Microstructure, Mechanical Properties & Corrosion Behavior of Duplex 2209 in Electro-Slag Strip Cladding over low carbon steel substrate: a Review Paper

•

0 likes•344 views

The purpose of this research work is todetermine the microstructure and mechanical properties of Stainless steel (Duplex 2209 and S.S 309) weld overlay on Low carbon steel plate (SA 516 Grade 70) developing multilayers. The buffer layer is done by using S.S 309 L strip electrode of 60mm width following by top layers of Duplex 2209.The Process used is Electro Slag Strip Cladding due to its unique properties like high deposition rate and low dilution level.The Microstructure characterization will be examinedby the use of SEM/EDS. In mechanical properties Micro hardnesswill be examined. Residual stress analysis will be done by XRD. The intergranular stress corrosion study will also be carried out as per ASTM G-5 standards.

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

Experimental Investigation of Process Parameters on Inconel 925 for EDM Process by using Taguchi Method

Research Paper Published by:

Vishal Kumar Jaiswal

M.Tech (Production and Industrial Engineering)

Paper Source:

http://www.ijsrd.com/articles/IJSRDV6I50198.pdf

http://ijsrd.com/Article.php?manuscript=IJSRDV6I50198Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...

Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...Vishal Kumar Jaiswal

The main objective of this project is to be produce copper reinforced metal matrix composite (MMC) layers using micron sized AlN particles via friction stir processing (FSP) in order to enhance surface mechanical properties. Micro structural evaluation using Optical Microscopy (OM) and Scanning Electron Microscopy (SEM) indicated that an increase in traverse speed and a decrease in rotational speed cause a reduction in the grain size of different groove width (0,0.4,0.8,1.2 mm) of stir zone (SZ) for the specimens friction stir processed (FSPed) without AlN particles. It was found that upon addition of AlN particles, wear properties were improved. This behavior was further supported by SEM images of wear surfaces. Results demonstrated that the micro composite produced by FSP exhibited enhanced wear resistance and higher average friction coefficient in comparison with pure copper. Tensile properties and fracture characteristics of the specimens FSPed with and without AlN particles and pure copper were also evaluated. According to the results, the MMC layer produced by FSP showed higher strength and lower elongation than pure copper while a remarkable elongation was observed for FSPed specimen without AlN particles and been greatly developed by the use of AlN.Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...

Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...Association of Scientists, Developers and Faculties

More Related Content

What's hot

Experimental Investigation of Process Parameters on Inconel 925 for EDM Process by using Taguchi Method

Research Paper Published by:

Vishal Kumar Jaiswal

M.Tech (Production and Industrial Engineering)

Paper Source:

http://www.ijsrd.com/articles/IJSRDV6I50198.pdf

http://ijsrd.com/Article.php?manuscript=IJSRDV6I50198Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...

Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...Vishal Kumar Jaiswal

The main objective of this project is to be produce copper reinforced metal matrix composite (MMC) layers using micron sized AlN particles via friction stir processing (FSP) in order to enhance surface mechanical properties. Micro structural evaluation using Optical Microscopy (OM) and Scanning Electron Microscopy (SEM) indicated that an increase in traverse speed and a decrease in rotational speed cause a reduction in the grain size of different groove width (0,0.4,0.8,1.2 mm) of stir zone (SZ) for the specimens friction stir processed (FSPed) without AlN particles. It was found that upon addition of AlN particles, wear properties were improved. This behavior was further supported by SEM images of wear surfaces. Results demonstrated that the micro composite produced by FSP exhibited enhanced wear resistance and higher average friction coefficient in comparison with pure copper. Tensile properties and fracture characteristics of the specimens FSPed with and without AlN particles and pure copper were also evaluated. According to the results, the MMC layer produced by FSP showed higher strength and lower elongation than pure copper while a remarkable elongation was observed for FSPed specimen without AlN particles and been greatly developed by the use of AlN.Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...

Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...Association of Scientists, Developers and Faculties

What's hot (19)

Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...

Experimental Investigation of Process Parameters on Inconel 925 for EDM Proce...

Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...

Characterization of Copper Matrix Composite Reinforced with Aluminium Nitrate...

IRJET- Experimental Investigation into the Effect of Austempering on Mech...

IRJET- Experimental Investigation into the Effect of Austempering on Mech...

Investigation of 316L Stainless Steel by Flame Hardening Process

Investigation of 316L Stainless Steel by Flame Hardening Process

Electrochemical measurements of anodizing stainless steel type aisi

Electrochemical measurements of anodizing stainless steel type aisi

Study of effects of heat treatment on the hardness and microstructure of weld...

Study of effects of heat treatment on the hardness and microstructure of weld...

IRJET- Micro Structure Analysis of Tig Welded HSS 301 Alloy

IRJET- Micro Structure Analysis of Tig Welded HSS 301 Alloy

Hot corrosion performance of HVOF sprayed coatings

Hot corrosion performance of HVOF sprayed coatings

Study on Influence of heat treatment on Tribological properties of mild steel

Study on Influence of heat treatment on Tribological properties of mild steel

Viewers also liked

IJRET : International Journal of Research in Engineering and Technology is an international peer reviewed, online journal published by eSAT Publishing House for the enhancement of research in various disciplines of Engineering and Technology. The aim and scope of the journal is to provide an academic medium and an important reference for the advancement and dissemination of research results that support high-level learning, teaching and research in the fields of Engineering and Technology. We bring together Scientists, Academician, Field Engineers, Scholars and Students of related fields of Engineering and TechnologyEffect of process parameters on tensile strength in gas metal arc welded join...

Effect of process parameters on tensile strength in gas metal arc welded join...eSAT Publishing House

IJRETMicrostructure analysis and wear behaviour of al based metal matrix composite...

Microstructure analysis and wear behaviour of al based metal matrix composite...eSAT Publishing House

Viewers also liked (20)

Estimation Of Optimum Dilution In The GMAW Process Using Integrated ANN-SA

Estimation Of Optimum Dilution In The GMAW Process Using Integrated ANN-SA

Preliminary study of on cladding process on gray cast

Preliminary study of on cladding process on gray cast

Effect of process parameters on tensile strength in gas metal arc welded join...

Effect of process parameters on tensile strength in gas metal arc welded join...

International Journal of Engineering Research and Development

International Journal of Engineering Research and Development

Correlation between Soil Properties and External Corrosion Growth rate of Car...

Correlation between Soil Properties and External Corrosion Growth rate of Car...

Research Inventy : International Journal of Engineering and Science

Research Inventy : International Journal of Engineering and Science

A Study of microstructure and mechanical properties of 5083 Al-alloy welded w...

A Study of microstructure and mechanical properties of 5083 Al-alloy welded w...

Microstructure analysis and wear behaviour of al based metal matrix composite...

Microstructure analysis and wear behaviour of al based metal matrix composite...

Microstructure and Hardness of Aluminium Alloy- Fused Silica Particulate Comp...

Microstructure and Hardness of Aluminium Alloy- Fused Silica Particulate Comp...

Replacement of Natural Sand with Efficient Alternatives: Recent Advances in C...

Replacement of Natural Sand with Efficient Alternatives: Recent Advances in C...

Similar to Microstructure, Mechanical Properties & Corrosion Behavior of Duplex 2209 in Electro-Slag Strip Cladding over low carbon steel substrate: a Review Paper

this ppt is mainly based on the power systems related topic and in this ppt mainly consists of ac and dc weldings and which welding is used mainly and the importance of arc welding and electric welding and the techniques are also discussed in this and it is so helpful .and the safety requirements and the equipment used is also discussed in this topicpower systems ppt on Arc welding and Electric welding equipment and compariso...

power systems ppt on Arc welding and Electric welding equipment and compariso...sanjay kumar pediredla

Final Year Project in Punjab University B.Sc Engineering in Metallurgy and Material. Spot Welding, Testing, SEM, Spot welding final year project of b.sc engineering in metallurgy and materi...

Spot welding final year project of b.sc engineering in metallurgy and materi...University of the Punjab, Lahore, Pakistan

STATE OF ART IN MODERN RESISTANCE SPOT WELDINGSTATE OF ART IN MODERN RESISTANCE SPOT WELDING

STATE OF ART IN MODERN RESISTANCE SPOT WELDINGInternational Journal of Technical Research & Application

Similar to Microstructure, Mechanical Properties & Corrosion Behavior of Duplex 2209 in Electro-Slag Strip Cladding over low carbon steel substrate: a Review Paper (20)

Evaluation of Hardness of Bimetallic Weld joint between SA-508Gr3 and SS-304L

Evaluation of Hardness of Bimetallic Weld joint between SA-508Gr3 and SS-304L

Performance and Analysis of Weld Joint by using Two Dissimilar Electrodes E60...

Performance and Analysis of Weld Joint by using Two Dissimilar Electrodes E60...

Analysis of Machining Characteristics of Cryogenically Treated Die Steels Usi...

Analysis of Machining Characteristics of Cryogenically Treated Die Steels Usi...

Literature Review on Electrical Discharge Machining (EDM)

Literature Review on Electrical Discharge Machining (EDM)

Approach to simultaneous improvement of strength, ductility

Approach to simultaneous improvement of strength, ductility

power systems ppt on Arc welding and Electric welding equipment and compariso...

power systems ppt on Arc welding and Electric welding equipment and compariso...

IRJET- Influence of Process Parameters on Welded Joint by Laser Beam Welding

IRJET- Influence of Process Parameters on Welded Joint by Laser Beam Welding

Spot welding final year project of b.sc engineering in metallurgy and materi...

Spot welding final year project of b.sc engineering in metallurgy and materi...

IRJET- A Review on Parametric Optimization of Aluminium Alloy 5754 For MI...

IRJET- A Review on Parametric Optimization of Aluminium Alloy 5754 For MI...

Welcome to International Journal of Engineering Research and Development (IJERD)

Welcome to International Journal of Engineering Research and Development (IJERD)

ELECTRODEPOSITION OF Ni-Mg-Zn COATING BY VARYING TEMPERATURE ON MILD STEEL CH...

ELECTRODEPOSITION OF Ni-Mg-Zn COATING BY VARYING TEMPERATURE ON MILD STEEL CH...

Recently uploaded

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Call Girl Bhosari Indira Call Now: 8617697112 Bhosari Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Bhosari Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Bhosari understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Recently uploaded (20)

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

Microstructure, Mechanical Properties & Corrosion Behavior of Duplex 2209 in Electro-Slag Strip Cladding over low carbon steel substrate: a Review Paper

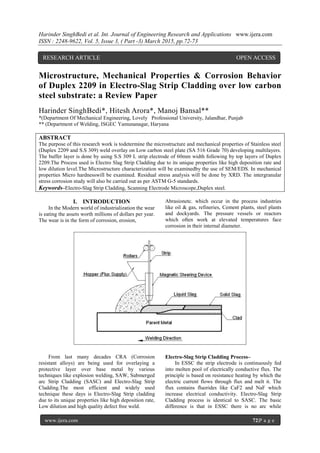

- 1. Harinder SinghBedi et al. Int. Journal of Engineering Research and Applications www.ijera.com ISSN : 2248-9622, Vol. 5, Issue 3, ( Part -3) March 2015, pp.72-73 www.ijera.com 72|P a g e Microstructure, Mechanical Properties & Corrosion Behavior of Duplex 2209 in Electro-Slag Strip Cladding over low carbon steel substrate: a Review Paper Harinder SinghBedi*, Hitesh Arora*, Manoj Bansal** *(Department Of Mechanical Engineering, Lovely Professional University, Jalandhar, Punjab ** (Department of Welding, ISGEC Yamunanagar, Haryana ABSTRACT The purpose of this research work is todetermine the microstructure and mechanical properties of Stainless steel (Duplex 2209 and S.S 309) weld overlay on Low carbon steel plate (SA 516 Grade 70) developing multilayers. The buffer layer is done by using S.S 309 L strip electrode of 60mm width following by top layers of Duplex 2209.The Process used is Electro Slag Strip Cladding due to its unique properties like high deposition rate and low dilution level.The Microstructure characterization will be examinedby the use of SEM/EDS. In mechanical properties Micro hardnesswill be examined. Residual stress analysis will be done by XRD. The intergranular stress corrosion study will also be carried out as per ASTM G-5 standards. Keywords–Electro-Slag Strip Cladding, Scanning Electrode Microscope,Duplex steel. I. INTRODUCTION In the Modern world of industrialization the wear is eating the assets worth millions of dollars per year. The wear is in the form of corrosion, erosion, Abrasionetc. which occur in the process industries like oil & gas, refineries, Cement plants, steel plants and dockyards. The pressure vessels or reactors which often work at elevated temperatures face corrosion in their internal diameter. From last many decades CRA (Corrosion resistant alloys) are being used for overlaying a protective layer over base metal by various techniques like explosion welding, SAW, Submerged arc Strip Cladding (SASC) and Electro-Slag Strip Cladding.The most efficient and widely used technique these days is Electro-Slag Strip cladding due to its unique properties like high deposition rate, Low dilution and high quality defect free weld. Electro-Slag Strip Cladding Process– In ESSC the strip electrode is continuously fed into molten pool of electrically conductive flux. The principle is based on resistance heating by which the electric current flows through flux and melt it. The flux contains fluorides like CaF2 and NaF which increase electrical conductivity. Electro-Slag Strip Cladding process is identical to SASC. The basic difference is that in ESSC there is no arc while RESEARCH ARTICLE OPEN ACCESS

- 2. Harinder SinghBedi et al. Int. Journal of Engineering Research and Applications www.ijera.com ISSN : 2248-9622, Vol. 5, Issue 3, ( Part -3) March 2015, pp.72-73 www.ijera.com 73|P a g e welding. The arc is strike just to start the weld. Due to unavailability of arc there is no ultraviolet radiation but only infra-red rays.The basic problem in this process is undercut. The problem arise due to electromagnetic pinch effect. The electromagnetic forces due to high current passing through the metal strip tends the flow of molten metal from sides to the center of the weld bead. To overcome this problem we apply an external magnetic field by using magnetic steering device in the opposite direction. The metal deposition rate is up to 52kg/hour which is highest among other processes. The dilution level is recorded as low as 10-15% among all processes. A straight polarity is used in ESSC. Arc voltage is kept low at 24-26V and current is high 400-2400 A depending on strip size Chemical Composition of Base Material and Strip electrode – This grade of steel is as per the standard specification of Pressure vessel plate, carbon steel for moderate and low temperature service. Its composition is as follows Elements Base Metal S.S 309 L Duplex 2209 Carbon, C 0.27 under ½”, 0.28 between ½” to 2” 0.009 0.008 Silicon, Si 0.15 - 0.40 0.13 0.43 Sulfur, S 0.035 0.0015 <0.000 5 Phosphorous, P 0.035 0.015 0.018 Manganese 0.85 - 1.20 1.68 1.51 Chromium - 20.34 22.95 Nickel - 13.45 8.59 Molybdenum - 2.84 3.02 Cobalt 0.023 0.11 Copper 0.078 0.12 Nitrogen 0.031 0.15 The strip electrode will be 60 mm X 0.5 mm dimension. The flux used consist of following by % SiO2 6 Al2O3 24 CaO + MgO 48 K2O + Na2O 2 F 32 II. Experimental Procedure - The base plate of SA 516 Grade 70 low carbon steel of 50 mm received in normalized, accelerated cooled and tempered condition. In first case the buffer layer with SS 309 L will be performed followed by second and third layer of Duplex 2209.The overlays then will be tested under SEM/EDX. Micro hardness will also be tested along with residual stress analysis by XRD. Welding parameters used in performing ESSC Parameters Range Welding current (I) 1200-1400 A Voltage (V) 22-26V Travel Speed 170 mm/min Pre heat 130 degree Celsius Interpass Max 200 Electrode extension (Stick Out) 12-15 mm Height of Flux 15mm Polarity DCEP III. CONCLUSION The analysis in this area over past few decades reveals that in ESSC generally Austenitic grades of Stainless Steel is used like 304, 309, 316 L etc. The review paper evaluates the new grade of Stainless steel i.e. Duplex 2209 which exhibits different mechanical and chemical properties as compared to conventional Austenitic Stainless steel. The mechanical properties along with corrosion behavior of the clad overlay will be evaluated. REFRENCES [1] Sunil D. Kahar et al ," Corrosion Behavior of Electro Slag Strip Cladding Weld Overlays in Different Acid Solutions ”, Int. Journal of Engineering Research and applications Vol. 3, Issue 4,july-aug 2013 pp.590-595, 2012 [2] Mitul Patel et al," Application of Electro Slag Strip Cladding for reactors in Hydrogen Based Refinery” [3] V.V Satya Prasad et al " Microstructure and Mechanical Properties of Electro Slag Strip Cladding and Explosively Clad Loy Alloy Steel: Stainless Steel .Indian Institute of metal 2012. [4] Ikuhisa Hamada et al , “Inter granular stress corrosion cracking behavior of niobium added type 308 stainless steel weld overlay metal in a stimulated BWR environment ”, Nuclear Engineering and Design 214(2002) 205-220 ELSEVIER. [5] J. H Delvetian et al ,"Strip Cladding of Main Propeller Shaft with Ni alloy 625, Low Ni alloy 625 & Ni alloy 59 by Electro Slag Strip Cladding” Society of Naval Architect s abd Marine Engineers USA. [6] D.W Yu & J.H Delvetian,"Electro Slag Surfacing: A Potential Process for Rebuilding and Restoration of ship components. Society of Naval Architect s and Marine Engineers USA. [7] Liane Smith,” Engineering with CLAD STEEL “Nickel Institute Technical Series N 10064 [8] www.voestalpine.com/welding