Resume de Edwin Mulero

•Télécharger en tant que DOCX, PDF•

1 j'aime•124 vues

Signaler

Partager

Signaler

Partager

Recommandé

Recommandé

Contenu connexe

En vedette

En vedette (20)

Product Design Trends in 2024 | Teenage Engineerings

Product Design Trends in 2024 | Teenage Engineerings

How Race, Age and Gender Shape Attitudes Towards Mental Health

How Race, Age and Gender Shape Attitudes Towards Mental Health

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

Content Methodology: A Best Practices Report (Webinar)

Content Methodology: A Best Practices Report (Webinar)

How to Prepare For a Successful Job Search for 2024

How to Prepare For a Successful Job Search for 2024

Social Media Marketing Trends 2024 // The Global Indie Insights

Social Media Marketing Trends 2024 // The Global Indie Insights

Trends In Paid Search: Navigating The Digital Landscape In 2024

Trends In Paid Search: Navigating The Digital Landscape In 2024

5 Public speaking tips from TED - Visualized summary

5 Public speaking tips from TED - Visualized summary

Google's Just Not That Into You: Understanding Core Updates & Search Intent

Google's Just Not That Into You: Understanding Core Updates & Search Intent

The six step guide to practical project management

The six step guide to practical project management

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Resume de Edwin Mulero

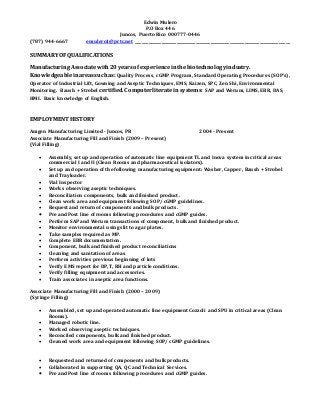

- 1. Edwin Mulero P.O Box 446 Juncos, Puerto Rico 000777-0446 (787) 944-6667 emulero1@prtc.net ________________________________________________________________________ SUMMARYOFQUALIFICATIONS ManufacturingAssociatewith20yearsof experienceinthebiotechnologyindustry. Knowledgeableinareassuchas: Quality Process, cGMP Program, Standard Operating Procedures (SOP’s), Operator of Industrial Lift, Gowning and Aseptic Techniques, EMS, Kaizen, SPC, Zen Shi, Environmental Monitoring. Baush + Strobel certified.Computerliteratein systems: SAP and Werum, LIMS, EBR, DAS, HMI. Basic knowledge of English. EMPLOYMENT HISTORY Amgen Manufacturing Limited - Juncos, PR 2004 - Present Associate Manufacturing Fill and Finish (2009 – Present) (Vial Filling) Assembly, set up and operation of automatic line equipment TL and Inova system in critical areas commercial I and II (Clean Rooms and pharmaceutical isolators). Set up and operation of the following manufacturing equipment: Washer, Capper, Baush + Strobel and Trayloader. Vial Inspector Works observing aseptic techniques. Reconciliation components, bulk and finished product. Clean work area and equipment following SOP/ cGMP guidelines. Request and return of components and bulk products. Pre and Post line of rooms following procedures and cGMP guides. Perform SAP and Werum transactions of component, bulk and finished product. Monitor environmental using slit to agar plates. Take samples required as MP. Complete EBR documentation. Component, bulk and finished product reconciliations Cleaning and sanitation of areas Perform activities previous beginning of lots Verify EMS report for DP,T, RH and particle conditions. Verify filling equipment and accessories. Train associates in aseptic area functions. Associate Manufacturing Fill and Finish (2000 – 2009) (Syringe Filling) Assembled, set up and operated automatic line equipment Cozzoli and SPU in critical areas (Clean Rooms). Managed robotic line. Worked observing aseptic techniques. Reconciled components, bulk and finished product. Cleaned work area and equipment following SOP/ cGMP guidelines. Requested and returned of components and bulk products. Collaborated in supporting QA, QC and Technical Services. Pre and Post line of rooms following procedures and cGMP guides.

- 2. Edwin Mulero P.O Box 446 Juncos, Puerto Rico 000777-0446 (787) 944-6667 emulero1@prtc.net ________________________________________________________________________ Performed SAP and Werum transactions of component, bulk and finished product. Monitored environmental using slit to agar plates. Took samples required as MP. Inspected Syringes. Completed EBR documentation. Component, bulk and finished product reconciliations Cleaning and sanitation of areas Performed activities previous beginning of lots Verified EMS report for DP,T, RH and particle conditions. Verified filling equipment and accessories. Trained associates in aseptic area functions. MFG. Operator III (1994 – 2000) (Packaging Operator) Checked production schedule and determined that adequate materials packing have been placed at line by material handlers. Set-up and operated automatic packing machines (all machines) to meet customer required packing pattern and protective materials required. Stop line and aside defective materials or packaging. Monitored conveyor system to and from packing machine and to manual palletizer. Cleaned minor jams from the line (any machine). Checked layer of for full pattern pack, replacing missing or defective product. Recorded production on production schedule. Counted, recorded and disposed of spoilage to designated location. Audited work of others to assure labeling is correct. Picks up WIP material and clinical material and store in warehouse; move to warehouse, all released raw material from RMQ. Identified and checked raw material to be released to other cost centers and move to appropriate areas. Followed SOP’s, MP’s and cGMP’s while doing all above duties. Prepared material and packaging components, cleans work area and equipment. Executed reconciliations, inspects crimps final product container and cleans processing equipment. Syntex - Humacao, PR 1993 - 1994 Manufacturing Process Operator Worked in the Formulation area: Fluid Bed Granulator “Glatt” with programmable logic computer system “PLC”, weighing, screening and milling areas. EDUCATIONALBACKGROUND Universidaddel Turabo Gurabo,Puerto Rico Bachelor’sDegreeAccountabilitythreeyears