Dr atif shahzad_sys_ management_lecture_10_risk management_fmea_vmea

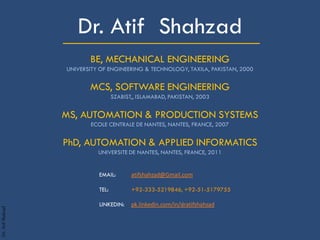

- 1. Dr.AtifShahzad _____________________Dr. Atif Shahzad BE, MECHANICAL ENGINEERING UNIVERSITY OF ENGINEERING & TECHNOLOGY, TAXILA, PAKISTAN, 2000 MCS, SOFTWARE ENGINEERING SZABIST,, ISLAMABAD, PAKISTAN, 2003 MS, AUTOMATION & PRODUCTION SYSTEMS ECOLE CENTRALE DE NANTES, NANTES, FRANCE, 2007 PhD, AUTOMATION & APPLIED INFORMATICS UNIVERSITE DE NANTES, NANTES, FRANCE, 2011 EMAIL: atifshahzad@Gmail.com TEL: +92-333-5219846, +92-51-5179755 LINKEDIN: pk.linkedin.com/in/dratifshahzad

- 4. Dr.AtifShahzad Why does it always seem we have plenty of time to fix our problems, but never enough time to prevent the problems by doing it right the first time?

- 5. Dr.AtifShahzad Today’s Lecture Introduction ¤ FMEA History ¤ What is FMEA ? Definitions What it Can Do For You? Types of FMEA Team Members Roles FMEA Terminology Getting Started with an FMEA ¤ The Worksheet ¤ FMEA Scoring 5

- 6. Dr.AtifShahzad Uncertainties that Plague Projects Uncertainties Offsets Mission Objectives ♦ Will the baseline system satisfy the needs & objectives? ♦ Are they the best ones? ♦ Thorough study ♦ Analyses ♦ Cost & schedule credibility Technical Factors ♦ Can baseline technology achieve the objectives? ♦ Can the specified technology be attained? ♦ Are all the requirements known? ♦ Technology development plan ♦ Paper studies ♦ Design reviews ♦ Establish performance margins ♦ Engineering model test and prototyping ♦ Test & evaluation Internal Factors ♦ Can the plan and strategy meet the objectives? ♦Resources •Manpower skills •Time •Facilities ♦Program strategy ♦Budget allocations ♦Contingency planning External Factors ♦ Will outside influences jeopardize the project? ♦Contingency ♦Robust design 6

- 7. Dr.AtifShahzad Project Risk Categories 7 Typical Technical Risk Sources Typical Programmatic Risk Sources Typical Supportability Risk Sources Typical Cost Risk Sources Typical Schedule Risk Sources • Physical properties • Material properties • Radiation properties • Testing/Modeling • Integration/Interface • Software Design • Safety • Requirement changes • Fault detection • Operating environment • Proven/Unproven technology • System complexity • Unique/Special Resources • COTS performance • Embedded training • Material availability • Personnel availability • Personnel skills • Safety • Security • Environmental impact • Communication problems • Labor strikes • Requirement changes • Stakeholder advocacy • Contractor stability • Funding continuity and profile • Regulatory changes • Reliability and maintainability • Training • Operations and support • Manpower considerations • Facility considerations • Interoperability considerations • System safety • Technical data • Sensitivity to technical risk • Sensitivity to programmatic risk • Sensitivity to supportability risk • Sensitivity to schedule risk • Labor rates • Estimating error • Sensitivity to technical risk • Sensitivity to programmatic risk • Sensitivity to supportability risk • Sensitivity to cost risk • Degree of currency • Number of critical path items • Estimating error

- 8. Dr.AtifShahzad Reactive Design Quality Transition to ... Predictive Design Quality Requirements: Flow down from Customer Expectations FROM TO “Test in” Quality Evolving Requirements Modeling / Simulation with Design / Process Capability Flow-up Statistical Quality Prediction “Design in” Quality Build & Test Measurement Design rework / tweaking Control Critical Design Parameters Reactive to Proactive

- 9. Dr.AtifShahzad Project and Project Management Project is a temporary sequence of unique, complex, and connected activities having one goal or purpose and that must be completed by specific time, within budget, and according to specification. Project Management is the process of scoping, planning, staffing, organizing, directing, and controlling the development of an acceptable system at a minimum cost within a specified time frame. 9

- 10. Dr.AtifShahzad Reliability Reliability is the probability that the system-of- interest will not fail for a given period of time under specified operating conditions ¤ Reliability is an inherent system design characteristic ¤ Reliability plays a key role in determining the system’s cost-effectiveness ¤ Ref: NASA Systems Engineering Handbook (1995 version) 10

- 11. Dr.AtifShahzad Reliability engineering is a specialty discipline within the systems engineering process. Reflected in key activities: ¤ Design - including design features that ensure the system can perform in the predicted physical environment throughout the mission. ¤ Trade studies - reliability as a figure of merit. Often traded with cost. ¤ Modeling - reliability prediction models, reflecting environmental considerations and applicable experience from previous projects. ¤ Test - making independent predictions of system reliability for test planning/program; sets environmental test requirements and specifications for hardware qualification. 11 Reliability

- 13. Dr.AtifShahzad What are Risks and Risk Management? Risks are potential events that have negative impacts on safety or project technical performance, cost or schedule Risks are an inevitable fact of life – risks can be reduced but never eliminated Risk Management comprises purposeful thought to the sources, magnitude, and mitigation of risk, and actions directed toward its balanced reduction The same tools and perspectives that are used to discover, manage and reduce risks can be used to discover, manage and increase project opportunities - opportunity management 13

- 14. Dr.AtifShahzad What is Risk Management? Seeks or identifies risks Assesses the likelihood and impact of these risks Develops mitigation options for all identified risks Identifies the most significant risks and chooses which mitigation options to implement Tracks progress to confirm that cumulative project risk is indeed declining Communicates and documents the project risk status Repeats this process throughout the project life 14 Risk management is a continuous and iterative decision making technique designed to improve the probability of success. It is a proactive approach that:

- 15. Dr.AtifShahzad Risk Management Considers the Entire Development and Operations Life of a Project Risk Type Technical Performance Risk Cost Risk Programmatic Risk Schedule Risk Liability Risk Regulatory Risk Operational Risk Safety Risk Supportability Risk 15 Examples Failure to meet a spacecraft technical requirement or specification during verification Failure to stay within a cost cap for the project Failure to secure long-term political support Failure to meet a critical launch window Spacecraft deorbits prematurely causing damage over the debris footprint Failure to secure proper approvals for launch of nuclear materials Failure of spacecraft during mission Hazardous material release while fueling during ground operations Failure to resupply sufficient material to support human presence as planned

- 16. Dr.AtifShahzad Every NASA Space Flight Project Begins with a Plan for Risk Management This plan reflects the project’s risk management philosophy: ¤ Priority (criticality to long-term strategic plans) ¤ National significance ¤ Mission lifetime (primary baseline mission) ¤ Estimated project life cycle cost ¤ Launch constraints ¤ In-flight maintenance feasibility ¤ Alternative research opportunities or re-flight opportunities The risk management philosophy is reflected in a number of ways: ¤ Whether single point failures are allowed ¤ Whether the system is monitored continuously during operations ¤ How much slack is in the development schedule ¤ How technical resource margins (i.e., mass, power, etc.) are allocated throughout the development 16

- 17. Dr.AtifShahzad Other Factors to Consider in Assessing Risk (but not limited to)… Complexity of management and technical interfaces Design and test margins Mission criticality Availability and allocation of resources such as mass, power, volume, data volume, data rates, and computing resources Scheduling and manpower limitations Ability to adjust to cost and funding profile constraints Mission operations Data handling, i.e., acquisition, archiving, distribution and analysis Launch system characteristics Available facilities 17

- 18. Dr.AtifShahzad 18 Failure Mode and Effects Analysis Item Potential Potential S e v C l a s s O c c u r Current D e t e c R P N Responsibility Actions Results Failure Effects of Recommended & Target Function Mode Failure Potential Causes/ Mechanisms(s) Failure Controls Action(s) Completion Date D e t O c c R P N Actions Taken S e v What are the functions or requirements? What can go wrong? - No Function - Partially Degraded Function - Intermittent Function - Unintended Function What are the Effects? How bad is it? What are the Cause(s)? How often does it happen ? How can this be prevented and detected? How good is this method at detecting it? What can be done? - Design changes - Process changes - Special controls - Changes to standards, procedures, or guides Prevention/Detection Who is going to do it and when? What did they do and what are the outcomes

- 19. Dr.AtifShahzad Module Summary: Risk Risk is inevitable, so risks can be reduced but not eliminated. Risk management is a proactive systematic approach to assessing risks, generating alternatives and reducing cumulative project risk. Fault Tree Analysis is both a design and a diagnostic tool that estimates failure probabilities of initiators to estimate the failure of the pre-determined, undesirable, ‘top’ event. Failure Mode Effects Analysis is a design tool for identifying risk in the system design, with the intent of mitigating those risks with design changes. 19

- 20. FAILURE MODE & EFFECT ANALYSIS INTRODUCTION LECTURE # 8

- 21. Dr.AtifShahzad FAILURE MODE & EFFECT ANALYSIS ¤ Provide a Basic familiarization with a tool that aids in quantifying Severity Occurrences Detection of failures ¤ and guides the creation of corrective action process improvement and risk mitigation plans 21

- 22. FAILURE MODE & EFFECT ANALYSIS HISTORY LECTURE # 8

- 23. Dr.AtifShahzad FMEA History 23 This “type” of thinking has been around for hundreds of years. It was first formalized in the aerospace industry during the Apollo program in the 1960’s. Initial automotive adoption in the 1970’s. Potential serious & frequent safety issues. Required by QS-9000 & Advanced Product Quality Planning Process in 1994. Now adopted by many other industries. For all automotive suppliers. Potential serious & frequent safety issues or loyalty issues.

- 24. Dr.AtifShahzad What is FMEA ? 24 Cause & effect, Root Cause Analysis, Fishbone Diagram Etc Failure Mode Effect Analysis

- 25. Dr.AtifShahzad What is FMEA ? INCOSE Handbook definition of FMECA: ¤ “Means of recording and determining the following: What functions the equipment is required to perform How those functions could fail Possible causes of the failures Effects the failures would have on the equipment or system The criticality of the failures” 25

- 26. Dr.AtifShahzad What is FMEA ? 26 Definition: FMEA is an Engineering “Reliability Tool” That: Helps define, identify, prioritize, and eliminate known and/or potential failures of the system, design, or manufacturing process before they reach the customer. The goal is to eliminate the Failure Modes and reduce their risks. Provides structure for a Cross Functional Critique of a design or a Process Facilitates inter-departmental dialog. Is a mental discipline “great” engineering teams go through, when critiquing what might go wrong with the product or process. Is a living document which ultimately helps prevent, and not react to problems.

- 27. Dr.AtifShahzad What is FMEA ? 27 What it can do for you! 1. Identifies Design or process related Failure Modes before they happen. 2. Determines the Effect & Severity of these failure modes. 3. Identifies the Causes and probability of Occurrence of the Failure Modes. 4. Identifies the Controls and their Effectiveness. 5. Quantifies and prioritizes the Risks associated with the Failure Modes. 6. Develops & documents Action Plans that will occur to reduce risk.

- 28. Dr.AtifShahzad When to Use Early stages (Define) to understand process and identify problem areas Analyze data (Analyze) to help identify root causes Determine best solutions (Improve) with lowest risk Close out stage (Control) to document improvement and identify actions needed to continue to reduce risk 28

- 29. FAILURE MODE & EFFECT ANALYSIS TYPES LECTURE # 8

- 30. Dr.AtifShahzad Types of FMEAs ? 30 System/Concept “S/CFMEA”- (Driven by System functions) A system is a organized set of parts or subsystems to accomplish one or more functions. System FMEAs are typically very early, before specific hardware has been determined. Design “DFMEA”- (Driven by part or component functions) A Design / Part is a unit of physical hardware that is considered a single replaceable part with respect to repair. Design FMEAs are typically done later in the development process when specific hardware has been determined. Process “PFMEA”- (Driven by process functions & part characteristics) A Process is a sequence of tasks that is organized to produce a product or provide a service. A Process FMEA can involve fabrication, assembly, transactions or services.

- 31. Dr.AtifShahzad Types of FMEAs ? 31 System/Concept “S/CFMEA”- (Driven by System functions) A system is a organized set of parts or subsystems to accomplish one or more functions. System FMEAs are typically very early, before specific hardware has been determined. Design “DFMEA”- (Driven by part or component functions) A Design / Part is a unit of physical hardware that is considered a single replaceable part with respect to repair. Design FMEAs are typically done later in the development process when specific hardware has been determined. Process “PFMEA”- (Driven by process functions & part characteristics) A Process is a sequence of tasks that is organized to produce a product or provide a service. A Process FMEA can involve fabrication, assembly, transactions or services.

- 32. FAILURE MODE & EFFECT ANALYSIS TEAM LECTURE # 8

- 33. Dr.AtifShahzad The FMEA Team Roles 33 FMEA Core Team 4 – 6 Members Expertise in Product / Process Cross functional Honest Communication Active participation Positive attitude Respects other opinions Participates in team decisions Champion / Sponsor Provides resources & support Attends some meetings Promotes team efforts Shares authority / power with team Kicks off team Implements recommendations Recorder Keeps documentation of teams efforts FMEA chart keeper Coordinates meeting rooms/time Distributes meeting rooms & agendas Facilitator “Watchdog“ of the process Keeps team on track FMEA Process expertise Encourages / develops team dynamics Communicates assertively Ensures everyone participates Team Leader “Watchdog” of the project Good leadership skills Respected & relaxed Leads but doesn’t dominate Maintains full team participation Typically lead engineer

- 34. FAILURE MODE & EFFECT ANALYSIS TERMINOLOGY LECTURE # 8

- 35. Dr.AtifShahzad FMEA Terminology 35 1.) Failure Modes: (Specific loss of a function) is a concise description of how a part , system, or manufacturing process may potentially fail to perform its functions. 2.) Failure Mode“Effect”: A description of the consequence or Ramification of a system or part failure. A typical failure mode may have several “effects” depending on which customer you consider. 3.) Severity Rating: (Seriousness of the Effect) Severity is the numerical rating of the impact on customers. When multiple effects exist for a given failure mode, enter the worst case severity on the worksheet to calculate risk. 4.) Failure Mode“Causes”: A description of the design or process deficiency (global cause or root level cause) that results in the failure mode . You must look at the causes not the symptoms of the failure. Most failure Modes have more than one Cause.

- 36. Dr.AtifShahzad FMEA Terminology (continued) 36 5.) Occurrence Rating: Is an estimate number of frequencies or cumulative number of failures (based on experience) that will occur (in our design concept) for a given cause over the intended “life of the design”. 6.) Failure Mode“Controls”: The mechanisms, methods, tests, procedures, or controls that we have in place to PREVENT the Cause of the Failure Mode or DETECT the Failure Mode or Cause should it occur . Design Controls prevent or detect the Failure Mode prior to engineering release 7.) Detection Rating: A numerical rating of the probability that a given set of controls WILL DISCOVER a specific Cause of Failure Mode to prevent bad parts leaving the facility or getting to the ultimate customer. Assuming that the cause of the failure did occur, assess the capabilities of the controls to find the design flaw..

- 37. Dr.AtifShahzad FMEA Terminology (continued) 37 8.) Risk Priority Number (RPN): Is the product of Severity, Occurrence, & Detection. Risk= RPN= S x O x D Often the RPN’s are sorted from high to low for consideration in the action planning step (Caution, RPN’s can be misleading- you must look for patterns). 9.) Action Planning: A thoroughly thought out and well developed FMEA With High Risk Patterns that is not followed with corrective actions has little or no value, other than having a chart for an audit Action plans should be taken very seriously. If ignored, you have probably wasted much of your valuable time. Based on the FMEA analysis, strategies to reduce risk are focused on: Reducing the Severity Rating. Reducing the Occurrence Rating. Reducing the detection Rating.

- 38. FAILURE MODE & EFFECT ANALYSIS GETTING STARTED LECTURE # 8

- 39. Dr.AtifShahzad Getting Started on FMEA 39 Determine “Controls” Detection Rating Determine “Effects” of The Failure Mode Severity Rating What Must be done before FMEA Begins! Determine “Causes” of The Failure Mode Occurrence Rating Determine Product or Process Functions Determine Failure Modes of Function Understand your Customer Needs Develop & Evaluate Product/Process Concepts Create an Effective FMEA Team Develop and Drive Action Plan Ready? 1 3 2 4 6 =QFD =Brain Storming =4 to 6 Consensus Based Multi Level Experts = What we are and are not working Define the FMEA Scope 5 Calculate & Assess Risk 6 7

- 40. FAILURE MODE & EFFECT ANALYSIS WORKSHEET LECTURE # 8

- 41. Dr.AtifShahzad FMEA Worksheet 41 Process or Product Name Prepared by: Page _____ of ______ Person Responsible Date (Orig) ___________ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t R P N Actions Recommended S e v O c c D e t R P N Sev : Severity of the failure (what impact will it have on our process?) Occ : How likely is the event to occur (probability of occurrence) Det : How likely can the event be detected in time to do something about it RPN: Risk Priority Number (multiply Sev, Occ, and Det)

- 42. Dr.AtifShahzad The FMEA Worksheet 42 Product or Process Failure Mode Failure Effects S E V Causes O C C Controls D E T R P N Actions / Plans Resp. & Target Complete Date p S E V p O C C p D E T p R P N 1 62 3 4 5 7 Determine Product or Process Functions Determine Failure Modes of Function Determine “Effects” of The Failure Mode Severity Rating Determine “Causes” of The Failure Mode Occurrence Rating Determine “Controls” Detection Rating Calculate & Assess Risk Develop and Drive Action Plan If an FMEA was created during the Design Phase of the Program, USE IT! Create an Action Plan for YOUR ROOT CAUSE and Re-Evaluate the RPN Accordingly

- 43. FAILURE MODE & EFFECT ANALYSIS SCORING LECTURE # 8

- 45. Dr.AtifShahzad FMEA Scoring 45 Severity Severity of Effect Rating May endanger machine or operator. Hazardous without warning 10 May endanger machine or operator. Hazardous with warning 9 Major disruption to production line. Loss of primary function, 100% scrap. Possible jig lock and Major loss of Takt Time 8 Reduced primary function performance. Product requires repair or Major Variance. Noticeable loss of Takt Time 7 Medium disruption of production. Possible scrap. Noticeable loss of takt time. Loss of secondary function performance. Requires repair or Minor Variance 6 Minor disruption to production. Product must be repaired. Reduced secondary function performance. 5 Minor defect, product repaired or "Use-As-Is" disposition. 4 Fit & Finish item. Minor defect, may be reprocessed on-line. 3 Minor Nonconformance, may be reprocessed on-line. 2 None No effect 1 ExtremeHighModerateLow

- 46. Dr.AtifShahzad FMEA Scoring 46 Occurrence Likelihood of Occurrence Failure Rate Capability (Cpk) Rating 1 in 2 < .33 10 1 in 3 > .33 9 1 in 8 > .51 8 1 in 20 > .67 7 1 in 80 > .83 6 1 in 400 > 1.00 5 1 in 2000 > 1.17 4 Process is in statistical control. 1 in 15k > 1.33 3 Low Process is in statistical control. Only isolated failures associated with almost identical processes. 1 in 150k > 1.50 2 Remote Failure is unlikely. No known failures associated with almost identical processes. 1 in 1.5M > 1.67 1 Failure is almost inevitable Process is not in statistical control. Similar processes have experienced problems. Process is in statistical control but with isolated failures. Previous processes have experienced occasional failures or out-of-control conditions. VeryHighHighModerate

- 47. Dr.AtifShahzad FMEA Scoring 47 Detection Likelihood that control will detect failure Rating VeryLow No known control(s) available to detect failure mode. 10 9 8 7 6 5 4 3 2 1 The process automatically detects failure. Controls will almost certainly detect the existence of a failure. Controls have a good chance of detecting the existence of a failure LowModerateHighVeryHigh Controls have a remote chance of detecting the failure. Controls may detect the existence of a failure

- 48. Dr.AtifShahzad FMEA Rankings Severity Occurrence Detection Hazardous without warning Very high and almost inevitable Cannot detect or detection with very low probability Loss of primary function High repeated failures Remote or low chance of detection Loss of secondary function Moderate failures Low detection probability Minor defect Occasional failures Moderate detection probability No effect Failure Unlikely Almost certain detection48 Rating 10 1 High Low Source: The Black Belt Memory Jogger, Six Sigma Academy

- 49. Dr.AtifShahzad FMEA Scoring 49 RPN or Risk Priority Number Severity x Occurrence x Detection= RPN The Calculation !

- 50. Dr.AtifShahzad Failure Modes & Effect Analysis 50 (FMEA) Part or Process Improvement FMEA is a technique utilized to define, identify, and eliminate known or potential failures or errors from a product or a process. Identify each candidate Part or Process, list likely failure mode, causes, and current controls Prioritize risk by using a ranking scale for severity, occurrence, and detection Mitigate risk – Can controls be added to reduce risk? Recalculate RPN. Characteristics with high Risk Priority Numbers should be selected for Improvement and Action Plans Created Recalculate RPN After Completion of Action Plans to Validate Improvements Product or Process Failure Mode Failure Effects S E V Causes O C C Controls D E T R P N Actions / Plans Resp. & Target Complete Date p S E V p O C C p D E T p R P N Hole Drilling Oversize Hole Unable to Install BP Fastener Wrong Drill Bit Used Ball Gage Visual Insp5 8 3 120 Kit Drill Bits 010103 5 11 5

- 51. Dr.AtifShahzad Failure Mode and Effects Analysis (FMEA) is only a tool to identify potential or actual points of failure and identify corrective action.

- 52. FAILURE MODE & EFFECT ANALYSIS EXAMPLE LECTURE # 8

- 53. Dr.AtifShahzad Process for FMEA Process to Change Oil in a Car 53 3000 miles driven Drive car on lift Fill with new oil Drain Oil Replace Filter Take Car off lift Process Complete

- 54. Dr.AtifShahzad How to Complete the FMEA Step 1. Complete header information Step 2. Identify steps in the process Step 3. Brainstorm potential ways the area of study could theoretically fail (failure modes) Suggestion: Use Affinity Diagram as a brainstorming tool 54

- 55. Dr.AtifShahzad FMEA Worksheet 55 Process or Product Name Change Oil in Car Prepared by: Leon Page _1____ of __1____ Person Responsible Leon Mechanic Date (Orig) __26 Mar 2013___ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t R P N Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil— Mech anic Wrong type of oil Engine wear No oil added Engine Failure Sev - Severity of the failure (what impact will it have on our process?) Occ – How likely is the event to occur (probability of occurrence) Det – How likely can the event be detected in time to do something about it RPN – Risk Priority Number (multiply Sev, Occ, and Det)

- 56. Dr.AtifShahzad How to Complete a FMEA Step 4 For each failure mode, determine impact or effect on the product or operation using criteria table (next slide) Rate this impact in the column labeled SEV (severity) 56

- 57. Dr.AtifShahzad Severity (SEV) Rating SEV Severity Product/Process Criteria 1 None No effect 2 Very Minor Defect would be noticed by most discriminating customers. A portion of the product may have to be reworked on line but out of station 3 Minor Defect would be noticed by average customers. A portion of the product (<100%) may have to be reworked on line but out of station 4 Very Low Defect would be noticed by most customers. 100% of the product may have to be sorted and a portion (<100%) reworked 5 Low Comfort/convenience item(s) would be operable at a reduced level of performance. 100% of the product may have to be reworked 6 Moderate Comfort/convenience item(s) would be inoperable. A portion (<100%) of the product may have to be scrapped 7 High Product would be operable with reduced primary function. Product may have to be sorted and a portion (<100%) scrapped. 8 Very High Product would experience complete loss of primary function. 100% of the product may have to be scrapped 9 Hazardous Warning Failure would endanger machine or operator with a warning 10 Hazardous w/out Warning Failure would endanger machine or operator without a warning 57

- 58. Dr.AtifShahzad FMEA Worksheet 58 Process or Product Name Change Oil in Car Prepared by: Leon Page _____ of ______ Person Responsible Leon Mechanic Date (Orig) __26 Mar 2013___ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t R P N Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil— Mech anic Wrong type of oil Engine wear 2 No oil added Engine Failure 1 0 Sev - Severity of the failure (what impact will it have on our process?) Occ – How likely is the event to occur (probability of occurrence) Det – How likely can the event be detected in time to do something about it RPN – Risk Priority Number (multiply Sev, Occ, and Det)

- 59. Dr.AtifShahzad How to Complete a FMEA Step 5 For each potential failure mode identify one or more potential causes (Could use Affinity Diagram again to brainstorm ideas) Rate the probability of each potential cause occurring based on criteria table (next slide) Place the rating in the column labeled OCC (occurrence). 59

- 60. Dr.AtifShahzad FMEA Occurrence (OCC Rating) OCC Occurrence Criteria 1 Remote 1 in 1,500,000 Very unlikely to occur 2 Low 1 in 150,000 3 Low 1 in 15,000 Unlikely to occur 4 Moderate 1 in 2,000 5 Moderate 1 in 400 Moderate chance to occur 6 Moderate 1 in 80 7 High 1 in 20 High probability that the event will occur 8 High 1 in 8 9 Very High 1 in 3 Almost certain to occur 10 Very High > 1 in 2 60

- 61. Dr.AtifShahzad FMEA Worksheet 61 Process or Product Name Change Oil in Car Prepared by: Leon Page _____ of ______ Person Responsible Leon Mechanic Date (Orig) __26 Mar 2013___ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t R P N Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil— Mech anic Wrong type of oil Engine wear 2 Mis- labeled 3 No oil added Engine Failure 1 0 Hurrying 3 Sev - Severity of the failure (what impact will it have on our process?) Occ – How likely is the event to occur (probability of occurrence) Det – How likely can the event be detected in time to do something about it RPN – Risk Priority Number (multiply Sev, Occ, and Det)

- 62. Dr.AtifShahzad How to Complete the FMEA Step 6 Identify current controls or detection Rate ability of each current control to prevent or detect the failure mode once it occurs using criteria table (next slide) Place rating in Det column 62

- 63. Dr.AtifShahzad FMEA Detection (DET) Rating DET Detection Criteria 1 Almost Certain Current Controls are almost certain to detect/prevent the failure mode 2 Very High Very high likelihood that current controls will detect/prevent the failure mode 3 High High Likelihood that current controls will detect/prevent the failure mode 4 Mod. High Moderately High likelihood that current controls will detect/prevent the failure mode 5 Moderate High Likelihood that current controls will detect/prevent the failure mode 6 Low Low likelihood that current controls will detect/prevent failure mode 7 Very Low Very Low likelihood that current controls will detect /prevent the failure mode 8 Remote Remote likelihood that current controls will detect/prevent the failure mode 9 Very Remote Very remote likelihood that current controls will detect/prevent the failure mode 63

- 64. Dr.AtifShahzad FMEA Worksheet 64 Process or Product Name Change Oil in Car Prepared by: Leon Page _____ of ______ Person Responsible Leon Mechanic Date (Orig) __26 Mar 2013___ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t RPN Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil from supplier Wrong type of oil Engine wear 2 Misread oil chart for vehicle 3 None 9 No oil added Engine Failure 1 0 Hurrying 3 Engine light 3 Sev - Severity of the failure (what impact will it have on our process?) Occ – How likely is the event to occur (probability of occurrence) Det – How likely can the event be detected in time to do something about it RPN – Risk Priority Number (multiply Sev, Occ, and Det)

- 65. Dr.AtifShahzad How to Complete the FMEA Process Step Key Process Input Potentia l Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t RPN Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil from supplier Wrong type of oil Engine wear 2 Misread oil chart for vehicle 3 None 9 54 No oil added Engine Failure 1 0 Hurrying 3 Engine light 3 90 65 Step 7 Multiply SEV, OCC and DET ratings and place the value in the RPN (risk priority number) column. The largest RPN numbers should get the greatest focus. For those RPN numbers which warrant corrective action, recommended actions and the person responsible for implementation should be listed. SEV * OCC * DET = RPN ( 2 * 3 * 9 = 54 )

- 66. Dr.AtifShahzad Action Results Step 8 After corrective action has been taken, place summary of the results in the ‘Actions Recommended’ block Assign new value for: ¤ Severity ¤ Occurrence ¤ Detection Calculate new RPN number 66

- 67. Dr.AtifShahzad FMEA Worksheet 67 Process or Product Name Change Oil in Car Prepared by: Leon Page _____ of ______ Person Responsible Leon Mechanic Date (Orig) __26 Mar 2013___ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t RPN Actions Recommended S e v O c c D e t R P N Fill with new oil New Oil from supplier Wrong type of oil Engine wear 2 Misread oil chart for vehicle 3 None 9 54 No oil added Engine Failure 1 0 Hurrying 3 Engine light 3 90 Oil level checked by partner 1 0 3 1 3 0 Sev - Severity of the failure (what impact will it have on our process?) Occ – How likely is the event to occur (probability of occurrence) Det – How likely can the event be detected in time to do something about it RPN – Risk Priority Number (multiply Sev, Occ, and Det)

- 68. Dr.AtifShahzad FMEA Example 68 Source: Quality Digest/ August 2006 Quality Service at the Special Olympics World Games, Tang Xiaofen Process or Product Name: Hotel Service at Special Olympics Prepared by: Page _____ of ______ Person Responsible: Joe Quality Date (Orig) ___________ Revised __________ Process Step Key Process Input Potential Failure Mode Potential Failure Effect S e v Potential Causes O c c Current Controls D e t R P N Actions Recommended S e v O c c D e t R P N Register guest Service Desk Cannot Register in time Complaints 5 Lack of language and communicat ion skills, support of volunteers not sufficient 4 No plan on training content; training and volunteer support sufficient 3 72 Provide Guest Services Guest Support Lack of barrier- free facility Inconvenien ce and injury 10 Cannot provide barrier-free facility 3 Providing barrier-free facility 7 210 Provide Meals Food Service Food goes bad Disease or injury 10 Past shelf life 6 No control of raw material 8 240 Provide Medical Service Medical Service Service not in time Illness changes for worse 10 No 24 Hour service 6 12 hour service 3 180

- 69. Dr.AtifShahzad Summary FMEA identifies risk in our processes ¤ Impact/Severity ¤ Probability of Occurrence ¤ Detection Helps identify what can go wrong and what we should fix Can be used in multiple stages of process improvement 69

- 70. Dr.AtifShahzad Continuous Improvement Process improvement not a linear process Never really ends Journey not a destination 70 Define Measure Analyze Improve Control

- 71. VARIATION MODE & EFFECT ANALYSIS EXAMPLE LECTURE # 8

- 72. Dr.AtifShahzad What is Robust Design? Robust design: performance is insensitive to variations. Simply doing a trade study to optimize the value of F would lead the designer to pick this point Example: We want to pick x to maximize F F x This means that values of F as low as this can be expected! What if I pick this point instead?

- 73. Dr.AtifShahzad X Y μoptimal± ΔX μrobust± ΔX Optimal Design Robust Design Performance Design Variable Uncertainties are often present and practically impossible to avoid in many real world engineering design problems. For instance, if a design is very sensitive to small geometric variations, which may arise either due to manufacturing processes, and/or in-service degradation due to erosion processes and foreign object damage, and/or drifts in operating conditions, it may not be desirable to use this design. Hence optimization without taking uncertainty into consideration generally leads to designs that should not be labeled as optimal but rather potentially high risk designs that are likely to perform badly when put to practical use. What is Robust Design?

- 74. Dr.AtifShahzad Robust design is used to minimize the effect (on performance parameters, Y) of variations in controllable and/or uncontrollable factors (design variables, X) without eliminating the sources of variations (e.g. wind), Reliability-based design has been widely applied to ensure that a system performance meets the pre-specified target with a required probability level X Y μoptimal± ΔX μrobust± ΔX Optimal Design Robust Design Performance Design Variable What is Robust Design?

- 75. Dr.AtifShahzad VMEA Many Failures are caused by Variations ( e.g. Strength, loads etc) Deductive method of identifying and managing sources of variation Casual breakdown of Key product characteristics ( Cause and Effect diagram) Sensitivity Assessment of sensitivity coefficients of variation sources affecting the targeted KPI Variation Size assessment via SD calculations Gauss approximation Variation Risk Assessment and Prioritization through spread of variation calculations Safety factor of Design is then calculated as ratio between low quintile of Design parameters and median of design parameters 75

- 76. Dr.AtifShahzad Challenge “We are what we repeatedly do. Excellence, therefore, is not an act but a habit.” -- Aristotle 76

- 77. QUESTIONS

- 78. THANK YOU FOR YOUR INTEREST