and they have to decide what will be done with these surplus employees. No Layoff Policy No one will be laid off because of a quality or productivity improvement. People whose jobs are eliminated will be retrained for equivalent or more responsible jobs. This doesn’t mean that it may not be necessary to lay employees off due to a business downturn. Future of ICM Executives around the world are now looking at building a culture that supports creativity and innovation. ICM has distanced itself from PCM so that it can be applied to all types of changes in personnel, sales and marketing, and legal. The depth and breadth of the ICM methodology penetrates into every part of the organization. Our studies indicate that there is a direct correlation between the employee’s levels of satisfaction and enthusiasm related to the company and his or her ability to accept high stress levels of change without causing disruption to the organization. Life-cycle for product or project Project Life Cycle 1. Concept exploration and definition 2. Documentation and validation 3. Engineering and manufacturing development 4. Production and deployment 5. Operations and support Product Life Cycle 1. Concept and definition 2. Design and development 3. Creating the product service 4. Installation 5. Operations and maintenance 6. Disposal

- 26. Chapter 7: Management Action Executive Leadership My grandmother taught me that if you want to bring about change in an organization, do it like sweeping the stairs. She said, “Always start at the top and sweep down.” H. J. Harrington Why Managers First Managers are responsible for the following: ● Allocating resources ● Establishing the organization’s structure ● Selecting the leaders ● Developing the processes ● Setting performance standards ● Making job assignments ● Preparing the job description ● Providing the measurement and reward systems ● Setting priorities ● Selecting and training employees Management Leadership The following are the major roadblocks to improvement within most organizations: ● Lack of employee trust ● Lack of management credibility ● Lack of training ● Poor communication ● Fear of risk-taking ● Untimely decision-making ● Misdirected measurements systems ● Lack of continuity ● Lack of employee loyalty ● Lack of delegation Typical mistakes that management makes that destroy credibility are as follows: ● Hiding bad news from employees ● Saying half-truths or outright lying ● Not living up to the mission, values, and visions ● Not taking action on poor performers ● Dodging decisions

- 27. Why Top Management Keeps ICM at Arm’s Length Some of the best ways to convince management that they should support and actively lead the ICM process efforts are: 1. Competitive benchmarking 2. Market studies 3. Customer surveys/focus groups 4. Cost analysis 5. Improvement-needs analysis 6. Customer-loss analysis Why the organization needs to improve ?? ● Get a “bigger piece of the pie” (increase market share) ● Create a “bigger pie” for everyone ● Improve the bottom line ● Ensure long-term survival and growth ● Increase job security ● Combat competitive pressure Management’s Role The following is a list of requirements for employee involvement and participative management to thrive within the work environment: ● Management will have to share the power and responsibility. ● Management must provide the employees with much more information than they have in the past. ● Participative management/employee involvement needs to be practiced at all levels of management. ● Management needs to trust their employees in order to earn the trust of their employees. ● Management needs to feel comfortable with decentralized decision-making. ● Management needs to stop performing hindsight appraisals. ● Management must encourage an environment where failures are accepted as being part of the learning cycle, and risk-taking is a dominant trait of the people who get ahead. ● Time must be made available to train the employees in how to make decisions, learn new jobs, and perform business analysis. ● Management must have the courage to reject poor solutions but take time to explain why the suggestion is being rejected. Basic Beliefs ● Delegation ● Appraisal ● Disagreement ● Be Decisive ● Positive Attitude

- 28. ● Five Way Communication system ● Invest Innovative manager MANAGERS ARE ULTIMATELY HELD ACCOUNTABLE ● The management team is held responsible for the organization’s performance. ● Organization performance is directly reflected in their promotions, salaries, and longevity with the organization. ● The management should step up to their responsibility to improve the quality, reliability, and productivity of organizations. ● Management must be involved in the implementation of any improvement process. RECOGNIZING GOOD AND BAD PERFORMANCE—THE FEEDBACK PROCESS ● Today’s manager must provide ongoing, continuous feedback on both the negative and positive aspects of performance. ● Use positive feedback to reinforce desired behavior patterns. ● The best positive feedback occurs in public, at a meeting, on a bulletin board, with a group of associates, and so on. ● Most managers find it difficult to give negative feedback but feel it is the primary reason that they have their job. ● The challenge for management today is to provide negative feedback in a constructive way. participative management to thrive How to get Employees to Work ● Management Threats ● Self Motivation ● Employees Involvement ● Communication-Communication-Communication ● Town Meeting to get employees to work, new middle manager THE NEW MIDDLE MANAGER ● When Top-Level Management truly accepts their role as planners and direction-setters, they distance themselves from day to day Problem encounter in Business. ● This provide Middle Mangers, a role of running the organization and ensure continues improvement. ● Old micro-management attitude need to replaced with macro-management, which have wide viewpoint and understands the inter-functional relationship.

- 29. ● Middle managers should provide the parental figure for the first-level managers and the employees. ● In the improvement process, they are the teachers, the coaches, the friends, and the mentors The key few traits of a new generation middle manager are as follows: ● Develop close working relationships and understanding of their customers. ● Have the capability to focus on the “big picture” and manage it. ● Provide education, guidance, and mentoring to the first-line manager. ● Focus on the process rather than the activities. ● Help employees learn from failure rather than punish them for it. ● Concentrate on why problems occur rather than who caused them. MANAGEMENT’S CHANGE PROCESS ● Managers must change before they can expect the employees to change.. ● Improvement must start at the top of the management ladder and flow down layer by layer ● The organization needs to invest in training and preparing the management team for their new roles. ● The correct cycle is to first thaw out the old personality, then reshape it into a more desirable new personality, and freeze the new personality into the daily working habits, practices, and beliefs of the organization. recognizing good and bad performance Chapter 8: Rewards and Recognition Reward The word reward is defined as something given or offered for a special service or to compensate for effort expended. Rewards can be subdivided into the following categories: 1. ¢Compensation—to financially reimburse for service(s) provided 2. Award—to bestow a gift for performance or quality 3. Recognition—to show appreciation for behaving in a desired way

- 30. INTRODUCTION TO REWARDS AND RECOGNITION A good reward process has eight major objectives, often referred to as “Ingredients of an Organization’s Reward Process”: To provide recognition to employees who make unusual contributions to the organization to stimulate additional effort for further improvement To show the organization’s appreciation for superior performance To ensure maximum benefits from the reward process by an effective communication system that highlights the individuals who were recognized To provide many ways to recognize employees for their efforts and stimulate management creativity in the reward process To ensure that management understands that variation enhances the impact of the reward process To improve morale through the proper use of rewards To reinforce behavioral patterns that management would like to see continued To ensure that the employees recognized are perceived as earning the recognition by their fellow employees Tools and methodologies The reward process needs to be designed, taking into consideration the following points: 1. Organizational culture 2. Desired behavioral patterns 3. Employee priorities 4. Behavior/reward timing relationships 5. Ease of use The basic for change and quality improvement reward process hierarchy Types of Rewards 1. Financial compensation 2. Monetary awards 3. Group/team rewards 4. Public personal recognition

- 31. 5. Private personal recognition 6. Peer rewards 7. Customer rewards 8. Organizational awards Implementation of the Reward process The following guidelines should be considered when developing the reward process for your organization: Reward fund The organization should set aside a specific amount of money that the reward process will use. This amount will set the boundaries that the reward process will operate within. Reward task team (RTT) This team will be used to design or update the reward process. Present reward process The RTT should pull together a list of all of the formal and informal rewards that are used within the organization today. Desired behaviors The RIT should prepare a list of the desired behaviors. Present reward process analysis The present reward process should be reviewed to identify the rewards that are not in keeping with the organization’s present and projected future culture and visions. Desired behavior analysis Each desired behavior is now compared to the reward categories to see which category or categories should be used to reinforce the desired behavior. Each behavior should have at least two ways of rewarding people that practice the behavior. Reward usage guide When the reward process is defined, a reward usage guide should be prepared. This guide should define the purpose of each of the reward categories and the procedures that are used to formally process the reward. This guide will be used to help management and employees to understand the reward process, and to help standardize the way rewards are used throughout the organization.

- 32. Management training One of the most neglected parts of most management training processes is how to use the reward process. As a result, most managers are far too conservative with their approach to rewards, while others misuse them. Chapter 9: Optimization of CX Many of the requirements of ISO 9001 affect CX. The guidance in the context of three stages of CX management maturity is: 1. Starting CX: Breaking Cross-Functional Barriers 2. Operating CX: Key Implementation Elements 3. Maintaining CX: Sustainability STARTING CX: CROSS FUNCTIONAL BARRIERS If CX management is a new concept in your organization, this section will help you identify what is needed as you begin this journey. Breaking silos, as described in an earlier chapter, is perhaps the biggest obstacle organizations face in delivering a best in class customer experience. This is particularly true in large corporations where multiple layers of management and specialization get in the way of cross functional partnership. Sometimes individuals go through whole careers without ever interacting with a customer directly or without developing a clear understanding of how their actions affect people at the receiving end of the organization’s solutions. In the context of customer experience, highly siloed environments lead to local optimization where functions define customer success in narrow ways. As a former colleague used to say, a mind set that focuses on “my end of the boat is not sinking” will not add up to an optimal customer experience. A successful approach to breaking cross functional barriers includes the following elements: 1. Customer experience priority 2. Intended outcome 3. Strategy 4. Execution plan 5. Cross Functional team 6. Feedback loop Customer experience priority Making customer experience a company priority may sound easy to do, as if it were just a matter of getting your senior executive to “say the word.” The reality is much different, as organizations are confronted with a blinding array of challenges ranging from competition to security threats to shifting customer buying patterns. Organizations have to choose where to invest their resources and therefore where they set priorities. In many cases, executives would say “quality is table stakes” or “customer experience is a given.” While these are true statements, they may denote a tendency to take things for granted. The desired approach is to

- 33. make customer experience an explicit element of what your organization stands for and make it something that you emphasize in conversations with employees as well as external audiences Feedback Loop To determine opportunities for improvement, a robust feedback loop will ensure continuous improvement, required by Clause 10 Improvement, of ISO 9001. There are many vehicles and modalities to listen to or collect feedback from customers. Here are some common modalities of customer feedback that we will discuss in further detail: 1. Satisfaction surveys 2. Live interviews 3. Focus groups 4. Customer support cases 5. Customer facing employees CX key performance indicators “What gets measured gets done” is the phrase that tells the story. For this reason, Clause 9 (Performance Evaluation) of ISO 9001 has requirements pertaining to monitoring, measuring, and conducting analysis of the data to implement appropriate processes to improve where there are opportunities to do so. Like other critical aspects of the business, agreed upon CX metrics will help in evaluating overall performance of the business and quality management system effectiveness, and at the same time, answer two critical questions: 1. What aspect of the CX needs improvement? 2. Is the improvement activity having the desired effect once action has been taken? Metrics affect all the phases of the CX lifecycle and are typically carried out by different functional areas. Achieving cross functional agreement on metrics can be challenging, as each function would like to define and control its own area. A good practice here is to have a neutral third party (an outside entity or corporate function) who is responsible for defining and driving the CX key performance indicators; this is similar to the role that corporate finance plays for other business indicators. However, the definition and management of the metrics need to be done in a transparent and collaborative fashion. A dashboard that shows trends for each of these metrics can be used to drive governance discussions during functional and management reviews. It is important to integrate quality and customer experience insights into the rhythm of how the business runs. A balanced scorecard approach is used frequently to run the business. These scorecards are used as part of regular operations reviews and the scorecard tends to be organized into four quadrants: 1. Financial 2. Operations 3. People 4. Customer

- 34. Financial. This quadrant of the scorecard reflects information showing the financial health of the organization. Typical metrics include revenue trends, market share, profitability, outstanding debts, and so forth Operations. This quadrant reflects information showing how efficiently the organization runs. This includes the policies and processes established from beginning to end for design and development such as controls, outsourcing, traceability, and non-conformances. Among others, the metrics include production levels relative to capacity, speed of innovation, and so forth. People. This quadrant reflects information showing the trends and status for people relevant indicators. Typical metrics here include attrition rate, hiring trends, span of control, employee engagement, and so forth. Customer. This quadrant reflects information showing the health of the customer relationships. This is where customer experience and quality data will be shown. Different types of metrics are needed in order to manage the customer experience. It is imperative to use the right metric for the right purpose or it can lead to inaction and/ or endless debate. For example, trying to use the “check engine” message on your car dashboard to diagnose a problem with the engine can be frustrating. This metric can tell you that there is something wrong with the engine, but it can’t help you analyze the problem any further. You need additional data to do that. Unfortunately, there is no perfect metric when it comes to balancing breadth and depth of information. Strategic metrics tend to provide a broader or general view of customer experience, but because of their broad nature, they lack sufficient specificity to drive action. Likewise, you can have metrics that can give you actionability but lack the broad perspective of a strategic metric. Trying to build actionability into strategic metrics can be a frustrating exercise. Our recommendation is to realize that you need different metrics for different objectives, and therefore understand what you have and what you need. Main CX metrics focusing Quality components These can be organized into three main groups: Group 1. These measure customer sentiment, loyalty, or perception. They measure the customer’s emotional state, asking “how does the customer feel” upon experiencing any interaction with the organization, ranging from watching an advertisement to using a product or service. As discussed in section 2.2, this information is essential to engage in a business transaction with the organization. As a consumer, you likely will avoid merchants that engender negative feelings, particularly if you have an alternative.

- 35. Historically, customer satisfaction (CSAT) has been used as the primary indicator of customer perception. CSAT is measured in a scale from 1 to 5, where 5 is best and 1 is worst. The feedback is provided by customers through surveys that include questions that refer to key aspects of the customer experience. For example, customers might be asked to rate their level of satisfaction with technical support from 1 to 5. Survey administration is done in such a way that you can capture a statistically significant sample of your total customer base. You also need to track the respondents to the survey based on their role within the customer context—buyer or user, executive or administrator, and so forth. Finally, you need to segment appropriately the responses based on market, geography, and so forth. In addition to the numerical score, CSAT surveys typically include a free form component (verbatim) where customers have the option to provide additional comments to support their score. In our experience, verbatim analysis or text analytics can be frequently overlooked in light of the quantifiable nature of numerical scores. However, this information is important in lending a customer voice to metrics such that change agents can be used to drive action and create empathy. Over the past few years, an increasing number of organizations are moving from CSAT-based measures of loyalty towards Net Promoter Score (NPS*—Registered trademark of Fred Reichheld, Bain & Company, and Satmetrix). NPS asks the customer’s “likelihood to recommend” given his or her interactions with the organization. NPS is seen as providing a more direct connection to the business since “recommending” implies a deeper level of advocacy than simply “being satisfied.” Like CSAT, NPS is collected via surveys but customers are provided with a scale of 0 through 10. The lower scores (0 to 6) are considered detractors. Those in the middle (7–8) are known as passive. Those with higher scores (9–10) are known as promoters. Net Promoter Score is calculated by subtracting the percentage of detractors from the percentage of promoters. The passive contributes towards calculation of total scores (denominator to calculate percentages), but does not otherwise factor in the Net Promoter formula. Like CSAT, NPS also has a free-form section for additional context. NPS becomes an even stronger indicator when it is correlated with key business indicators such as wallet share, customer acquisition/loss rates, and so forth. Rather than averaging across geographies and segments, establishing those correlations at the regional or solution level is proven to be more insightful. Group 2. These measure customer pain or friction associated with customer interactions. In the traditional product quality context, friction metrics would be software or hardware failure rates or mean time between failures. Product quality continues to be the foundation of customer experience. However, when considering the totality of customer interactions, friction points could include measures of how difficult it is to get pre sale information, purchasing process, licensing process,

- 36. technical support, and so forth. These types of metrics are a good “double click” on Group 1 metrics, as they get closer to where the customer pain is and therefore closer to what can be done to mitigate it. Groups inside the organization would use Group 2 metrics to track the success of their internal quality improvement initiatives. These metrics are typically used to drive internal accountability to customer experience. When statistical process control techniques are applied to Group 2 metrics, organizations are able to proactively identify and address customer pain. Proactive indicators help the business identify negative trends based on relatively small sample sizes, in other words, limited customer impact. These techniques allow corrective actions to begin before a pervasive issue affecting a larger customer population is observed, allowing faster turnaround time on issues. Group 2 metrics are used for the development of predictive indicators. Leading/ predictive indicators rely on pre shipment data to identify issues before customers experience them. Cause and effect are difficult to prove in most cases, but correlation analysis between this data and Group 2 metrics, coupled with a good understanding of internal business processes, yields the best results. A successful predictive analytics program requires a very tight partnership between the business units and the corporate function defining the metric. Examples of these internal metrics are in process indicators showing adoption of critical to quality practices. Capturing customer expectations requires a deeper understanding of how customers intend to use the solution. The telecommunications industry classifies the network elements on the basis of their role or place in the network (PIN). Each PIN can be associated with a certain set of expectations—in terms of product quality for example. Generalizing this concept to different industry segments can lead to segmentation of customers based on their expectations. If you can further quantify those expectations and measure performance (Group 2 metrics) relative to them, then you are going from minimizing pain into achieving customer delight. A final consideration when looking at Group 2 metrics is how to manage their proliferation. As you would track a metric for each customer touchpoint, the more touch points you have, the more metrics you need. The situation can get unwieldy if the number of touchpoints is large. It is important to create a layer of abstraction that simplifies the management of the metrics without precluding “double clicks'' for additional details. A best practice here is to create indexes that serve as abstraction mechanisms for multiple metrics. You could also create heat maps that combine multiple indicators into a single visual representation. The heat map could guide decision makers to the areas that need attention, while still providing a holistic view of the end to end customer lifecycle. Group 3. These measure customer outcomes from inside out and outside in perspectives. These metrics can also be called so what metrics, as they help in understanding if the pain measured in Group 2 is actually getting in the way of the customer achieving its objectives and/or the organization meeting its financial goals.

- 37. ● Inside Out metrics. These are internal indicators that help understand if solutions are delivering value to customers. Customers will stay away from solutions that provide none or limited value. You can monitor worsening trends on customer acquisition, customer losses, wallet share, and so forth, and use that as compelling evidence for customer experience improvement action. When used at the right level of granularity, the balanced scorecard discussed previously can provide similar indications. ● Outside-in metrics. These are indicators used by customers to assess if products/services are delivering the desired value. They can be very diverse, however, they can be grouped into a few basic categories: – ○ Cost Savings. Is this product or service saving me money? So the measure associated with this is cost saving relative to some baseline. If customers are not saving as much as they expected, then they are not satisfied. For example, a customer who buys a video conference solution to save money on employee travel would want to measure “travel savings” over the life of the solution. ○ Time Savings. Is this solution saving me time? The outcome metric associated with this is time reduction relative to some baseline. Time Savings can be associated with increased productivity, which allows a customer operation to scale to higher throughput. ○ Simplification. Is this product removing complexity? This is an important consideration in a world where the speed of business continues to increase. In addition to the previous metrics, unstructured data play a key role in driving a culture of quality and customer experience. For instance, top executives develop a strong sense of problematic trends in quality through their regular conversations with customers even if they cannot quantify them. Unstructured data can serve as a source of anecdotal evidence that backs metric data in telling the story of what the customer is going through, thereby creating empathy. Also, in some cases, metric data acquisition can be difficult and unstructured data can point clearly to what needs to be fixed. It is important, particularly in a strong culture of metric based continuous improvement, that you prevent the absence of structured data from becoming an obstacle to driving improvement activities. So a healthy mix of both structured and unstructured data should always be sought when running the business of quality and customer experience. OPERATING CX: MAIN ELEMENTS Hopefully, at this point you will have a change plan in motion that looks to drive CX and break cross functional barriers. This planning is one of the most important parts of running your business and helps to identify a roadmap to achieve goals and objectives. Without careful planning, it is similar to embarking for a destination without consulting a map. If you are lucky, you may reach the destination eventually, but it may take you longer, may increase your costs, may take more time than expected, and so on. The process of planning begins by conducting a holistic analysis of your current situation (your operations and the environment you operate in) and identifying what needs to be improved based on key performance indicators. From there, planning involves envisioning the results you want to achieve and identifying the steps required

- 38. to get there. Here are some key elements to consider in order to ensure your operations are reflective of a CX mind-set: 1. Innovation 2. Leadership 3. Support 4. Customer knowledge 5. Knowledge management 6. Change management 7. People empowerment 8. Risks 9. Improvement and root cause analysis Chapter 10: Transforming existing Quality Management System into CX Centric Model Establishing of a governing body A quality policy or CX strategy cannot be realized without an effective governance body. The need for governance is less about employees intentionally sabotaging the customer experience and more about surfacing and holding accountable individuals or departments operating in misalignment with the stated CX strategy. Inconsistent business priorities across functions are a typical source of gaps in the delivered customer experience. Factors of effective governance: ● Strong sponsorship directly from the CEO ● Strong leadership that encourages debate but moves the discussion forward ● Cross Functional representation ensuring critical departments are on the table ● Metrics that truly reflect customer sentiment ● Operational rigor ensuring actions are assigned, completed in a timely fashion, and consequences are enforced for inaction areas to focus Identifying the right set of activities in terms of numbers and relevance that would have the greatest impact in CX can be challenging. There is always more to do to improve CX than time and resources to do them. If you find yourself in this situation, the place to start is always with the customer. Use their direct and indirect voice to guide the decision making process. All of these are great sources of customer input. Once the data are gathered, analytics are applied to help identify the areas of focus. Pareto analysis of customer support cases is conducted, as a measure of where customer pain exists. The higher frequency items take the highest priority for

- 39. action through improvement activities. The benefit of this approach is that you can readily see reductions in customer complaints as improvement activities are implemented and sustained. Beyond data and analytics, the decision of which areas to focus on will require other considerations. Some of these include: 1. Cost implications 2. Cross Functional ownership 3. Time implications Cost Implications Having a good return on investment analysis is a must when considering an improvement activity. However, the ability to undertake costly re-work can often get in the way. A common hurdle is the lack of “quantifiable benefit” associated with quality improvement activities. Reduction in customer found non-conformances does not easily translate to a clear revenue upside and/or operational cost reduction, although the latter is much more manageable. In our experience, simple consistent “conversion models” (for example, converting nonconformance reduction to opportunity cost), are always preferred over complex models that are difficult to explain, understand and get buy-in for. Cross-Functional Ownership Not all customer experience improvement activities fall neatly within organizational boundaries. It is often the case that improvement activities require coordination/collaboration between multiple divisions or functions. Industry-wide, there is a reliance on corporate functions to settle, allocate, and mediate to solve a common customer issue. As we discussed previously, cross functional governance provides the foundation for these types of decisions and transactions. Time implications Some problems are easier to solve than others. We typically refer to those as “low hanging fruit” due to the ease with which they can be addressed. In a change management context, tackling easy problems during the early phases of the project can create a sense of progress and success that can motivate the team to tackle harder issues. Harder problems are broken into small, manageable projects that can be completed in a quarterly cadence. This allows teams to more accurately track their progress. Finally, it is important to consider the time to resolution in terms of the customer or market situation. A class of unique problems should not be solved internally because customers cannot wait for the solution and the market will move to the next latest alternative. This is particularly true in areas where the life expectancy of the solution is short compared to the time for solving the problem. cross functional team formation How each functional department aligns and delivers to CX strategy will obviously differ based on the role they play. However, a common success factor in how departments drive corrective CX actions is the inclusion of cross-functional members to ensure clarity of what the department needs to do and also what other departments expect. Multi-level governance is created to ensure clarity of decision making across large enterprises. At the corporate level, decisions and operational tracking will be at a higher level of abstraction. However, the information is granular enough to ascertain status and the accountability is clear enough to assign ownership for action. At the function level, decision and operational tracking

- 40. will be at a level commensurate with the functional scope. The corporate board reviews the company level abstractions of the metrics, while functional boards see renditions of the same metrics pertaining to the solution. As with the corporate governance board, functional boards need active engagement and sponsorship of functional leaders. There is no substitute for this. In the absence of leadership engagement, boards become frustrated sharing forums with little or no impact. Beyond leadership and common metrics, operational rigor is the next required ingredient for success. When metrics do not meet the pre established goals, actions need to be assigned by the leaders with clear expectations of resolution time. A discipline of reviewing and tracking the status of assigned action status until resolution should be emphasized. bridging the gaps into existing QMS As customer experience improvement priorities get identified, they need to be integrated into the quality objectives that underpin the quality policy. The reliance on common quality metrics as the interface between CX, quality improvement priorities, and QMS objectives is a best practice. Beyond achieving alignment between CX improvements and quality objectives, the QMS will define how people, processes, and tools allow you to deliver to the quality standards and objectives. The QMS must be congruent with CX strategy and associated expectations. A continuous improvement loop needs to exist to ensure corrective actions are not only being applied on WHAT is being delivered but also on HOW things are being delivered. Four capabilities need to be highlighted: 1. Process discipline 2. Training 3. Tools 4. Communications Process Discipline This is a set of interdependent activities that are required to achieve consistent results. As teams learn, whether from their own experience or from others, they utilize the process as the container to capture the lessons that have been learned. An organization with discipline of process definition and continual process improvement is likely to be characterized as a learning organization. The absence of discipline typically leads to the opposite result, where there is no learning from experience. Training Just like process, training helps ensure lessons from the past are leveraged in the future. In the context of a QMS, it is important to build focused training around critical to quality practices, quality policy, quality objectives, common quality metrics, and improvement action approaches. As solution offerings evolve, roles, responsibilities, and proficiencies will evolve as well. The success of the business will depend, to a great measure, on the critical skills and expertise that

- 41. employees have. In many organizations, employees are required to support multiple roles, in other words, wear many hats. Training often gets relegated to the very end of a project because managers do not want it to “get in the way.” But similar to having a preference for a properlytrained mechanic looking after our cars, we need to take responsibility for making training a priority for customers who would also prefer trained individuals for their purchased solutions. A well-documented, realistic training plan resulting into cost efficiencies becomes a differentiator when it comes to competitors who have less focus on training. Some of the most common training vehicles used include: ● Instructor-led classroom training ● Computer-based training (CBT) ● On-the-job training (OJT) Computer Based training (CBT) allows employees to get trained whenever it is convenient with short-use, case-based training modules that are accessible through the web. This self paced delivery method grants geographically dispersed personnel with 24/7 access to training, which becomes part of a full learning library consisting of training modules and student guides that are available at any time for future reference. On The Job training (OJT) allows operations staff to reinforce what they learn during classroom training and/or CBT, as well as provides an opportunity to ask questions in real time. OJT involves having training staff on-site where the job is being performed to help with solution features. Approach to Training Development. ● Analysis ● Design ● Development ● Implementation ● Evaluation Tools Tools play many roles in the QMS, and they are important in the specific context of training for at least two reasons: 1. Knowledge capture 2. Automation Knowledge Capture. In previous sections we spoke about the importance of having process discipline to capture lessons from experience (yours and industry). Workflow tools can be leveraged as containers of these lessons. A success factor is the ability to keep them updated with the latest lessons that have been learned. Automation. Today’s urgent demand for best solutions that can be supplied with a high level of quality requires automation. The importance of automation cannot be downplayed as it helps in reducing waste, as well as reducing costs associated with production and lead times.

- 42. Automation has brought significant advantages not only in the manufacturing world but also in service and software worlds, and has given a new flexibility to organizations in the redevelopment and redesign of their products. Along with other benefits, it has helped in increasing: ● Productivity ● Safety ● Speed of doing overall business ● Consistency of execution Communication Communication helps ensure consistency of messages, regular cadence, and clarity calls to action. Those with experience in people management or leadership will resonate with the importance of having clarity of purpose and coherence of message. Individuals at the receiving end can get confused or numb to the barrage of information. For this reason, leveraging communication specialists in the area of quality management will make the difference between a successful and an ineffective QMS. It is ideal to create a communication plan that describes: What: Objective you want to accomplish with your communications How: How the objectives can be accomplished, including defining the appropriate tools Who: The audience to whom your communications will be addressed When: Timing and sequence Impact: Measuring the results of the communication plan Communications will include all written, spoken, and electronic interactions with the target audience. These may include, but are not limited to: ● Digital signage ● Committee and board communiqués ● Printed publications ● Online communications ● Email signatures ● Marketing and sales tools ● Legal and legislative documents ● Voice mail messages ● Corporate identity materials, including special badge, ● letterhead, logo, and envelopes ● Employee surveys ● Certificates and awards