Co-op_Poster_III_rev01-mjg

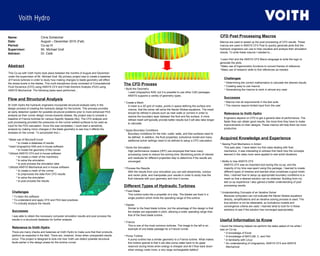

- 1. Abstract This Co-op with Voith Hydro took place between the months of August and December under the supervision of Mr. Michael Graf. My primary project was to create a baseline of Francis turbines in order to study how making changes to blade geometry will effect the stress levels in the blades. This multi-disciplinary study consisted of Computational Fluid Dynamics (CFD) using ANSYS CFX and Finite Element Analysis (FEA) using ANSYS Mechanical. The following tasks were performed… Flow and Structural Analysis Acquired Knowledge and Experience Useful Information to Know At Voith Hydro the hydraulic engineers incorporate structural analysis early in the design process of creating the hydraulic design for the turbine. This process provides an early detection system for possible structural problems prior to more enhanced FEA analysis as their runner design moves towards release. My project was to compile a baseline of Francis turbines for various Specific Speeds (Nq). The CFD analysis and post processing provided the pressures on the runner wetted surfaces to be used as input for the FEA calculation. Once this was completed, I could start a sensitivity analysis by making minor changes in the blade geometry to see how it effects the stresses on the runner. To accomplish this I... Made use of Microsoft Excel to create a database of results Used Unigraphics NX6 and in-house software to model the geometry of the runner Utilized ANSYS CFX and in-house software to create a mesh of the machinery to solve the simulation to post process the simulation data Utilized ANSYS Mechanical and in-house software to create a mesh of the runner to preprocess the data from CFD results to solve the simulation to post process the results I found the following helped me perform the tasks asked of me while I was on Co-op. A knowledge of Excel A knowledge of MATLAB, C, and Perl A familiarity with Linux An understanding of Unigraphics, ANSYS CFX and ANSYS Mechanical Challenges Determining the correct mathematics to calculate the desired results Creating easy to use macros Generalizing the macros to work in almost any case Successes Macros met all requirements in the test suite The macros require limited input from the user Relevance to Voith Hydro Engineers depend on CFD to get a general idea of performance. The faster they can obtain good results, the more time they have to make improvements on their designs. These macros will help them be more productive. Challenges Successes Relevance to Voith Hydro Name: Chris Schleicher Date: August – December 2010 (Fall) Period: Co-op III Supervisor: Mr. Michael Graf Advisor: Dr. Celik Seeing Fluid Mechanics in Action This past year, I have taken my first class dealing with fluid mechanics. It was interesting to witness first hand how the concepts learned in the class room were applied to real world situations. Ability to Use ANSYS CFX ANSYS CFX was an important tool during this co-op, and the majority of my time was spent using this package. I learned to create different types of meshes and learned what constitutes a good mesh. Also, I learned how to setup up appropriate boundary conditions to a mesh so that a desired solution can be obtained. Building from my last co-op experience I also gained a better understanding of post processing results. Understanding Concepts of an Iterative Solver Because computers can not evaluate the Navier-Stokes equations directly, simplifications and an iterative solving process is used. The true solution is not be obtainable, so turbulence models and convergence criteria are used. I learned what to look for in these solutions to see if the solution has converged appropriately. To learn the software To understand and apply CFD and FEA best practices To critically analyze the results There are many checks and balances at Voith Hydro to make sure that their products perform as expected in the field. There are, however, times when unexpected results occur. This project is designed to look into how Voith can detect possible structural faults earlier in the design phase for the turbine runner. Different Types of Hydraulic Turbines Fixed Blade This turbine looks like a propeller of a ship. The blades are fixed in a single position which limits the operating range of this turbine. Kaplan Similar to the fixed blade turbine, but the advantage of this design is that the blades are adjustable in pitch; allowing a wider operating range than that of the fixed blade turbine. Francis This is one of the most common turbines. The image to the left is an example of one blade passage for a Francis runner. Pump Turbine A pump turbine has a similar geometry to a Francis turbine. What makes this turbine special is that it can also pump water back to its upper reservoir during times when energy is cheaper and let it flow back down when energy costs more; a very large rechargeable battery! I was able to obtain the necessary computer simulation results and post process the results in a structured database for further analysis. The CFD Process Build the Geometry I used Unigraphics NX6, but it is possible to use other CAD packages. ANSYS supports a variety of geometry types. Create a Mesh A mesh is a 3D grid of nodes, points in space defining the surface and volume, that the solver will solve the Navier-Stokes equations. The mesh should be refined in places such as near walls or corners in order to resolve the boundary layer between the fluid and the surface. A more refined mesh will typically provide better results but it will also take longer to calculate. Apply Boundary Conditions Boundary conditions for the inlet, outlet, walls, and free surfaces need to be defined. In addition, the fluid properties, turbulence model and many additional solver settings need to be defined to setup a CFD calculation. Solve the Simulation High performance clusters (HPC) are employed that have many processing cores to reduce the solving time. Monitoring points of interest and residuals for different properties help to determine if the results are converged. Process the Results With the results from your simulation you can add streamlines, contour and vector plots, and manipulate your results in order to study how the fluid interacts with your geometry and how it moves. CFD Post Processing Macros Macros are used to speed up the post processing of CFD results. These macros are used in ANSYS CFX Post to quickly generate plots that the hydraulic engineers can use to help visualize and analyze their simulation results. To write these macros I needed to... Learn Perl and the ANSYS CFX Macro language to write the logic to generate the plots. Make use of trigonometric functions to convert frames of reference. Make use of research skills to find references as needed.