Principles of Pre-reforming Technology

- 2. Contents Pre-reforming Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 3. Markets Towns Gas • Naphtha => Town Gas, reforming & methanation • Market declining due to NG availability Hydrogen • Utility/chemical/refinery • C1 though to naphtha => H2 • Feedstock flexibility/smaller primary • Growing market for pre-reforming

- 4. Markets (contd) Methanol • Retrofits, increase output/efficiency • Growing market, technology enabler, big reactors Ammonia • Retrofits only GTL • 1,2 stage • Very big reactors

- 5. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 6. Flow-schemes - what does Pre-Reforming do? What is the aim of a pre-reformer? To react hydrocarbon feed with steam to give a methane rich product suitable for further downstream reforming. Pre-reforming works as an adiabatic steam reforming step over a Ni based catalyst. The basis for the reforming may be considered as the reaction between a hydrocarbon and steam • steam / methane reaction • water / gas shift reaction

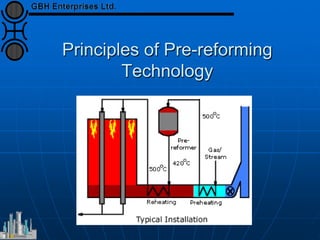

- 7. Prereformer Installation Pre- Heating Re- Heating Gas/Steam VSG-Z101 Pre-reformer 500ºC 500ºC 450ºC

- 8. Flow Scheme - Desulfurization Pre-Reforming catalyst is poisoned by sulfur. The performance of the sulfur removal system is important for the pre-reformer. The sulfur removal system may be designed in accordance with any well proven system but must achieve less than 0.1 ppm wt sulfur throughout the catalyst life. Ultra-purification recommended for natural gas applications

- 9. Advantages of Pre-reforming Fuel savings over stand alone primary reformer Reduced capital cost of reformer Higher primary reformer preheat temperatures Lower involuntary steam production Increased feedstock flexibility Higher activity primary reforming catalyst for naphtha based plants Lower overall steam to carbon ratios Provides protection for the main reformer Reliable and easy operation

- 10. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 11. Feedstock Following feeds may be fed to a pre- reformer reactor • Natural gas • Refinery Off Gas • Synthesis Gas derived from coal/oil gasification • LPG’s • Naphtha (up to FBP 240°C) • Kerosene • Methanol • Ethanol

- 12. Feedstock Feed Specification Poisons in feed Sulfur < 0.1 ppm wt Chloride < 1.0 ppm wt * Total heavy metals < 1.0 ppm wt (inc Lead) * Lead < 0.2 ppm wt * * - inlet purification section Steam Quality Sodium < 0.2 ppm wt Chloride < 0.1 ppm wt Sulphide < 0.1 ppm wt Silica < 0.1 ppm wt

- 13. Feedstock contd For naphtha feeds over pre-reforming catalyst there are limits on • Aromatic content – normally 10 wt% • Naphthene content – normally 25 wt% • When considered together < 40 wt% has been applied

- 14. Feedstock contd Following feedstock data is required for assessment of performance: •Gas and LPG feeds •Full composition •Level of impurities •For Naphtha feeds •PONA analysis •Level of impurities •C/H ratio and molecular weight •FBP

- 15. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 16. Pre Reformer Loading Extremely important to achieve a uniform loading Any zones of low or high voidage will reduce catalyst life • Check man-way plugs No meshes should be used in the vessel Thermocouples must be positioned correctly and height recorded Loading procedure will be provided Loading assistance may be provided

- 17. Prereformer Installation Adiabatic Pre-Reformer Axial flow with Thermowell Bed of pre-reforming catalyst.

- 18. Pre-reformer Start-up Drying Heating Start-up Reduction

- 19. Catalyst Drying For catalyst subjected to low temperature (ie <0oC) Dry using Nitrogen 175 to 250°C NG can be used below 200°C 4 to 24 hours Dry air, not suitable for prereduced First start-up of prereduced

- 20. Catalyst Heating Normally heated using nitrogen Absorbed moisture Initial heating rate, 50°C per hour Max temp differential in bed 100°C At 200°C, 70°C per hour Heating till peak 400°C, min 370°C High circ rate, max pd 2 bar

- 21. Catalyst Heating continued Warm-up rates Rapid warm-up minimises energy usage/time Traditional constraints of equipment Controllability Limited by mechanical considerations of vessel Catalyst, 150-170oC per hour

- 22. Catalyst Heating contd Limits on impurities * Oxygen 1% vol Carbon Dioxide 1% vol Carbon Monoxide 1% vol Methane 1% vol Hydrogen 1% vol Ethane 100 ppm vol Sulfur 0.1 ppm wt * For the initial warm up. Lower limits for already activated or prereduced catalyst

- 23. Catalyst Heating contd Holding at temperature Not recommended 2% hydrogen added Temperature reduced to 350°C

- 24. Catalyst Start-up When operating temperature has been achieved Check for build-up of carbon oxides and hydrocarbons Addition of 10 mol % Hydrogen Followed by steam Introduce process feed, maintain safe S:F ratio Ensure feed lines are drained and warmed Vent steam to atmosphere before cutting in

- 25. Heating using Natural Gas Using NG as heating medium No impurities Immediate start-up 50°C per hour, max differential 100°C At 200°C introduce steam • Min S:C 0.3kg/kg at 200°C • Min S:C 0.5kg/kg at 400°C to 450°C • Increase to design feed and S:F

- 26. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 27. Process benefits of pre-reforming Moves reforming load from Primary Better reformer design • Higher thermal efficiency in radiant box • Raises pre-heat temps before carbon formation issues • Feedstock flexibility Reduced steam export • Heat is recovered from duct Demonstrated using case studies

- 28. Process Benefits- Case Study Case 1 – Base Case – no pre-reformer installed Case 2 – Pre-reformer installed Case 3 – Pre-reformer installed and plant rate increased until firing on the reformer is the same as Case 1

- 29. Effect of a Pre-reformer on Primary Reformer Performance Parameter Units Case 1 Plant rate % 100 Methane slip mol % (dry) 12.84 ATE °C 1.8 Pressure drop bar 1.26 Maximum TWT °C 809 Fluegas temperature °C 898 Radiant efficiency % 68.7 Fuel rate change % 0 Case 2 100 12.76 1.1 1.28 803 885 69.4 -8.8 Case 3 109 12.79 1.3 1.49 807 898 68.7 0

- 30. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 31. Effect of a Pre-reformer on Primary Reformer Performance For new plants, there are CAPEX benefits • Can reduce tube count on a new hydrogen plant by over 5% • Fuel usage can be reduced by 8% For existing plant, excellent revamp opportunity • Additional throughput or feedstock flexibility In summary • Significant potential economic benefits • Overall benefits plant specific

- 32. Effect of a Pre-reformer on Primary Reformer Performance contd Good performance depends on good design and preparation of the reactor It is not simply another catalyst bed Guaranteed operation assumes plug flow through the bed Guaranteed operation relies on good catalyst management

- 33. Effect of a Pre-reformer on Primary Reformer Performance contd Travelling (or multi-point) thermocouple Catalyst Graded Ceramic Balls Catalyst discharge nozzle (alternative) Catalyst discharge nozzle (typical)

- 34. Effect of a Pre-reformer on Primary Reformer Performance contd Good performance is achieved through Even gas distribution Adequate temperature measurement Thorough pre-commissioning Correct catalyst charging procedures Good operating practices

- 35. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 36. Pre Reforming Data Analysis Good data is key to understanding performance of the pre reformer Data includes • Temperatures inlet and outlet the bed • Temperatures through the bed • Gas analysis inlet and outlet bed • Feedstock and steam flows inlet bed • Bed pressure drop trend

- 37. Pre Reforming Data Analysis Careful monitoring of temperatures inlet, outlet and through the bed allows • Problems to be detected early on Sulfur poisoning, wetting etc • Problems to be resolved before there has been too much damage caused • Estimation of residual life

- 38. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 39. Reaction Profile Reaction Zone Length End Of Reaction Zone Thermoneutral Point Minimum Reaction Temperature Beginning Of Reaction Zone Preheat Temperature Temperature°C Distance through bed

- 40. Reaction Profile end of reaction zone methanation and shift reactions dominate bed shrinkage or deactivation Temperature°C Distance through bed endotherm steam reforming reaction dominates

- 41. Reaction Profile By monitoring relative movement of specific points on the profile, • See if there is sulfur poisoning • See if there is excessive sintering • See if there is mal-distribution But rate changes will affect positions of profiles

- 42. Temperature Profiles - Rate

- 43. Temperature Profiles Natural Gas - Effect of Plant Rate Changes in plant rate affect profile • Increases in rate Increases the length of profile Decreases the gradient • Can be mistaken for sintering

- 44. Temperature Profiles - Changes in Inlet Temperature

- 45. Temperature Profiles Changes in Inlet Temperature Increases in inlet temperature • Shorten profile length • Steeper profile gradient • Change exit temperature

- 46. Temperature Profiles Maldistribution TI Maldistribution due to wetting/agglomeration

- 48. Temperature Profiles Natural Gas Temp Position along Bed Std NG Sintering (Lazy profile) Poisoning (Flat inlet)

- 49. Temperature Profiles Naphtha Temp Position along Bed Std Naphtha Sintering (Lazy profile) Poisoning (Flat inlet) Polymeric Carbon (deepen endotherm)

- 50. Contents GBHE pre-reforming background • Markets • Flow-schemes • Feed-stocks • Catalyst handling, loading & start-up Benefits of a pre-reformer • Case studies • Effects upon primary reformer • Data analysis • Reactor temperature profiles • Catalyst management Summary

- 51. Catalyst Management Draw the pre-reformer catalyst profile weekly Examine profile and check for • poisoning • carbon polymer formation • sintering Plot “end of reaction zone” (EOZ or Z90) against time

- 52. Catalyst Management - EOZ Distance through bed Temperature

- 53. Predicting End-of-Life The EOZ (or Z90) plot is the most useful tool Waiting for ethane or higher hydrocarbon slip is too late Ultimate limits are when feed preheat limitations are reached when C2 + slip is unacceptable for reforming catalyst • EOL of VSG-Z101 catalyst often taken to be when C2 + slip of 2000 ppm v/v of the wet rich gas.

- 54. Summary Successful Pre-reforming requires • A good catalyst • Careful Operation/Procedures GBHE VSG-Z101 catalysts are well suited to withstand operating rigors And come with the GBHE Experience - the learning which is so essential to well advised operation