Xii.lrfd and stan dard aastho design of concrete bridge

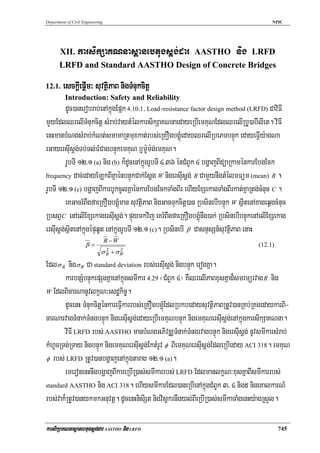

- 1. Department of Civil Engineering NPIC XII. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD LRFD and Standard AASTHO Design of Concrete Bridges 12.1. esckþIepþIm³ suvtßiPaB nigTMnukcitþ Introduction: Safety and Reliability dUc)anerobrab;enAkñúgEpñk 4.10.1/ Load-resistance factor design method (LRFD) CaviFI mYyEdlQrelITMnukcitþ sMrab;vaytMélkarsikSaKNnaedayeRbIemKuNEdlQrelIRbU)ab‘IlIet. viFI enHmanbMNgsMrab;kMNt;smamaRtmuxkat;rbs;eRKOgbgÁMúedayQrelIRbePTbnÞúk edayeFVIy:agNa eGayersIusþg;Tb;Tl;FMCagbnÞúkemKuN b¤m:Um:g;emKuN. rUbTI 12>1 (a) nig (b) k¾dUcenAkñúgrUbTI 4>36 énCMBUk 4 bgðajBIdüaRkaménkarEbgEck frequency dac;edayELkBIKñaénbnÞúkCak;Esþg W nigersIusþg; R CamYynwgtMélmFüm (mean) R . rUbTI 12>1 (c) bgðajBIkarbUkcUlKñaénkarEbgEckTaMgBIr ehIyExSekagTaMgBIrkat;KñaRtg;cMnuc C . eKGacrMBwgfaeRKOgbgÁúMman suvtßiPaB nigGacTukcitþ)an RbsinebIbnÞúk W sßitenAxageqVgcMnuc RbsBV C enAelIExSekagersIusþg;. pÞúymkvij eKrMBwgfaeRKOgbgÁúMnwg)ak; RbsinebIbnÞúkenAelIExSekag ersIusþg;sßitenAkñúgépÞqUt enAkñúgrUbTI 12>1 (c). RbsinebI β CasnÞsSn_suvtßiPaB enaH R −W β= (12.1) σR 2 + σW 2 Edl σ R nig σ W Ca standard deviation rbs;ersIusþg; nigbnÞúk erogKña. karbnSMbnÞúkepSgKñaenAkñúgsmIkar 4.29 ¬CMBUk 4¦ KWQrelIPaBxusKñad¾smrmürvag R nig W EdlBicarNanUvlkçN³esdækic©. dUcenH TMnukcitþénkareFVIkarrbs;eRKOgbgÁúMEdlRbkbedaysuvtßiPaBRtUv)anRKb;RKgedaykarBi- carNarvagTMnak;TMngbnÞúk nigersIusþg;edayeRbIemKuNbnÞúk nigemKuNersIusþg;enAkñúgkarsikSaKNna. viFI LRFD rbs; AASTHO manbMNgGPivDÄTMnak;TMngrvagbnÞúk nigersIusþg; nUvsmIkarsMrab; kMhUcRTg;RTay nigbnÞúk nigemKuNersIusþg;EktMrUv φ BIemKuNersIusþg;EdleRbIeday ACI 318. emKuN φ rbs; LRFD RtUv)anbgðajenAkñúgtarag 12>1 (a). emeronenHnwgbgðajBIkareRbIR)as;smIkarrbs; LRFD EdlmanlkçN³xusKñaBIsmIkarrbs; standard AASTHO nig ACI 318. ehIysmIkarEdl)aneRbIenAkñúgCMBUk 3/ 4 nig5 nigeKalkarN_ rbs;vak¾RtUv)anykmkGnuvtþ. dUcenHnisiSt nigvisVkrnwgyl;BIeRbIR)as;smIkaTaMgenHy:agRsYl. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 745

- 2. T.Chhay viTüasßanCatiBhubec©keTskm<úCa LRFD and Standard AASTHO Design of Concrete Bridges 746

- 3. Department of Civil Engineering NPIC 12.2. lkçN³bec©keTsénbnÞúkrfynþrbs; LRFD nig AASTHO Standard (LFD) AASTHO Standard (LFD) and LRFD Truck Load Specification karsikSaKNnaBIGgát;ebtugeRbkugRtaMgrbs;s<anRtUv)aneFVIeLIgedayeKarBeTAtam AASTHO (American Association of Highway and Transportation Officials). kñúgkarsikSaKNnaeRKOgbgÁúM EpñkxagelI (superstructure) rbs;s<an eKRtuveRCIserIs nigdak;pøÚvcracrN_ (traffic lane) nigbnÞúky:ag NaEdleFVIeGaymankugRtaMgGtibrmaenAkñúgGgát;eRKOgbgÁúM. kardak;bnÞúkGefrenAelIs<anRtUvman standard truck b¤ lane load EdlsmmUleTAnwg truck trains. sMrab;s<anrfePøIg (railway bridge), tMrUvkarRtUv)ankMNt;eday AREA (American Railway Engineering Association). CaTUeTA tMrUvkarsMrab;kMNt;smamaRtmuxkat;eRKOgbgÁúMrbs;Ggát;TMreRcIn GnuvtþtambTdæan ACI nig PCI. 12.2.1. bnÞúk Load kardak;bnÞúk highway mancMNat;fñak;bTdæan 4KW³ H20, H15, Hs20 nig HS15. kardak;bnÞúk HS15 KWesμInwg 75%énkardak;bnÞúk HS20. RbsinebImankardak;bnÞúkepSgeRkABIenH eKRtUveFVIkarEk karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 747

- 4. T.Chhay viTüasßanCatiBhubec©keTskm<úCa tMrUvTMgn;sMrab; standard truck nig land load EdlRtUvKñatamlkçN³smamaRt. eKsikSaKNna s<an Highway sMrab;kardak;bnÞúk HS20-44 b¤kardak;bnÞúkEdlmanePøArfynþ (axles) BIrEdlmanKMlatBIKña 14 ft ehIy axle nImYy²manTMgn; 24,000lb edayeKRtUvdak;bnÞúky:agNaedIm,ITTYl)ankugRtaMgFM. rUbTI 12>2 bgðajBIbnÞúk standard H Truck ehIyrUbTI 12>3 bgðajBIbnÞúk standard HS truck CamYynwgKMlatkg;rfynþ nigkarEbgEckbnÞúk. rUbTI 12>4 bgðajBI lane load smmUlsMrab; H 20-44, HS 20-44, H 15-44 nig HS 15-44. rUbTI 12>5 bgðajBIRbB½n§kMrals<anepSg²EdleKeRbICa TUeTA. (i) T§iBlTgáic (impact): bnÞúkcl½t (movable load) TamTarnUvkarGnuBaØatPaBTgáic EdlCaEpñk mYyrbs;bnÞúkGefr. eKGackMNt;va)antam standard AASTHO (LFD) 50 I= ≤ 30% (12.2) L + 125 Edl I= PaKryT§iBlTgáic (impact fraction) L = RbEvgKitCa feet rbs;cMENkénElVgEdlkardak;bnÞúkeFVIeGaymankugRtaMgGti- brmaenAkñúgGgát;enaH. LRFD and Standard AASTHO Design of Concrete Bridges 748

- 5. Department of Civil Engineering NPIC karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 749

- 6. T.Chhay viTüasßanCatiBhubec©keTskm<úCa LRFD and Standard AASTHO Design of Concrete Bridges 750

- 7. Department of Civil Engineering NPIC RbEvgdak;bnÞúk L sMrab;Ggát;TTwg (transverse member) dUcCaFñwmkMral (floor beam) CaRb- Evgrbs;Ggát;EdlKitBIG½kSeTAG½kS. (ii) kMlaMgtamTisbeNþay (Longitudinal Forces): eKRtUvdak;nUvkMlaMgtambeNþayesμInwg 5% énbnÞúkGefrenARKb; lane TaMgGs;EdlRTcracrN_kñúgTisedAdUcKña. épÞbnÞúk EdlKμanT§iBl Tgáic RtUvmanlkçN³dUcxageRkam³ land load + bnÞúkcMcMnuc RtUv)andak;enAelIElVgy:agNaedIm,IbegáItkugRtaMgGtibrma. bnÞúkcM cMnuc nigbnÞúkBRgayRtUv)anBicarNaBRgayesμIelITTwg 10 ft enAelIExSEdl EkgeTAnwgG½kSrbs; land. eKsnμt;TIRbCMuTMgn;rbs; longitudinal force manTItaMg enARtg; 6 ft BIelIkMral. eKGnuvtþemKuNkat;bnßyenAeBl traffic lane CaeRcInRtUv)andak;bnÞúkkñúgeBlCamYyKña dUcenA kñúgEpñk (iv) xageRkam. (iii) kMlaMgcakp©itedk (Centrifugal Horizontal Force): kMlaMgenHekItBIclnarbs;rfynþenA elIExSekag. eKkMNt;vaCaPaKryrbs;bnÞúkGefr edayKμanT§iBlTgáic dUcxageRkam³ 6.68S 2 C = 0.00117 S 2 D = (12.3) R Edl C=kMlaMgcakp©itKitCaPaKryrbs;bnÞúkGefrEdlKμamT§iBlTgáic S = el,ÓnKNna (design speed) KitCa miles kñúgmYyema:g D = dWeRkrbs;kMeNag R = kaMrbs;ExSekag KitCa ft (iv) karkat;bnßyGaMgtg;sIuetbnÞúk (Reduction in Load Intensity): enAeBlEdlkugRtaMgGti- brmaRtUv)anbegáIteLIgedaykardak;bnÞúkenAelI traffic lanes CaeRcInkñúgeBlCamYyKña eKRtUv eFVIkarkat;bnßyGaMgtg;sIuetbnÞúkdUcxageRkam³ PaKry mYy b¤BIr lane 100 bI lane 90 bYn lane b¤eRcInCagenH 75 karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 751

- 8. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 12.2.2. karEbgEckbnÞúkkg;enAelIkMrals<an³ lkçN³bec©keTssþg;dar AASTHO Wheel Load Distribution on Bridge Decks: Standard AASHTO Specifications (LFD) (i) kMlaMgkat; (Shear): minmankarEbgEckbnÞúkkg; (wheel load) tamTisbeNþaysMrab; wheel load b¤ axle load enAxagcug enAeBlKNnakMlaMgkat;xagcug nigRbtikmμenAkñúgFñwmTTwg (transverse beam) b¤FñwmbeNþay (longitudinal beam). (ii) m:Um:g;Bt;begáag³ FñwmbeNþay (Bending moment: longitudinal beam) kñúgkarKNnam:Um:g;begáagenAkñúg longitudinal beam b¤ stringer eKminGnuBaØateGaymankar BRgaybnÞúkkg;tamTisbeNþayeT. sMrab;Ggát;ebtugeRbkugRtaMg kñúgkrNI stringer xagkñúg m:Um:g;Bt;bnÞúkGefrsMrab; stringer nImYy²RtUv)ankMNt;edayGnuvtþcMENkén wheel load eTAelI stringer dUcxageRkam (iii) Side by Side Precast Beams in Multi-Beam Decks s<anBhuFñwm (multi-beam bridge) RtUv)ansagsg;eLIgCamYynwgFñwmebtugGarem: b¤Fñwmebtug eRbkugRtaMgcak;Rsab;Edldak;Ek,rKñaelITMr. GnþrGMeBI (interaction) rvagFñwmRtUv)anbegáIteLIg eday continuous longitudinal shear key EdleRbIrYmpSMCamYynwg transverse tie EdlGacrg b¤minrgeRbkugRtaMg dUcCab‘ULúg r)arEdk b¤kabeRbkugRtaMg b¤k¾meFüa)ayemkanicepSgeTot. eKRtUvkar Full-depth rigid end diaphragm edIm,IFanakarBRgaybnÞúkeGayl¥sMrab;FñwmrUbrag channel, single-stemmed tee beam nig multi-stemmed tee beam. kñúgkarkMNt;m:Um:g;Bt;begáagenAkñúgs<anebtugBhuFñwmcak;Rsab; ¬ebtugGarem: b¤eRbkug RtaMg¦ eKsnμt;faminmankarBRgaybnÞúkkg;tamTisbeNþayeT. m:Um:g;Bt;begáagbnÞúkGefr sMrab;muxkat;nImYy²RtUv)ankMNt;edayGnuvtþcMENkén wheel load ¬TaMgmux nigeRkay¦ Edl kMNt;edaysmIkarxageRkameTAelIFñwm LRFD and Standard AASTHO Design of Concrete Bridges 752

- 9. Department of Civil Engineering NPIC S Load Frcation = D Edl S= TTwgrbs;Ggát;cak;Rsab; D = (5.75 − 0.5 N L ) + 0.7 N L (1 − 0.2C )2 enAeBlEdl C ≤ 5 D = (5.75 − 0.5 N L ) enAeBlEdl C > 5 NL = cMnYn traffic lane C = K (W / L ) Edl W = TTwgTaMgmUlrbs;s<anEdlvas;EkgeTAnwgr:tbeNþay L = RbEvgElVgEdlvas;RsbeTAnwgr:tbeNþay. sMrab;r:tEdlman end diaphragm cak;enAnwgkEnøg ykRbEvgcenøaH end diaphragms K = [(1 + μ )I / J ]1 / 2 RbsinebItMélrbs; I / J FMCag 5.0 karBRgaybnÞúkRtUv)ankMNt;edayeRbIviFIEdlsuRkitCag dUcCa Articulated Plate Theory b¤ Grillage Analysis. Edl I = mU:m:g;niclPaB J = efrrmYl Saint-Venant μ = pleFobB½rs‘ugrbs;r:t sMrab;viFIEdlkat;EtsuRkit eKkMNt;tMélrbs; J edayeRbIsmIkarxageRkam sMrab;FñwmctuekaNEdlKμanRbehag/ FñwmGkSr C/ Fñwm Tee J = ∑{1 / 3)bt (1 − 0.630t / b )} ( 3 Edl RbEvgrbs;FatubgÁúMctuekaNnImYy²EdlmanenAkñúgmuxkat; b= t = kMras;rbs;FatubgÁúMctuekaNnImYy²EdlmanenAkñúgmuxkat; søab nigeCIgrbs;muxkat;EdlmaneCIg b¤muxkat;GkSr C RtUv)anKitCaFatubgÁúMctuekaNdac; edayELkEdltMélrbs;vaRtUv)anbUkbBa©ÚlKñaedIm,IKNna J . cMNaMfa sMrab;FñwmctuekaN EdlmanRbehagmUl tMélrbs; J GacKitCatMélRbhak;RbEhledayeRbIsmIkarxagelIsMrab; muxkat;ctuekaN nigedayminKitRbehag. sMrab;Fñwmmuxkat;RbGb;³ J= ( 2tt f (b − t )2 d − t f )2 bt + dt f − t 2 − t 2 f Edl b= TTwgsrubrbs;RbGb; karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 753

- 10. T.Chhay viTüasßanCatiBhubec©keTskm<úCa d= kMBs;srubrbs;RbGb; t = kMras;rbs;RTnugTaMgsgçag t f = kMras;rbs;søabTaMgBIr rUbmnþsnμt;fasøabTaMgBIrmankMras;esμIKña ehIyeKeRbIkMras;rbs;søabEtmYyeT. dUcKñasMrab; RTnug. sMrab;karsikSaKNnabzm eKGaceRbItMélrbs; K xageRkam³ (iv) kugRtaMgenAkñúgebtug (Stresses in Concrete) krNI I³ bnÞúkTaMgGs;edayrYmbBa©ÚlTaMgeRbkugRtaMg ¬ D + L + P / S ¦ f c = 0.6 f 'c f t = 6 f 'c krNI II³ eRbkugRtaMg + bnÞúkefrTaMgGs; ¬D+ P/S ¦ f c = 0.4 f 'c f t = 6 f 'c krNI III³ 12 ¬eRbkugRtaMg + bnÞúkefr¦ + bnÞúkGefr [0.5(D + P / S ) + L] f c = 0.4 f 'c f t = 6 f 'c 12.2.3. m:Um:g;Bt;begáagenAkñúgkMrals<an³ lkçN³bec©keTssþg;dar AASTHO (LFD) Bending Moments in Bridge Decks Slabs: Standard AASHTO Specifications (LFD) karKNnam:Um:g;Bt;manBIrRbePT³ RbePT A nigRbePT B sMrab;EdkBRgwgEdlEkg nigRsb eTAnwgcracrN_ erogKña. S = RbEvgElVgRbsiT§PaB LRFD and Standard AASTHO Design of Concrete Bridges 754

- 11. Department of Civil Engineering NPIC TTwgrbs;kMralEdleKEbgEck wheel load BIelIva E= P = bnÞúkenAelIkg;xageRkaymYyrbs; truck ¬ P15 b¤ P20 ¦ P15 = 12,000lb sMrab;kardak;;bnÞúk HS 15 P20 = 16,000lb sMrab;kardak;bnÞúk HS 20 (a) krNI A- EdkemEkgeTAnwgcracrN_ ¬ElVgEdlmanRbEvgBI 2 eTA 24 ft ¦ eKkMNt;m:Um:g;bnÞúkGefrsMrab;ElVgsamBaØtamsmIkarxageRkam sMrab;kardak;bnÞúk H 20 ⎛S + 2⎞ ML = ⎜ ⎟ P20 (12.4a) ⎝ 32 ⎠ sMrab;kardak;bnÞúk H 15 ⎛ S + 2⎞ ML = ⎜ ⎟ P15 (12.4b) ⎝ 32 ⎠ Edl M L KitCa ft − lb / ft énTTwgkMral sMrab;kMralEdlCab;elITMrbI b¤eRcInCagenH eKRtUvGnuvtþemKuNénPaBCab; 0.80 eTAelI smIkar 12.4 (a) nig 12.4 (b). (b) krNI B- EdkemRsbeTAnwgcracrN_ sMrab; wheel load TTwgEbgEck E KYresμInwg = 4 + 0.06S ≤ 7.0 ft . Lane loads RtUv)an BRgayelITTwg 2E dUcxageRkam³ sMrab;kardak;bnÞúk H 20 S ≤ 50 ft ³ M L = 900 S (12.4c) S = 50 − 100 ft ³ M L = 1000 S (12.4d) Edl M L KitCa ft − lb sMrab;kardak;bnÞúk H 15 kat;bnßy 25% BItMélenAkñúgsmIkar 12.4 (c) nig 12.4(d). 12.2.4. bnÞúkxül; Wind Loads edayKitbBa©ÚlbnÞúkxül; épÞRbQmesμInwgplbUkénépÞrbs;Ggát;TaMgGs;edayrYmbBa©ÚlTaMg RbB½n§kMral nigbgáan; dUceXIjenAkñúgkMritnIv:U 90o eTAnwgG½kSbeNþayrbs;eRKOgbgÁúM. karsikSaKNna KUrEp¥kelIel,Ónxül; V = 100mph(160km / h). RkLaépÞrgsMBaFRtUv)ankat;dUcerobrab;enAkñúg AASTHO. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 755

- 12. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 12.2.5. kMlaMgrBa¢ÜydI Seismic Forces eKGaceRbITaMgviFIkMlaMgsþaTicsmmUl (equivalent static force method) nig response spectrum method sMrab;karsikSaKNnaeRKOgbgÁúMEdlGgát;TMrmanPaBrwgRkajRbhak;RbEhlKña. karlMGitmanenAkñúg AASTHO. karerobrab;bEnßmsMrab; earthquake response, fundamental period énrMj½r nig International Building Code (IBC 2000) RtUv)anerobrab;enAkñúg Nawy. E.G., Reinforced Concrete. 12.2.6. karbnSMbnÞúk AASTHO LFD AASTHO LFD Load Combination karsikSaKNnaKYrKitRkuménkarbnSMbnÞúkEbbNaedIm,IeGay)anlkçxNÐkugRtaMgGtibrmaenA kñúgGgát;EdlBicarNa. eKmanRkuménkardak;bnÞúkeRkamlkçxNÐbnÞúkesvakmμ³ Rkum I³ D + (L + I ) + CF + E + B + SF Rkum II³ D + E + B + SF + W Rkum III³ D + (L + I ) + CF + E + B + SF + W + WL + LF Rkum IV³ D + (L + I ) + CF + E + SF + (R + S + T ) Rkum V³ D + E + B + SF + W + (R + S + T ) Rkum VI³ D + (L + I ) + CF + E + B + SF Rkum VII³ D + E + B + SF + EQ Rkum VIII³ D + (L + I ) + CF + E + B + SF + ICE Rkum IX³ D + E + B + SF + W + ICE Rkum X³ D + (L + I ) + E Edl D = bnÞúkefr L = bnÞúkGefr I = bnÞúkGefrTgáic E = sMBaFdI B = PaBGacGENþt (buoyancy) W = bgÁúMxül;enAelIGaKar WL = bnÞúkxül;enAelIbnÞúkGefr − 100lb / ft LRFD and Standard AASTHO Design of Concrete Bridges 756

- 13. Department of Civil Engineering NPIC bnÞúkbeNþayEdl)anBIbnÞúkGefr LF = CF = kMlaMgcakp©it R = karrYjxøIrbs; rib S = karrYmmaD T = sItuNðPaB EQ = kMlaMgrBa¢ÜydI SF = sMBaFrMhUrrbs;Twk ICE = sMBaFTwkkk sMrab; load factor design eKRtUvKuN)a:ra:Em:RtelIkmunCamYynwgemKuNbnÞúkenAkñúgtarag 12>1(b). sMrab;bnÞúkemKuN tMélRKumKW elxRkum (N ) = γ [β D D + β L (L + I ) + β C CF + β E E + β B B + β S SF + βW W + βWLWL + β L LF + β R (R + S + T ) + β EQ EQ + β ICE ICE ] (12.5) emKuNbnÞúkEdlRtUvGnuvtþeTAelIbnSMbnÞúkKWdUcxageRkam³ β E = 0.7 sMrab;bnÞúkbBaÄrenAelIRbGb;ebtugGarem: = 1.0 sMrab;bnÞúkxag (lateral load) enAelIRbGb;ebtugGarem: = 1.0 sMrab;bnÞúkbBaÄr nigbnÞúkxagenAelIlU (culvert) déTeTot = 1.0 nig 0.5 sMrab;bnÞúkxagenAelIeRKagrwg ¬RtYtBinitükardak;bnÞúkEdllub sMrab;RkumCak;lak;¦ β E = 1.3 sMrab;sMBaFxagrbs;dIenAeBlRtYtBinitüm:Um:g;viC¢manenAkñúgeRKagrwg (rigid frame) lU b¤lURbGb;ebtugGarem: β D = 0.75 enAeBlRtYtBinitüGgát;sMrab;bnÞúktamG½kSGb,brma nigm:Um:g;Gtibrma sMrab;cMNakp©itGtibrma sMrab;karsikSaKNnassr. = 1.0 enAeBlRtYtBinitüsMRab;bnÞúktamG½kSGtibrma nigm:Um:g;Gb,brma = 1.0 sMrab;Ggát;rgkarTaj nigkarBt;begáag. tarag 12>1 (b) eGaytMélénemKuN β sMrab;)a:ra:Em:RtbnÞúkepSg²enAkñúgsmIkar 12.5 sMrab;lkçN³bec©keTs standard AASTHO. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 757

- 14. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 12.2.7. karbnSMbnÞúk LRFD LRFD Load Combinations karbnSMbnÞúkedayeRbIlkçN³bec©keTs LRFD xusKñaBIlkçN³bec©keTs standard AASTHO. taragxageRkam ³ 12>2 eTAdl; 12>3 bgðajBIbnSMbnÞúktMrUvkar ehIytarag 12>4 dl; 12>7 bgðaj BIsmIkarkMlaMgkat; nigsmIkarm:Um:g;EdlRtUveRbIenAkñúgkarsikSaKNna. Epñk 12.1.1 bgðajBIemKuNer sIusþg; LRFD φ EdlxusKñaBIemKuNkat;bnßyersIusþg; standard AASTHO φ . eKRtUvcMNaMfa enAkñúg LRFD and Standard AASTHO Design of Concrete Bridges 758

- 15. Department of Civil Engineering NPIC lkçN³bec©keTs standard eKeRbI lane load b¤ truck load kñúgkarKNnabnÞúkGefr. lkçN³bec©keTs LRFD TamTareGayeRbInUvbnSMrvag lane load nig truck load kñúgkarkMNt;bnÞúkGefr. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 759

- 16. T.Chhay viTüasßanCatiBhubec©keTskm<úCa tMélemKuNersIusþg; LRFD φ RtUv)aneGayenAkñúgtarag 12>1 (a). eKGaceRbIsmIkarenAkñúgtarag 12>4 nig 12>5 edIm,IKNnam:Um:g;Bt;begáagGtibrma nigkMlaMg kat;GtibrmaRKb;cMnucTaMgGs;kñúgmYy lane sMrab; HS 20 truck CamYynwgkarkMNt;EdlbgðajenAkñúg tarag. eKyktMélEdlKNnaRtwmBak;kNþaledIm,ITTYl)ankMlaMgkat; nigm:Um:g;kñúgExSkg; (line of wheel). smIkarenAkñúgtaragRtUv)ankMNt;RtwmElVgTMrsamBaØ nigminrYmbBa©ÚlT§iBlTgáiceT. eKGackMNt;m:Um:g;Bt;Gtibrma nigkMlaMgkat;GtibrmakñúgmYy lane enARtg;cMnucNamYyenAelI ElVgsMrab; lane load 0.64kip / ft BIsmIkarEdlsMrYlehIydUcxageRkam³ kMlaMgkat;Gtibrma VLL = 02.64 (L − x)2 L (12.6a) 0.64( x )(L − x ) m:Um:g;Gtibrma M LL = 2 (12.6b) Edl x = cMgayBITMrxageqVg L = ElVgFñwm LL = lane load TamTarT§iBlTgáic (impact factor) FMCag standard specification. ehIy LEFD Specification vak¾TamTarnUvkarBicarNaBIsßanPaBkMNt; fatigue. sMrab; fatigue eKRtUvBicarNa truck load Biess. LRFD and Standard AASTHO Design of Concrete Bridges 760

- 17. Department of Civil Engineering NPIC vapSMeLIgBI single design truck EdlmanTMgn; axle dUcKñanwgGIVEdleRbIenAkñúgsßanPaBkMNt;déTepSg eTot b:uEnþvamanKMlatefr 30 ft cenøaH axle 32kips . tarag 12>6 bgðajBI impact factor IM sMrab; RbePTsßanPaBkMNt;epSg². tarag 12>7 bgðajBIsmIkarsMrab;KNnam:Um:g;Bt;GtibrmakñúgmYy lane EdlbNþalBIkardak; bnÞúk HL-93 fatigue truck. eKRtUvKuNtMélEdlTTYl)anBItaragedayemKuN 0.5 edIm,ITTYl)antMél kñúgmYyExSkg;rfynþ (line of wheel). karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 761

- 18. T.Chhay viTüasßanCatiBhubec©keTskm<úCa Ca HL-93 truck configuration EdlrYmmanbnSM³ LRFD design live load (a) Design truck b¤ design tandem CamYynwg dynamic allowance. Design truck KWdUcKñanwg HS20 design truck EdlmankMNt;enAkñúg Standard AASTHO specification. Design tandem pSMeLIgeday axle 25kips mYyKUr EdlmanKMlatBIKña 4 ft . (b) Design lane load 0.64kip / ft edayminman dynamic allowance. LRFD and Standard AASTHO Design of Concrete Bridges 762

- 19. Department of Civil Engineering NPIC 12.3. karBicarNaBIkarsikSaKNnakarBt;begáag Flexural Design Considerations 12.3.1. bMErbMrYlénbMErbMrYlrageFob ε nigemKuN φ ³ viFIbMErbMrYlrageFobkMNt; Strain ε and Factor φ Variations: The Strain Limits Approach sMrab;kareFVIkarCalkçN³sVit (ductile behavior) rbs;muxkat; PaKryEdkBRgwgRtUvmantMél tUcCagPaKrybMErbMrYlrageFobkMNt;lMnwg (balanced limit strain) EdlrgkarBt;begáag dUcbgðajenA kñúgEpñk 4.12.3. eKminRtUvkareRbIEdnx<s;bMputénbrimaNEdkenAkñúgFñwmeT RbsinebIbMErbMrYlrageFob minFMCagbMErbMrYlrageFobkMNt; ehIyeKeRbIemKuN φ smrmü. bMErbMrYlrageFobrgkarTajEdnx<s;bM put ε t = 0.005in. / in. edaysarbMErbMrYlrageFobkMNt;mantMélRbhak;RbEhlnwg 75%énPaKry Edk balanced enAkñúg code elIkmun ehIyvaCaeKalkarN_rbs;viFIenH ¬rUbTI 12>6¦. eKKitBicarNa bMErbMrYlrageFobkMNt;enARtg;nIv:UEdkrgkarTajxageRkAbMput mann½yfa enARtg;TIRbCMuTMgn;énRsTab; EdkEdlenAEk,répÞrgkarTajrbs;muxkat;CageK. kan;EtCak;ElkCagenH ε t = 0.0041 EdlRtUvnwg f y ≅ 230,000 psi enAkñúgEdkeRbkugRtaMg. sMrab;viFI AASTHO LRFD tMélkMNt;rbs;pleFobkMBs;G½kSNWt c elIkMBs;RbsiT§PaB rbs;Fñwm d t RtUv)aneKykesμInwg 0.42 enAkñúgviFIbMErbMrYlragkMNt; (strain limits approach) EdleK GacehAmüa:geTotfa unified approach. viFIenHCaviFIEdlFana strain-compatibility edayeRbIbMEr bMrYlFmμta nigsmIkarkugRtaMgedayminKitfaGgát;enHBRgwgedayEdk b¤edayeRbkugRtaMg b¤edayeRb kugRtaMgedayEpñk. kMBs; d t enAkñúgpleFob c / d t køayCa d p RbsinebIeKmineRbIEdkBRgwgFmμtaeT enaH. tarag 12>9 énEpñk 12.7 bgðajBIkareRbobeFobTUeTArvagviFIsaRsþ ACI nig LRFD sMrab; kMNt;EdktMrUvkarenAkñúgGgát;rgkarBt;begáag. eKRtUveRbItMélbMErbMrYlrageFob ε t FMCag 0.005in. / in. dUcCag 0.007 eTA 0.009in. / in. . sMrab;muxkat; beam-column bMErbMrYlrageFobénmux limit compression-controlled KW ε t = 0.002 . karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 763

- 20. T.Chhay viTüasßanCatiBhubec©keTskm<úCa eKeRbI ε t = 0.002 CaeKalsMrab; yield strain dMbUg ε y = f y / Es = 0.002 eTaHbICatMélenHGacERb RbYledayGaRs½yeTAnwgRbePTEdkEdleRbIk¾eday. rUbTI 12>7 bgðajBIEdnkMNt;énbMErbMrYlrag eFobsMrab;muxkat;ebtug tension-controlled nig compression-controlled sMrab;RKb;krNITaMgGs; ¬BRgwgedayEdk nigrgeRbkugRtaMg¦ Edl ε t = 0.003(dt / c − 1) . LRFD and Standard AASTHO Design of Concrete Bridges 764

- 21. Department of Civil Engineering NPIC enAeBl net tensile strain enAkñúgEdkrgkarTajxageRkAbMputFMRKb;RKan; ¬FMCag b¤esμInwg 0.005 ¦ muxkat;RtUv)ankMNt;Ca tensioned-controlled section EdlvamankarRbkasGasnñBIkar)ak; RKb;RKan;CamYynwgPaBdabFM nigekItmansñameRbH. enAeBlEdl net tensile strain enAkñúgEdkrgkar TajxageRkAbMputtUc ¬tUcCag b¤esμInwg compression-controlled strain limit¦ eKrMBwgvanwgekItman lkçxNÐ)ak;edaylkçN³RsYy CamYynwgkarRbkasGasnñBIkar)ak;d¾tictYcbMput. lkçxNÐ balanced strain ekItmanenARtg;muxkat;EdlbMErbMrYlrageFobGtibrmaenAsrésrgkar sgát;xageRkAbMputmantMélesμInwg 0.003 kñúgeBldMNalKñaCamYynwg yield strain dMbUg ε y = f y / Es enAkñúgEdkrgkarTajEdlRtUvnwg net tensile strain enAkñúgEdkrgkarTajEdlkMNt;enAkñúgviFIenH enA eBlEdltMélrbs; ε t = 0.002in. / in. . eKminGaceRbIviFIenHenAkñúgkarKNnaFñwmEdlrgkarBt;begáagEdlminrgkarsgát;eT. enAkñúg Ggát;EbbenH bMErbMrYlrageFob ε t enAkñúgEdkrgkarTajxageRkAbMputminRtUvFMCag 0.0075 sMrab;kar Gnuvtþ. 12.3.2. ersIusþg;m:Um:g;Bt;begáagemKuN Factored Flexural Resistance m:Um:g;Tb;Tl;karBt;begáagemKuN M t = φM n (12.7) EdlemKuNersIusþg; φ = 1.0 . enAkñúgkarviPaK strain compatibility eKENnaMeGaykat;bnßyemKuN φ BItMél 1.0 sMrab; net tensile strain 0.005 eTA 0.7 sMrab; net tensile strain 0.002 enAkñúgEdkrgkarTajxageRkAbMput man n½yfa ⎡d ⎤ 0.7 ≤ φ = 0.50 + 0.30 ⎢ ext − 1⎥ ≤ 1.0 (12.8) ⎣ c ⎦ Edl dext Ca dt énRsTab;xageRkAbMputrbs;EdkBRgwg KWRsTab;EdkEdlenAEk,rsrésrgkarTajxag eRkAbMputrbs;muxkat;ebtugeRbkugRtaMg. 12.3.3. )a:r:aEm:RtKNnakarBt;begáag Flexural Design Parameters smIkarsMrab;KNnaersIusþg;m:Um:g; nominal rbs;muxkat;eRbkugRtaMgeday LRFD method KW Rsedonwg standard AASTHO ehIyk¾RsedogKñanwgviFIsaRsþKNnaersIusþg;rbs; ACI 318 EdlENnaM karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 765

- 22. T.Chhay viTüasßanCatiBhubec©keTskm<úCa enAkñúgEpñk 4.11 énCMBUk 4. ersIusþg;KNnacugeRkay (ultimate design strength) f ps énEdkBRgwg EdlGacKNnatamviFI strain-compatibility dUckñúg]TahrN_ 4>19 b¤edayviFIRbEhl (approximate method) EdleRbIsmIkarxageRkam³ ⎛ c ⎞ f ps = f pu ⎜1 − k ⎟ (12.9a) ⎜ dp ⎟ ⎝ ⎠ ⎛ f py ⎞ Edl k = 2⎜1.04 − ⎜ ⎟ f pu ⎟ (12.9b) ⎝ ⎠ = 0.28 sMrab; low relaxation steel sMrab; unbonded tendons/ ⎛ dp −c⎞ f ps = f pe + 900⎜ ⎜ l ⎟ ⎟ (12.9c) ⎝ e ⎠ Edl le = 2li / (2 + N s ) RbEvg embedment/ li = RbEvgkabeRbkugRtaMgcenøaH anchorage/ N s = cMnYn tendon le = enAkñúg standard AASTHO specification eKGac)a:n;RbmaNkugRtaMgmFümdMbUgenAkñúgEdkeRbkug RtaMgBIsmIkarxageRkam³ ⎛ γ f pu ⎞ f ps = f pu ⎜1 − ρ ⎜ β ⎟ (12.9c) ⎝ 1 f 'c ⎟ ⎠ eKTTYl)ankMBs;rbs;G½kSNWt c BIsmIkarxageRkam³ (a) muxkat;EdkDub (Doubly reinforced section)³ A ps f pu + As f y − A' s f ' y c= (12.10) f pu 0.85 f 'c β1 + kA ps dp Edl f ' y = yield strength rbs;Edkrgkarsgát; (b) muxkat;mansøab (Flanged section)³ Aps f pu + As f y − A' s f ' s −0.85 f 'c β1 (b − bw )h f c= (12.11) f pu 0.85 f 'c β1bw + kAps dp Edl bw = TTwgRTnug d p = cMgayBIsrésrgkarsgát;xageRkAbMputeTATIRbCMuTMgn;rbs;EdkeRbkugRtaMg LRFD and Standard AASTHO Design of Concrete Bridges 766

- 23. Department of Civil Engineering NPIC 12.3.4. EdnkMNt;rbs;EdkBRgwg Reinforcement Limits (a) EdnkMNt;EdkBRgwgGtibrma (Maximum reinforcement limits)³ brimaNGtibrmarbs;EdkrgeRbkugRtaMg b¤EdkminrgeRbkugRtaMgRtUvmantMély:agNaedIm,I c ≤ 0.42 (12.12a) de A ps f ps d p + As f y d s Edl de = A ps f ps + As f y (12.12b) (b) EdnkMNt;EdkBRgwgGb,brma (Minimum reinforcement)³ enARKb;muxkat;TaMgGs; brimaNEdkrgeRbkugRtaMg nigEdkminrgeRbkugRtaMgRtUvRKb;RKanedIm,I begáItersIusþg;Tb;Tl;karBt;begáagemKuN M t y:agehacNas;RtUvesμInwg 1.2M cr EdlkMNt; edayEp¥kelIeKalkarN_viPaKeGLasÞic b¤esIμnwg 1.33dgénm:Um:g;emKuNEdlTamTaredaybnSM bnÞúk. ⎡S ⎤ M cr = ( f r + f ce )S b − M dnc ⎢ bc − 1⎥ (12.13) ⎣ Sb ⎦ Edl M dnc = m:Um:g;EdlbNþalBI non-composite dead load Sb = m:UDulmuxkat; non-composite S bc = m:UDulmuxkat;smas f r = m:UDuldac; (modulus of rupture) = 7.5 f 'c psi = 0.24 f 'c ksi f ce = kugRtaMgsgát;enAkñúgebtugedaysarEteRbkugRtaMgRbsiT§PaB ¬eRkaykMhatbg;¦ enARtg;srésrgkarTajxageRkAbMputrbs;muxkat;EdlkugRtaMgTajekItBIbnÞúk xageRkA. 12.4. karBicarNaBIkarsikSaKNnakMlaMgkat; Shear Design Considerations 12.4.1. The Modified Compression Field Theory RTwsþI compression field sMrab;kMlaMgkat; nigsMrab;kMlaMgkat;EdlpSMCamYynwgkarrmYlRtUv)an erobrab;enAkñúgEpñk 5.17.3 énCMBUk 5. enAeBlEdlmankarrmYl eKsnμt;faebtugminTb;Tl;karTajeT bnÞab;BImansñameRbH ehIyEdn (field) én compressive strut Tb;Tl;kMlaMgkat;Ggát;RTUg. mMu θ rbs; strut enHERbRbYlGaRs½ynwgbMErbMrYlrageFobbeNþay (longitudinal strain), bMErbMrYlrageFobxag (transverse strain) nigbMErbMrYlrageFobem (principal strain) enAkñúgRTnug³ karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 767

- 24. T.Chhay viTüasßanCatiBhubec©keTskm<úCa ε x − ε2 tan 2 θ = (12.14) εt − ε2 Edl εx =bMErbMrYlrageFobbeNþayrbs;RTnug ¬rgkarTaj viC¢man¦ ε t = bMErbMrYlrageFobTTWg ¬rgkarTaj viC¢man¦ ε 2 = bMErbMrYlrageFobrgkarsgát;em GviC¢man rUbTI 12>8 bgðajEdnkugRtaMg (stress field) enAkñúgRTnugrbs;FñwmEdlminrgeRbkugRtaMgmun nigeRkay eBlmansñameRbH. muneBlFñwmeRbH kMlaMgkat;RtUv)anTb;Tl;edaykugRtaMgTajGgát;RTUg nigkugRtaMg sgát;Ggát;RTUgesμIKña edayeFVIGMeBItammMu 45o ¬rUbTI 12>8(a)¦. eRkayeBlmansñameRbH sñameRbH Ggát;RTUgEdlekItBIkugRtaMgTajenAkñgebtugRtUv)ankat;bnßyy:ageRcIn. ú enAkñúgRTwsþI compression field eKsnμt;fakugRtaMgTajem f1 = 0 dUcenAkñúgrUbTI 12>8 (b) eRkayeBlebtugeRbH. RTwsþI modified compression field KitbBa©ÚlkarcUlrYménkugRtaMgTajenA kñúgebtugcenøaHsñameRbH dUcenAkñúgrUbTI 12>8 (c). BIrgVg;kugRtaMgm: (Mohr’s stress circle) enAkñúgrUb TI 5>2 (b) enAkñúgCMBUk 5 CamYynwgrUbTI 12>8 (c) eKGacTTYl)ansmIkarxageRkam f 2 = (tan θ + cot θ )v − f1 (12.15a) EdlkugRtaMgkMlaMgkat;Gnuvtþn_KW v= V = ( Vu − θV p ) (12.15b) bw jd φbw d v ( dv = d p − a / 2 ) nig bw = TTwgRTnugRbsiT§PaB. eKGackMNt;EdkRTnugrgkarTaj (tension web reinforcement) Av EdlTamTarsMrab;eFVIeGaykugRtaMgsgát;manlMnwgdUcxageRkam Av f v = ( f 2 sin 2 θ − f1 cos 2 θ )bw s (12.16) LRFD and Standard AASTHO Design of Concrete Bridges 768

- 25. Department of Civil Engineering NPIC Edl Av fv CabgÁúMbBaÄrén balancing tensile force edIm,IbiTP¢ab;sñameRbHeRTtEdlmanmMu θ nig f v CakugRtaMgmFümenAkñúgEdkkgbBaÄr. edayCMnYs f 2 enAkñúgsmIkar 12.15(a) eTAkñúgsmIkar 12.16 eyIg)an³ Av f v V = f1bw d v cot θ + d v cot θ (12.17) s Edl V tMNageGayVn ehIyvaesμInwg (Vc + Vs ) / Edl Vs CakMlaMgkat;EdlTb;Tl;edayEdkkg bBaÄr. 12.4.2. smIkarKNna Design Expressions tamkarsnμt;EdlmanlkçN³sMrYl eKGacerobcMsmIkareKalén modified compression field theory eLIgvij dUcenHeKGackMNt;ersIusþg;kMlaMgkat; nominal Vn enAkñúgebtugeRbkugRtaMg Vn = Vc + Vs + V p (12.18) Edl Vc = ersIusþg;kMlaMgkat; nominal EdleGayedaykugRtaMgTajenAkñúgebtug Vs = ersIusþg;kMlaMgkat; nominal EdleGayedaykugRtaMgTajenAkñúgEdkRTnug V p = ersIusþg;kMlaMgkat; nominal EdleGayedaybgÁúMkugRtaMgbBaÄrénEdkeRbkugRtaMg harped b¤ draped tamTisbeNþay. 12.4.2.1. AASTHO Standard Specification (LFD) karpþl;eGayrbs; AASTHO standard nig ACI 318 KWmanlkçN³RsedogKña edayeKyk Vc nUv tMélEdltUcCagkñúgcMeNamsmIkarTaMgBIrxageRkamEdlbgðaj nigerobrab;y:aglMGitenAkñúgEpñk 5.5.1 nig 5.5.2 énCMBUk 5³ (a) kMlaMgkat;Bt;begáag (Flexural shear)³ Vi M cr Vci = 0.6 f 'c bw d + (12.19) M max (b) kMlaMgkat;RTnug (Web shear)³ Vcw = [3.5 f 'c + 0.3 f c ]bw d + V p (12.20) sMrab; AASTHO smIkarm:Um:g;eRbH (cracking moment) KW ( M cr = St 6 f 'c + f pe − f d ) karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 769

- 26. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 12.4.2.2. LRFD Specification karpþl;eGayrbs; LRFD AASTHO TTYlsÁal;viFIBIr³ (a) Strut-and-tie model EdlGacGnuvtþ)anRKb;ragGrNImaRtrbs;muxkat;TaMgGs;Edlman lkçN³Fmμta nigminCab;. (b) Modified compression field EdlEp¥lelIm:UEdl truss EdlmanmMuERbRbYl EdlenAkñúgenaHeK GnuBaØateGayERbRbYlCMralrbs; diagonal compression field. vaxusBIviFI LFD Rtg;kar snμt;mMu θ eGayesμInwg 45o ¬EdlkñúgenHebtugsuT§k¾cUlrYmeFVIkarEdr¦ ehIy Vc RtUv)anGnuvtþ karTajEdlqøgkat; compression diagonal dUcerobrab;enAkñúgEpñk 12.4.1. eKykersIusþg; nominal nUvtMélEdltUcCageKkñúgcMeNam³ Vn = Vc + Vs + V p (12.21) b¤ Vn = 0.25 f 'c bv d v (12.22) Edl TTwgRTnugRbsiT§PaB bv = d v = kMBs;kMlaMgkat;RbsiT§PaB ≈ (d p − a / 2 ) a = kMBs;rbs;bøúksgát; muxkat;eRKaHfñaksMrab;kMlaMgkat;sßitenAcMgay dv b¤ (0.5dv cot θ ) edayykmYyNaEdlFM Cag. eKyktMél dv BIkarKNnaersIusþg;Bt;begáagkNþalElVg. ersIusþg;kMlaMgkat; nominal rbs;ebtugsuT§ Vc EdlKitCa psi KW Vc = β f 'c bv d v (12.23) nigKitCa ksi Vc = 0.0361β f 'c bv d v (12.24) emKuN 0.0361 KW 1 / 1000 EdlCaemKuNsMrab;bMElgBI psi eTA ksi . eKykersIusþg;kMlaMgkat;énkarcUlrYmrbs;EdkRTnugbBaÄrKW Av f y d v cot θ Vs = (12.25) s eKRtUvdak;Edkkg (transverse shear reinforcement) enAeBlEdlkMlaMgkat;emKuN Vu FMCaglT§PaB Tb;kMlaMgkat;rbs;ebtugsuT§ b¤ ( Vu > 0.5φ Vc + V p ) (12.26) EdlemKuNkat;bnßyersIusþg; φ RtUv)anykBItarag 12>1(a). LRFD and Standard AASTHO Design of Concrete Bridges 770

- 27. Department of Civil Engineering NPIC elIsBIenH enAeBlEdlkMlaMgRbtikmμrbs;FñwmbBa¢Únkarsgát;eTAcugrbs;Ggát;dUcEdlekItman enAkñúgkrNICaeRcIn eKykmuxkat;eRKaHfñak;enARtg;TItaMgq¶ayCag 0.5dv cot θ b¤ dv EdlvaBIépÞrbs; TMr. edIm,IkMNt;ersIusþg;kMlaMgkat; nominal rbs;Ggát;eRbkugRtaMg visVkrKNnaeRKOgbgÁúMRtUvkMNt; tMélrbs; β nig θ EdlRtUvkatsMrab;kMNt;Vc nig Vs enAkñúgsmIkar 12.21 nig 12.22. sMrab;muxkat; ebtugminrgeRbkugRtaMg eKyk β = 2.0 nigθ = 45o . sMrab;muxkat;ebtugeRbkugRtaMg/ trial-and- adjustment eRbItMél β tUc. tarag 12>8 bgðajBItMélrbs; β nig θ sMrab;tMélepSg²rbs; ε x . eKTTYl)anbMErbMrYlrageFob ε x enAkñúgEdkrgkarTajBIsmIkarxageRkam RbsinebImuxkat;y:ag ehacNas;manEdkTTwg (transverse reinforcement) Gb,brma ⎡ Mu ⎤ ⎢ d + 0.5 N u + 0.5Vu cot θ − Aps f po ⎥ εx = ⎢ u ⎥ ≤ 0.002 ⎢ ( 2 Es As + E ps A ) ⎥ (12.27) ⎢ ⎣ ⎥ ⎦ Edl . f po ≅ 0.70 f pu eKRtUvKuNtMélenAkñúgsmIkar 12.27 nwgBIr RbsinebImuxkat;manEdkkgticCagEdkkgGb,- brma. kugRtaMg f po CakugRtaMgenAkñúgkabeRbkugRtaMgenAeBlGnuvtþeRbkugRtaMg (jacking) sMrab;Ggát; karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 771

- 28. T.Chhay viTüasßanCatiBhubec©keTskm<úCa rgeRbkugRtaMgCamun (pretensioned member) ehIysMrab;suvtßiPaB vaCakugRtaMgmFümsMrab;EdkeRb kugRtaMgenAkñúgGgát;rgeRbkugRtaMgCaeRkay (post-tensioned member). sMrab;kabeRbkugRtaMgFmμta eKyk f po = 0.75 f pu sMrab;TaMgGgát; pretensioned nigTaMgGgát; post-tensioned. f ce = kugRtaMgsgát;rbs;ebtugenARtg;TIRbCMuTMgn;rbs;muxkat;smasEdlTb;Tl;nwgbnÞúkGefr b¤enARtg;TIRbsBVrvagRTnug nigsøab RbsinebIvasßitenAkñúgsøabEdlbNþalBIeRbkugRtaMg nigm:Um:g;Bt;EdlTb;Tl;edaymuxkat;cak;Rsab;EdleFVIkarEtxøÜnÉg mann½yfamunnwgeFVI karCamuxkat;smas. f pe = kugRtaMgRbsiT§PaBenAkñúgEdkeRbkugRtaMgeRkayeBlxatbg;/ CalkçN³suvtßiPaB eKyk f po CaeRbkugRtaMgRbsiT§PaB f pe . RbsinebIbMErbMrYlrageFobenAkñúgEdkrgkarTajGviC¢man eKRtUvKuN ε x CamYynwgemKuN Fε EdlmansmIkardUcxageRkam Es As + E ps Aps Fε = (12.28) Ec Ac + Es As + E ps Aps Edl Ac = RkLaépÞrbs;muxkat;ebtugénEpñkrgkarTajedaykarBt;begáagrbs;Ggát; dUcbgðajenA kñúgrUbTI 12>9. EdkbeNþayRtUvmansmamaRty:agNaedIm,IeGaymuxkat;FñwmnImYy²bMeBjsmIkarxageRkam³ Mu N ⎛V ⎞ As f s + Aps f ps ≥ + 0.5 u + ⎜ u + 0.5Vs + V p ⎟ cot θ ⎜φ ⎟ (12.29) d vφ φ ⎝ ⎠ BIsmIkar AASTHO elIkmun GBaØat β CaemKuNy:agsMxan;kñúgkarkMNt;ersIusþg;kMlaMgkat; Fmμta (nominal) Vc dUcenAkñúgsmIkar 12.21. karbgðajtMélrbs; β EdlEp¥kelI compression LRFD and Standard AASTHO Design of Concrete Bridges 772

- 29. Department of Civil Engineering NPIC field theory enAkñúgtarag 12>8 bgðajfatMélTaMgenHhak;minGaceRbI)ansMrab;pleFob (v / f 'c ) FMCag 0.125 enAeBlEdlbMErbMrYlrageFobtUcCag 0.005 . Hsu )anerobrab;nUvPaBBi)akenH EdlekIt eLIgenAeBlkMNt;tMélkugRtaMgkMlaMgkat;sñameRbH (crack shear stress) vci mann½yfa lT§PaBén crack interface edIm,IepÞrkugRtaMgkMlaMgkat;EdlGaRs½yelITMhMsñameRbH w enAkñúgsmIkarxageRkam 2.16 f 'c 0.18 f 'c vci ≤ psi, w(in.) vci ≤ MPa, w(mm ) 24 w 24 w 0 .3 + 0 .3 + a + 0.63 a + 16 HsuesñIeGayeRbI vci = 0 edIm,IrkSalMnwg nigPaBRtUvKña (compatibility). ehIy mMusñameRbH θ enAkñúgtY Vs énsmIkar 12.25 KWCamMucenøaHkugRtaMg¬bMErbMrYlrageFob¦EdkbeNþay nigkugRtaMg ¬bMEr bMrYlrageFob¦sgát;emrbs;ebtug. edaysarEbbenH kugRtaMgkMlaMgsgát;tambeNþayG½kSemesμInwg sUnü. ehIy karerobrabenHGnuvtþenAkñúgkarpþl;eGayrbs; LRFD sMrab;krNIénbnSMkMlaMgkat; nigkar rmYl. 12.4.2.3. KMlatGtibrmarbs;EdkRTnug Maximum Spacing of Web Reinforcement KMlatGnuBaØatGtibrma s rbs;EdkRTnugKWtMélEdltUcCageKkñúgcMeNam s ≤ 0.75h b¤ 24in. RbsinebI Vs > 4 f 'c bwd / KMlatGnuBaØatGtibrmaRtUv)ankat;bnßy 50% . 12.5. Horizontal Interface Shear eKalkarN_én horizontal interface shear eRkamGMeBI service load nig ultimate load RtUv)an erobrab;eBjeljenAkñúgCMBUk 5 Epñk 5.7 EdlrYmman]TahrN_bgðajEdlGnuelamtamtMrUvkar ACI 318 nig PCI. AASTHO standard specification tMrUveGayersIusþg;kMlaMgkat;tamTisedk nominal Vnh dUcKñanwgersIusþg;kMlaMgkat;rbs; ACI enAeBlEdleKmineRbI dowel reinforcement mann½yfakug RtaMgGnuBaØatGtibrmaKW 80 psi . vaxusKña enAeBleKeRbI dowel reinforcement Gb,brma Edlkñúg enaHkugRtaMgkMlaMgkat;edkGnuBaØatGtibrmaKW 350 psi EdlCMnYseGay 500 psi EdlGnuBaØateday ACI. tamkarGegát nigBiesaFn_d¾sIuCMerArbs; Nawy )anbgðajeGayeXIjfakugRtaMgGnuBaØatBitCa tUcEmnETn. karBiesaFbgðajfa sUm,IEtersIusþg;dMbUgeRkamlkçxNÐsItuNðPaB sub-freezing/ vaGac karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 773

- 30. T.Chhay viTüasßanCatiBhubec©keTskm<úCa TTYlersIusþg;eRkamGMeBI ultimate load FMCag 1200 psi(8.3MPa) edayeRbI dowel reinforcement bBaÄr. Standard AASTHO TamTardUcxageRkam³ (a) enAeBleKmindak; vertical ties Vnh = 80bv d (12.30a) (b) enAeBleKmindak; vertical ties Gb,brma Vnh = 500bv d (12.30b) (c) RkLaépÞtMrUvkarrbs; Avh FMCag vertical ties Gb,brma dp Vnh = 500bv d + 0.40 Avh f y (12.30b) s Edl kMlaMgkat;bBaÄremKuN Vu = φVnh Vnh = ersIusþg;kMlaMgkat;edk nominal φ = 0.90 Gb,brma = 50bv s / f y Avh bv = TTwgrbs;muxkat;enARtg;épÞb:HEdlRtUvviPaKkMlaMgkat;edk b p = cMgayBIsrésrgkarsgát;xageRkAbMputeTATIRbCMuTMgn;rbs;EdkeRbkugRtaMg b:uEnþ minRtUvyktUcCag 0.80h s = kMlatGtibrmarbs; dowel b:uEnþminRtUvFMCagbYndgénTTwgRTnugEdltUcCageK rbs;Ggát;TMr b¤ 24in. . LRFD specification min)anpþl;nUveKalkarN_ENnaMsMrab;KNnakMlaMgkat;edk Vnh eT. dUcenH eKGaceRbIsmIkarxageRkam Vu vuh = (12.31) bv d v Edl kugRtaMgkMlaMgkat;edkemKuN vuh = Vu = kMlaMgkat;bBaÄremKuN d v = cMgaycenøaHkMlaMgpÁÜbénkMlaMgTaj nigénkMlaMgsgát; = (d − a / 2 ) bv = TTwg interface LRFD kMNt;eGayKNnaersIusþg;kMlaMgkat; nominal rbs; interface surface Vn edayeRbI smIkarxageRkam³ [ Vn = cAcv + μ Av f y + Pc ] (12.32) LRFD and Standard AASTHO Design of Concrete Bridges 774

- 31. Department of Civil Engineering NPIC nig vuh Acv ≤ φVn (12.33) Edl c=emKuNs¥it (cohesion factor) μ = emKuNkkit Acv = RkLaépÞ interface rbs;ebtugEdlBak;B½n§nwgkarepÞrkMlaMgkat; Avf = RkLaépÞrbs;EdkkMlaMgkat;Edlkat;tambøg;kMlaMgkat;enAkñúgRkLaépÞ Ac Pc = kMlaMg net compressive Gcié®nþy_EdlEkgeTAnwgbøg;kMlaMgkat; ¬Gaclubecal eday lkçxNÐsuvtßiPaB¦ f y = yield strength rbs; dowel reinforcement CaTUeTA eKEtgEteFVIeGayépÞxagelIbMputrbs;Ggát;cak;Rsab;manlkçN³eRKIm ¬CMerARbEhl 0.24in. ¦ edIm,Icak;ebtugTMgn;FmμtabEnßm dUcerobrab;enAkñúgEpñk 5.7. LRFD ENnaMnUvsmIkarsMrYl 12.32 nig 12.33 dUcxageRkamEdlmanxñatCa ksi ³ ⎛ Avf ⎞ vuh ≤ φ ⎜ 0.1 + ⎜ ⎟ (12.34) ⎝ Acv ⎟ ⎠ EdlRkLaépÞGb,brma 0.05bv s Avf = (12.35) fy ehIy eKRtUvykersIusþg;kMlaMgkat; nominal nUvtMéltUcCageKkñúgcMeNam Vn ≤ 0.20 f 'c Acv (12.36a) b¤ Vn = 0.80 Acv (12.36b) emKuNs¥it c nigemKuNkkit μ enAkñúgsmIkar 12.32 mantMéldUcxageRkamsMrab;lkçxNÐCak;lak; rbs; interacting surface³ (a) ebtugEdlcak;kñúgeBlCamYyKña c = 145 psi μ = 1.4λ (b) ebtugEdlcak;elIebtugrwg nigs¥atehIyépÞrbs;vaeRKIm c = 100 psi μ = 1.0λ (c) ebtugEdlcak;elIebtugrwg s¥at nigminmansarFatuehIyépÞrbs;vamineRKIm c = 75 psi μ = 0.6λ (d) ebtugRtUv)ancak;f<k;eTAnwg as-rolled structural steel eday headed stud b¤eday reinforcing bars EdlRKb;EdkTaMgGs;P¢ab;CamYynwgebtugKWs¥atminmanlabfñaM karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 775

- 32. T.Chhay viTüasßanCatiBhubec©keTskm<úCa c = 25 psi μ = 0.7λ Edl sMrab;ebtugdg;sIuetFmμta λ = 1 .0 = 0.85 sMrab; sand-low-density concrete = 0.75 sMrab;ebtugEdlmandg;sIuettUcdéTTaMgGs; xN³Edl LRFD AASTHO specification TamTareGaydak;EdkGb,brmaedayminKittMél rbs;kugRtaMgenARtg; interface, GñkKNnaGaceRCIserIsedIm,IkMNt;EdkenHeTAnwgkrNIEdlVuh / φ FM Cag 100 psi(0.7MPa ) . kareFVIEbbenH edIm,IeGayRsbeTAnwg ACI 318 Code specification nig standard AASTHO specification. 12.5.1. KMlat Dowel Reinforcement Gtibrma KMlatGnuBØatGtibrmarbs; dowel KW (i) RbsinebI Vu < 0.1 f 'c bv d v KMlatGtibrma s ≤ 0.8d v ≤ 24in. (ii) RbsinebI Vu > 0.1 f 'c bv d v KMlatGtibrma s ≤ 0.4d v ≤ 12in. 12.6. bnSMkMlaMgkat; nigkarrmYl Combined Shear and Torsion kareobrab;enAkñúgEpñk 12.4.1 GMBI compression field theory CamYynwgEpñk 5.17.3 bgðajBI karbMErbMrYlrageFob kMlaMgkat; nigGgát;rgkarsgát;Ggát;RTUg. rUbTI 5>38/ 5>39 nig 5>40 bgðajBI rUbragxUcRTg;RTayrbs;muxkat;eRKaHfñak;enAeBlrgm:Um:g;rmYl (torsional moment). eKsnμt;eGay bEnßmkugRtaMgkat;EdlbNþalBIkarmYl nigkMlaMgkat;enAelIRCugmçagrbs;muxkat; nigdak;eGayRbqaMg enAelIRCugQm. Edk transverse closed tie RtUv)ansikSaKNnasMrab;RCugEdlenAkñúgenaHeKRtUv bEnßmbnSMénT§iBlkMlaMgkat; nigkMlaMgrmYl. bnÞúkxageRkAEdlbgáeGaymanm:Um:g;rmYlFMbMputmindUcKñanwgbnÞúkEdlbgáeGaymankMlaMgkat; GtibrmaenARtg;muxkat;eRKaHfñak;eT. eKalbMNgrbs;GñksikSaKNnaKWbUkbBa©ÚltMélx<s;bMputénkar rmYl nigtMélx<s;bMputrbs;kMlaMgkat;kñúgkarKNnaEdkRTnug. enHBitCamansuvtßiPaB. eKGaceRbIPaB xusKñaénkMlaMgTaMgBIrenH edIm,IKNna transverse reinforcement sMrab;kMlaMgrmYlx<s;bMput CamYynwg kMlaMgkat;EdlekIteLIgkñúgeBlCamYyKña b¤k¾KNnasMrab;kMlaMgkat;x<s;bMput CamYynwgkMlaMgrmYlEdl ekIteLIgkñúgeBlCamYyKña edayykmYyNaEdlnaMeGaymanersIusþg;x<s;bMput. LRFD eRbIm:Um:g;Edl LRFD and Standard AASTHO Design of Concrete Bridges 776

- 33. Department of Civil Engineering NPIC Tb;Tl;karrmYl nominal dUcKñanwg ACI³ 2 Ao At f y cot θ Tn = (12.37) s Edl RkLaépÞmuxkat;EdlB½T§CMuvijeday shear flow path EdlrYmbBa©ÚlTaMgRbehag Ao = At = RkLaépÞrbs;eCIgmYyénEdkrgkarTajbiTCit θ = mMuénsñameRbHEdl)aneRCIserIseday trial-and-adjustment edayeRbItarag 12>8 edIm,IkMNt;tMélrbs; θ / eKTTYl)anbMErbMrYlrageFob ε x enAkñúgEdkrgkarTajBIsmIkar 12.27 elIkElgsMrab;karCMnYs Vu eday 2 ⎛PT ⎞ Vu = Vu2 +⎜ h u ⎜ 2A ⎟ ⎟ (12.38) ⎝ o ⎠ eKTTYlbrimaN transverse reinforcement tMrUvkarsMrab;kMlaMgkat;BIsmIkar 12.21(a) CamYy nwgsmIkar 12.23(a) nig 12.25 mann½yfa Av f y d v cot θ Vn = β f 'c bv d v + +Vp (12.39) s dUcenH sMrab;kMlaMgkat;KitCa lb nigkugRtaMgKitCa psi Av Vn − (β f 'c bv d v + V p ) = (12.40a) s f y d v cot θ RbsinebIeKeRbIxñat ksi eKRtUvKuN β eday 0.0316 . ehIysMrab;karrmYl BIsmIkar 12.31 At Tn = (12.40b) s 2 Ao f y cot θ RkLaépÞsrubrbs;EdkRTnug (web reinforcement) KW Avt Av A = +2 t (12.40c) s s s eKTTYl)anmMu θ BIrUbTI 12>9 edayeRbIkugRtaMgkMlaMgkat; v dUcxageRkam (a) muxkat;RbGb;³ Vu − φV p T p Ph V= + (12.41) φbv d v φAoh 2 (b) muxkat;epSgeTot³ 2 2 ⎛ Vu − φV p ⎞ ⎛ Tu Ph ⎞ V= ⎜ ⎟ +⎜ ⎟ (12.42) ⎜ φb d ⎟ ⎜ φA 2 ⎟ ⎝ v v ⎠ ⎝ oh ⎠ Edl Ph = brimaRtrbs;ExSG½kSén enclosed transverse torsion reinforcement karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 777

- 34. T.Chhay viTüasßanCatiBhubec©keTskm<úCa Aoh = RkLaépÞbiTCitedayExSG½kSén closed torsional reinforcement xageRkAeK bMput Ao = gross area B½T§CMuvijeday shear flow path ¬emIlrUbTI 5>45 sMrab;karbgðaj Ao nig Aoh Edl Ao ≅ 0.85 Aoh ¦ Tu = m:Um:g;rmYlemKuN φ = emKuNersIusþg; eKTTYl)antMélrbs; β enAkñúgsmIkar 12.39 sMrab;kMNt;ersIusþg;kMlaMgkat; Vc énebtugsuT§enAkñúgRT- nugBI chart enAkñúgrUbTI 12>9. edIm,IeCosvagkMueGayEdkbeNþay yield eKRtUvRtYtBinitüfaEdkrgkar Bt;enAelIépÞrgkarTajRtUvEtsmamaRtedIm,IbMeBjlkçxNÐxageRkam³ 2 ⎛ 0.45Tu Po ⎞ φ (As f y + A ps f ps ) ( ) M ≥ u + 0.5 N u + cot θ Vu − 0.5Vs − V p 2 +⎜ ⎜ 2A ⎟ ⎟ (12.43) dv ⎝ o ⎠ Edl Po = brimaRtrbs; shear flow path N u = kMlaMgtamG½kSGnuvtþn_/ ykviC¢manRbsinebICakMlaMgsgát; 12.7. AASTHO-LRFD Flexural-Strength Design Specifications vs. ACI Code Provisions vamanPaBxusKñarvagviFIrbs; AASTHO-LEFD flexural-strength design specification nig ACI-318 code provisions. viFI LRFD KWEp¥kelItMélkMNt;rbs;bMErbMrYlrageFobEdlerobrab;enAkñúg Epñk 12.3 nigRKb;RKgedaypleFobénkMBs;G¾kSNWt c elIkMBs;RbsiT§PaB d e . viFIenHk¾RtUv)aneK ehA fa unified approach edaysarvaGacGnuvtþ)ansMrab;karsikSaKNnasßanPaBkMNt;cugeRkay (ultimate) cMeBaHGgát;ebtugGarem: Ggát;ebtugeRbkugRtaMg nigGgát;ebtugeRbkugRtaMgedayEpñk. eK)anGnuvtþ ACI 318 code strength provision sMrab;kMNt; ultimate design strength f ps enAkñúg ]TahrN_CaeRcIndUcmanenAkñúgEpñk 4.9 nig 4.10. eKGnuvtþvaenAkñúgkarsikSaKNnaGgát;ebtugeRbkug RtaMgeBjelj nigGgát;ebtugeRbkugRtaMgedayEpñkenAkñúgeRKOgbgÁúMsMNg;. AASTHO standard specification bc©úb,nñEdlKNnasmamaRtmuxkat;Ggát;ebtugeRbkugRtaMgEdlrgkarBt;KWGnuvtþtam ACI code provisions. LRFD alternative EdlCaviFI rational design TamTarkarGnuvtþ strain limits unified procedure. taragTI 12>9 bgðajBIkareRbobeFobCasegçbEdlbgðajPaBxusKñarvag smIkarEdl)ankMNt;enAkñúgviFITaMgBIrenH. LRFD and Standard AASTHO Design of Concrete Bridges 778

- 35. Department of Civil Engineering NPIC karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 779

- 36. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 12.8. viFIsikSaKNnaCaCMhan² Step-by-Step Design Procedure (LRFD) xageRkamCakarsegçbénCMhankñúgkarsikSaKNna³ !> kMNt;faetIeKRtUveRCIserIskMlaMgeRbkugRtaMgedayEpñk b¤Gt; @> eRCIserIsm:Um:g;Bt; nigkMlaMgkat;BItarag 12.2(a) nig (b) Epñk 12.7. LRFD and Standard AASTHO Design of Concrete Bridges 780

- 37. Department of Civil Engineering NPIC #> GnuvtþtamCMhanbnþbnÞab;sMrab;KNnaGgátr; gkarBt;begáagEdlmanerobrab;enAkñúgCMhan 2 rhUtdl;CMhanTI 10 énEpñk 4.13 kñúgCMBUk 4 nig flowchart énrUbTI 12>10 enAeBleRbI LRFD method sMrab;karKNnaGgát;rgkarBt;begáag. CaTUeTA d v = (d e − a / 2) . $> kMNt;kMlaMgkat;emKuN Vu EdlbNþalBIbnÞúkGnuvtþn_TaMgGs;enARtg;muxkat;eRKaHEdlsßit enAcMgay d v b¤ 0.5d v cot θ BIépÞrbs;TMr edayykmYyNaEdlFMCageK Edl d e = kMBs;RbsiT§PaBdUcbgðajenAkñúgtarag 12>9 = d p RbsinebIeKmineRbIEdkBRgwgFmμta %> KNnabgÁúMkMlaMgkat;rbs;kabeRbkugRtaMg VP . kugRtaMgkMlaMgkat;emKuNKW Vu − φV p v= φbv d v kugRtaMgkMlaMgkat;EdlGacman nominal vc = v / h ^> KNna v / f 'c nigsnμt;tMélrbs; θ . karsnμt;dMbUgd¾l¥sMrab;FñwmrgeRbkugRtaMgKW θ = 25o &> KNnabMErbMrYlrageFobenAkñúgEdkrgkarTajedIm,ITTYl)antMélsakl,gθ nig β enAkñúg tarag 12>8 ⎡ Mu ⎤ ⎢ d + 0.5 N u + 0.5Vu cot θ − A ps f po ⎥ εx = ⎢ v ⎥ Fe ≤ 0.002 ⎢ ( 2 E s As + E ps A ps ) ⎥ ⎢ ⎥ ⎣ ⎦ Edl f po ≅ 0.70 f pu kugRtaMgsgát;enAkñúgebtugenARtg;TIRbCMuTMgn;rbs;EdkTajedayKitTaMgkMlaMg f ce = eRbkugRtaMgbnÞab;BIkMhatbg; nigbnÞúkGcié®nþTaMgGs;. RbsinebIbMErbMrYlrageFobenAkñúgEdkrgkarTajGviC¢man eKRtUvKuN ε x edayemKuN Fε ³ E s As + E ps A ps Fε = Ec Ac + E s As + E ps A ps Ac =RkLaépÞrbs;ebtugenAEpñkrgkarTajedaysarBt;begáagrbs;Ggát; *> bBa©ÚleTAkñúg LRFD rUbTI 12>9 mþgeTot CamYynwgtMél v / f 'c nig ε x RbsinebImMu θ min mantMélEk,rnwgtMélsnμt;enAkñúgkarsakl,geLIgdMbUgeTenaH edIm,ITTYl)antMélEktMrUv rbs; β . ebImindUecñaHeT KNna Vc BIsmIkar 12.23 Edl Vc = β f 'c bv d v (lb) b¤ Vc = 0.0316β f 'c bv d v (kip ) edayeRbItMél β Edl)anBI chart enAkñúgrUbTI 12>9. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 781

- 38. T.Chhay viTüasßanCatiBhubec©keTskm<úCa (> KNna Vs sMrab;EdkRTnug eRkayeBlkMNt;tMélrbs; Vc rYcehIy. kMNt;KMlatrbs;Edk kMlaMgkat;EdlRtUvKñaBI³ bv s Av = 0.036 f 'c fy !0> enAkñúgtMbn;énkugRtaMgkat;FM FanafabrimaNrbs;EdkbeNþay As nig Aps RtUvbMeBj smIkarxageRkam³ ⎡M N ⎛V ⎞ ⎤ As f y + A ps f ps ≥ ⎢ u + 0.5 u + ⎜ u − 0.5Vs − V p ⎟ cot θ ⎥ ⎜φ ⎟ ⎣ d vφ φ ⎝ ⎠ ⎦ eKENnaMeGayeFVIkarRtYtBinitüenARtg;épÞén bearing EdlsßitenAelIRbEvgepÞrrbs; strand EdlminmanekItkMlaMgeRbkugRtaMgRbsiT§PaBeBjelj. !!> enAeBlmankarrmYlrYmpSMCamYynwgkMlaMgkat; nigkarBt;begáag eKcaM)ac;RtUvGnuvtþtamCM hanxageRkam kMlaMgrmYl nominal Tn = 2 Ao At sf y cot θ bMErbMrYlrageFobenAkñúgEdkrgkarTaj ⎡M ⎛PT ⎞ ⎤ ⎢ u + 0.5 N u + 0.5 cot θ Vu2 + ⎜ h u ⎜ 2A ⎟ − A ps f po ⎥ ⎟ ⎢ dv ⎝ o ⎠ ⎥ εs = ⎢ ⎥ Fe ≤ 0.002 ⎢ ( 2 E s As + E ps A ps ) ⎥ ⎢ ⎥ ⎣ ⎦ Edl f po = 0.70 f pu ersIusþg;kMlaMgkat; nominal Av f y d v cot θ Vn = Vc + Vs + V p = β f 'c bv d v + +Vp s Edl d v = (d p − a / 2) EdkkMlaMgkat; Av Vn − 0.0316 β f 'c bv d v + V p = s f y d v cot θ kMlaMgKitCa kips ehIykugRtaMgKitCa ksi . sMrab;kareRbI lb nig psi ykemKuN 0.0316 ecj. EdkrmYl LRFD and Standard AASTHO Design of Concrete Bridges 782

- 39. Department of Civil Engineering NPIC At Tn = s 2 Ao f y cot θ EdkRTnugbiTCitsrub (total web closed ties reinforcement) Avt Av A = +2 t s s s kugRtaMgkMlaMgkat; v sMrab;TTYl)anmMu θ (a) muxkat;RbGb;³ Vu − φV p TPh v= + φbv d v φAo h 2 (b) muxkat;epSgeTot 2 2 ⎛ Vu − φV p ⎞ ⎛ TPh ⎞ v= ⎜ ⎟ +⎜ ⎟ ⎜ φb d ⎟ ⎜ φA 2 ⎟ ⎝ v v ⎠ ⎝ oh ⎠ edIm,IeCosvagkMueGayEdkrgkarTajbeNþay yield³ 2 ⎛ 0.45Tu Ph ⎞ φ (As f s + A ps f ps ) ( ) M ≥ u + 0.5 N u + cot θ Vn − 0.5Vt − V p 2 +⎜ ⎜ 2A ⎟ ⎟ dv ⎝ o ⎠ !@> RtYtBinitükMlaMgkat; interface edk³ vn Acv ≤ φVn Edl ( Vn = cAcv + μ Avf f y ) ⎛ Avf ⎞ vuh ≤ φ ⎜ 0.1 + ⎜ ⎟ ⎟ ⎝ Acv ⎠ Edl Avf = 0.05bv s fy ¬ f y KitCa ksi ¦ ykersIusþg;kMlaMgkat; nominal CatMéltUcCageKkñúgcMeNam Vn ≤ 0.20 f 'c Acv b¤ Vn ≤ 0.80 Acv Edl c = emKuNs¥it (cohesion factor) μ = emKuNkkit Acr = RkLaépÞ interface ebtug = bv I v Avf = RkLaépÞrbs;EdkkMlaMgkat;Edlkat;tambøg;kMlaMgenAkñúgépÞ Acv φ = emKuNkat;bnßyersIusþg; kñúgkrNIEdl vuh / φ > 100 psi eKRtUvkMritEdnkMNt;rbs; Avf . karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 783

- 40. T.Chhay viTüasßanCatiBhubec©keTskm<úCa rUbTI 12>10 bgðajBI flowchart sMrab;CMhanEdlRtUvGnuvtþedIm,IkMNt;ersIusþg;m:Um:g; nominal sMrab; bonded tendons nig unbonded tendons. !#> KMlatGnuBaØatGtibrmarbs;EdkkMlaMgkat;RTnug (web shear reinforcement) s ≤ 0.75h ≤ 24in. RbsinebI Vs > 4 f 'c bwd / kat;bnßyKMlat 50% sMrab;KMlat dowel reinforcement RbsinebI Vu < 0.1 f 'c bv d v / s ≤ 0.8d v ≤ 24in. RbsinebI Vu > 0.1 f 'c bv d v / s ≤ 0.4d v ≤ 12in. Edl bv = TTwgénépÞb:HsMrab;kMlaMgkat;edk LRFD and Standard AASTHO Design of Concrete Bridges 784

- 41. Department of Civil Engineering NPIC 12.9. LFRD Design of Bulb-Tee Bridge Deck ]TahrN_ 12>1³ sikSaKNnaFñwm AASTHO-PCI bulb-tee xagkñúgEdlmanTMrsamBaØéns<ankMral smas EdlKμan skews. FñwmenHmanRbEvg 120 ft (36.6m) . eRKOgbgÁúMEpñkxagelI (superstructure) pSMeLIgeday pretensioned beam cMnYn 6 EdlmanKMlatBImYyeTAmYycMgay 9 ft (2.74m) EdlKitBI G½kSeTAG½kS dUcbgðajenAkñúgrUbTI 12>11. s<anmankMras;ebtugcak;enAnwgkEnøgkMras; 8in.(203mm) CamYynwg wearing surface BIxagelIkMras; 2in. . bnÞúkGefrKNnaKW HL-93 AASTHO-LRFD fatigue loading. snμt;fas<anenHsßitenAkñúgtMbn;rBa¢ÜydItUc. eKeGay kugRtaMgGnuBaØatGtibrma³ kMrals<an f 'c = 4,000 psi ebtugTMng;Fmμta f c = 0.60 f 'c = 2,400 psi Fñwm bulb-tee f 'c = 6,500 psi lkçN³muxkat;³ f 'ci = 5,500 psi Ac = 767in.2 f c = 0.60 f 'c = 3.900 psi Service III h = 72in. f c = 0.45 f 'c = 2,925 psi Service I I c = 545,894in.4 f ci = 0.60 f 'c = 3,480 psi cb = 36.60in. karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 785

- 42. T.Chhay viTüasßanCatiBhubec©keTskm<úCa f t = 6 f 'c = 484 psi ct = 35.40in. f pu = 270,000 psi S b = 14,915in.3 f py = 0.90 f pu = 243,000 psi S t = 15,421in.3 I c 545,894 f pi = 0.75 f pu = 202,500 psi r2 = = = 712in.2 Ac 767 f y = 60,000 psi WD = 799 plf E ps = 28.5 ⋅10 6 psi E s = 29.0 ⋅10 6 psi dMeNaHRsay³ !> TTwgkMralbMElg (Transformed Deck slab controlling width) KNnaTTwgsøabbMElg Ecs = 33w1.5 f 'c = 33 × (1.5)1.5 4,000 = 3,830ksi enAeBlepÞr Eci = 33(1.5)1.5 5,500 = 4,500ksi eRkam service Ece = 33(1.5)1.5 6,500 = 4,890ksi TTwgsøabRbsiT§PaBKWtMéltUcCageKkñúgcMeNam (i) 1 4 ElVg = 1204×12 = 360in. (ii) 12h f + kMras;RTnugEdlFMCageK b¤ TTwgsøabxagelI/ b = 12 × 7.5 + 0.5 × 42 = 111in. 1 2 (iii) KMlatmFümrvagFñwm = 9 × 12 = 108in. dUcenH TTwgsøab = 108in. LRFD and Standard AASTHO Design of Concrete Bridges 786

- 43. Department of Civil Engineering NPIC pleFobm:UDul ns = Ecs = 3,,830 = 0.78 Ec 4 890 TTwgbMElg (transformed) bm = nsb = 0.78 ×108 = 84in. @> lkçN³rbs;muxkat;smas eKmincaM)ac;KitBIkarcUlrYmén deck concrete haunch eTAkñúg I 'c eT edaysarPaBekag (camber) rbs;Ggát;cak;Rsab;. A'c = 1,397in.2 h = 80in. I cc = 1,095,290in.4 cbc = 54.6in. eTAsrésxageRkambMput ctc = 72 − 54.6 = 17.4in. eTAsrésxagelIbMputrbs;Fñwmcak;Rsab; ctsc = 80 − 54.6 = 25.4in. eTAsrésxagelIbMputrbs;kMral 1,095,290 S bc = = 20,060in.3 54.6 1,095,290 Sc = t = 62,950in.3 17.4 1,095,290 Sc = ts = 55,284in.3 25.4 × 0.78 #> m:Um:g;Bt;begáag nigkMlaMgkat; (bending moments and shear forces) kMral³ WSD1 = 12 × 9 × 150 = 900ib / ft 8 TMgn;bgáan;éd (barrier weight)³ WSD2 = 2barriers(300lb / ft ) = 100lb / ft 6beams ³ 2in. future-wearing surface WSD3 = 2 × 48 ft 12 6beams × 150 = 200lb / ft bnÞúkGefr (truck load) enAkñúg LRFD Ep¥kelI HL-93 truck fatigue loading. clear width BIrUbTI 12>12 = 48 ft (14.6cm ) cMnYn lanes = 12 = 4 lanes 48 (a) emKuNEbgEcksMrab;m:Um:g; (Distribution factor for moment) sMrab; lane load 2 b¤eRcInCagenH emKuNEbgEckbnÞúksMrab;m:Um:g;Bt; (tarag 12>3b) 0.2 ⎛ 0.1 ⎛ S ⎞ 0.6 ⎛S⎞ K ⎞ DFM = 0.075 + ⎜ ⎟ ⎜ ⎟ ⎜ g ⎟ ⎝ 9.5 ⎠ ⎝L⎠ ⎜ 12t 3 L ⎟ ⎝ s ⎠ karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 787

- 44. T.Chhay viTüasßanCatiBhubec©keTskm<úCa kñúgkrNIEdl KMlatFñwm³ 3.5 ≤ S ≤ 16 Cak;Esþg S = 9.0 ft O.K. kMrals<an³ 4.5 ≤ Ts ≤ 12 Cak;Esþg Ts = 7.5in. O.K. ElVg³ 20 ≤ L ≤ 240 Cak;Esþg L = 120 ft O.K. cMnUnFñwm³ Nb > 4 Cak;Esþg N b = 6 O.K. e g = cMgayrvagTIRbCMuTMgn;rbs;Fñwm nigkMral 7.5 = + 0.5 + 35.4 = 39.65in. 2 E 4,890 n= c = = 1.28 E sc 3,830 ( K g = n I c + Ac e g 2 ) [ = 1.28 545,894 + 767(39.65)2 = 2,242,191in.4 ] 0. 1 ⎛ 9 ⎞ 0.6 ⎛ 9 ⎞ 0.2 ⎡ 2,242,191 ⎤ dUcenH DFM = 0.075 + ⎜ ⎟ ⎜ ⎟ ⎢ ⎥ = 0.732 lanes/beam ⎝ 9 .5 ⎠ ⎝ 120 ⎠ ⎢12(7.5) (120 ) ⎥ 3 ⎣ ⎦ sMrab; design lane load mYy/ BItarag 12>3b 0.3 ⎛ 0.1 ⎛S⎞ 0.4 ⎛S⎞ K ⎞ DFM = 0.06 + ⎜ ⎟ ⎜ ⎟ ⎜ g ⎟ ⎝ 14 ⎠ ⎝ L⎠ ⎜ 12t 3 L ⎟ ⎝ s ⎠ 0. 3 ⎡ 0. 1 2,242,191 ⎤ 0. 4 ⎛9⎞ ⎛ 9 ⎞ = 0.06 + ⎜ ⎟ ⎜ ⎟ ⎢ ⎥ = 0.499 lanes/beam ⎝ 14 ⎠ ⎝ 120 ⎠ ⎢12(7.5) (120 ) ⎥ 3 ⎣ ⎦ dUcenH krNI lane load BIr b¤eRcInCagBIr eK)anemKuNEbgEcgm:Um:g;FMCag dUcenHeK)an DFM = 0.732 lanes/beam Fatigue mement m:Um:g;RtUv)anKitsMrab; single design truck EdlmanTMgn;ePøA (axle) dUcKña dUcenAkñúg sßanPaBkMNt;déTeTot b:uEnþCamYynwgKMlatefr 30 ft cenøaH 32kips axles. eKeRbI lane factor 1.2 sMrab; fatigue edIm,Ikat;bnßyemKuN DFM Edllub. BItarag 12>2a/ emKuN bnÞúk (load factor) KW 0.75 ehIyemKuNTgáic (impact factor) (IM) sMrab; fatigue = 15% . dUcenH m:Um:g;Bt; fatigue truckload køayCa³ M f = (bending moment per lane)(DFM / 1.2)(1 + IM ) ⎛ 0.499 ⎞ b¤ M f = (bending moment per lane)⎜ ⎝ 1.2 ⎠ ⎟(1 + 0.15) LRFD and Standard AASTHO Design of Concrete Bridges 788

- 45. Department of Civil Engineering NPIC = (bending moment per lane)(0.415)(1.15) = (0.478)(bending moment per lane) (b) emKuNEbgEcksMrab;kMlaMgkat; (Distribution factor for shear) BItarag 12>3 (a)/ sMrab; lane load BIr b¤eRcInCagenH 2 ⎛S⎞ ⎛S ⎞ DFV = 0.2 + ⎜ ⎟ − ⎜ ⎟ ⎝ 12 ⎠ ⎝ 36 ⎠ kñúgkrNIEdl³ KMlatFñwm³ 3.5 ≤ S ≤ 16 Cak;Esþg S = 9.0 ft O.K. kMrals<an³ 4.5 ≤ Ts ≤ 12 Cak;Esþg Ts = 7.5in. O.K. ElVg³ 20 ≤ L ≤ 240 Cak;Esþg L = 120 ft O.K. 10,000 ≤ K g ≤ 7,000,000 Cak;Esþg K g = 2,242,191in.4 O.K. 2 ⎛9⎞ ⎛ 9 ⎞ dUcenH/ DFV = 0.2 + ⎜ ⎟ − ⎜ ⎟ = 0.887 lanes/beam ⎝ 12 ⎠ ⎝ 36 ⎠ sMrab; design lane load mYy/ BItarag 12>3a ⎛ S ⎞ ⎛ 9.0 ⎞ DFV = 0.36 + ⎜ ⎟ = 0.36⎜ ⎟ = 0.720 lanes/beam ⎝ 25.0 ⎠ ⎝ 25.0 ⎠ dUcenH krNI lane load BIr b¤eRcInCagBIr eK)anemKuNEbgEcgkMlaMgkat;FMCag dUcenHeK)an DFV = 0.887 lanes/beam $> bnSMbnÞúk (Load combinations) bnÞúkemKuNsrub/ Q = η ∑ γ i qi Edl η = emKuNEdlTak;TgeTAnwgPaBsVit (ductility)/ GBaØatelIs (redundancy) nigPaB sMxan;éndMeNIrkar (operational importance) γ i = emKuNbnÞúk qi = bnÞúk yk η = 1.0 sMrab;RKb;karGnuvtþTaMgGs;enAkñúg]TahrN_enH eFVIkarGegátRKb;bnSMbnÞúkTaMgGs;EdlmanenAkñúgtarag 12>2 (a) nig (b). krNIEdllubKW dUcxageRkam³ (a) Service I sMrab;kugRtaMgsgát;enAkñúgGgát;ebtugeRbkugRtaMg karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 789

- 46. T.Chhay viTüasßanCatiBhubec©keTskm<úCa Q = 1.0(DC + DW ) + 1.0(LL + IM ) (b) Service III sMrab;kugRtaMgTajenAkñúgGgát;ebtugeRbkugRtaMg Q = 1.0(DC + DW ) + 0.8(LL + IM ) (c) Strength I sMrab; ultimate strength: tMélGtibrmarbs; Q = 1.25DC + 1.50DW + 1.75(LL + IM ) tMélGb,brmarbs; Q = 0.90DC + 0.65DW + 1.75(LL + IM ) (d) Fatigue sMrab;RtYtBinitükugRtaMgenAkñúg strands Q = 0.75(LL + IM ) (fatigue Q CabnSMbnÞúkBiesssMrab;RtYtBinitükugRtaMgTajenAkñúg strands EdlbNþal BIbnÞúkGefr nig dynamic allowance) %> kMlaMgkat; nigm:Um:g;Bt;KμanemKuN (Unfactored shear forces and bending moments) (a) Truck Loads kMlaMgkat; truck load: VLT = (shear force per lane)(DFV )(1 + IM ) = (shear force per line )(0.887 )(1 + 0.33) = 1.180(shear force per lane)kips m:Um:g;Bt; truck load: M LT = (moment per lane)(DFM )(1 + IM ) = (moment per lane)(0.732 )(1 + 0.33) = 0.974(moment per lane) ft − kips LT = bnÞúkGefrrbs; truck (b) Lane Loads sMrab; lane load EdlminmanGnuvtþ dynamic allowance VLL = (shear force per lane)(DFV ) = (shear force per lane)(0.887 )kips M LL = (moment per lane)(DFM ) = (moment per lane)(0.732 ) ft − kips Lane load BIrUbTI 12>4/ bnÞúkenAelIs<anenHdUcbgðajenAkñúgrUbTI 12>12. LRFD and Standard AASTHO Design of Concrete Bridges 790

- 47. Department of Civil Engineering NPIC ^> KNnam:Um:g; nigkMlaMgkat; (Computation of moments and shears) (a) Lane Loads ¬ DFV = 0.887, DFM = 0.732 ¦ (i) muxkat;TMr³ kMlaMgkat;enARtg;TMrxageqVg (x = 0) BIsmIkar 12.6(a) nigrUbTI 12>12³ VLL = 0.64 (L − x )2 (DFV ) 2L = 0.64 (120)2 (0.887) = 34.1kisp 2 × 120 BIsmIkar 12.6 (b)/ nig DFM = 0.732 0.64( x )(L − x ) M LL = (DFM ) = 0 ft − kip 2 (ii) muxkat;enARtg; 24tf BITMr³ kMNt; VLL nig M LL enARtg; x = 24 ft BITMrxageqVg VLL = 0.64 (120 − 24)2 (0.887) = 21.8kips 2 × 120 0.64(24)(120 − 24) M LL = (0.732) = 539.7 ft − kip 2 ¬ (b) Truck live loads DFV = 1.180, DFM = 0.974 ¦ eKRtUvKitbBa©Úl Impact factor IM = 33% dUcenH eyIgTTYl)antMél DFV nig DFM FMCag mun (i) muxkat;TMr³ BItarag 12>4/ 72[(L − x ) − 9.33] VLT = (DFV ) L karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 791

- 48. T.Chhay viTüasßanCatiBhubec©keTskm<úCa 72[(120 − 0.0) − 9.33] = (1.180) = 78.1kips 120 BItarag 12>5/ 72(x )[(L − x ) − 9.33] M LT = (DFM ) L = 0 ft − kip sMrab;mU:m:g;Rtg;TMr (ii) muxkat;enARtg; 24 ft BITMr ³ 72[(120 − 24) − 9.33] VLT = (1.180) = 61.4kips 120 72(24)[(120 − 24) − 9.33] M LT = (0.974) = 1215.0 ft − kip 120 (c) Fatigue moment enARtg; 24 ft ¬ DFM = 0.478 ¦ BItarag 12>7 72( x )[(L − x ) − 18.22] Mf = (DFF ) L BIelIkmun/ DFF = 0.478 72(24)[(120 − 24) − 18.22] dUcenH Mf = 120 (0.478) = 535.8 ft − kip (d) Shears and moments EdlbNþalBIbnÞúkefr bnÞúkEdlRtUvBicarNaKWTMgn;Fñwm ¬WD ¦ bUknwgkMral deck nig haunches ¬WSD1 ¦ nig wearing surface ¬ WSD3 ¦ EdlRtUvRkalenAeBlGnaKt. edaysarvaCaFñwmTMrsamBaØ dUcenHkMlaMgkat; nigm:Um:g;tambeNþayElVgKW³ V x = WD (0.5L − x ) M x = 0.5WD x(L − x ) Kitmuxkat;Rtg; 24 ft BITMrxagxageqVg ehIyKNnakMlaMgkat; nigm:Um:g;EdlbNþalBITMgn;pÞal; WD = 0.799kip / ft ³ V x = 0.799(0.5 × 120 − 24) = 28.8kips M x = 0.5 × 0.799 × 24(120 − 24) = 920.4 ft − kip tarag 12>10 nig 12>11 bgðajBIkMlaMg nigm:Um:g;EdlRtUvkarsMrab;sikSaKNnaFñwmxagkñúg. eKRtUvcMNaMfakarKNnaedayédedIm,ITTYl)antaragEbbenHRtUvkarcMNayeBlevlay:ageRcIn. eKmankmμviFIkMuBüÚT½rEdlbegáIteLIgedayGKÁnaykdæandwkCBa¢Ún (state DOT) CaeRcIn EdlxøH manenAkñúg internet dUcCa Washington State DOT Program. LRFD and Standard AASTHO Design of Concrete Bridges 792

- 49. Department of Civil Engineering NPIC &> sikSaKNnaFñwm bulb-tee eRbkugRtaMgxagkñúg (Computation of moments and shears) ¬!¦ kareRCIserIskabeRbkugRtaMg (Selection of Prestressing Strands) sMrab;bnSMbnÞúk Service-III/ kugRtaMgsrésxageRkam fb KW³ M D + M S M b + M WS + 0.8(M LT + M LL ) fb = + Sb S bc Edl MD = m:Um:g;TMgn;pÞal;EdlKμanemKuN/ ft − kip M S = m:Um:g;EdlKμanemKuNEdlbNþalBITMgn;kMral nig haunch, ft − kip M b = m:Um:g;bgáan;édEdlKμanemKuN/ ft − kip M WS = m:Um:g; wearing surface EdlKμanemKuN/ ft − kip karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 793

- 50. T.Chhay viTüasßanCatiBhubec©keTskm<úCa M LT = m:Um:g;bnÞúk truck EdlKμanemKuN/ ft − kip M LL = m:Um:g; lane load EdlKμanemKuN/ ft − kip BIelIkmun/ Sb = 14,915in.3 S bc = 20,090in.3 BItarag 12>10 nig 12>11/ kugRtaMgkNþalElVgxageRkamenARtg;srésxageRkameRkam GMeBI service load KW f bc = 1,438.2 + 1,659.6 (12) + 180 + 360 + 0.8(1,830.3 + 843.2) (12) 14,915 20,090 = 2.50 + 1.60 ≅ 4.10ksi(T ) kugRtaMg 4.10ksi(T ) nwgRtUv)anlubbM)at;edaykMlaMgeRbkugRtaMg. kugRtaMgTajGnuBaØatGti- brma³ f t = 6.0 f 'c psi = 6 6,500 = 484 psi = 0.484ksi kugRtaMgsgát;eRbkugRtaMgtMrUvkarenARtg;srésxageRkambMput³ f cb = (4.1 − 0.48) = 3.62ksi snμt;facMgayBITIRbCMuTMgn;rbs;EdkeRbkugRtaMgeTAsrésxageRkambMput = 0.05h = 0.05(72 ) = 3.6in. yk 4in. / dUcenH ec = 36.6 − 4.0 = 32.6in. dUcbgðajenAkñúg]TahrN_énCMBUk 4 P ×e f bp EdlbNþalBIeRbkugRtaMg = e + e c P A c S b b¤ fbp = 767 + P14×,915.6 = 3.62ksi Pe e 32 eyIgTTYl)an Pe = 1,037kips snμt;kMhateRbkugRtaMgsrub = 25% 1,037 Pi = = 1,383kips 1 − 0.25 snμt;eRbI 7-wire 270-K low-relaxation strands Ggát;p©it 0.5in. ¬ Aps = 0.153in.2 ¦ cMnYntMrUvkarén strands = 0.153,383 .5 = 44.6strands 1 × 202 eRkayBIkarGnuvtþ trial and adjustment/ eyIgsakl,gmuxkat;Edlman 48 strand dUcbgðaj enAkñúgrUbTI 12>13. enAeBl strand ticCag 48 eFVIeGaykugRtaMgTajenARtg;srésxageRkam bMputeRkamGMeBI service load FMCagkugRtaMgGnuBaØatGtibrma ft = 484 psi . Strand cMnYn 20 LRFD and Standard AASTHO Design of Concrete Bridges 794

- 51. Department of Civil Engineering NPIC RtUv)an harp enARtg; 0.4L . dUcenH 36 strands enArkSaPaBRtg;enAkñúgFñwm ¬emIlrUbTI 12> 13¦. BIsmμtikmμ/ cb = 36.60in. ehIy ct = 72 − 36.60 = 35.40in. ee = cb − [2 × 70 + 2 × 68 + 2 × 66 + 2 × 64 + 2 × 62 + 2 × 60 + 4 × 8 + 8 × 6 + 12 × 4 + 12 × 2] / 48 = 36.60 − 19.42 = 17.28in. ec = cb − [2 × 12 + 12 × 4 + 8 × 6 + 8 × 4 + 2 × 10 + 2 × 12 + 2 × 14 + 2 × 16 + 2 × 18 + 2 × 20] / 48 = 36.6 − 6.92 = 29.68in. eKeGay f pi = 0.75 f pu = 202,500 psi Pi = (48)(0.153)(202.5) = 1,488kips eRkayeBlGnuvtþnUvkarviPaK step-by-step rbs;kMhateRbkugRtaMg dUcenAkñúgCMBUk 3 Epñk 3.9 kMhatbg;eRbkugRtaMgsrubRtUv)ankMNt;edaymantMélesμInwg 26.4% . f pe = 202.5(1 − 0.264) = 149.0ksi dUcenH/ Pe = 1488(1 − 0.264) = 1095.0kips karsikSaKNnas<anebtugsþg;dar AASTHO nig LRFD 795

- 52. T.Chhay viTüasßanCatiBhubec©keTskm<úCa ¬@¦ RtYtBinitükugRtaMgEdlKμanemKuNrbs;ebtug (Check of Concrete Unfactored Stresses) (a) kugRtaMgenAeBlepÞr eRbkugRtaMgedIm f pi = 0.7 f pu = 0.7 × 270 = 202.5ksi . karGnuvtþFmμtasnμt;fakMhat bg; relaxation edImenAeBlrgeRbkugRtaMgmanbrimaNBI 9% eTA10% . eRbIkarkat; bnßy 10% enAkñúg f pi Pi = 0.90 × 1,488 = 1,339kips dUcenH Pi = 0.9(202.5)(0.153 × 48) = 1,338kips (i) muxkat;Rtg;TMr BICMBUk 4/ smIkar 4.1(a) ⎛ ee ct ⎞ M D Pi ft =− ⎜1 − 2 ⎟ − t ⎝ Ac r ⎠ S 1,338 ⎛ 17.28 × 35.4 ⎞ =− 767 ⎝ ⎜1 − 712 ⎟ − 0 = −0.25ksi(C ) ⎠ / minrgkarTaj/ O.K. P ⎛ ec ⎞ M f b = − i ⎜1 + e 2b ⎟ + D Ac ⎝ r ⎠ Sb 1,339 ⎛ 17.28 × 36.3 ⎞ =− ⎜1 + ⎟+0 767 ⎝ 712 ⎠ = 3.29ksi(C ) < kugRtaMgGnuBaØat f c = 3.48ksi O.K. (ii) muxkat;kNþalElVg 1,338 ⎛ 29.68 × 36.60 ⎞ 1,438 ×12 ft =− ⎜1 − ⎟− 767 ⎝ 712 ⎠ 15,421 = 0.917 − 1.119 = −0.202ksi(C ) / minmanrgkugRtaMgTaj/ dUcenH O.K. 1,339 ⎛ 29.68 × 36.6 ⎞ 1,438 ×12 fb = − ⎜1 + ⎟+ 767 ⎝ 712 ⎠ 14,915 = −4.513 + 1.157 = −3.356ksi(C ) < kugRtaMgGnuBaØat f 'ci = 5.50ksi O.K. (b) kugRtaMgenAeBl Service (i) muxkat;kNþalElVg BICMBUk 4/ smIkar 4.3(a) nig 4.3(b): Pe ⎛ ec ct ⎞ MT ft =− ⎜1 − 2 ⎟ − t ≤ fc Ac ⎝ r ⎠ Sc Pe ⎛ ec cb ⎞ M T fb = − ⎜1 + 2 ⎟ + ≤ ft Ac ⎝ r ⎠ S cb LRFD and Standard AASTHO Design of Concrete Bridges 796