bukky

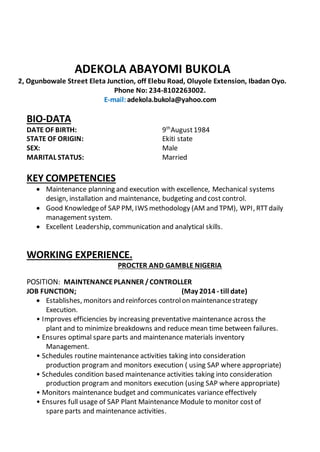

- 1. ADEKOLA ABAYOMI BUKOLA 2, Ogunbowale Street Eleta Junction, off Elebu Road, Oluyole Extension, Ibadan Oyo. Phone No: 234-8102263002. E-mail:adekola.bukola@yahoo.com BIO-DATA DATE OF BIRTH: 9th August1984 STATE OF ORIGIN: Ekiti state SEX: Male MARITAL STATUS: Married KEY COMPETENCIES Maintenance planning and execution with excellence, Mechanical systems design, installation and maintenance, budgeting and cost control. Good Knowledgeof SAP PM, IWS methodology (AM and TPM), WPI, RTTdaily management system. Excellent Leadership, communication and analytical skills. WORKING EXPERIENCE. PROCTER AND GAMBLE NIGERIA POSITION: MAINTENANCEPLANNER /CONTROLLER JOB FUNCTION; (May 2014 - till date) Establishes, monitors and reinforces controlon maintenancestrategy Execution. • Improves efficiencies by increasing preventative maintenance across the plant and to minimize breakdowns and reduce mean time between failures. • Ensures optimal spare parts and maintenance materials inventory Management. • Schedules routine maintenance activities taking into consideration production program and monitors execution ( using SAP where appropriate) • Schedules condition based maintenance activities taking into consideration production program and monitors execution (using SAP where appropriate) • Monitors maintenance budget and communicates variance effectively • Ensures full usage of SAP Plant Maintenance Module to monitor cost of spare parts and maintenance activities.

- 2. •Own Maintenance Planning & Scheduling RTT DMS, report Planned Task Completion, Backlog and Breakdown on daily and MTD basis spending • Own PIT(plan intervention time) Stop Plan and share it for alignment • Monitor PIT Stop for adherence and quality execution • Work with Storeroomon minor spares availability with regular safety stock review • Raise External work request via BBP and Low-Value Purchase • Lead Daily PIT Stop plan execution • Create and ensure closure of notifications and work orders using SAP PM • Tracks spare parts orders and ensures timely delivery using SAP • Technical resource to train team and execute SAP PM • Lead Maintenance critiques and update Job Plans for maintenance tasks POSITION: PACKAGING DEPARMENTOPERATIONS LEADER. JOB FUNCTION; (July 2011-April 2014) Ensureall packaging equipment operate at >80% efficiency and availability. Driveprocess reliability to target within Packing operation Review and update Time Based Maintenance schedule for all equipment in Packing and driveadherence to TBM. Plan and lead the implementation of preventive and Proactive maintenance (TPM) using SAP Maintenance and TBM on productionequipment to prevent equipment failure in conjunction with the maintenance planner. Analyzeproduction equipment performance, identify and prioritize and execute improvement actions and projects for processes, facilities and tooling. Drivewith excellence the execution of all AM (DH, CIL, and CL) DMS within the line teams. Create Maintenance standards and AssistTech Ops with documentation and technical information required for change proposals (using theSIMPTWW format). Schedule, coordinateand superviseexternal contractors performing equipment maintenance and repair. Participate in the creating of annual equipment maintenance budget. POSITION: PHC DEPARTMENT PROCESS LEADER. (Jan 2010-June 2011) Driveprocess reliability to target within Packing operation Update and define CL (Variable, Static & Auto Settings) for all Packing equipment Review and update Time Based Maintenance schedule for all equipment in Packing and for electrical components and drive adherence to TBM. Lead all Electrical and process improvementprojects in Packing operation Drivewith excellence the execution of all AM (DH, CIL, CL) DMS within the line teams

- 3. Identify rootcauses and driveexecution of countermeasures of electrical systems, Process failures and breakdowns. Driveto zero all operational losses in Packing operation POSITION: AUTONOMOUS MAINTENANCE/TEAM LEADER (Dec 2008 –Jan 2010) Lead and Qualify Department equipment on AM step 3 Roll out Abnormality handling DMS in the department. Roll out CIL tracking DMS in the department Roll out OPL management in the department. Roll out Kaizen DMS in the department Carry out a monthly collation of Department's A.M progress (equipment& people) vs. Plan and reporting of results. Ensurethat people are finding and fixing defects on the line to reduce loses on the line. Reward and recognition for the AM teams using the Site’s Matrix Reduce the set up/inspection time on Masipack Bagger POSITION: LINETECHNCIAN. (JULY 2006- NOV. 2008) Operate and maintain Eurosicma pillow packaging equipment. Operate and maintain Eurosicma pillow packaging equipment. Performequipment disassembly, set-up, cleaning, and sanitizing tasks in support of production operations. Sap end User for the team. EDUCATION HISTORY THE POLYTECHNIC IBADAN 2009 Higher National Diploma in Mechanical Engineering FEDERAL POLYTECHNIC ILARO 2006 National Diploma in Mechanical Engineering QUEEM MARISMODEL COLLEGE, LAGOS 2001 Senior secondary schoolcertificate OTHER TRAININGS&QUALIFICATIONS. SAP PM Training April 2014 5 days Quality Key Element Training October 2011

- 4. UPS (universalProblemsolving tools) Jan 2011 PM (predictivemaintenance) college Sept. 2011 Basic Electrical Safety Training December 2009 Root CauseAnalyses Dec, 2009. 2 day Quality AssuranceKey ElementTraining June, 2008. Multiple Cause Analyses March, 2008. Quick Risk Prediction March, 2008 Chemical Management. Feb, 2008. Technology transfer and Training on pillow pack machine April 2008 REFEREES. Mr. Odekunbi Sunday Maintenance Engineer/Line Leader ThroatDrops Department, Procter and gamble Nigeria Limited, Ibadan, Oyo state. 07043319147 Mr. SeunIlori Land and Survey Lagos state Ministry of works Lagos. 08023081315