Deformation

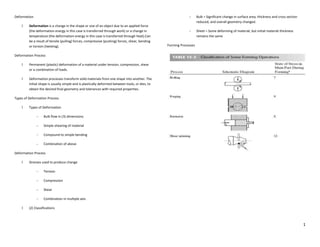

- 1. Deformation – Bulk = Significant change in surface area, thickness and cross section reduced, and overall geometry changed. l Deformation is a change in the shape or size of an object due to an applied force (the deformation energy in this case is transferred through work) or a change in – Sheet = Some deforming of material, but initial material thickness temperature (the deformation energy in this case is transferred through heat).Can remains the same be a result of tensile (pulling) forces, compressive (pushing) forces, shear, bending or torsion (twisting). Forming Processes Deformation Process l Permanent (plastic) deformation of a material under tension, compression, shear or a combination of loads. l Deformation processes transform solid materials from one shape into another. The initial shape is usually simple and is plastically deformed between tools, or dies, to obtain the desired final geometry and tolerances with required properties. Types of Deformation Process l Types of Deformation – Bulk flow in (3) dimensions – Simple shearing of material – Compound to simple bending – Combination of above Deformation Process l Stresses used to produce change – Tension – Compression – Shear – Combination in multiple axis l (2) Classifications 1

- 2. – Dependent » Process determines outcome – Independent / Dependent l Figure 15-1 Schematic representation of a metalforming system showing independent variables, dependent variables, and the various means of linking the two. Work Ranges l (2) Types of mechanical work where material undergoes plastic deformation l Hot Working (HW) l Cold Working (CW) Definition of HW vs. CW Process Variables l HW is performed above the recrystallization temp of the material and CW is done below the recryllization temp of the material. l (3) Classification l Recystallization Temp- “The approximate minimum temp at which complete – Independent recyrallization of a cold worked metal occurs within a specified time.” » Controlled by the engineer » -Heat Treaters’s Guide, American Society for Metals 2

- 3. Definition of HW vs. CW l Approximate temperature ranges – HW - .6 melt temp. of the material – WW - .3 to .6 melt temp of the material – CW - less than .3 of the material » Example - 1020 CRS 950 - 1300F Figure 15-3 Cross section of a 4-in.-diameter case copper bar polished and etched to show the as-cast grain structure. Hot Working l When HW a metal is in a plastic state and is easily formed. The forces required to deform the metal are less than CW. Some mechanical properties of the metal are improved due to process characteristics. l At elevated temperatures, metal microstructures are rebuilding continually through the recrystallization process which allows for much higher deformation. Advantages to HW l Porosity in metal is largely eliminated Figure 15-4 Flow structure of a hot-forged gear blank. Note how flow is parallel to all critical surfaces. (Courtesy of Bethlehem Steel Corporation, l Impurities (inclusions) are broken up and distributed through the metal Bethlehem, PA.) l Course grains are refined Advantages to HW l Due to grain refinement, the physical properties are generally improved l Amount of energy necessary to change the shape of the raw material in a plastic state is far less than if the material was “cold.” » Ductility and resistance to impact are improved l Economical compared to CW » Strength is increased Disadvantages to HW Advantages to HW l High working temp. can result in rapid oxidation/scaling of surface = poor surface finish l Generally, close tolerances are hard to control l Equipment and tool maintenance costs are high Primary HW Processes 3

- 4. l Rolling l Forging l Extrusion l Pipe & tube manufacturing l Drawing Rolling l Heated metal is passed between rotating rolls to reduce the cross-section. Forging l The plastic deformation of metals, typically at elevated temperatures, using compressive forces exerted through a die to conform the metal to a desired shape. l Process advantages: – Closing of voids in the metal – Reduced machining time – Improve the physical properties of the starting metal l Process disadvantages: Rolling – Possible scale inclusions in forging l One of the primary first process to convert raw material into finished product. – Tooling cost can be high l Starting material (Ingots) are rolled into blooms, billets, or slabs by feeding material – Usually not used for short production runs through successive pairs of rolls. Forging Methods » Bloom - square or rectangular cross section with a thickness greater than 6” and a width no greater than 2x’s the thickness l Open-Die Drop Hammer - heated metal is placed between dies—a force is delivered with a steam hammer. » Billets - square or circular cross section - - smaller than a bloom – Accuracy is not good » Slabs - rectangular in shape(width is greater than 2x’s the thickness), slabs are rolled into plate, sheet, and strips. – Complicated shapes are difficult to produce 4

- 5. Forging Methods l Impression Die Drop Hammer Forging - Hot pliable metal is forces into the shape of closed impression dies. This process is typically performed in a progressive method through a series of dies to control the flow. – 2 Types of drop forge hammers » Steam » Gravity l Press Forging – Large….thick work – Slow Squeezing action penetrates entire work piece producing uniform deformation – Dies are typically heated to: » Assist surface flow » Reduce surface heat loss » Assist in obtaining close tolerances and surface finish – Two types of presses -- mechanical and hydraulic » Hydraulic - up to 50,000 tons Hot Extrusion l A plastic deformation process in which metal is forces under pressure to flow through a single, or series of dies until the desired shape is produced. l Advantages l Upset forging – Wide variety of shapes – Grip a bar—heat the end—forge into desired shape – High production rates » Product examples – Improved microstructure and physical properties l Bolts – Close tolerances are possible l Engine valves 5

- 6. – Economical l Advantages – Design flexibility l No heat required Pipe, Tube, and Wire Manufacturing l Better surface finish • Tube - Butt or electric welding and Piercing l Superior dimensional control---little or no secondary operations l Strength, fatigue, and wear properties are improved l Improved machinability l Disadvantages Increased stress in material—strain hard Roll Alignment Roll Alignment, specifically, is the alignment and measurement of roll parallelism in plant machinery that is typically used to feed sheet materials. Typical industrial applications include: Paper and Pulp manufacture Printing Works Textile Mills All types of Sheet Manufacturing Drawing l Flat sheet or a plate of metal is forced into a recess with a depth more than several Problems associated with the misalignment of Rolls include: times the starting materials thickness. Drift and tracking of sheet materials during feed Wrinkling and Breakages in paper / material Cold Working Uneven gloss rate in paper manufacture High scrap rates of material l CW is done below the recrystallization point of the material. In CW, greater forces are required to transform the raw metal into the desired shape. Roll Alignment Process Industrial Applications for Roll Alignment l One major advantage…..as the grain deformation proceeds greater resistance to The Headbox: the action is building resulting in improved strength and hardness (strain hardness). The Foil Section: The Press Section: l CW is a high volume production process. The Dryer Section: l Similar processes as HW—major differences include The Winder: The Coating Section: l Forces required Roll Alignment - Head Box It is important that the breast roll is parallel to the apron board. If the air gap l Temperature range differs, it will cause problems with the consistency of the paper. It is also important that the apron board is straight and the slice gap is correct in order to get a uniform l Equipment specifications output of paper pulp on to the forming table. 6

- 7. Benefits: Increased production capacity Uniform paper structure and thickness Reduced rate of scrap paper Roll Alignment - Finishing Calendars Increased efficiency in the dewatering process and possibility to increase The parallelism is important in the calendar, both vertically and horizontally, or the production speed roll nip will differ over the roll length. In some calendars, there is a nip offset that Reduced risk of breaking the slice tip has to be considered. Benefits: Roll Alignment - Dryer Section Uniform gloss In this section, the problems are similar to the press sections, although we would Reduced scrap production like to point out the problem with wrinkles and breakages in the paper sheets. The Increased time between roll replacement amount of rolls in the web path is large in the dryer section and increases the Possibility to increase production speed importance of roll parallelism. Turret Punching Benefits: Increased uptime is a process, where work piece are punched to make a desired hole of a metal sheet. Increased time between felt changes it is a CNC machine used for performing punching (a turret puncher) to a material such Reduced scrap production us sheet of metal or plastic . Increased product quality Turret punching is a cold work process. This entails that material properties remain Possibility to increase production speed unchanged as they are not exposed to thermal impact during machining. Roll Alignment - Forming Table Process In this section, parallelism between the breast roll and the drive rolls is important, process produces shapes by selectively removing material from sheet metals. These sheets or the drift and wear of the wire will be affected. The surface of the paper sheet is are clamped into the machine on a table that is programmed to move to a specific affected if the dandy roll is not parallel to the forming table. The pick up roll and X/Y location within the matrix of the machine. The correct punch shape and size is the couch roll may cause breakages and wrinkles if they are not kept parallel, and selected at the turret and the machine actuates the punch to produce the desired the suction process may be affected. The levelling of the forming table is another hole. important factor in this section, that will especially affect the de-watering pro-cess and the deterioration of the foils. Benefits: Punching Characteristics Efficient de-watering process and uniform fibre structure will improve the paper quality Increased de-watering capability gives possibility to Increase production speed Increased lifetime of the wire Reduced energy consumption for the vacuum pumps Roll Alignment – Winders Poor parallelism between the calendar rolls, the reel drum and spool may create problems with a high rate of scrap paper as a result. Also the paper may drift sideways during the reeling, creating problems with wrinkles and difficulties when cutting the paper. Benefits: Less scrap paper 7

- 8. Punching Characteristics This would not be possible with conventional metal cutting operations. Punching is the most cost effective process of making holes in strip or sheet metal Rotary swaging can be applied up to a work piece length of some 1000 for average to high fabrication mm. It is able to create multiple shaped holes Creates a burnished region roll-over, and die break on sidewall of the resulting hole Usually a cold working process, used to reduce the diameter, produce a Materials supported taper, or add point to a round work piece. It can also impart internal Sheet Metals including: shapes in hollow work pieces through the use of a mandrel (the shape Aluminum must have a constant cross-section. Galvanized Steel Mechanism of Rotary Swaging Process Carbon Steel Stainless Steel A solid rod or tube is subjected to a radial impact by a set of rotating dies wherein a radial Brass movements of the dies are obtained by rotating them between pairs of opposite rollers in a Bronze cage. The work piece is stationary and dies rotate striking the work piece in the centre of the Copper die retainer or housing. Constant hammer blows gradually reduce the metal in size. It is then Monel taken to another machine and reduces further in size until the desired size is obtained. Plastic Advantages The dies close over the work piece and form the material. When the backers are in-between Fast and accurate over and over again without variation. two roll positions, the centrifugal forces will move them apart, making it possible for the die Take a less time of work than the manual punching machine. to open, while the dies are rotating around the work piece. The operation continues several CNC punching machines commonly handle up to 1200 hits per minute and many times and the result is a reduced round cross section of tube, bar or wire. have automated loading systems allowing for continuous operation. All kinds of metal can be turret punched, also hard stainless spring steel and some Advantages of Rotary Swaging Process polymere types can be turret punched. Disadvantages 1. Net-shape production A turret punching machine is an expensive machine the achievable tolerances are extremely tight so that final machining is in most It cannot punch a metal with a thickness of 6mm. cases not required. This enables significant material savings and reduces the Occupies large space in the work area. number of production stages, resulting in lower piece prices. Warping may occur if many holes are punched or much material is removed from 2. Broad applicability, significant weight savings the sheet rotary swaging can produce a multitude of different external and internal forms. Weight savings in the range of 30% - 50% can generally be achieved by rotary swaging versus conventional production methods. 3. High product quality Rotary Swaging Process The uninterrupted grain flow of the material together with the work hardening resulting from the process increases the strength of the work piece. The quality of Rotary swaging is a very fast metal forming process, eg. 4-6 parts per swaged surfaces is at the level of ground surfaces. minute. In addition to the speed of manufacture, the swaging process 4. High forming ratios, material freedom itself improves the mechanical strength properties of the work piece due Rotary swaging achieves high forming ratios without requiring hot forming. The to the work hardening phenomenon. favorable distribution of stresses during forming and the homogenous course of processing permit the forming of even brittle materials. Aging 8

- 9. 5. Cold and hot forming Two Types of Rotary Swaging Machine Rotary swaging forms materials in the cold, semi-hot and hot temperature range. There are two basic types of rotary swaging machine, the standard (also known as a tagging 6. Environmental acceptability machine), and the butt swaging machine. A butt swaging machine works by having sets of Unlike many other forming processes, rotary swaging does not require any surface wedges that close the dies onto the workpiece by inserting them between the annular rollers treatment on the blank. The oil, if required, is in a closed cycle. and the dies, normally by the use of a foot pedal. A butt swaging machine can allow a work 7. Versatility piece to be inserted without the dies closing on it, for example a three foot workpiece can be Rotary swaging machines have short change-over times. The swaging dies and the inserted 12 inches and then the dies closed, drawn through until 12 inches remain and the dies are then released, the finished work piece would then, for example, be four feet long machine setting can be changed within a few minutes. but still of its initial diameter for a foot at each end. 8. Short production times high efficiency The construction of rotary swaging machines permits combination of several processing modules for efficient multi-station transfer lines so that net-shape parts can be produced with high outputs. The robust easy to maintain construction ensures high efficiency rates. Disadvantage of Rotary Swaging Process The process variables affect the quality of swaged product such as dimensional precision, surface roughness of the product. Defect could be found to occur at a value of more than 2.0 mm/rev in forming speed. The dimensional precision of swaged product depends on the percentage reduction of outer diameter and forming speed. Key Benefits of RS 1. Improves mechanical strength property of the work piece due to the work hardening phenomenon. 2. Weight optimization combined with forming of internal geometries. Since the material volume of the workpiece remains constant, a reduction of the outside diameter of a solid bar would lead to an increased length of the same workpiece. In the case of a drive shaft for a passenger car made of a solid bar, 20% material savings can be obtained by rotary swaging compared to traditional metal cutting techniques. 3. A third key benefit of rotary swaging is the excellent surface quality, and is directly comparable with a ground surface. More specifically, a surface roughness of Ra 0.1- 0.3 can be obtained for internal geometries, and on outer surfaces for recess swaging Ra 0.6-1.0 can be guaranteed. 4. A fourth benefit that certainly shall not be neglected is the very long and reliable service life of the swaging tools. As a rule of thumb, the tools do not wear out but crack, which means that only good parts are swaged until tool breakage. Another rule of thumb is that swaging tools made of tungsten carbide have a 4-5 times longer service life than tools made of tool steel. So for large production series, carbide tools should be applied. 9

- 10. Spring Forming A spring is a device that changes its shape in response to an external force, returning to its original shape when the force is removed. The energy expended in deforming the spring is stored in it and can be recovered when the spring returns to its original shape. Types of Spring Raw Materials Extension spring Steel alloys are the most commonly used spring materials. The most popular alloys include high-carbon (such as the music wire used for guitar strings), oil-tempered low-carbon, a coiled spring whose coils normally touch each other; as a force is applied to stretch the chrome silicon, chrome vanadium, and stainless steel spring, the coils separate. Spring Forming Processes Coiling One consists of winding the wire around a shaft called an arbor or mandrel. This may be done on a dedicated spring-winding machine, a lathe, an electric hand drill with the mandrel secured in the chuck, or a winding machine operated by hand cranking. A guiding mechanism, such as the lead screw on a lathe, must be used to align the wire into the desired Compression spring pitch (distance between successive coils) as it wraps around the mandrel. a coiled spring with space between successive coils; when a force is applied to shorten the Thicker wire or bar stock can be coiled into springs if the metal is heated to make it flexible. spring, the coils are pushed closer together. Hardening Whether the steel has been coiled hot or cold, the process has created stress within the material. To relieve this stress and allow the steel to maintain its characteristic resilience, the spring must be tempered by heat treating it. The spring is heated in an oven, held at the appropriate temperature for a predetermined time, and then allowed to cool slowly. Finishing Grinding. If the design calls for flat ends on the spring, the ends are ground at this stage of the manufacturing process. The spring is mounted in a jig to ensure the correct orientation Torsion spring during grinding, and it is held against a rotating abrasive wheel until the desired degree of flatness is obtained designed so the applied force twists the coil into a tighter spiral. Common examples of torsion springs are found in clipboards and butterfly hair clips. Shot Peening This process strengthens the steel to resist metal fatigue and cracking during its lifetime of repeated flexings. The entire surface of the spring is exposed to a barrage of tiny steel balls that hammer it smooth and compress the steel that lies just below the surface. 10

- 11. Coating. To prevent corrosion, the entire surface of the spring is protected by painting it, - road barriers dipping it in liquid rubber, or plating it with another metal such as zinc or chromium. One process, called mechanical plating, involves tumbling the spring in a container with metallic Forging powder, water, accelerant chemicals, and tiny glass beads that pound the metallic powder -manufacturing process involving the shaping of metal using localized compression onto the spring surface forces/metal is heated and is shaped. The Future Resultant of forged metal Springs that support keys on touchpads and keyboards 1. Drawing- increase length ,decrease cross sectional A manufacturer of test equipment used in semiconductor production has developed a 2. Upsetting- decrease length, increase cross sectional microspring contact technology. 3. Squeezing- change length, change cross sectional area A manufacturer of test equipment used in semiconductor production has developed a micro spring contact technology. Three Roll Forming Roll Forming is a continues bending operation in which a long strip of metal (typically coiled metal) is passed through consecutive set of rolls. Each performing only an incremental part of the bend until the desired cross sectional area profile or obtained. Passes on three consecutive set of rolls . Forming plate ,sheet, bars, beams, angles,. Rollers on a pyramid like positions. Advantages 1. Increased production and less downtime 2. Defects are easier to control 3. Lengths are not limited Dies- material can jam or double-up in production material conveyor between the prenotch press and the roll former equal to or greater than the longest part. Conclusion Roll forming method is better than the conventional method terms of labour productivity. It can be used of work hours to install structural components by using roll forming is less compared to the cast in situ-method. Typical applications -rooftop 11