XR3 Hybrid

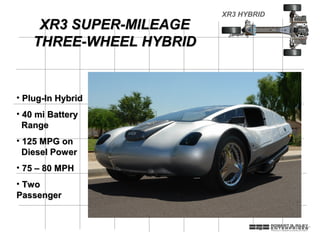

- 1. XR3 HYBRID XR3 SUPER-MILEAGE THREE-WHEEL HYBRID • Plug-In Hybrid • 40 mi Battery Range • 125 MPG on Diesel Power • 75 – 80 MPH • Two Passenger

- 2. XR3 HYBRID A Few PREDESSORS UrbaCar 1974 650 lb Curb Weight Trimuter 1980 Urba Electric 1977 850 lb Curb Weight 60 mpg Constant-Speed Motor 55 mpg 60 mph Speed Controlled by CVT 65 mph Tri-Magnum 1983 Motorcycle Power Train 1250 lb Curb Weight 45-50 mpg 100+ mph

- 3. XR3 HYBRID EARLY CONCEPT RENDERINGS • High-Performance Orientation • Tilting Suspension • Single-Occupant • Motorcycle Power Train • Fair-Weather Sports Car A blend of motorcycle and automotive styling cues create a conceptually different product

- 5. XR3 HYBRID CHASSIS LAYOUT Designed to Maximize Power Train Options Four Li-Ion Batteries in Front & Two in Tunnel Air Spring at Each Wheel Clutch Kubota 23 hp Motor Diesel Engine Urethane Mount 4 Places Front & Rear of Tunnel Two-Stage Timing Belt Drive Electric Drive & Suspension Tunnel Frame • Parallel Hybrid Architecture • Electric & ICE Power Systems Decoupled ICE Drive & Suspension Within the Vehicle

- 6. XR3 HYBRID ICE DRIVE & FRONT SUSPENSION Mounting Hard-Points (4 places) Shifter (Mounts to Tunnel Inside Cabin) Suspension Air Reservoir Air Spring Inflation Pressure Controls Ride Height & Accounts for Vehicles Having Weight Throttle/Mode Integrator EASM File Kubota D902 Diesel Engine Stabilizer Bar also Serves as Locator Link For Lower Control Arms

- 7. XR3 HYBRID FRONT CLIP REMOVED

- 8. XR3 HYBRID TUNNEL FRAME Route Fuel Filler Through Here Sheet Metal Skin Bolt to Front Sub- Frame Using Urethane Vibration Isolator (4 places) 3 Gallon Fuel Tank Li-Ion Battery (2) Rectangular EASM File Steel Frame

- 9. XR3 HYBRID ELECTRIC DRIVE & SUSPENSION Air Spring Varying Air Pressure Accounts Urethane Vibration for Weight of Different Power Isolator 4 Places System Configurations Motor Frame is a Structural Element of Rear Housing Trailing Arm Pivots on Jackshaft Axis Trailing Arm Internally Trussed EASM File

- 10. ELECTRIC DRIVE XR3 HYBRID Tight packaging allows the motor to serve as a structural element. EASM File INTEGRATOR/MODE CONTROL

- 11. XR3 HYBRID FOAM CORE COMPOSITE BODY STEP 1: Build Foam Body STEP 2: Fiberglass Over to Create a Foam Core Composite STEP 3: Smooth & Level With Body Filler

- 12. XR3 HYBRID XR3 HYBRID 125 – 225 MPG 40 MI BATTERY-ONLY RANGE

Notes de l'éditeur

- The slide shows the recently completed prototype of the XR3 – a self-financed in-house project. I am the design team, Melissa Beckner did much of the SolidWorks modeling and layout for the manual, and Bill Beckner comprised half of the prototyping team. My wife, Galiya, did much of the image-setting for the manual, and as you’ll see later on, she filled in as a photographic model. The XR3 is a parallel hybrid using Li-Ion batteries and a 23 hp, three cylinder diesel engine. The diesel engine drives the two front wheels through a VW Beetle Type One transmission. And the electric motor drives the single rear wheel through a two-stage timing belt drive. So it’s an all-wheel-drive vehicle. I say “vehicle” because according to the Federal Uniform Vehicle Code, a three-wheel vehicle is a motorcycle. If it had four wheels, then I’d be calling it a “car.” Tonight I’ll provide a little background on the vehicle – why it exists – and I’ll give a technical overview. Feel free to ask questions, but I will leave time for questions at the end of the presentation.

- As many of you probably know, my automotive work has centered on, for lack of a better description, alternative car design. The first vehicle was a four-wheel, 650-pound two-place commuter car called UrbaCar, developed in the early ’70’s. It was a very basic car, and it achieved nearly 60 mpg in the days when production cars were averaging about 12 – 15 mpg. UrbaCar appeared on the cover of Mechanix Illustrated magazine in 1974 as a do-it-yourself project and it was a huge success. We sold about 10,000 - 12,000 sets of plans, and it started the series of DIY cars that ran in either Popular Mechanics or Mechanix Illustrated magazine through 1984. Income from plans paid for each successive development project. We could not have continued year after year without the support of people who bought plans. Urba Electric, Trimuter, and Tri-Magnum each sold about 30,000 sets of plans. So I was lucky enough to be able to pursue this kind of work and make a living while doing it. Each of these cars was design around an unconventional power train and distinctive styling that set them apart from production automobiles of the period. Nearly all of them were either battery-electric, hybrid, or super-fuel-economy IC cars. I phased out that operation in 1986 - which went by the name of Quincy-Lynn Enterprises - and I’ve been working as an independent product design consultant since about 1989.

- This is an early concept rendering of the XR3. I used a drawing of this concept as a sort of “theme image” at the beginning of the chapter on three-wheelers in the Second Edition of, “Alternative Cars in the 21 st Century”. Obviously, I did not carry through with the single-occupant performance-orientation embodied in the rendering. But this was the core idea that established the styling theme for the XR3 – the one that was actually built. When I begin a new vehicle project I like to create a first run at styling, just to set the theme and have a visual marker to work toward. And of course you can’t make a concept rendering until you have at least a general idea of vehicle packaging and layout. The vehicle in the rendering was envisioned as having a motorcycle power train driving a single rear wheel. To give it an eco-friendly orientation, I considered using compressed natural gas as a fuel. That big round element right behind the seat was potentially the CNG tank. I was intrigued by the work sponsored by Atlanta Gas Light (along with a few other natural gas providers) to develop the technology for storing natural gas at low pressure on a carbon bed – a process called “Adsorption.” Successful adsorption storage would open the way for a low-pressure CNG vehicle that could be refueled at home using a relatively inexpensive two-stage compressor. Their research had produced a breakthrough – according to my contact there. The goal of styling was to give it strong motorcycle cues as a way of differentiating it from an automobile. People identify certain styling elements as belonging to certain types of products. Motorcycles, for example, do not look like automobiles. And they would not look like automobiles even if they had more wheels. In fact, they would not look like automobiles even if they had a body. The rendering shows a product that has a body similar to automobiles, but it’s obviously not an automobile. Consumers identify certain styling elements as belonging to motorcycles and they identify very different styling elements as belonging to automobiles. These product-specific styling cues tell consumers what the vehicle is and what it does. Consumers also have certain expectations of particular products due to their experience of that type of product. For example, you might not be able to get away with an open-sided car that you have to step over the side in order to enter, but those are perfectly acceptable attributes of a motorcycle. People do not expect to see air conditioning in a motorcycle, but they expect it in an automobile.

- When I became serious about building the XR3 – about three years ago - the world had become different. Much to my surprise, all those things I had been saying about environmental degradation, the end of cheap oil, and the economic calamity caused by oil dependence had become true. So I was no longer interested in building a performance vehicle. Instead, I wanted to stretch fuel economy to the max, and get away from liquid fuel altogether whenever it was possible to do so. The obvious answer was a plug-in hybrid. Space for two occupants with side-by-side seating was also important. I don’t think there’s much of a market for a single-place vehicle, and I think people much prefer side-by-side seating. Next, I decided to eliminate the tilting suspension system. The ability to lean into turns provides huge dynamic benefits. But there are real-world challenges too - inherent vehicle-dynamics problems that make it difficult to design for atypical conditions – for example, when a vehicle looses traction and spins out. Also, the width necessary for side-by-side seating conflicts with the design attributes of a body that has to roll as much as 50 degrees off vertical in order to remain in balance with turn forces. (Normally, motorcycles are design for a 55 degree lean angle before any part of the machine contacts the ground.) And since I already knew how to design a three-wheel vehicle that has the rollover stability of a conventional passenger car, the idea of taking on a complex suspension development project, along with inherent width limitations, did not make much sense. So I decided to go with a conventional suspension system. Once those decisions were made, I went to work on restyling the vehicle so it would have space for the two power systems and two occupants seated side-by-side. This slide shows computer renderings of the final design. I’ll point out a few interesting things about the styling. In the beginning, those elements that fit along the rocker panel region of the body were just styling elements. As time went on, I invented the idea that the finned feature was a radiator and the fairing further back was there to hide the belt on one side and the exhaust on the other side. But the real purpose was originally to hide the bottom of the passenger zone, which extends below the body, beginning just behind the front wheels. To get a sense of the impact on styling, imagine what it would do to the vehicle’s appearance if the lower body line was brought down to hide the passenger zone and the rear power train. The body would look very thick from the front wheels to the rear wheel. It would loose a lot of its sleekness. So I simply made the lower bodyline pleasing, and then I put features along the sides to hide the exposed elements. The plenum-chamber-looking element at the front hides the engine (and serves as a removable hood). The engine actually protrudes through the hood at that point. I wanted to keep the hood short and low, but the engine prevented me from doing it. I worked three months on a styling solution – how to style the hood to achieve the effect I was looking for – until I gave up trying to cover it and simply let the engine protrude through the hood. The plenum chamber was a styling element designed to hide the top of the engine. But it actually proved to be a practical feature as well. It provided good airflow through the engine room, and when it’s removed, nearly the entire engine room is open for servicing.

- This slide shows the layout of the chassis. The XR3 is a plug-in parallel hybrid, which means that batteries are recharged using wall-plug electricity and both power systems deliver power to the ground in order to propel the vehicle. It has three driver-selectable modes of operation – diesel-only, battery-only, and a hybrid mode in which both power systems are active. The two power systems are not connected within the vehicle. The ground makes the connection between the two systems. Aside from a simple electro-mechanical “throttle Integrator”, the power systems are completely independent within the vehicle. So there are no computer controls necessary to make the two systems work together. It’s a very simple system. To get a sense of how it works, consider that in the hybrid mode the XR3 is essentially a diesel-powered vehicle and the electric power system is used as a sort of electric “supercharger” or “passing gear” to enhance acceleration. When operating at a steady-state speed, the electric power system is shut off (depending on speed and road conditions). When extra acceleration is needed, depressing the accelerator pedal past a certain point powers up the motor and adds up to 50 hp to the 23 hp available from the diesel engine. The ICE power system is carried by a sub-frame that bolts to the front of the tunnel. This front sub-assembly includes the front suspension and steering systems and the entire ICE power train. Likewise, the electric power train is attached to an independent sub-frame, which bolts to the rear of the tunnel. So the rear sub-assembly is a fully integrated power system consisting of a trailing arm suspension, the motor, and a two-stage timing belt drive that transfers power to the single rear wheel. The clutch on the driver’s side is used to decouple the motor from the jackshaft so the diesel engine does not have to overcome the inertial loads of spinning up the armature during acceleration. Notice the air spring at each of the wheels. The XR3 rides like it was on air (and it corners like it was on rails). And you can lower the ride-height at highway speeds to improve aerodynamics. But there was another consideration that compelled the choice of air springs. If the vehicle is configured differently - for example by leaving out the electric power system and making it a diesel-only vehicle, then it will end up about 600 pounds lighter. The difference in weight can be accounted for by adjusting the pressure in the air springs. Or if it’s configured for battery-only power, the vehicle will end up heavier. Again, adjusting the pressure in the air springs can account for the difference. At the outset, I wanted to design a chassis so it could be easily reconfigured for different markets and preferences. As a build-it-yourself project, this is important because no two builders have the same goals in mind. And everyone likes to experiment – try to improve on the design. Looking ahead to kit cars and turn-key vehicles, the ability to set up the power train according to a customer’s budget and power-sources preferences was also important. That’s the reason I designed a chassis having the three separate sub-assemblies. You can configure it as a battery-only vehicle by simply leaving off the ICE power train components, letting the front wheels free-wheel, and adding more batteries up front to provide increased range and keep the CG in the correct location. It’s possible to end up with a battery-only vehicle having a range on the order of 100 miles. Or you can leave off the electric power train and batteries and end up with a diesel-only vehicle that’s about 600 pounds lighter, has fuel economy of up to 125 mpg, and costs less than half to build. Or you can install a FWD automotive power train and sacrifice fuel economy for greater acceleration and top speed. Depending on the power train choices, the frame itself does not have to be redesigned – with the possible exception of moving some structural members to accommodate the space needed for the particular power train choice. If you wanted to install a large automotive power train, for example, there will likely be interference issues to resolve. And you may run out of space under the hood. That’s one of the reasons the front clip is entirely removable (as you’ll see later on). A different front clip can be restyled to accommodate a much larger engine. So modularity and the ability to account for different power train choices were important metrics that guided the design.

- The front sub-assembly carries the entire combustion power train, plus four of the six Li-Ion batteries for the electric power train at the rear. The suspension and steering systems, as well as the engine and transmission, are integral to this sub-assembly. The suspension and steering systems are purpose-built. In other words, they are not from an existing production car. This sub-assembly bolts to the front of the tunnel using the four brackets on the rear face to the large 2 x 4 inch cross-members.

- This image shows the finished vehicle with the front clip removed. It takes about 10 minutes to remove the entire front of the body. The front clip floats in place. It is not rigidly attached to the passenger zone. It is connected two places on each side using flexible mounts. It’s also connected to the front sub-frame at six places. The goal has been to keep ICE power train vibrations out of the passenger zone. This mounting system does a pretty good job of it.

- The tunnel carries two of the Li-Ion batteries and a three-gallon fuel tank. The fuel tank is located at the rear of the tunnel. It’s a simple structure having a rectangular steel frame that is covered with a sheet-metal skin. In fact, the tunnel could be made entirely of formed metal. I’ve designed it so the body bolts to the tunnel. In other words, the body – or rather the passenger zone portion of the body - is not connected to the front or rear power trains/subassemblies. The idea is to isolate the passenger zone from vibrations produced by the power trains. The electric power train does not produce much vibration. But road noise from the rear tire and harmonics produced by the timing belt are there. It doesn’t take much to keep those kinds of high-frequency vibrations out of the passenger zone. The diesel engine is another story. Although a three-cylinder engine is inherently in balance, a diesel is notorious for producing harsh, low-frequency vibrations. Low-frequency vibrations are damped out by the soft motor mounts (part of the front subassembly), and high-frequency vibrations are further isolated by those mounts at the front of the tunnel.

- Again, the rear subassembly consists of the electric power train and the rear suspension. Urethane mounts isolate high-frequency vibrations from the tunnel. The motor is actually a structural element of the rear housing. In the absence of the electric power system, a structural element – a length of six-inch diameter steel tubing, for example, has to be installed where the motor would normally fit. You can’t simply leave off the motor and rely on this aluminum housing to carry the loads of the rear wheel. During diesel-only operation, the clutch, located on the left side, disengages at the motor from the jackshaft so the engine does not have to drag the motor armature up to speed. In other words, we want to motor to remain at rest when driving in the diesel-only mode. Notice that the trailing arm pivots around the jackshaft axis. This is done to hold the secondary timing belt drive at a constant center-distance.

- This slide shows the electric power train sitting outside the vehicle (upper image) and the rear sub-assembly in place in the finished vehicle (lower image). The rear fender must bounce with the rear wheel. So the fender is attached to the trailing arm. Just to confuse everyone, we’ve used a Dodge Neon rotor mounted to a Chevy Cavalier FWD hub, and a Honda Prelude caliper with built-in parking brake. The axle that extends from the timing belt pulley through the carrier to the Chevy cavalier FWD hub was specially made by Phoenix Rack & Axle here in Phoenix. This setup allows us to leave off the electric power train and end up with a correctly supported free-wheeling rear wheel. The most innovative part of the electric drive system is what I’ve been calling the “Integrator/Mode Control”. This device is actuated by the accelerator pedal inside the cabin. In the battery-only mode, the controller puts power to the motor as soon as the accelerator pedal is depressed. So it operates just like any other EV. In the diesel-only and hybrid modes, the lever that holds the Curtis PB-6 is rotated rearward. This delays activation of the controller so the motor is powered up late. In other words, the first part of accelerator-pedal-depression operates only the throttle on the diesel engine. It has no effect on the electric drive system. But as the diesel engine approaches full throttle, the PB-6 control begins to power up the motor. At full accelerator pedal depression, both power systems are operating at maximum output. So you jump from 23 hp 73 hp with increasing depression of the accelerator pedal. The net effect is that acceleration energy comes from the grid system, not from installing a larger engine and burning more liquid fuel throughout the driving cycle. With lower installed power the engine can run closer to its region of lowest bsfc (brake specific fuel consumption). In lay terms, that means that it consumes the least amount of fuel per unit of output. The obvious question is “what happens when batteries run down.” Well, you continue on your way on diesel power alone. And acceleration is not really bad. It’s about like one of the old VW Beetles when they were first imported into the U.S. in the 1950s – okay, but not great. The real benefit, however, comes from the ability to leave the diesel off for those trips that are within the range of batteries. Acceleration is great on battery power alone, the ride is much quieter, you do not have to shift gears, and you burn no fuel and produce zero pollution.

- These three simple steps are a big simplification of the body construction process. What you see in the photos consumes more man-hours than the entire rest of the build. There is no mold. One simply builds the body of urethane foam and then it becomes rigid when fiberglass has been applied. This type of structure results in a light and strong body. For side intrusion protection, the entire side of the body, from the arm-rests down, is filled with urethane foam – about 6 inches thick. Rear impacts are taken by the rear tire. Frontal impacts are taken by about 5 inches of foam across the front. The canopy ends up with a steel roll cage laminated inside. The vehicle has about a 1.2-G rollover threshold, which is on par with a conventional sedan. But still, the best advice is to avoid getting into a crashing-match with an SUV.

- Here’s the finished vehicle. The prototype is on display out in the foyer. You might recognize the model - my beautiful wife Galiya, who’s here with me tonight. I also want to acknowledge some of the other members of the team. My granddaughter, Melissa Beckner, who did all the SolidWorks modeling, the layout of the manual, and the html for the CD-ROM – only 20 years old and already a seasoned CAD operator. Her father, Bill Beckner, who actually did most of the prototype build. And of course, my wife Galiya Hafizova-Riley who did all the image-setting. I’d be happy to take questions.