Technical specification EEE

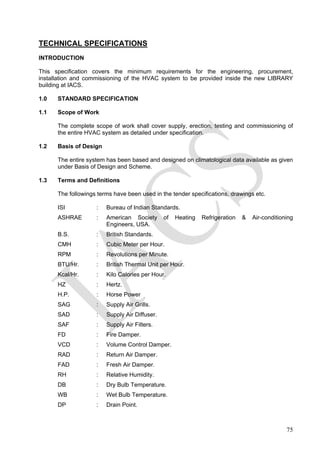

- 1. TECHNICAL SPECIFICATIONS INTRODUCTION This specification covers the minimum requirements for the engineering, procurement, installation and commissioning of the HVAC system to be provided inside the new LIBRARY building at IACS. 1.0 STANDARD SPECIFICATION 1.1 Scope of Work The complete scope of work shall cover supply, erection, testing and commissioning of the entire HVAC system as detailed under specification. 1.2 Basis of Design The entire system has been based and designed on climatological data available as given under Basis of Design and Scheme. 1.3 Terms and Definitions The followings terms have been used in the tender specifications, drawings etc. ISI : Bureau of Indian Standards. ASHRAE : American Society of Heating Refrigeration & Air-conditioning Engineers, USA. B.S. : British Standards. CMH : Cubic Meter per Hour. RPM : Revolutions per Minute. BTU/Hr. : British Thermal Unit per Hour. Kcal/Hr. : Kilo Calories per Hour. HZ : Hertz. H.P. : Horse Power SAG : Supply Air Grills. SAD : Supply Air Diffuser. SAF : Supply Air Filters. FD : Fire Damper. VCD : Volume Control Damper. RAD : Return Air Damper. FAD : Fresh Air Damper. RH : Relative Humidity. DB : Dry Bulb Temperature. WB : Wet Bulb Temperature. DP : Drain Point. 75

- 2. 1.4 The codes, regulation as detailed below shall be followed in this contract :- 1. Safety code for air-conditioning (revised) amendment 1 : IS 659 : 1964 (reaffirmed 1991) 2. Safety code for mechanical Refrigeration : IS 660 : 1963 (reaffirmed 1991) 3. Testing of refrigeration compressors : IS 5111 : 1993 4. Aircooled heat exchangers (amendment 1) : IS 10470 : 1983 (reaffirmed 1991) 5. Packaged Air-conditioner(amendment 1991) : IS 8148 : 1976 (reaffirmed 1991) 6. Thermostats for use in refrigeration etc. : IS 11338 : 1965 (reaffirmed 1991) 7. Metal Duct Work : IS 655 : 1963 (reaffirmed 1991) 8. Steel for general structural purpose : IS 2062 : 1992 9. Refrigeration : As per ASHRAE / ISI Airconditioning & Refrigeration Air-conditioning institute Standards. 10. Hot Dip Zinc Coated Steel Tubes : IS 4736 : 1968 11. Colour code for the identification of pipe lines : IS 2379 : 1963 12. Specific requirements for the direct switching of the individual motors. : IS 4064 ( Part II) 1978 13. PVC insulated ( HD) Electric Cables for working voltage up including 1100 Volts. : IS : 1554 ( Part I) 14. HRC Cartridge fuse links upto 650 Volts. : IS 2208 : 1976 15. Starter : IS 8554 ( Part I) 1979 16. Inspection and testing of installation : IS 732 ( Part III) 1979 17. Galvanized steel wire for fencing : IS 277 : 1977 18. Three phase induction motors : IS : 325 19. PVC insulated ( heavy duty ) cables for working voltage up to 1.1. KV and up to 11 KV Grade respectively. : IS 1554 : 1981 Part I & II 20. Code for practice for electrical wiring installations. : IS 732 : 1989 21. Code for practice for earthing : IS 3043 76

- 3. 22. Specification for single phase small A/C & universal motors : IS : 996 23. Circuit breaker A.C : IS 2516 : 1980 Part I & II 24. Contactors for A.C for voltage upto 1100 V. : IS 2959 : 1975 25. Low voltage switch gear and control gear assemblies. : IS 8623 : 1993 Part I & II 26. Code of practice for selection of starters for AC induction motors : IS 3914 27. Specification for cables glands : IS 4821 28. Code for selection, installation & maintenance of switch gear and control gear. : IS 10118 :1982 Part I to IV 29. Conduits for electrical installations : IS 9537 : 1981 Part I to IV 30. Permissible limits of noise level for rotating electrical machines. : IS 12065 : 1987 31. Code of practice for installation and maintenance of motors : IS 3106 : 1966 32. HRC catridge fuse links upto 650 volts : IS : 2208 33. PVC insulated ( heavy duty) electric cables for working voltage upto & including 1100 watts. : IS ; 1554 ( Part I) 34. Method for testing Panel type air filters for AC purposes. : IS 7613 : 1975 (reaffirmed1991) 35. Unbounded glass wool for thermal insulation (1st. Revision) : IS 3690 : 1974 36. Expanded polystrene for thermal insulation purposes. ( 1st. revision) : IS 4671 ; 1984 (reaffirmed) 1.5 Safety Codes The following IS codes shall be followed: Safety code for mechanical refrigeration : IS 660 Safety code for air conditioning : IS 659 Safety code for scaffolds & ladders : IS 3696 Code of practice for fire precaution in Welding & cutting operations : IS 3016 Code for safety procedures and practices In electrical works : IS 5216 77

- 4. Code of practice for safety and health Requirements in electrical & gas welding And cutting operations. : IS 3696 1.6 Spacs All shop drawings shall be prepared by the A.C Contractor after examining the architectural & AC drawings. 2.0 DESIGN CONDITIONS The design parameters to be used for detailed design of the air conditioning system as follows: 2.1 Outside Ambient Conditions Summer : DB: 40o C (105o F) & WB: 28.33o C (83o F). Monsoon: DB: 32.2o C (90o F) & WB: 30o C (86o F). Equipment performs to the above ambient conditions and not fail in conditions of 43o C DB (dry bulb). 2.2 Inside Design Condition: Room Temperature : 23o C + 1.1o C Relative Humidity : 55% + 5% Detail Input conditions are mentioned below: Sl. No. A.C space Area (Sft) Occu- pancy Lighting (W/sft) Equip- ment (KW) Fresh Air (cfm) Sensi- ble Load (BTU/ hr) Total load (BTU/ hr) ADP (oF) Dehmfd Air (cfm) Rem arks 1 2 3 4 5 6 7 8 9 10 11 12 First floor Library 12877.00 150.00 1.50 5.00 2250 560,131 602,985 54 21,884 3.0 DESIGN PARAMETES 3.1 Ducting work a) Method of Duct Design Equal friction method : b) Maximum air velocity in supply duct FPM : 1200.0 c) Maximum air velocity in return duct FPM : 800.0 d) Friction loss in duct (maxm) MM Wg in 100 Mt run : 6.66 e) Maximum Velocity at supply air grill outlet FPM : 150.0 78

- 5. 3.2 Insulation Maximum temperature rise in the supply air duct from Air-handlers outlet to farthest outlet in ºC 1.10 4.0 NOISE AND VIBRATION CONTROLS 4.1 The air conditioning contractor must take all necessary precautions to have minimum noise generation and its transmission. Minimum vibration as permitted by IS relevant code shall be ensured. A few points for guidance only are given below: a) Double fire retardant flexible connections shall be provided from air discharge to outlet of air-handler to the duct. b) Vibration isolation pads of suitable thickness commensurate to loading for isolation of vibration shall be provided under all equipments. in consultation with manufacturer for proper selection of vibration isolators c) Flexible conduit connections of minimum diameter of 50mm to motors shall be provided. All loops should be large enough to allow connections to remain flexible. d) All conduit connection where conduits are 60mm or larger shall be made of 1.2 meters minimum length conduit installed in the shape of U and grossly slack to provide maximum vibration isolation. e) The floor supported piping shall be mounted on pipe supports with 7.5mm ribbed neoprene pads between the base plate of the pipes and the floors. f) All items suspended from false ceiling shall be isolated on separate hangers. g) In case of ducts, conduits, pipes & tubes the annular space between construction and penetrating element shall be sealed with sand cement plaster. h) The supply duct starting from air handling unit & plenum shall be provided with 12 mm thick acoustic lining as indicated in the tender drawings. i) The air-conditioning contractor shall take all other precautions or shall make his own arrangements even if not specified in the tender documents for eliminating high noise levels & shall minimize vibrations in all mechanical equipments without any additional cost. 5.0 GENERAL DESCRIPTION AND SPECIFICATION OF THE SYSTEM PROPOSED The air-conditioning of the IACS Kolkata shall be based on the air cooled Floor Mounted Type package unit for 1st Floor area. The 1st Floor area shall be air-conditioned by the Air Cooled Floor Mounted type packaged air conditioning unit. The Installed capacity of the A. C. Unit shall be 90 TR (approximately) (4 Nos 15 TR Air Cooled Scroll Package Unit as working + 2 Nos 15 TR unit as standby) The Condenser for the package unit shall be located outside the building and on a MS structure. The Supply air main ducting from the package Units shall be run above the false ceiling to the conditioned space as per layout enclosed with tender. The Conditioned air shall be distributed through the ceiling mounted type diffuser/ Grill as per distribution arrangement indicated in the drawings. 79

- 6. The return air shall be mixed with fresh air before passage over the cooling coils. The fresh air intake shall be complete with Air Intake Louvers with insect screen, & Manual & Motorized Volume Control damper. The Motorized VCD will be controlled through a CO2 Sensor and a controller. Vendor has to select the controller in such a way that, set point of CO2 level and actual CO2 quantum can be seen on the controller and the controller can give necessary 0-10mA output to the Motorized damper in such a way that based on the actual level of CO2 the fresh air damper will open / Close. The Controller should be such that, the minimum & Maximum value of the operating range can be adjusted in the controller. The Ductwork shall have provision for Volume control dampers for balancing the system. The entire supply air duct shall be insulated with the CLASS O ANTIMICROBIAL type 13 mm thick Nitrile rubber with Al. Foil Faced. All the Terminal Diffuser / Grill also with Al. Volume Control damper to have proper air distribution inside Conditioned area and for balancing purpose. To control the Noise level inside area as per noise level mentioned above, acoustic lining shall be provided inside the Duct up to three meters (3M) from the indoor unit mouth as mentioned in the drawing. Necessary Motorized Type Fire damper with spring return type actuator for supply air duct and Fusible link type fire damper as per UL555 shall be provided for Return air path for fire protection. Necessary electrical interlocking arrangement shall be provided with fire damper & Evaporator fan motor to shut down the AC fan on detection of fire. 5.1 Air cooled Package A. C. System Evaporator Section (Indoor unit): The evaporator fan should be with DIDW type centrifugal fan of AMCA certified having with the minimum followings: • C45 carbon steel shaft • Anti corrosion paint on shaft for durability • Self-aligning and hermetically sealed durable ball bearings • Tab-lock blades • Statically and dynamically balanced to grade G4 (according to ISO 1940) The capacity of the each Evaporator fan for 16.5TR unit should be 6800 CFM. The Static pressure for the fan should be 35mm WG. The fan motor should have belt driven type with variable pitch pulley to adjust the CFM during commissioning & maintenance. The evaporator section should have with 4R deep cooling coil and with 50mm thick Synthetic washable type pre filter with 90% efficiency down to 10 micron. The Filter & Coil face velocity should not be more than 500 FPM. Each unit should have multiple scroll compressors. The unit should also with either Thermostatic or Electronic expansion valve. The drain pan of the indoor unit should be insulated with proper sandwich insulation to protect condensation. Oppose blade type Volume control damper to be provided outside the mouth of unit with ON / OFF marking for proper controlling & adjustment of Air quantity as per design condition. Following Protections should be considered for Each Package unit: 1. Single Phase & Phase reversal protection 2. High Pressure Cut out 80

- 7. 3. Low pressure cut out. 4. Over Voltage & Under Voltage Protection. 5. Over load trip . The Microprocessor Controller should have the following features: 1. In the power saving mode, when the compressor is off, the condenser fan should also remain off. 2. Room temperature set point and the actual room temp. to be displayed though Electronic temperature sensor. 3. Programmable operation feature for one year with real time clock. 4. Auto restart after restoration of power. 5. Fault Diagnosis feature. 6. Anti recycle feature. Condenser The Air Cooled Condenser should be with aerofoil type low power consumption fan, heat exchanger to be coated with golden anticorrosive on aluminum Fins surface. The Cooling coil to be design in such a way that the package unit can work upto 45o C. Refrigerant Pipe: The indoor & outdoor unit to be connected with the hard drawn copper pipe of minimum 18G thickness. All the elbow & reducer should be with the same thickness of the pipe. The size of the refrigerant pipes to be done by the vendor based of actual pipe length etc. The Refrigerant pipes should be Pressure tested at 400 PSI / 200 PSI and shall hold the pressure for 24 hrs. Proper Vacuuming should be done before charging of the refrigerant. Pipe Supports All refrigerant piping shall be supported to prevent deflection, bulking and vibration. Piping shall be supported at all changes in direction and at intervals of not more than 1.2 meters on straight runs. Pipe supports and clamps shall be subject to approval of consultant. Pipe work on roofs and floors shall be supported on off-set clamps, floor. The Pipe support stands shall be bolted to the concrete slab or steel members. Vertical pipe work shall be supported with trapeze hangers with rods suspended from inserts. Condensate drain pipe supports shall be capable of vertical adjustment after installation of piping. All pipe works passing through the walls, floors and roof slabs shall be provided with pipe sleeves of adequate size to allow the passage of insulation. Electrical Cabling All the connected Power cable should be with Al. Ar. Cable of 1100 V grade & control cable should be with Cu. Ar. Cable of 1100 V grade. The minimum size of Power cable should be 4 sqmm Aluminium & for control cable 2.5 sqmm copper. The incoming supply of the MCC should be with MCCB & all outgoing feeder should be with MCB & for compressor MCCB of suitable rating. The Outdoor Structure should be such that proper maintenance is possible and isolators to be provided near condensers with necessary 81

- 8. interlock with package unit, so that for maintenance / emergency condensers can switch off. Noise Levels Noise level inside the conditioned area resulting from the units shall not exceed the following: - NC 35 for office area All running equipments shall be isolated from the building structure and the support isolated from other items of equipment. All the units shall have anti-vibration mountings of approved make and these shall be subject to approval of the consultant. All the Air distribution system should be designed in such a way so that inside noise level should be within NC 35. Vibration Isolators All plant shall be isolated from the building structure and the support isolated from other items of equipment. The package units’ shall have anti-vibration mountings of approved make subject to consultants approval. Multi-layer rubber pads with square grid convolutions on both sides, spaced with steel shims and of a thickness to suit the points of uniform loading of the plant item but of a minimum thickness of 32 mm shall be spaced not more than 750 to 1000 mm apart. 6.0 DUCTWORK STANDARD SPECIFICATION FOR AIR CIRCULATION SYSTEM This section deals with supply, erection, testing & balancing of GI sheet metal duct work and air registers conforming to specifications as given below: Material for Ducing The duct shall be fabricated out of galvanised sheet, class VIII (Zinc coating 120 gm/m²ƒnas per the parameters given below which are conforming to IS 655-1963. Maximum Thickness Type of Transverse Bracing Upto 600 0.63 S-drive, pocket or bar, slips, on 2.5 m ceners None 601 to 750 0.63 S-drive, pocket or bar, slips, on 2.5 m Centers, S-drive 25 mm pocket, or 25 mm bar slips on 2.5 m centers. 25 x 25 x 3 mm, angles, 1.2 m from joint. 82

- 9. 751 to 1000 0.80 Drive, 25 mm pocket or 25 mm bar slips, on 2.5 m centers 40 x 40 mm angles connections. 25 x 25 x 3 mm angles, 1.2 m from joint. 1001 to 1500 0.80 40 mm bar slips, with 35 x 3 mm bar reinforcing on 2.5 m centers 40 x 40 x 3 mm angles, 1.2 m from joints. 1501 to 2250 40 x 40 mm angle connections, or 40 mm bar slips, 1 m maximum centers with 35 x 3 mm bar reinforcing. 40 x 40 3 mm diagonal angles, or 40 x 40 x 3 mm angle 60 cm from joint. * Ducts 2250 mm and larger require special field study for hanging and supporting methods. In addition to above the following points should be also taken into account while fabrication of ducts. a) All ducts of size larger than 450mm shall be cross broken. b) All ducts shall be supported from the ceiling / slab by means of MS rods of dia 9mm with MS angle of size 40 x 40 x 5 mm at the bottom with neoprene pad in between the duct & MS angle. The ducts shall be suspended from the ceiling with the help of dash fasteners. Provision for necessary ancillary materials required for hanging the ducts shall be arranged by the contractor. c) The vanes shall be provided wherever required and shall be securely fastened to prevent noise & vibration. d) The rubber gasket shall be installed between duct flanges in all connections and joints. e) All flanges and supports should be primer coated. f) The flexible joints shall be fitted to the delivery side of AHU fans with Fire Retardant Double canvass. The length of flexible joints should not be less than 150 mm and not more than 300 mm between face. g) The ducting work can be modified if deemed necessary in consultation with the Engineer in Charge to suit actual site conditions in the building. h) Box Type Dampers & Splitters These dampers shall be provided in the ducting work for proper control and balancing of air distribution. All dampers shall be louver type robust construction. These dampers shall be fitted with easily accessible operating mechanism, complete with links, levers, quadrant for proper control and setting in a desired position. The position of the handle of the damper operating mechanism shall be clearly visible and shall indicate the position of the damper in the duct. All dampers, splitters shall be fabricated out of G.S. sheet of two gauges higher than the duct 83

- 10. piece having these fittings. Dampers shall be installed in duct at all required locations. No extra payment shall be made separately since these form part of Air Circulation System. NOTE: In case angle iron supports are not feasible to be installed for supporting the ducts due to height constraint then the contractor shall support the ducts with M.S flats of at least double the thickness of the angle iron supports. A) THE SUPPLY AND RETURN AIR GRILLS AND CEILING DIFFUSERS The supply and return air grills and ceiling diffusers shall be made of powder coated extruded aluminum sections. The supply air grills / diffusers shall be provided with screw operated opposed blade volume control device made of extruded aluminum in black anodized finish. All grills / diffusers shall have soft continuous rubber / foam gasket between the periphery of the grills / diffusers and surface on which it has to be mounted. The colour of grills / diffuser shall be as per the approval of the Engineer in Charge. B) LINEAR SUPPLY AND RETURN GRILLS The linear continuous supply / return air grills shall be made of powder coated extruded aluminum construction with fixed horizontal bars. The thickness of fixed bar louvers shall be 5mm in front and the flange shall be 20mm wide with round edges. The register shall be suitable for concealed fixing and horizontal bars of the grills shall mechanically crimp from the back to hold them. The colour of grills shall be as per the approval of the Engineer in Charge. The volume control device made of extruded aluminum construction in black anodized finish shall be provided in supply air duct collars only. C) SQUARE / RECTANGULAR CEILING DIFFUSERS The square / rectangular ceiling diffusers shall be made of powder coated extruded aluminum construction with flush fixed pattern. The diffusers shall have Anti-Smudge ring and spring loaded removable central core in various pattern for air flow direction. The diffusers shall be mounted by concealed screw fixing arrangement. The volume control device of extruded aluminum construction in black anodized finish shall be provided in supply air diffusers. The colour of diffuser shall be as per the approval of the Engineer in Charge. D) VOLUME CONTROL DEVICE The opposed blade volume control device shall be made of Powder Coated extruded aluminum construction in black anodized finish. Opposed blades shall be pivoted to extruded aluminum frame with Nylon bushes. Specially designed blade shall have an overlapping lip which shall ensure a tight closure. E) FRESH AIR INTAKE LOUVERS WITH BIRD SCREEN The fresh air intake louvers at least 50mm deep will be made of powder coated extruded aluminum construction. Bird / insect screen will be provided with the intake louvers. The blades shall be inclined at 45 degree on a 40mm blade pitch to minimize water ingress. The lowest blade of the assembly shall be extended out slightly to facilitate disposal of rain water without falling on door / wall on which it is mounted. 84

- 11. The intake louvers shall be provided with factory fitted aluminum construction volume control dampers in black anodized finish. PAINTING All ducts collar / shoot behind the grills / diffuser shall be given at least two coats oil black enamel paints. TESTING The complete duct system shall be tested for air leakage & complete air distribution system shall be balanced in accordance with air quantities indicated on the approved drawing STANDARD SPECIFICATION OF THERMAL / ACOUSTIC INSULATION This section deals with supply and fixing of thermal / acoustic insulation of ducts, pipes etc. as per the specification given in this section. MATERIAL OF INSULATION The insulation material of the following kind shall be used for cold insulation. a) FOR DUCT INSULATION WITH CLASS O ANTI-MICROBIAL TYPE 13MM NITRIAL RUBBER HAVING FOLLOWING SPECIFICATION: - Insulation material shall be Closed Cell Elastomeric Nitrile Rubber - Density of Material shall be between 40 to 60 Kg/m3 - Thermal conductivity of elastomeric Nitrile rubber shall not exceed 0.033 W/mK at mean temperature of 0°C - Insulation material shall have anti-microbial product, which is EPA (Environmental Protection Agency), USA approved, as an integral part of insulation that cannot be washed off or worn off. - It shall give enhanced level of protection against harmful Microbes such as bacteria, mold, mildew and fungi and should confirm to following standards: Fungi Resistance – ASTM G21 and Bacterial resistance –ASTM 2180 / ASTM G 22. - The insulation shall have fire performance such that it passes Class 1 as per BS476 Part 7 for surface spread of flame as per BS 476 and also pass Fire Propagation requirement as per BS476 Part 6 to meet the Class ‘O’ Fire category as per 1991 Building Regulations (England & Wales) and the Building Standards (Scotland) Regulations 1990 - Material should be FM (Factory Mutual), USA approved. 85

- 12. - Water vapour permeability shall not exceed 1.74 x 10-14 Kg / (m.s.Pa), i.e. Moisture Diffusion Resistance Factor or ‘µ’ value should be minimum 10000. - The Insulation materials should be with self adhesive type and with Al. Foil Faced to protect against mechanical damage. The Thermal conductivity values in W/m. K of fiberglass shall confirm to following: Mean Temperature o C Density in Kg/cmt Thermal Conductivity W/m.k For Duct Lining 25 o C 32 0.032 50 o C 32 0.035 The sample of insulation material shall be submitted for approval to the Engineer in Charge and the sample shall be tested for thermal conductivity values by the contractor at his own expense. Adhesive used for setting the insulation shall be non-flammable, vapor proof, CPRX compound. INSULATION ON SHEET METAL DUCTING The thickness of insulation used on ducting shall be as detailed below: Conditioned space a) Supply Air Duct Insulated with 13 mm thick Aluminium faced Close cell Nitril Rubber The application of insulation should be carried out in workman like manner as detailed below Insulation of Ducting with Aluminium FACSD Fibre Glass a) Duct surface to be cleaned thoroughly b) To apply two coats of adhesive Compound. c) To fix factory pre-laminated aluminium faced self adhesive type close cell Nitril rubber of specified thickness. d) Fix self-adhesive aluminum tape of 50 mm width on all longitudinal / Transverse joints. e) Finally fix PVC straps of 19mm width at every 300mm centre to centre. 86

- 13. 87 ACOUSTIC LINING OF DUCT The material to be used for duct lining shall be 25mm thick resin bonded fiber glass having a density of 32 Kg/m³ or 12 mm thick fibre glass rigid board of density 48 Kg/m³ & covered with 0.5 mm thick perforated aluminum sheet. The lining of initial length of the duct shall be done as shown in the tender layout drawings & shall be carried out as follows. a) Clean the duct piece thoroughly, b) To apply two coats of CRPX compound. c) Fix the fiber glass of suitable thickness & cover with fiber glass tissue paper. d) Cover the insulation board with 0.5mm thick perforated aluminium sheet with at least 20% to 25% perforations e) Secure the aluminium sheet with GI frame work with cadmium coated self taping screws with washers. Special Notes: 1. All the party should submit the Equipment rating chart at different temperature / outside condition. 2. Compressor ratting chart should be submitted along with tender for proper technical evaluation of the capacity offered. 3. Vendor should submit the technical Data Sheet & Shop drawing within 7 days from date of issue of order for necessary approval by consultant before physically start the work at site. 4. After Commissioning vendor should conduct performance testing of the entire system for 72 hrs. 5. Vendor should submit the complete operation & maintenance manual containing As Built Drawing, Do’s & Don’t, Operation procedure, Set points of different parameters, Catalogue & Technical details etc.