The incredible stories of indian manufacturing

- 1. August -2019 VOL 8 ISSUE 02 Emami Building and Strengthening a New India Cement www.insightssuccess.in The Incredible Stories of Indian Manufacturing

- 4. SME-SMO Executives Manoj Shelge Circulation Manager Tanaji Digital Marketing Manager Prashant Chevale Technical Specialist Amar, Pratiksha Co-designer Mayur Koli Art & Picture Editor Rahul Kavnekar Art & Design Head Amol Kamble Associate Designer Poonam Mahajan Copyright © 2019 Insights Success Media and Technology Pvt. Ltd., All rights reserved. The content and images used in this magazine should not be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission from Insights Success Media and Technology Pvt. Ltd. Reprint rights remain solely with Insights Success. Printed and Published by Insights Success Media and Technology Pvt. Ltd. Corporate Ofces: Insights Success Media Tech LLC 555 Metro Place North, Suite 100, Dublin, OH 43017, United States Phone - (614)-602-1754 Email: info@insightssuccess.com For Subscription: www.insightssuccess.com Insights Success Media and Technology Pvt. Ltd. Ofce No. 22 & 510, Rainbow Plaza, Shivar Chowk, Pimple Saudagar, Pune, Maharashtra 411017 Phone - India: +91 7410079881/ 82/ 83/ 84/ 85 Email: info@insightssuccess.in For Subscription: www.insightssuccess.in sales@insightssuccess.com AUGUST, 2019 Follow us on : www.facebook.com/insightssuccess/ollow us on : www https://twitter.com/insightssuccess Cover Price : RS. 150/- Editor-in-Chief Pooja M. Bansal Managing Editor Rahul Niraj Executive Editor Sneha Sinha RNI NUMBER: MAHENG/2018/75953 Business Development Executive Shraddha, Kaustubh Business Development Lead Joan Ranbhise

- 5. From the Editor ndia’s industrial and manufacturing sector is deeply Irooted in its history. The handicrafts created by local artisans using locally available raw material and indigenous tools ruled trades and were famous across the globe. Textile manufacturing has been known as the gift of Indian peninsula to the world. Indian textile has draped the world since time immemorial. While manufacturing industries flourished under the rule of several dynasties that ruled the Indian sub-continent for ages, things became a bit stagnant under the British Rule. The real beginning of the modem industry in India started with the establishment of the cotton textile industry at Mumbai in 1854. After Independence, several policies were made to boost the manufacturing sector and bring India to the forefront of manufacturing in the world. But the initial policies and structure didn’t do the magic they were expected to do. The Gulf Oil Crisis, Agriculture Issues and the political turmoil in the country, added to the woes. In 1991, with Liberalization and introduction of Foreign Direct Investment (FDI), opened up new avenues. The key objective was to bring growth, boost productivity, provide employment and optimally utilize human resources. Gradually, with educational reforms, policy reforms, political stability, and several new and innovative initiatives, India now stands as an attractive hub for foreign investments in the manufacturing sector. Smart phones, luxury automobiles, among others, have set up or are looking to establish their manufacturing base in the country. The current Make in India Initiative is focused on boosting the manufacturing industry and Goods and Services Tax (GST) is expected to make India a common market with a GDP of US$ 2.5 trillion. The Indian Manufacturing Sector is poised to reach US$ 1 trillion by 2025 and India is expected to become the fifth largest manufacturing country in the world by the end of the year 2020. With such a positive impetus, the manufacturers are waiting to realize the long-held dream of putting India in the top ranks. Lubricating the Manufacturing Sector of India Sneha Sinha

- 6. COVER STORY CXO STANDPOINT ARTICLE 08 24 Evolving Manufacturing The Essence of Innovation in Indian Manufacturing Emami Cement Building and Strengthening a New India Trends to Watch Cement Manufacturing: Opportunities and Challenges 34

- 7. INTERVIEW WITH INSIGHTS SUCCESS 26 EMDET Designing and Manufacturing for Automotive 20 Ayoki Fabricon Building a Progressive Economy 32 Drona Aviation Providing Innovators with a Robust Platform 18 Deesha Impex Manufacturing and Exporting High-Quality Precision Equipment CONT ENTS 38 Neoplast Engineering Providing Quality and Innovative Plastic Processing Machines since 1973

- 8. Ideating and Manufacturing a New India he Manufacturing Sector of a country is a principal indicator of its economic Tdevelopment. Besides providing the population with its basic needs, it leads to a diversified economy. In India, Manufacturing has emerged as one of the high growth sectors. The sector is currently witnessing huge investments, both domestic and foreign. This issue of Insights Success, celebrates “The Incredible Stories of Indian Manufacturing”. The companies in this issue are an eclectic mix of proven credibility and new innovative ideas that are set to create the mark of a new India on the world map. The Cover Story of this issue features Emami Cement, a leading cement manufacturing company in Eastern India and a part of Emami Group of Companies; an Indian Conglomerate. Also featuring in this issue are Drona Aviation, an IIT-Bombay based startup building an ecosystem for drone innovation, NeoPlast, a renowned, reputed and reliable partner for the plastic processing machinery in Global market and Deesha Impex, a reliable manufacturer and exporter of plastic equipment and machinery. The issue also highlights the CXO Standpoint of Dibyajyoti Guha and Debalina Roy, Star Cement Limited. The insightful interviews of Ganesh Kumar, Managing Director of Ayoki Fabricon Pvt Ltd and Ranjot Singh, CEO & MD of Emdet Jamshedpur Pvt Ltd showcase their manufacturing stories. Go through our in-house article The Essence of Innovation in Indian Manufacturing from Evolving Manufacturing. We hope you enjoy reading this issue as much as we did while creating it!! Incredible Stories The of Indian Manufacturing

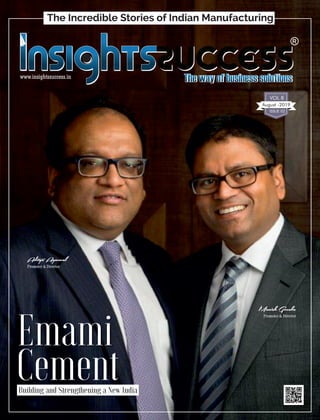

- 10. Aditya Agarwal & Manish Goenka Promoter & Director

- 11. Emami CementBuilding and Strengthening a New India cover Story “The year 2018-19 rode on strong demand in the East, which helped the cement business to break all its previous records and earn gross revenue of Rs 1800 Cr approx.”

- 12. The City of Joy, Kolkata is home to Emami Group of Companies; an Indian Conglomerate that has eleven key businesses with a presence in over sixty-three countries with a turnover of around Rs 20,000 crores and a workforce over 25,000 people. The Group has its presence in diversified sectors such as FMCG, newsprint and packaging boards, edible oil, biodiesel, real estate, hospitals, ballpoint tip, retail pharmacy chain, retail book & leisure store, cement, solar power and contemporary art. The Emami Group has several leading companies under its umbrella and some of them include Emami Limited (Flagship company of the Group); Emami Paper Mills Limited; Emami Agrotech Limited; CRI Limited; Emami Realty Limited and many more. Founding Partners Emami Group’s foundation was laid in 1974 when childhood friends, Radhe Shyam Agarwal and Radhe Shyam Goenka, came together to set up a company - Kemco Chemicals, an ayurvedic medicine and cosmetic manufacturing unit. The vision and innovative approach of founders transformed Kemco Chemicals into India’s one of the leading and listed Companies - Emami Limited, which is the flagship company of the Group. Both the founders are currently the Joint Chairman of the Emami Group of Companies. Setting foot into the Cement Market Emami Group forayed into cement business by incorporating a separate company - Emami Cement Limited on June 13, 2007. The company began its journey with an integrated cement plant with a clinker capacity of 1.98 million tonnes per annum (MTPA), and cement capacity of 2.50 MTPA at Risda in Chhattisgarh in 2016. At present, Emami Cement has four cement plants in operation with an installed capacity of 8.1 MTPA. It has an integrated cement plant at Risda in Chhattisgarh and three grinding units, one each at Panagarh in West Bengal, Bhabua in Bihar, and Jajpur in Odisha. By 2020, the company’s cement capacity is all set to increase to 9.3 MTPA. Its cement is sold under the brand name - ‘Emami Double Bull Cement’. During the period of 2008-2019, Emami Cement has invested a total of over Rs 4000 crore for setting up three green-field plants and also for acquiring a grinding unit in Bihar. Team Cement – Uniting the Best Headquartered at Kolkata, the cement company’s core team includes Manish Goenka, Whole-time Director & Executive Chairman; Aditya Vardhan Agarwal, Promoter Director; Vivek Chawla, Whole-time Director & CEO; Vinit Kumar Tiwari, Chief Marketing Officer; Rajiv Ranjan Thakur, Chief Financial Officer; Samar Banerjee, Vice President – HR, and Debendra Banthiya, Company Secretary. Vivek Chawla, the current CEO, has over 35 years of experience in cement and aluminium industries working across functions including management, operations, sales and marketing, projects and commercial. He joined Emami Cement in August 2016. Emami Cement launched its cement under the brand ‘Double Bull’, which signifies the promise of strength in its cement. The ‘Emami Double Bull’ brand was launched in the markets of West Bengal, Odisha, Madhya Pradesh,

- 13. Vivek Chawla CEO Incredible Stories The of Indian Manufacturing

- 14. Maharashtra, Jharkhand, Bihar, Chhattisgarh and Uttar Pradesh. Thus the company is positioning itself to capture a significant market share in East and Central India. At present, Emami Cement has four cement plants in operation, comprising an integrated cement plant at Risda in Chhattisgarh and three grinding units, one each at Panagarh in West Bengal, Bhabua in Bihar, and Jajpur in Odisha. Products that Speak for themselves The company markets all its products under the ‘Emami Double Bull’ brand. It has a wide portfolio of products which includes Portland Pozzolana Cement (“PPC”), Portland Slag Cement (“PSC”), 43 and 53 Grade Ordinary Portland Cement (“OPC”) and composite cement. It primarily sells its cement to retail and institutional customers in the states of West Bengal, Chhattisgarh, Odisha, Jharkhand, Bihar, Maharashtra and Madhya Pradesh and a part of Eastern UP. Premium PSC offering is sold under the brand ‘Emami Double Bull SUBH’ and premium PPC offering is sold under the brand ‘Emami Double Bull MASTER’. It sells its products to institutional customers directly under the ‘PROCEM’ brand. Emami’s cement’s plants with stand-alone capacities – alphabetically listed Nos Cement Plants District State Clinker Capacity MTPA 2019 Cement Capacity MTPA 2019 Estd Year 1 2 3 4 Bhabua Grinding Unit Kalinganagar Grinding Unit Panagarh Grinding Unit Risda Cement Plant TOTAL Bhabua Jajpur Burdwan B. Bazaar Bihar Odisha WB CHG 0.00 0.00 0.00 3.20 3.20 0.6* 2.00 2.50* 3.00* 8.1 2012# 2018 2017 2016 # Emami acquired Bhabua GU in 2018 * Expansion of 1.2 MTPA cement capacity is expected in year 2020. This would increase Emami’s Overall installed capacity to 9.3 MTPA. Better Technology, Better Products Emami is committed to delivering the best and consistent quality of cement to its customers. In its endeavour to do so, it has installed state-of-the-art technologies in all its factories and ensured superior quality control procedures at every stage of cement preparation. It has cutting edge technologies from FL Smith of Denmark and GEBR Pfeiffer of Germany. Automation of Quality Control Lab has been the biggest step towards this. The robotic lab has been installed in its integrated unit for automatic sample collection from the site at a set frequency and testing of every sample with 100% accuracy and real-time correction. It not only helps to monitor the quality but also ensures consistency. The latest version of testing equipment XRF, XRD, PSD testing machines, pelletizing machines etc have been installed in all its plants for the highest level of precision and accuracy in quality checks. A Cross Belt Analyser has been installed on limestone feed belt to prepare uniform quality stockpile for the best quality cement. Vertical Roller Mills which gives best particle size distribution among all types of grinding mills (like ball mill, tube mill, roller press etc) have been installed for raw meal, coal and cement grinding. This helps in producing best and uniform quality cement at the lowest power consumption. New Generation equipment like 6 Stage Pre-calciner, High Momentum Kiln Burner, Cross-bar cooler have been installed in its plants to produce best quality clinker and cement.

- 15. Our product portfolio contains 20% premium product; whose quality performance is best in the industry. “ Along with producing the best quality cement, the company also believes in delivering the best serviceability to its customers. It has automated logistics system inside its plants, installed GPS in the dedicated fleet of trucks, to improve truck TATs and hence ensure better serviceability to the customers. Internationally acclaimed advanced software like SAP and PULSE have been introduced in its system. This has improved the operations in terms of quality and delivery, ensuring better service to our dealers and customers Keeping Environment in Mind Emami is committed to reduce carbon footprint in its cement manufacturing process. With its state-of-art processing technologies, it has been able to maximise slag & flyash addition to highest limits set by BIS. This “The company has a total clinker capacity of 3.2 MTPA and cement capacity of 8.1 MTPA”

- 16. is done without compromising on its superior cement quality standards. It needs specific mention that flyash and slag are disposed from power and steel plants which else would have to be used as landfill if not consumed, thereby polluting environment and eroding the fertile soil. High-efficiency equipment and upgraded operating processes have been adopted to operate with Industry’s best power and fuel consumption thereby reducing CO2 emission in the manufacturing process. A few of them are; · Waste Heat Recovery System which can produce12 MW power by recuperating heat from hot flue exit gases of pre-heater and cooler, thus utilising thermal energy which else would have got lost in the environment. · CFBC boilers in CPP with ~3000 kCal/kWh heat rate with negligible water loss. · Cross – Bar Clinker cooler with ~ 70% heat recuperation efficiency · Continuous emission monitoring system at stacks for process and emission control. · Plan to install alternate fuel storing & firing system to replace ~ 5-10% of fossil fuels with alternative fuels. Holistic Development Emami joins Govt of India in its movement to create “New India” by playing a pivotal role in the development of rural and urban life of India. It has participated in different Govt infrastructure developmental schemes (like Smart City Mission, Pradhan Mantri Gram Sadak Yojana, etc) providing a concessional rate for its cement. Its cement factories are located in rural regions and it considers rural development as its solemn responsibility to co-exist with the communities around the plant. Various skill development programs like sewing and beautician training courses for women, English and personality development classes at nearby Govt. High Schools, etc have been conducted time to time by the organization. Health camps & awareness program on health, sanitation and road safety for local villagers are conducted periodically. Other developmental activities like village road construction, green belt development, pond deepening, revamping of ailing Govt schools are few major activities done by the organisation. Inside the factories, it is committed in providing safe and healthy work environment for all employees. It targets Zero accidents and is continuously working to develop advanced safety infrastructure and culture inside the plant premises. Entrepreneurs - Defining the Economy Vivek Chawla views start-ups as the future of India as they play a significant role in economic growth. They create job opportunities and bring innovative concepts & technology adding incredible value in overall development of the country. Govt of India’s new Scheme- “Startup India” can effectively minimise a lot of challenges that they have to face. He adds and advises young entrepreneurs to, “Stay positive and embrace each challenge as a learning opportunity. Plan financial model, conduct market research and have an accountant and legal counsel on board. They need to be patient as profit generation generally takes min 2 years to surface.” Eyeing the Future Emami Cement has planned to have a national presence in the next five years by setting up cement plants in Andhra Pradesh and Rajasthan, where the company has already acquired limestone mines. The company aims to be among the top few players in the cement industry. The company is looking at acquiring smaller integrated cement units in Central and East India and proposes to have a manufacturing capacity of 15 to 20 MTPA in the next three to five years. “ During the period of 2008-2019, Emami Cement has invested a total of over Rs 4000 crore for setting up three green-eld plants and also for acquiring the grinding unit in Bihar”

- 17. Global Subscription Yes I would like to subscribe to Insights Success Magazine. Address : Country :City : State : Zip : Date : CORPORATE OFFICE Name : Telephone : Email : Insights Success Media and Technology Pvt. Ltd. Ofce No. 22 & 510, Rainbow Plaza, Shivar Chowk, Pimple Saudagar, Pune, Maharashtra 411017 Phone - India: +91 7410079881/ 82/ 83/ 84/ 85 USA: 302-319-9947 Email: info@insightssuccess.in For Subcription: www.insightssuccess.in Cheque should be drawn in favour of : INSIGHTS SUCCESS MEDIA AND TECH PVT. LTD.

- 20. than 1200 man-years of engineering expertise to customize precision. Headquartered at Ahmedabad, Gujarat, it boasts of a state-of-the-art sales and service network across the globe. Its R&D team constantly monitors the trends in the industry and in tandem with the manufacturing team, innovates the pioneering technologies intending to generate a high degree of customer satisfaction. These innovations have, today, produced a range of high- quality precision testing equipment and created a range that caters to any testing machinery needs of the plastic industries of any size. Khagen adds, “We believe that technology should be right-sized with the process designed to minimize waste and customized to enhance performance with an embedded ‘Customer First Approach’. Our homegrown Adeveloping economy like India often produces a lot of opportunities to those who are willing to go the extra mile and make a difference. Another encouraging factor is that people are looking for indigenous products which are making the manufacturing industry look very hopeful. Sensing the opportunity in the early 2005, Khagen Mehta, a first- generation entrepreneur with a strong background in merchandise export especially in the plastics industry, established Deesha Impex. His vision was to create an organization that helped the plastics industry across the globe by delivering consistent quality products. Deesha Impex, now, is a reliable manufacturer and exporter offering engineering precision and quality in performance, and a professional commitment towards buyers anywhere in the world. Acknowledging Entrepreneurial Dreams As the Partner of Deesha Impex, Khagen makes sure that the machinery his company manufactures is of world-class quality. He believes that the dreams of a satisfied clientele must become his own— so that, they come alive to reality. Having expanded his reach over frontiers, Khagen’s fifteen years of experience in exporting machinery of technical precision and excellence has made the world smaller, forging strong links, and building confidence anew in the minds of sceptics. More About the Company Deesha has been redefining quality through innovation and customization. The genesis of its precision lies in its team of world-class connected professionals with more DEESHA IMPEX MANUFACTURING AND EXPORTING HIGH-QUALITY PRECISION EQUIPMENT AUGUST 2019 Khagen Mehta Founder, Partner 18

- 21. Our ‘Customer First’ approach drives us to serve our customers anytime anywhere in the world ‘‘‘‘ Incredible Stories The of Indian Manufacturing TQM Technique ensures the right quality at the appropriate cost in every product.” Precise Products Deesha started with Laboratory Equipments in 2005, and now it has started production of Plastic Extrusion, Injection Moulding and Plastic Testing Equipment too. It assures expert inspection of every export consignment so that the machinery and equipment meet all the criteria specified by the clients. Each machine in every category and every configuration is manufactured to fulfil the technical criteria in customer specifications. Engineering, Precision and Excellence are the founding values and the USP of Deesha. It believes in using technology for continual improvement in quality and software for ensuring precision and improving the quality of the end product. Its global network of sales and service functions with glocal attitude to deliver the highest degree of customer satisfaction. A Growing Sector While the opportunities are opening up, the challenges persist in the sector. Being an MSME, the biggest challenge Deesha faces is that of finance. This is especially more pronounced since the founder is a first- generation entrepreneur making generating continuous finance an arduous task. Being in the global markets, the other challenge is the volatility in the currency markets. The competition for foreign products in the market also proves to be a challenge. Initiatives like Make in India have helped raise the profile of India as a manufacturing nation, but at the ground level, a lot of work till need to be done to improve the ease of doing business and for reducing the burden of needless compliance especially in the MSME sector. The Journey Continues Khagen has gone through the struggle and pains of being an entrepreneur before emerging as a winner with Deesha. This gives him a unique position wherein he can easily identify with the young entrepreneurs in the sector. So his advice to the budding entrepreneurs is: “Be patient, be persistent, always focus on quality, cost and speed so that the highest degree of customer satisfaction is achieved. Never take short cuts.” As for Deesha’s future, the company is reaching out to potential customers relying on extensive marketing of its products through Exhibitions. Khagen adds, “We are having exports in about 35 countries. The company is trying to expand in Extrusion, Injection Moulding machine with extensive marketing in various countries with the help of Good staff.” AUGUST 2019 19

- 22. AUGUST 201920

- 23. AUGUST 2019 21

- 24. AUGUST 201922

- 26. The Essence of Innovationin Indian Manufacturing hange is an evident factor in everyone’s lives may Cit be a person or an organization. The thing that matters the most is the gravity of the change. Whether it is positively reinforcing or negatively derailing one’s work. The dynamics of the Indian manufacturing industries have shown the country’s capacity to create a versatile palette of products from various segments and its ability to deliver. Innovations in the industry have been a constant driving force, inspiring different sets of qualitative goods, types of equipment and peripherals to be manufactured indigenously. Innovation is defined as ‘a process by which varying degrees of measurable value enhancement is planned and achieved in any commercial activity,’ by the Indian government’s National Knowledge Commission. According to one independent report, the country still has a lot of merit when innovations in manufacturing are to be considered. One of the largest advantages the manufacturing sector has is the market’s enormous diversity in consumer’s tastes and preferences. The things that have led to frugal inventions are price sensitivity and value consciousness amongst the consumers. A rapidly growing young generation of the middle-class is creating a huge demand for advanced products which need to be satiated. However, Manufacturing in India is in a dire need of overcoming the challenges pertaining to the industry such as insufficient infrastructure and access to reliable power solutions. Hence, innovation in the optimization of expensive energy consumption is really galvanizing. The strongest motivator for the Indian manufacturing sector could arguably be innovative technologies. A forerunner for this is definitely access to cutting-edge research and present world-class technological advancements. Over a few years, the industry has seen numerous opportunities along with having a concentration on research and development. All of this, under the microscope with a specific focus on enhancing competitiveness. Growth Impetus In the past seven years, manufacturing in India has expanded its reach at a compounded annual growth rate (CAGR) of 8.5%. It is just moderately excessive figure than that of the overall economic GDP which increased at CAGR of 8.4%. Even though this performance is considered to be somewhat good, the manufacturing space in India needs to step up majorly if the industry wants to keep up with the government’s ambitions. In order to be globally competitive, Indian businesses require to be innovative and different across the value chain. This is possible when there is an availability of technology, equipment, financial resources along with reasonably economical trained labor force. The Manufacturing activity in India grew at its fastest pace during the last three months from May this year, which was led by consumables. The government has indicated signs of high growth in the future. Innovation in Creation There are a lot of companies bringing innovative products related to the Indian manufacturing sector and creating or filling niches in the market. Some new products are revolutionary in nature and are putting the manufacturing sector of India on a pedestal for sure. A few of them are listed below: AUGUST 201924

- 27. 1. FARO’s Cobalt Design 3D Scanner, which is for industrial use. Mainly, for design professionals. The global leader for 3D measurement and imaging solutions, FARO introduced Cobalt Design structured light scanner product which significantly reduces data capture time and delivers quick results. 2. NORDAC PRO SK 500P by Nord Drivesystems. It possesses the state-of-the-art control cabinet inverter with the latest component technology and ultimate levels of functionality, connectivity, and modularity. 3. FAR launches Versys VF-15. It is a fully automatic short bar feeder, which completely eliminates setup changes over time like Pusher/Pushrod manual changing, and bar stock center adjustment, etc. 4. Igus 3D Printers, which makes building any spare parts of machinery quite easy. The company provides 3D printing services and gets the product delivered within a few hours of its designing. Lastly, The Indian manufacturing sector has the capacity to position itself at around $ 1 Trillion by 2025. India is expected to be ranked amongst the top three growth economies and manufacturing hub or focal point of the world by the year 2020. Due to the implementation of the Goods and Services Tax (GST), India is on the path to becoming a common market with a Gross Domestic Product (GDP) of $2.5 Trillion. The Indian government envisages a holistic approach towards the development of the nation with a plan of concurrent expansion related to industrial corridors and smart cities. The corridors are supposed to assist further in integrating, monitoring and developing a beneficial environment along with the industrial development. All of this will promote advanced practices in manufacturing processes in India. - Darshan Parmar AUGUST 2019 25

- 28. EMDETDesigning and Manufacturing for Automotive Emdet Jamshedpur Pvt Ltd has been in the business of manufacturing auto rubber components for over four decades now. Founded by Late Shri Upkar Singh, the legacy is being carried forward by his son Mr Ranjot Singh. Mr Ranjot Singh AUGUST 201926

- 29. AWARDS The following Interview divulges more details about the company, its working and goals. 1. Kindly brief us about the Founder/CEO and the motivation behind venturing into this particular industry. Late Shri. Upkar Singh had established this company in 1978, for manufacturing/supplying automobile rubber parts to Tata Motors & Hindustan Motors. Mr. Ranjot Singh (S/o Late Shri Upkar Singh ) is a commerce graduate from Delhi University. He is the C.E.O. & M.D. of Emdet Jamshedpur Pvt Ltd & has an experience of 23 years of automobile industry. He has guided the company to become a leading Manufacturer Indian Automobile Industry. Measuring and Benchmarking the quality of products supplied to customers in order to put more attentions is the greatest challenge. He has initiated various new innovations to strengthen our competitiveness. His potential of brain storming & innovate policies in a focussed manner has led EMDET to get recognized by major OEM’s. The company has plants at Jamshedpur, (Jharkhand) & at Faridabad ( Haryana ) in India, and is manufacturing/supplying with its high grade products to major OEM’s in INDIA including large and medium scale companies in INDIA. Mr. Ranjot Singh, is associated with ACMA for over 10 years & is presently the Deputy Chairman of Eastern Zone. 2. Kindly brief us about the company. Emdet Jamshedpur Pvt. Ltd. an IATF 16949:2016 Certified Company. Established in 1978, offering world class multi application products like Hoses, Flexible Hoses, Gaskets, Metal to Rubber Molded Parts, Engine Mountings, Sheet Metal Stamping & Profiled Steel Tubes, Low Pressure Hoses Silicon Hoses, sub assemblies etc for automobile industries. Emdet has multiple plant locations, PAN INDIA. Emdet’s manufacturing facilities have a competitive edge being based on the state-of- the-art modern machinery like DESMA Injection Moulding Machine, including online hose and profile extrusion line, backed by latest testing equipment’s to ensure consistent quality. Company is widely recognized for its highly inter dependent process of New Product Development (NPD). We are also making products meeting ROHS & GADLS requirements, which are environment friendly. Due to our best infrastructure, we have a very strong relationship in maintain - Just in Time (JIT) practices for our customer’s product requirements. Emdet’s main concentration is totally on the development of quality products for the International and Indian Markets. Company has always been recognized as the best performers in our category of Rubber Products. Companies primary customers are major OEM’s in India, i.e; TATA MOTORS LTD, TATA CUMMINS LTD., ASHOK LEYLAND, VOLVO, EICHER. Emdet’s uses high quality raw materials like EPDM Rubber, Silicone Rubber, Neoprene Rubber, SBR, Natural Rubber, HNBR, ECO, Viton, Fluro Silicon, Nitrile Rubber etc. Company works with a vision to guide and focus decision making, create balance between the competing interest of various customers, motivate and inspire organizational members and become a ZERO ppm company. We are delighted to men on that EMDET JAMSHEDPUR PVT LTD, have been recognized as winners of two key categories of FRP/Rubber/Plas c Category as THE BEST PERFORMER IN *: RESPONSE TO NEW PART DEVELOPMENT *:, and also awarded THE BEST PERFORMER IN *: ADHERENCE TO DELIVERY SCHEDULE *:, by Tata Motors Limited. Since we were the best company of the above categories in the Eastern Part of India, we are very proud that EMDET was successful in winning these awards. Interview with Insightssuccess AUGUST 2019 27

- 30. 3. What are the different products and services? 4. What is the USP of the company that serves as an advantage over competitors and benefits clients/customers? Please share awards and recognitions. TOOL ROOM Our in house tool room facility includes latest machines and our design engineers use latest design software to develop innovative products to meet stringent customer requirements for new product development. All our activities are effectively monitored through a ERP systems that not only helps us manufacture at low costs , reduce wastages but also ensures seamless flow of activities from receipt of customer enquiry to supply and service of parts for enhance customer satisfaction. we have a strong ability in maintaining, just in time (JIT) and Kanban practices to meet 100 % on time delivery for our customers’ requirements. Our infrastructure, by itself, is sufficient to explain our manufacturing performance related to competitive advantage that is not only limited to strict shop floor practices Emdet is having an automated chemical weighing system in our centralized Rubber mixing unit to ensure the quality of mixing is processed correctly. The mixing is done by using dispersion Kneader and open roll mixing mill technology. Our other key equipments include Desma Injection moulding machines, Vacuum and transfer Moulding machines, Online hose extrusion and profile lines, shot blasting, phosphating & automatic bonding agent application, gas fired boilers etc. Facilities for Testing Raw materials, Rubber compounds and product validation. Emdet has a complete in house facility to test and validate all the parameters that affect the product performance including Raw materials and product life cycle. AUGUST 201928

- 31. Product vaalidation Static Test Axial / Radial Test Deflection Test Endurance Testing( Hoses and Molded parts) Burst Pressure Test Leak Test for Pipes and crimped hoses Milipore Testing Other Miscellaneous Test Low Temperature Test Air /Oiling/ Coolant Ageing Material Testing Tensile Strength Elongation Test Mooney Viscometer Ozone Test Low Temperature Test Compression Set Ash Content Chemical Analysis For Compound & Raw materials Humidity Chamber Tests conducted at our inhouse Lab 5. Share with us the challenges faced by companies in the Automobile Component Manufacturing Industry. The focus of the Govt must be timely rolled out of reforms, reviving investments and proactively guarding against external risks. AUGUST 2019 29

- 32. Computerised chemical weighing system Kneaders/Mixing Mills Desma Rubber Injection Molding ( 4000 ccm) Online Hose extrusion lines Automatic Transfer Molding Machines Molding Infra red Profile Extrusion Lines Automatic Compression Molding Machines Cold Feed Extruder Vaccum Presses Calendaring ( Fabric Rubberising) Shot Blasting Knitting Rubber to metal Adhesive application system Braiding De Flashing systems Gas fired Boilers Ink Jet printer for Traceability Vulcanizing Mixing Mills (separate for coloured compounds) Component Washing and cleaning systems Sheet Metal And Metal Pipe Bending, Prototyping and Tool Room Facility Computersied 3 Axis Pipe bending (0-30mm) 150 MtMechanical Stamping Press Mig Welding 100 MT Mechanical Stamping Press Spot Welding 50 Mt Mechanical Stamping Press Shapers Lathes Milling Machines List of Key Equipments for Molded and Extruded Parts 6. How is the company leveraging technology for better products? Technology and process upgradation has always been a core value at Emdet. Our plant is equipped with most technologically advanced and world class manufacturing and testing facilities We consider the best infrastructure to be an overall organizational phenomenon. Accordingly, we have developed and tested a model that includes the best infrastructure practices to provide an environment in which our company performs more effectively. 7. How does the firm intend to handle its Societal and Environmental Responsibility? We follow different CSR activities & environmental responsibilities is part of it. 8. What would be your advice for the budding start-ups and entrepreneurs in the industry? Great challenge for start-ups and entrepreneurs, as the slowdown in the economy continues throughout the quarter and has a profound impact in all sectors of the automotive industry ranging from two wheelers, passenger cars to commercial vehicles. India’s manufacturing sector lost growth momentum in June due to slower order growth. 9. Brief us about the company’s future perspectives. We are in process to register with Railways & Defence. AUGUST 201930

- 34. The history of learning by doing is superannuated. That is how we all start learning about things and our surroundings as toddlers. Same holds true for technology too. The best way to learn a new technology is to start using it. There’s no match to hands-on experience and by using it, we step up the innovation in the said field. History is full of incidents wherein things were discovered or invented when scientists were actually working on projects of a different nature. The ecosystem that is created when people come together to work on or experiment on technology, techniques and science theories leads to better understanding and innovations that uplift the world. Aiming to create a similar ecosystem in India for drone innovation is an IIT Bombay startup – Drona Aviation. It is doing this through its educational and tinkering drone platform - Pluto. Arduino revolutionized electronics and Raspberry Pi changed computing. With Pluto, the founders aim to do the same in drones. The Young Minds The startup has been founded by Apurva Godbole, Prasanna Shevare and Dinesh Sain. Apurva is a 2008 graduate of IIT Bombay. Prasanna is a 2009 graduate of VIT Vellore and was a PhD student in Aerospace Dept. of IIT Bombay. Dinesh is a 2014 graduate of Aerospace Engg from IIT Bombay. The team has been working in the field of drones since 2010. Prasanna and Dinesh especially have led teams to drone competitions nationally and internationally and won awards. These include IMAV France, ICUG Spain, MICAV Bengaluru, Techfest Mumbai, Zephyr, BITS Goa among others. Prasanna Shevare was awarded Tech Mahindra Young Engineer Award for the same. DRONA AVIATIONPROVIDING INNOVATORS WITH A ROBUST PLATFORM Prasanna Shevare Co-founder Apurva Godbole Co-founder Dinesh Sain Co-founder AUGUST 201932

- 35. While working on these competitions, they faced a bunch of problems that slowed down their innovation process. They started Drona Aviation to solve these problems so that more and more people can jump into drone innovations and realize a $127 billion industry globally. For Tinkerers and More Drona is building Pluto drone platform. This includes hardware, software, content and community. Hardware includes 2 modular crash-proof and easily programmable drones christened Pluto 1.2 and Pluto X. Pluto 1.2 – Pluto is a DIY Nano-Drone that is easy to build and features the ‘Primus V4’ Flight Controller which can be programmed using Cygnus Open Source IDE. Pluto X – Pluto X’s standard kit contains a drone, an X-breakout to further experiment by tinkerers, smartphone app, Cygnus IDE, Proptool, camera module and more. This is accompanied by an API-based programming platform Cygnus. It also has a lot of learning content which has been adopted by the Niti Aayog as the formal drone module for their more than three thousand ‘Atal Tinkering Labs’ across India. The final component of this platform is the community of tinkerers where they build drone ideas and showcase to the world. For a startup like Drona, which deals with consumer hardware, raising investments from the market is a major hitch. Also, the vendor network in India is still evolving so it takes special time and efforts to build those capabilities in India. This reduces the development pace and increases the time to the market for the products significantly. But, then entrepreneurial ventures are never without challenges! The founders believe in the presence of a manufacturing ecosystem like China. They feel that entrepreneurs from India can compete only through open source collaborative development. With that context, they decided to build not only a product but a platform. A platform on which, tinkerers and developers can build their ideas and innovations and showcase to the world, to be precise. In the process, they are open sourcing portions of the hardware, all the software and learning content that they are creating is being open sourced to decentralize and democratize drone innovations. Words of Experience Apurva’s advice to fellow entrepreneurs and tinkerers is “Focus on understanding the problem statement and the pain point clearly. The more time you spend on it, the more ideas you’ll come up with for the best way to solve them. Once you have figured out one solution, build a prototype and deploy asap. It may not be the best but it will give you an idea of whether / how well does it work and what changes you need to make in it in the next steps towards the final solution.” Focusing on the Future Drona has strongly used 3D designing & printing for its initial prototyping and sales. It has also been working with some of the best available PCB manufacturers and assembly companies for its products, both at prototyping as well as final product stage. As the next steps, it will focus on reaching out to more schools and colleges and build distribution channels in the US and the Middle East. We are creating technology which our users can work with to create innovative ideas and products ‘‘‘‘ Incredible Stories The of Indian Manufacturing AUGUST 2019 33

- 36. Opportunities and Challenges nd ndia is the 2 largest cement producer in the world Iwith a production capacity of 502 million tonnes per annum in 2018 & is expected to touch 550 million tonnes by 2020. However the per capacity consumption of cement in India is 195kg which is far less than the world average of 500kg & 1000kg of China. This certainly is a big opportunity for the cement companies in India to bridge the gap & in turn increase turnover. However despite the overall outlook being positive, the cement industry is facing a situation of over-capacity. This is also coupled with the interventions by the Competition Commission of India & the populist State Governments, which has led to pressures of not increasing prices despite the increase in cost of raw material & process fuel. Shortage of domestic coal & increasing cost of imported coal is also adding to the overall increase in production cost. On the other hand cost of electricity in India is higher compared to any of the peer countries & captive power plant is not feasible for smaller companies. The logistics cost for cement is also high since a lot of the cement is still transported through road transport which pushes the cost of cement. The current Railways capacity is not adequate enough for transportation. All of these are clouding to a situation of higher costs & lower margins especially for the weaker players in the short term. To increase the demand, cement prices have to be attractive for consumers. Higher prices always act as a disincentive & gives encouragement to substitute products to cement. However opportunity today for the cement manufacturers to reduce prices is low since by & large the cement industry is cost effective & profiteering is rare. One of the possible solutions to lower prices can be by reducing the current GST rates for cement which is quite amazingly clubbed with the luxury items slab. Cement being a mass consumable item & a product which is in sync with the progress of the nation through infrastructure & housing, the high rates may need a revisit. Another unique situation for the cement brands have been the advent of numerous brands smaller or bigger which has led to an increase in competition & lower market shares for all players since it is the share of the same pie & the pie’s increase in size has been fairly AUGUST 201934

- 37. Aboutthe Authors Debalina Roy, Sr. Manager – HR , Star Cement Limited has more than 11 years of experience in the areas of talent Management, Recruitment, Training & Development, Employee Engagement. Dibyajyoti Guha, DGM – Branding & Technical Services at Star Cement Limited has more than 15 years of experience in Brand Management & Strategy. He is a PGDBM & Advanced Marketing degree holder from IIM Calcutta. Trends to Watch Debalina Roy, Sr. Manager – HR Dibyajyoti Guha, DGM – Branding & Technical Services AUGUST 2019 35

- 38. slow. Hence for the numerous cement brands, branding & technical strategy becomes critical to get the share of mind of the consumers & the influencers. Cement being still a low involvement category for the consumers & no substantial product differentiation among various brands, TOMA or Top of the Mind Awareness becomes paramount. Hence to increase TOMA the cement brands are spending more on branding which is also increasing the overall cost for the manufacturers. With the advent of technology more & more consumers are today aware about the various brands available in the market. They have started to make their own brand choice decisions which have led to demanding the brand upfront to the retailers just like any other mass consumable brands, hence limiting the role of push strategy, the cost of which is lower than a pull strategy. It should be a constant endeavor of Human Resource Department of any cement company to create a high performing organization. A structured and robust Performance Management System, building competencies, improving employee performance and development, and driving better business results. Cement industry can attract the best of people by designing & structuring Rewards, Accolades, and Flexible Compensation & Benefits. Creating the supportive culture in the organization wherein people are open to innovate. Performance Coaching & Counseling can trigger a growth mindset in the minds of the Employees. Employees are the biggest assets of the organization. Overall despite the challenges being faced, the cement industry is here to grow with the growth story of the nation remaining intact. With the rise of income of the middle class, launch of various housing schemes by the government, easier home loans availability & infrastructure push by the government, the sun looks brighter for the industry & just like any other industry, the cement industry is also reinventing & innovating itself with newer technologies & processes to ride alongside the positive outlook of the nation. AUGUST 201936

- 40. are used to produce varied applications like PVC pipes, Masterbatch, medical plastics, PVC profiles, Cable compounding etc. Quality and quick After Sales Service is what Neoplast believes in and all the team members are trained to follow the same. Today, low-cost has become a marketing tool for new entrepreneurs who want to capture market share at a rapid pace, but than it comes only after compromise in quality. Neoplast propagates the fact that “The bitterness of poor quality lingers long after the cheap price is forgotten”. The company’s quality consciousness and experience of more than 4 decades serve as a major advantage over other players. Challenges Ahead At present, there are two major challenges for the plastic industry. The first is cost-competition from foreign Ever since plastics made their debut on the industrial screen in the year 1856, they have been used for various purposes across the globe. Its malleability and sturdiness have made it popular to create myriad objects of daily use as well as specific industrial usage. During the 1970s, when the Textile Industry was blooming in Ahmedabad, India, Founder Director, while working in a mill observed that the production was hampered due to the failure of certain key components of a machine. He was quick to realise the need for long-lasting components to replace those Metal Parts. He then worked on the idea of replacing metal components by long-lasting plastic parts and thus started the journey of Neoplast Engineering. Perfect Solutions for Specific Requirements Neoplast Engineering started as a family-owned business and is now a professionally managed corporate company in the field of Plastic Processing Machinery. Quality and Innovation are the key motivators behind the continuous growth of the company. Currently, it has 2 manufacturing facilities in Ahmedabad with an area of 2,25,000 sq.ft. To cater to its customers throughout India, it has 5 resident engineers stationed at strategic locations for faster services and 2 branch offices in New Delhi and Hyderabad that help in targeting new markets. Export is done to more than 18 countries viz-a-viz Middle East, Africa, Europe and USA which confirms Quality of Neoplast’s products. Neoplast is in manufacturing sector of Plastic Processing machinery that includes High-Speed Mixers, Material Conveying Systems, Extrusions with various downstream and Laboratory equipment. These machines NEOPLAST ENGINEERING PROVIDING QUALITY AND INNOVATIVE PLASTIC PROCESSING MACHINES SINCE 1973 Tushar Parikh Founder Director AUGUST 201938

- 41. We are amongst the very few Indian Manufacturers providing Turnkey solutions in this eld and enjoy a sizeable share of the market till date ‘‘‘‘ Incredible Stories The of Indian Manufacturing countries. The second and more critical is uninformed decisions like a blanket ban on plastics without proper policy formation. Mr. Tushar, Director, believes, “Plastics cannot be wiped off overnight as there are no substitutes in many applications. Proper industrial consultation and with the help of experts, ways to reduce the plastic waste can be achieved but sudden decisions have created a fear which hampers the growth and future of Plastic industry.” Leveraging Technology Management at Neoplast understands that technology is the key factor that plays a major role in the manufacturing industry as it determines the cost, delivery time, and performance of the product. Since everybody is shifting towards the Industry 4.0 platform, it has made sure that it’s equipment too are future-ready. With this, it can fetch details that not only help in future improvement but also reduce the downtime through predictive maintenance. It has also been able to provide faster service via Virtual Private Network (VPN) and furnish detailed reports for the management with which its in-house manufacturing has also improved that leads to consistency and lower production cost thereby generating profits. Word of Wisdom Per capita consumption of plastic in developed countries is almost 10 times more than that of India which makes the Plastic Industry a very lucrative one to venture into. At the same time, one has to be very conscious about the quality and technology with which they are going to try for manufacturing. Mr. Tushar feels, “Brand is not built in a day. One has to continuously strive for improvement, up-gradation and focus on quality and services rather than to focus on cost reduction. Looking towards the market potential, competition is increasing day-by-day. Thus it is very essential for newcomers to work on their profitability as they are unaware of the hidden factors which can hamper their profits.” Future Goals Neoplast is planning to increase its product basket to serve its customers in a better way. It will also be improvising on its service sector by introducing more technology and automation for a smooth after-sales experience to its customers. Apart from this, it will work on modernising its infrastructure to accommodate the growth and future expansions. AUGUST 2019 39