Cavitation effect

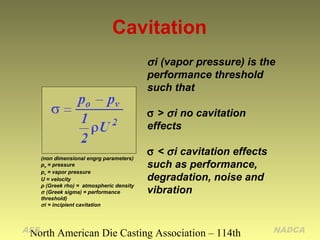

- 1. North American Die Casting Association – 114thAFS NADCA Cavitation σi (vapor pressure) is the performance threshold such that σ > σi no cavitation effects σ < σi cavitation effects such as performance, degradation, noise and vibration (non dimensional engrg parameters) po = pressure pv = vapor pressure U = velocity ρ (Greek rho) = atmospheric density σ (Greek sigma) = performance threshold) σi = incipient cavitation

- 2. North American Die Casting Association – 114thAFS NADCA Physics of Cavitation • Any device handling liquid is subject to cavitation • Local pressure that falls below saturated vapor pressure causes cavitation to occur • Resulting vapor cavities (void bubbles) collapse on surface material with high energy and heat • Inertial cavitation is commonly destructive

- 3. North American Die Casting Association – 114thAFS NADCA Collapse on the surface Spike generation as shown in 1- 18. Must have surface nucleation in order to collapse Surface – note formation of spike 10-18 as vacuum cavity collapses with high energy

- 4. North American Die Casting Association – 114thAFS NADCA Kinds of cavitation • Dynamic – produced by pressure variations in a flowing liquid – i.e. die casting • Acoustic – sound induced • Optic – photons of high energy – i.e. laser • Particle – elementary particle – proton bubble chamber. (dynamic and acoustic – liquid tension) (optic and particle – deposition of energy)

- 5. North American Die Casting Association – 114thAFS NADCA Dynamic stages • Traveling – moves with liquid flow • Fixed – steady state fixed (sheet or cloud) • Vortex – in cores of vortices of high sheer Incipient – term used to describe type and stage where cavitation appears Desinent – term used to describe when cavitation disappears

- 6. North American Die Casting Association – 114thAFS NADCA Stages, Cases, Types Propeller cavitation offers excellent examples of the basic types cloud cavitation tip vortex cavitation hub vortex cavitation propeller hull vortex cavitation sheet cavitation bubble cavitation Blade root cavitation

- 7. North American Die Casting Association – 114thAFS NADCA Example Vortex Incipient Dynamic liquid flow is left to right at a low velocity. Note – the beginning tiny stream of vortex bubbles on the tip of the obstruction As the velocity increases, actual vortexes can be seen along with sheet and some cloud cavitation – note – how the cavitation occurs on the opposite side of the flow direction. Similar to how core pins in die casting exhibit deterioration and soldering on the back side of flow

- 8. North American Die Casting Association – 114thAFS NADCA Video Examples flow decreasing flow direction

- 9. North American Die Casting Association – 114thAFS NADCA Hard to believe facts As the cavity bubbles collapse on the surface: • Bubbles collapse to a minute fraction of original size with immense focused force (4500 psi) • At total collapse a violent mechanism results temperature of bubble 5000 Kelvin or 8540 F (4727C) • By comparison sun’s surface temp is 5778 Kelvin) • Sonoluminescence (light) can be produced at collapse (Pistol Shrimp)

- 10. North American Die Casting Association – 114thAFS NADCA Inertial in HPDC dies Obstruction in a flowing water with flow from left to right - note how incipient cavitation moves to the back side of the core obstruction in the form of a cloud while at the top right the 150,000 rpm vortex stream is created. This is very representative of core deterioration from molten metal flow during HPDC. Slow motion photographs of water at high velocity flowing past an obstruction in its path creating pressure drops and cavitation

- 11. North American Die Casting Association – 114thAFS NADCA Not all cavitation is bad Non-inertial Submarine torpedoes Ultrasonics for cleaning Chemistry i.e. water purification Homogenization of paint or milk Medical for kidney stone removal or IV drug Badly soldered H-13 core on left. After cleaning ultrasonically with NaOH on right Courtesy of FISA

- 12. North American Die Casting Association – 114thAFS NADCA Occurrences Inertial & Non inertial • Aquatic animals – dolphins, tuna, shrimp • Plants – xylem vascular plant system • Humans – cracking knuckles, bullet wound • Geology – Scablands Mega flood • Dams – Spillways • Industry – Propellers, Pumps, Turbines High Pressure Die Casting Dies

- 13. North American Die Casting Association – 114thAFS NADCA Mega flood When a 2000ft high glacier ice dam broke, the high speed flood of water rushing over the land caused cavitation inception. The water’s massive volume (1/2 Lake Michigan), high speed (over 100ft/sec), and incipient vortex and sheet cavitation from obstacles along the way carved out this area of land between eastern Washington and western Montana about 15,000 years ago.

- 14. North American Die Casting Association – 114thAFS NADCA The 1964 SDCE Paper Abstract: Die steel is washed away by the blasting turbulent action of the molten metal entering the cavity. Pitting and breakout is an excessive extension of erosion. Conclusion: Theory could not be proven since the erosion occurs in the opposite location to where it should. Cavitation is what causes the failure which is evident by observing pressure drop locations and flow separation of the molten metal. Paper 25 – 01-64-03S

- 15. North American Die Casting Association – 114thAFS NADCA 1981 SDCE Paper Paper G-T81-123 Abstract Zinc die casting dies experience cavitation which damage the dies surface due to pressure releases at collapse Recommendations Control geometic factors, velocities, design, and material strength all dictate higher process control to reduce the effect and damage from cavitation

- 16. North American Die Casting Association – 114thAFS NADCA HPDC cavitation components • Local pressure of the metal falls below the saturated vapor pressure of the liquid • Occurs at sudden change of flow direction • Occurs at obstructions to flow that generate pressure variations • High velocities of flow at these locations • Two basic types: sheet and vortex

- 17. North American Die Casting Association – 114thAFS NADCA Breakout from Cavitation in HPDC Pitting, breakout, erosion, and washout commonly occur in the opposite locations of where they would be expected - on the low pressure side of the flowing liquid FLOW

- 18. North American Die Casting Association – 114thAFS NADCA Chicken and the Egg Does thermal fatigue cause breakout or does breakout lead to heat checking of the die’s surface? Can heat check cracking lead to breakout without incipient inertial cavitation? YES

- 19. North American Die Casting Association – 114thAFS NADCA Cavitation & Heat check Pressure drop location FLOW Cavitation Effect Heat check breakout? Cavitation effect exacerbates itself when more low vapor pressure develops from the disrupted flow patterns

- 20. North American Die Casting Association – 114thAFS NADCA Cavitation Exacerbated Gate Sheet and Possible Vortex Cavitation & Erosion exhibited sheet or cloud and vortex cavitation effect

- 21. North American Die Casting Association – 114thAFS NADCA How others buffer cavitation damage • Dam Spillways - Air slot • Diesel Engines – Coolant cylinders textured (patent 7146939 – manganese phosphate) • Ship Propellers & Rudders – design, pressures, buffer elastomer paint • Turbines, Pumps – design, operating parameters

- 22. North American Die Casting Association – 114thAFS NADCA Dam spillways concrete liner – Air slot Leap frog cavitation in the dam spillway – damages 150ft long – 32ft deepest – 40ft dia. The air slot installed (4ft wide x 4 ft deep 253 below spillway gate) creates a cushion of non vacuum bubbles that buffer the cavitation destructive force and allow higher flows Chunk of concrete Air bubble cushion Air slot

- 23. North American Die Casting Association – 114thAFS NADCA Diesel Engine Cavitation Bigger engines suffer from vibrations of the cylinder walls inducing alternating low and high pressures as the pistons move up and down. The resulting cavitation (like hitting the surface with a microscopic ball peen hammer) causes pit holes to develop in the cylinder wall that let cooling fluid leak into the cylinder wall.

- 24. North American Die Casting Association – 114thAFS NADCA Diesel Engine - Texturing Patent 7146939 – Dec 2006 It is feasible that this same buffering action takes place in compressive stress textured die surfaces with the cooling molten metal absorbing the cavitation shock along with the induced fatigue resistant substrate. Drawing of the diesel cylinder liner with textured manganese phosphate coating and resultant textured surface. Coating retains coolant which absorbs the cavitation impact energy of the collapsing cavities that damage the liner.

- 25. North American Die Casting Association – 114thAFS NADCA Propellers and Rudders The Navy and Marine industry spend billions on the prevention and cure of cavitation damage to ships’ propellers and rudders. Cavitation also affects power requirements for ships to attain their maximum speed.

- 26. North American Die Casting Association – 114thAFS NADCA Propeller and Rudder Design and Elastomer Paint Propeller Redesign USS ARLEIGH BURKE Class DDG 51) Destroyer Twisted Rudder Redesign Belzona 2141 & AER 48E Elastomer Surface

- 27. North American Die Casting Association – 114thAFS NADCA Pumps and Turbines sheet cavitation bubbles acting on a centrifugal pump impeller surface Impeller drawing showing discharge and cavitation location – low pressure side cavitation at the blade location of a turbine caused this damage Vortex (tip) cavitation at hub of turbine

- 28. North American Die Casting Association – 114thAFS NADCA Design and Operation Operation • Prevent dead head operation (occurs when the pump's discharge is closed either due to a blockage in the line or an inadvertently closed valve. ) stationary diffuser vanes rotating impeller double-volute wall Pump and turbine design changes to improve flow and reduce the possibility of cavitation • Prevent suction recirculation (fluid will start to recirculation or move in a reverse direction at the suction and at the discharge)

- 29. North American Die Casting Association – 114thAFS NADCA Application to HPDC Cavitation – controlled but not eliminated Factors to control or consider • Velocity of metal (dam spillway) • Extreme pressure variations (all) • Buffering the cavitation effect (diesel) • Fatigue resistance (compressive) • Design & Operation parameters (pumps)

- 30. North American Die Casting Association – 114thAFS NADCA Considerations • Simulation studies when designing • Better stronger and tougher die materials • Consideration regarding cavitation inception • Gate designs • Gate velocities • Increase the fatigue resistance • Buffering the harmful cavitation bubbles

- 31. North American Die Casting Association – 114thAFS NADCA Buffer by compressive texture? After 30,000 shots, there is no evidence of cavitation damage in the form of breakout, pitting, or erosion. Did the compressive texturing buffer cavitation? macro photo of casting surface shown belowtypical compressive finish for 47-48Rc

- 32. North American Die Casting Association – 114thAFS NADCA Conclusions and Summary 1. Anything handling liquid is subject to cavitation 2. Found in nature, geology, industry and hpdc 3. Inertial cavitation (flow and pressure) is destructive 4. Occurs when the local pressure falls below vapor pressure 5. Has always been assumed that molten metal is to blame 6. Very little investigation to date for hpdc cavitation 7. There is a need to study its effects to hpdc dies 8. Considerations include parameters from design to operation 9. You will never totally eliminate cavitation 10. Are there similar phenomena in HPDC?? 11. Can the cavitation effect be buffered in HPDC?