ASTM - A 36 steel properties and dimensions

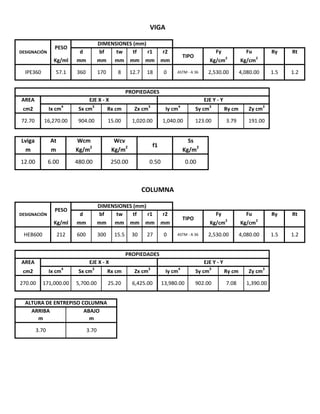

- 1. ASTM ‐ A 36 TIPO TIPO ASTM ‐ A 36 DIMENSIONES (mm) PROPIEDADES d bf 18 0 2,530.00 4,080.00 1.5 1.2 Kg/cm2 mm mm mm Rx cm Zx cm3 VIGA Fy Fu Ry Rt Kg/cm2 Iy cm4 Sy cm3 Ry cm Zy cm3 IPE360 57.1 360 170 8 12.7 EJE Y ‐ Y Kg/ml mm mm mm cm2 Ix cm4 Sx cm3 tw tf r1 r2 AREA EJE X ‐ X DESIGNACIÓN PESO 191.00 Ss m m Kg/m2 Kg/m 2 Kg/m 2 Lviga At Wcm Wcv f1 72.70 16,270.00 904.00 15.00 1,020.00 1,040.00 123.00 3.79 0.00 COLUMNA DESIGNACIÓN PESO DIMENSIONES (mm) d bf tw tf r1 12.00 6.00 480.00 250.00 0.50 mm mm Kg/cm 2 HEB600 212 600 300 15.5 30 PROPIEDADES AREA EJE X ‐ X EJE Y ‐ Y Kg/cm2 r2 Fy Fu Ry Rt 27 0 2,530.00 4,080.00 1.5 1.2 Kg/ml mm mm mm mm 3.70 3.70 ARRIBA ABAJO m m Sy cm 3 Ry cm Zy cm3 270.00 171,000.00 5,700.00 25.20 6,425.00 13,980.00 902.00 cm2 Ix cm 4 Sx cm3 Rx cm Zx cm3 Iy cm4 7.08 1,390.00 ALTURA DE ENTREPISO COLUMNA

- 2. TIPO Fy Fu Kg/cm 2 Kg/cm 2 ASTM ‐ A 36 2,530.00 4,080.00 PLANCHA PERNO TIPO A325 Ft Fv Kg/cm 2 Kg/cm2 6,330.00 4,220.00 AGUJERO ESTÁNDAR TIPO + db mm 3.00 28.575 1 1/4" 31.75 1 3/8" 34.925 1 1/2" 38.1 1 3/4" 44.45 2" 50.8 TIPO FExx Kg/cm 2 E60XX 4,220.00 ELECTRODODiametro pulg mm 1/2" 12.7 5/8" 15.875 de mm 22 30 32 38 45 58 2 1/8" 53.975 2 1/4" 57.15 2 1/2" 63.5 Pfoinicial mm 23 27 32 37 42 47 51 56 61 72 82 87 92 102 3/4" 19.05 7/8" 22.225 1" 25.4 1 1/8" 62 67 78 89 95 101 112 Pb mm 39 48 58 67 77 88 96 105 115 134 153 162 172 191 52 UNIÓN 4ES 256 266 220 140 150 120 Pfo 114 38 140 64 64 tbf bbf d tp bp g Pfi Pb Máximo Mínimo 19 mm Parametro UNIÓN 4E mm 10 235 152 1400 349 57 13 273 178 152 102 114 38 ‐ ‐ Máximo Mínimo mm mm 19 10 152 610 349 38 13 273 178 152 83 140 44 229 ‐ LIMITACIONES UNIÓN 4E UNIÓN 4ES UNIÓN 8ES mm mm mm 12.7 12.7 12.7 170 170 170 360 360 360 45 31 26 UNIÓN 8ES Máximo Mínimo mm mm 25 14 311 190 914 457 64 19 SI 50 64 64 50 67‐ ‐ COLOCADO COLOCADO UNIÓN 4E UNIÓN 4ES UNIÓN 8ES mm mm mm SI SI SI ‐ 381 229 152 127 51 41 95 89 44 51 41 Parametro tbf bbf d tp bp g Pfi Pfo Pb SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI SI ‐ ‐ NO

- 3. MOMENTO MAXIMO PROBABLE ALTURA DE PLANCHA 4E y 4Es = + + = x + = 1.21 47 52 112 122 1. 2. 2.1. Lst = tan 30° hst 1.31 Mpr Mpr = Cpr x Ry x Fy = Cpr = Fy + Fu ≤ 1.20 Cpr = 1.20 2 x FY 2 x FY Cpr = Fy + Fu = ANSI/AISC 358‐16 (2.4‐2) / Pag. 9.2‐8 de tfvigahst Pfo 2 hst dviga X1 mm 43 Cpr x Ry = 1.80 1 3/4" 47 1 1/4" 51 1 3/8" 56 1 1/2" 61 hplancha Diametro Pfoinicial pulg mm 1/2" 23 5/8" 27 3/4" 32 7/8" 37 1" 42 1 1/8" 72 2" 82 2 1/8" 87 2 1/4" ANSI/AISC 358‐16 (6.9‐1) / Pag. 9.2‐26 Tfviga mm 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 Pfo 57 62 67 71 76 81 92 102 107 Pfoinicial + Tfviga Tfviga 12.70 mm 92 2 1/2" 102 = Fy = 446.75 Fypr = 4,554.00 Kg/cm2 = 446.75 MPa Fupr = 7,344.00 Kg/cm2 = 720.45 MPa Mf Mpr = 1.00 % de carga = 100.00 %4,645,080.00 Kg x cm = 46,450.80 Kg x m = 455.68 KN x m x Zx ANSI/AISC 358‐16 (2.4.1) / Pag. 9.2‐7

- 4. 8Es = + + + = x + 954 515 115 134 1196 724 172 191 57.15 63.5 2" 95 337 1034 619 153 162 105 256 234 7/8" 50 38 155 670 269 58 67 19.05 22.225 55 45 177 714 307 1 1/4" 64 872 218 796 444 655 409 96 105 760 347 77 88 25.4 28.575 mm Diametro 1/2" 36 22 97 554 169 40 30 118 596 205 39 48 12.7 15.875 89 44.45 1" 584 1 3/4" 2.2. hst Pfo de tfviga hplancha 2 Pfo de hst hplancha Lst pulg mm mm mm mm mm 378 Lst = hst tan 30° 45 1 3/8" 69 2 1/8" 100 38.1 31.75 34.925 1 1/2" 74 115 60 85 584 604 622 642 686 728 750 772 814 122 131 141 163 212 227 245 283 319 338 357 394 74.00 85.00 95.00 50.8 53.975 2 1/4" 3/4" 5/8" 1/2" pulg Pfo mm 36.00 40.00 45.00 194 105.00 115.00 de 95 mm 22 30 32 38 45 52 58 62 67 78 89 101 112 dviga Pb 5/8" mm 58 70 77 88 100 476 500 514 536 560 1 1/8" 1 1/4" 1 3/8" 1 1/2" 1 3/4" 2" 2 1/8" 2 1/4" 2 1/2" 1" 7/8" hst 50.00 55.00 60.00 64.00 69.00 112 hplancha mm Lst mm 184 195 206 227 101 hst 122 134 153 174 2 1/2" 3/4" 1 1/8" 100.00 78 52 200 95 67 112 418 58 297 ANSI/AISC 358‐16 (6.9‐1) / Pag. 9.2‐26 Pb mm 32 135 630 101 378 1116 357 1074 62 236 832 Diametro mm 12.7 15.875 19.05 22.225 25.4 28.575 31.75 34.925 38.1 44.45 50.8 53.975 57.15 63.5

- 5. DISTANCIA DE LA CARA DE LA COLUMNA A LA ROTULA PLASTICA "Sh" 130.21 151.21 163.21 182.21 203.21 223.21 241.21 256.21 274.21 2 1/4" 2 1/2" 51.00 cm 2 = 2 1/8" 348.21 367.21 1 1/2" 1 3/4" 312.21 1 1/4" 1 3/8" 1" 1 1/8" Sh2Sh1 = = 180.00 mm 4E 18.00 cm dviga 3/4" 3. = 3 x bfviga 180.00 mm = tfviga 386.21 423.21 2" 7/8" 18.00 cm Sh = Lst + tp 4ES tp(INICIAL) = Sh 1/2" 5/8" =Min ( Sh1 Diametro pulg Sh mm 2.30 Sh2 ) ANSI/AISC 358‐16 ‐ (Sect. 2.3.) / Pag. 9.2‐5 ANSI/AISC 358‐16 ‐ (Sect. 2.3.) / Pag. 9.2‐5 x = ; tp = 29.21 mm 29.21 mm = 25.00 mm= = 510.00 mm = Mpe Vu Rotula plástica s0 Mf sh

- 6. DISTANCIA ENTRE ROTULAS "Lh" DISTANCIA ENTRE ROTULAS = ‐ ‐ x 1 1/8" 374.686 2 1/8" 646.686 2 1/4" 682.686 2 1/2" 751.686 1 1/4" 11,143.79 1 1/2" 11,125.79 1 3/4" 11,087.79 2" Diametro Lh pulg mm 1/2" 11,220.00 5/8" 11,220.00 1 1/4" 11,220.00 3/4" 11,220.00 7/8" 11,220.00 1" 11,220.00 1 1/8" 11,220.00 1 1/4" 11,220.00 1 3/8" 11,220.00 1 3/8" 11,220.00 1 1/2" 11,220.00 1/2" 196.686 405.686 1 3/8" 436.686 1 1/2" 471.686 x tfviga = 27.69 mm 4. 5/8" 232.686 Diametro Sh pulg mm 1 3/4" 542.686 2" 611.686 tp(INICIAL) 8ES tp+ 3/4" 261.686 7/8" 296.686 = 2.18 1" 334.686 Sh = Lst Lh Lviga dcol 2 Sh 10,976.79 11,051.79 2 1/8" 11,032.79 2 1/4" 11,220.00 2 1/2" 11,220.00 4E 4ES Diametro Lh pulg mm 1/2" 11,269.79 5/8" 11,248.79 3/4" 11,236.79 7/8" 11,217.79 1" 11,196.79 1 1/8" 11,176.79 11,158.79 ANSI/AISC 358‐16 ‐ (Sect. 2.3.) / Pag. 9.2‐5 10,963.31 1 1/2" 10,928.31 tp = 27.69 mm 8ES Lh 1 3/8" Diametro 2 1/4" 10,717.31 2 1/2" 10,648.31 2" 11,220.00 2 1/8" 1 3/4" 10,857.31 2" 10,788.31 2 1/8" 10,753.31 2 1/4" 11,013.79 2 1/2" 1 3/4" pulg mm 1/2" 11,203.31 5/8" 11,167.31 3/4" 11,138.31 7/8" 11,103.31 1" 11,065.31 ANSI/AISC 358‐16 ‐ (Sect. 6.8.) / Pag. 9.2‐29 1 1/8" 11,025.31 1 1/4" 10,994.31

- 7. CARGAS GRAVITACIONALES SOBRE LA VIGA. = x + x + x + x = x = = x = = x = = = = = CORTE GRAVITACIONAL "Vgravitacional" x CORTE ULTIMO "Vu" x Wcm 0.20 Sf1 Cv 2,880.00 Kg / m Wu 1.20 Cp 1.20 Pp Cp At 5. S At Ss 0.00 Kg / m Pp 57.10 Kg / m Vgravitacional = 4E 4ES 8ES Diametro Vgravitacional Diametro Vgravitacional Diametro Vgravitacional Wu 4,274.52 Kg / m f1 0.50 6. Wu Lh Cv At Wcv 1,500.00 Kg / m 2 41.93 KN x m 5/8" 23,980.06 5/8" 24,041.59 5/8" 23,867.45 3/4" 23,980.06 3/4" 24,015.94 3/4" 23,805.47 pulg Kg pulg Kg pulg Kg 1/2" 23,980.06 1/2" 24,086.47 1/2" 23,944.39 1 1/8" 23,980.06 1 1/8" 23,887.71 1 1/8" 23,563.96 1 1/4" 23,980.06 1 1/4" 23,849.24 1 1/4" 23,497.71 7/8" 23,980.06 7/8" 23,975.33 7/8" 23,730.67 1" 23,980.06 1" 23,930.45 1" 23,649.45 1 3/4" 23,980.06 1 3/4" 23,697.49 1 3/4" 23,204.90 2" 23,980.06 2" 23,620.55 2" 23,057.43 1 3/8" 23,980.06 1 3/8" 23,817.18 1 3/8" 23,431.45 1 1/2" 23,980.06 1 1/2" 23,778.71 1 1/2" 23,356.65 2 1/2" 23,980.06 2 1/2" 23,460.25 2 1/2" 22,758.22 7. 2 Mpr 2 1/8" 23,980.06 2 1/8" 23,579.94 2 1/8" 22,982.63 2 1/4" 23,980.06 2 1/4" 23,539.33 2 1/4" 22,905.69 Lh Vu = + Vgravitacional ANSI/AISC 358‐16 (6.8‐2) / Pag. 9.2‐29 ANSI/AISC 358‐16 ‐ Sect. 5.8.] / Pag. 9.2‐18 ANSI/AISC 358‐16 ‐ Sect. 5.8.] / Pag. 9.2‐27 ANSI/AISC 358‐16 ‐ Sect. 5.8.] / Pag. 9.2‐27 Wu VuVuMpe Mpe Lh

- 8. MOMENTO MÁXIMO PROBABLE A LA CARA DE LA COLUMNA "Mf" 1 1/4" 31.75 1 3/8" 34.925 1 1/2" 38.1 1 3/4" 44.45 2 1/2" 63.5 50.8 53.975 57.15 63.5 4E Diametro pulg mm 1/2" 12.7 5/8" 15.875 3/4" 19.05 7/8" 22.225 1" 25.4 1 1/8" 28.575 1 1/4" 31.75 1 3/8" pulg 4ES 32,174.65 Kg 44.45 2 1/2" 32,260.06 1 1/2" 38.1 1 3/4" 44.45 2" 50.8 2 1/8" 53.975 2 1/4" 57.15 Diametro mm 12.7 7/8" 22.225 1" 25.4 1 1/8" 28.575 53.975 2 1/4" 57.15 2 1/2" 5/8" 15.875 3/4" 1" 25.4 28.575 1 1/4" 63.5 8ES 2" 50.8 2 1/8" 2 1/8" 53.975 15.875 19.05 22.225 25.4 28.575 31.75 34.925 38.1 44.45 50.8 53.975 57.15 63.5 15.875 19.05 22.225 25.4 28.575 3/4" Kg 1/2" 32,260.06 32,329.89 32,236.73 Vu Vu VuDiametro mm 12.7 Kg Diametro pulg mm 1/2" 12.7 31,947.6831.75 34.925 38.1 15.875 7/8" 32,260.06 32,256.97 32,097.68 1" 32,260.06 32,227.62 32,045.20 5/8" 32,260.06 32,300.40 32,186.52 3/4" 32,260.06 32,283.57 32,146.2019.05 22.225 25.4 34.925 1 1/8" 32,260.06 5/8" 15.875 3/4" 19.05 31,482.75 8. 2 1/8" 32,260.06 32,000.44 31,621.97 2 1/4" 32,260.06 31,974.36 31,574.05 1 3/4" 32,260.06 32,076.22 31,761.49 2" 32,260.06 32,026.57 31,668.75 28.575 1 3/8" 32,260.06 32,153.80 31,905.31 1 1/2" 32,260.06 32,128.82 32,199.72 31,990.17 1 1/4" 32,260.06 4E 4ES Diametro pulg mm 1/2" 12.71/2" 52,257.61 1/2" 50,660.48 Mf = Mpr + Vu x Sh 52,257.61 3/4" 51,719.80 54,863.01 7/8" 52,257.61 7/8" 52,328.34 55,973.73 5/8" 52,257.61 5/8" 51,334.94 53,940.15 Mf Mf Mf pulg Kg x m pulg Kg x m Kg x m 19.05 7/8" 22.225 52,791.31 Diametro mm 12.7 1 1/2" 52,257.61 1 1/2" 55,260.84 61,477.61 1 3/4" 52,257.61 1 3/4" 56,465.32 63,687.32 1 1/4" 52,257.61 1 1/4" 54,211.65 59,411.52 1 3/8" 52,257.61 1 3/8" 54,688.93 60,383.40 44.45 31.75 1 3/8" 34.925 1 1/2" 38.1 1 3/4" 44.45 31.75 34.925 38.1 1" 52,257.61 1" 52,999.77 57,175.88 1 1/8" 52,257.61 1 1/8" 53,638.10 58,437.07 68,005.96 2 1/2" 52,257.61 2 1/2" 59,961.23 70,115.94 2" 52,257.61 2" 57,602.77 65,822.13 2 1/8" 52,257.61 2 1/8" 58,201.68 66,900.29 50.8 53.975 57.15 63.5 2" 50.8 2 1/4" 52,257.61 2 1/4" 58,799.62 2 1/2" 63.5 1 1/8" ANSI/AISC 358‐16 (6.8‐1) / Pag. 9.2‐29 8ES 31,857.65 31,923.71 2 1/4" 57.15

- 9. DISTANCIAS "h" Para 4E y 4ES 85.00 ‐ Pfi 105.30 115.30 389.95 393.95 398.95 225.65 468.95 69.00 9. tfviga 2 h1 = dviga ‐ 2 1/2" 115.00 Pfi mm 36.30 40.30 45.30 50.30 55.30 60.30 64.30 69.30 74.30 85.30 95.30 100.30 1 3/8" ho 300.65 295.65 tfviga = dviga ‐ tfviga 2 + Pfo 1 1/2" 74.00 1 3/4" 3/4" 45.00 7/8" 50.00 60.00 1 1/4" 64.00 Pfo pulg mm ‐ mm 304.65 ho Diametro 4E y 4ES 266.65 427.95 255.65 438.95 245.65 448.95 240.65 453.95 235.65 458.95 290.65 403.95 285.65 408.95 280.65 413.95 276.65 417.95 271.65 422.95 h1 2 1/4" 105.00 1" 55.00 1 1/8" 2" 95.00 1/2" 36.00 5/8" 40.00 2 1/8" 100.00 mmmm 12.7 15.875 19.05 22.225 25.4 28.575 31.75 34.925 38.1 44.45 50.8 53.975 57.15 63.5 ANSI/AISC 358‐16 (6.8) / Pag. 9.2‐31

- 10. Para 8ES Diametro 8ES 5/8" 40.00 40.30 441.65 393.65 3/4" 45.00 45.30 456.65 398.65 48.00 58.00 pulg mm mm mm mm 1/2" 36.00 36.30 428.65 389.65 mm 39.00 h2 1 1/8" 60.00 60.30 501.65 413.65 1 1/4" 64.00 64.30 513.65 417.65 88.00 96.00 7/8" 50.00 50.30 470.65 403.65 1" 55.00 55.30 485.65 408.65 67.00 77.00 1 3/4" 85.00 85.30 572.65 438.65 2" 95.00 95.30 601.65 448.65 134.00 153.00 1 3/8" 69.00 69.30 527.65 422.65 1 1/2" 74.00 74.30 542.65 427.65 105.00 115.00 h1 = dviga ‐ tfviga 2 + Pfo + Pb 191.00 2 1/8" 100.00 100.30 615.65 453.65 2 1/4" 105.00 105.30 630.65 458.65 162.00 h3 = h2 h3 h4 mm mm h2 = h1 ‐ Pb 304.65 265.65 252.65 237.65 223.65 208.65 192.65 180.65 166.65 151.65 121.65 92.65 78.65 63.65 34.65 Pb 172.00 h1 2 1/2" 115.00 Pfi 300.65 295.65 290.65 285.65 280.65 276.65 271.65 266.65 255.65 245.65 240.65 235.65 225.65 h4 = h3 ‐ Pb 659.65 468.65 ‐ Pfo Pfi ‐ Pfo ‐ tfviga 115.30 mm 12.7 15.875 19.05 22.225 25.4 28.575 31.75 34.925 38.1 44.45 50.8 53.975 57.15 63.5 ANSI/AISC 358‐16 (6.8) / Pag. 9.2‐32

- 11. DIAMETRO DEL PERNO REQUERIDO POR TRACCIÓN. x x x x ( + ) x x x x ( + + + ) = x Para estado límite no ductil x x = : = = = = Para: 4E Y 4ES 8ES Fnv Fnv 6330 kg/cm² Øn 0.90 Fnt ANSI/AISC 358‐16 (2.4‐1) / Pag. 9.2‐7 Fnt ho h1 2 Mf Para: 10. db req'd = Π Øn nb 4 Vu < Øn x Rn Øn x 28.99508 pulg mm mm 16.44 db2 req'ddb2 req'd mm 16.44 16.44 16.44 16.44 16.44 h1 db1 req'd = h4 Ab Ab 2 Mf Π Øn Fnt h2 h3 16.44 db2 req'd ANSI/AISC 358‐16 Numero de pernos en zona comprimida. 16.44 5/8" 15.875 28.73797 nb 8 5/8" 15.875 4ES 8ES nb pulg mm mm 3/4" 19.05 21.01204 Vu > = 16.44 16.44 16.44 nb x Diametro db1 req'd Diametro db2 req'd mm 11.62 11.61 11.61 11.60 11.59 19.05 28.84549 mm 16.41 16.40 29.8166128.99508 22.225 21.22367 20.83457 11.56 11.55 11.54 > Øn nb Fv ANSI/AISC 358‐16 (6.8‐3) / Pag. 9.2‐29 ANSI/AISC 358‐16 (6.8‐4) / Pag. 9.2‐29 x "8ES" 4E 0.90 Ab 4 Π Øn 4,220.00 Kg/cm2 1/2" 16.42 16.42 16.46 16.45 16.45 16.44 16.43 12.7 28.99508 1/2" 12.7 28.54856 1/2" 12.7 20.6115 3/4" 19.05 11.58 11.57 db1 req'd Diametro db1 req'd 1 3/8" 34.925 28.99508 23.754 16.38 16.36 16.43 3/4" 25.4 pulg mm mm 1 1/8" 28.575 21.68566 1 3/4" 44.45 22.63888 57.15 30.75649 2 1/4" 57.15 23.39386 16.38 16.37 1 3/8" 34.925 29.66192 1 3/8" 34.925 22.04384 11.52 11.51 11.50 11.49 7/8" 22.225 28.99508 7/8" 22.225 29.0147 7/8" 1" 25.4 28.99508 1" 25.4 29.20025 1" 21.45037 2 1/8" 53.975 28.99508 2 1/8" 53.975 30.59971 2 1/8" 53.975 23.20291 2 1/4" 57.15 28.99508 2 1/4" 1 1/2" 38.1 1 1/4" 31.75 28.99508 1 1/4" 31.75 29.5322 1 1/4" 31.75 21.86572 1 1/2" 38.1 1 1/2" 38.1 22.24267 16.44 16.44 16.44 2 1/2" 63.5 2" 50.8 28.99508 2" 50.8 30.44187 2" 50.8 23.01518 (6.8‐11.) / Pag. 9.2‐33 1 3/4" 44.45 28.99508 1 3/4" 44.45 30.13981 1 1/8" 28.575 28.99508 1 1/8" 28.575 29.37557 5/8" 15.875 28.99508 "4E" y "4ES" 2 1/2" 63.5 28.99508 2 1/2" 63.5 31.05881

- 12. = = = ALTURA "Yp" 4E = = = = = = = = = = x + + x = = x + = = ( ; ) = = ‐ x x ‐ = = x ( + ) + = = = = ( ; ) = = + x = = + = > = = = (Tabla 6.2) / Pag. 9.2‐31 g1 dp twcolumna 2 r 133.00 mm Pfo 2 twcolumna 143.50 mm g3 bfviga 170.00 mm 2 7/8" bp2 bfviga 50.00 mm 220.00 mm pulg 1/2" 5/8" 53.975 57.15 63.5 29.00 28.575 31.75 34.925 29.00 50.8 2 1/8" twcolumna 11. 11.1. S = 1 2 x 29.66 1 1/2" 38.1 2 1/4" 2 1/2" db req'd mm 29.00 29.00 29.00 29.00 29.00 29.00 29.00 29.00 3/4" 7/8" 1" 1 1/8" 1 1/4" 1 3/8" 1 1/2" 1 3/4" 2" 30.14 2" 50.8 30.44 2 1/4" 57.15 g max g5 g6 g g2 bfviga 170.00 mm Diametro perno 1 1/4" g6 2 1/2" 63.52 1/2" 63.5 31.06 Diametro del perno a utilizar Pfo 276.65 mm 203.00 mm 140.00 mm g5 bfcolumna max g1 2 31.75 mm Diametro del perno a utilizar 7/8" 22.23 mm1 1/4" 31.75 mm Pfi 64.30 mm = 94.66 mm 31.75 mm1 1/4" Diametro del perno a utilizar 64.00 mm h1 pulg mm mm 1/2" 12.7 28.55 5/8" 15.875 28.74 3/4" 19.05 28.85 1 1/8" 23.75 23.20 bp 44.45 29.20 Diametro 4E 19.05 22.225 25.4 29.00 12.7 15.875 22.225 29.01 25.4 Diametro db req'd Diametro db req'd pulg mm mm 1/2" 12.7 29.00 29.00 22.225 21.22 1" 25.4 21.45 1 1/2" 38.1 22.24 1 1/8" 8ES 28.575 21.69 1 1/4" 31.75 21.87 1 3/8" 34.925 22.04 19.05 21.01 7/8" r twcolumna 139.00 mm bp 256.00 mm 23.39 2 1/8" 53.975 1 3/4" 44.45 22.64 2" 50.8 bp1 Pfi Pfi mm 1" 20.61 5/8" 15.875 20.83 3/4" 1.25 dp 28.575 29.38 1 1/4" 31.75 29.53 1 3/8" 34.925 23.02 x 29.82 1 3/4" 2 1/8" 53.97530.60 2 1/4" 57.15 30.7629.00 38.1 44.45 4ES g SSi 2 dg S S ho 417.95 mm 94.66 mm de 58.00 mm 2 de 256.00 mm 51.00 mmPfoinicial ANSI/AISC 358‐16 g3 g2 135.00 mm

- 13. 4ES = = = = = = = = = = = x + + = = ‐ x x ‐ = = ( ; ; ) = = ( ; ) = = x ( + ) + = = + x = = + = > = = = x Caso 1 ≤ Caso 2 > 8ES = = = Caso 1 (Tabla 6.3) / Pag. 9.2‐32 Caso 2 (Tabla 6.4) / Pag. 9.2‐33 bp2 x h1 x 1 gPfi +( Diametro perno 1 1/4" 31.75 mm x h1 x 2 ho x ( Pfi 1 Pfo ) 1 2 ‐ + 2bp + SYp = Pfoinicial 51.00 mm Pfi 64.30 mm Pfo 64.00 mm Yp = 1,559.07 mm 11.2. S = 1 x Bp x g = 99.87 mm 1 S ) + 2 S S 99.87 mm 2 twcolumna 149.25 mm 150.00 mm de 58.00 mmh1 276.65 mm ho 417.95 mm g1 bfviga 170.00 mm g2 Pfoinicial bfviga 50.00 mm 220.00 mm g3 bfcolumna 2 1.25 dp twcolumna 203.00 mm g max 139.00 mmtwcolumna Yp1 = 3,372.93 mm ( ) Yp1 = x h1 x ( 1 + ) + ho x ( 1 )+ bp1 g 2 de 266.00 mm bp 266.00 mmSi Pfi S Pfi Pfo 2 bp 2 1 S S 1 2 g + x h1 x ( Pfi + Pfi Yp2 = bp x h1 x ( 1 + 1 ) + ho x ( 1 + 3,884.57 mm de S Yp1 de S x ( S + Pfo ) 2 Pfi S Pfo gS h1 x ( Pfi + S ) + ho 1 ) + Yp2 2 de 38.00 mm Yp2 = ANSI/AISC 358‐16 ANSI/AISC 358‐16 g4 Yp = 3,372.93 mm 11.3. 7/8" 22.23 mm g4 g5 2 x ho x+ de +( Pfo ))S S = 1 x Bp x g = 76.68 mm Diametro perno dp min g1 g2 g3 149.25 mm g5 2 dg r

- 14. = = = = = = = = = = = x + + = = ‐ x x ‐ = = ( ; ; ) = = ( ; ) = = x ( + ) + = = + x = = + = > = = = x x x x x Caso 1 ≤ Caso 2 > Caso 1 Caso 2 226.00 mmg3 bfcolumna 2 1.25 dp twcolumna Yp1 = bp x h1 x 111.73 mm 120.00 mm bp1 g 2 de 196.00 mm bp 220.00 mm g1 bfviga 170.00 mm g2 Pfoinicial 2 twcolumna bp2 bfviga Pfi 50.30 mm Pfo 50.00 mm 2 ( 1 ) S ( 1 2 de ) + h2 x ( 1 Pfo + h2 ) 4 h1 x ) + h3 x ( 220.00 mm Yp = 4,622.33 mm S S + 1 ) Pfi + h4 x Pfi S S 76.68 mm 50.00 mm Pb + 2 g x Si Pfi Pfoinicial 37.00 mm ( de + ) 4 + h3 x ( Pfi + Pb ) 4 ( Pfo + Pb )+ 3 4 h2 x + 3 Pb ( S +h4 x Yp2 = bp x h1 2 x ( 1 S Yp1 = 4,622.33 mm ) + h2 + Pb2 + g 2 x h1 x ) 4 + Pb 2 + g x ( Pfi + Pb ) 4 + h4( Pfo + 3 Pb ) 4 + h3 S 1 ) Pfi + h4 x ( 1 ) x + h3 x ( ( S + Pb ) x g 4 Yp2 = 4,919.70 mm Yp1 de S Yp2de + 3 Pb S x ( 1 ) Pfo ( 120.00 mmdg r twcolumnag max g4 g5 h1 470.65 mm h2 403.65 mm h3 290.65 mm Pb 223.65 mm 67.00 mm g2 g3 111.73 mmg1g4 min h4 g5 2 dp

- 15. ESPESOR DE PLANCHA EXTREMA"tp" x = x x = ‐ tfvig x ESPESOR DE PLANCHA RIGIDIZADORES "tpr" = ANSI/AISC 358‐16 (2.4‐1) / Pag. 9.2‐7 TIPO Diametro pulg mm 4E 1 1/4" 31.75 ESPESOR DE PLANCHA EXTREMA A UTILIZAR 4ES 1 1/4" 31.75 8ES 7/8" TIPO Diametro pulg mm 4E 1 1/4" 31.75 h3 ‐ 470.65 Pt x 22.23 tp mm 45.00 31.00 26.00 tp mm 45.00 31.00 26.00 Mnp = 2 x Pt x ( h1 + h2 )+ h3 + h4 h2 x h4 ‐ ‐ ( ho + h1 ) ho mm 417.95 417.95 h1 mm 276.65 276.65 Mnp Kg x m 69,621.89 69,621.89 db2 4 Yp mm 1,559.07 3,372.93 Π 4,622.33403.65 290.65 223.65 4E y 4ES 8ES 4ES 1 1/4" 31.75 8ES 7/8" 22.23 Pt Kg 50,116.54 50,116.54 24,557.10 Mnp = 2 x Fyp 2530 kg/cm² Ød 1.00 tp mm 39.00 27.00 24.00 Mf Kg x m 52,257.61 54,211.65 7/8" 31.75 22.23 1,559.07 Yp mm 3,372.931 1/4" TIPO mm 0.56 x Fyplancha E 12. tp = 1 1/4" 31.75 59,411.52 68,199.99 mm mm mm ‐ ‐ ‐ ‐ 4E 4ES 8ES Diametro pulg 4,622.33 ANSI/AISC 358‐16 (6.8‐5) / Pag. 9.2‐29 Pt = Fnt 22.23 10.00 hst mm ‐ 122.00 155.00 tpr2 ≥ 0.56 x E Fyplancha hst TIPO Diametro tp2 pulg mm mm 8.00 8ES 7/8" tp mm ‐ 8.00 10.00 tp1 mm ‐ 8.00 8.00 RIGIDIZADOR A UTILIZAR ESPESOR DE PLANCHA E 4E 1 1/4" 31.75 2,100,000.00 Kg/cm2 1.11 Mf Ød Fyp Yp ANSI/AISC 358‐16 (6.8‐10) / Pag. 9.2‐33 ANSI/AISC 358‐16 (6.8‐10) / Pag. 9.2‐32 ‐ 4ES 1 1/4" 31.75 13. tpr1 = twviga x Fyplancha Fyviga = 8.00 mm hst tpr ≤ Ffu Ffu = Mf dvig156,094.58 171,066.87 Kg 150,468.21

- 16. FUERZAS EN LAS ALAS DE LA VIGA "Ffu" ‐ VERIFICACIÓN DE ESPESOR DE PLANCHA PARA" 4E" = Para estado límite ductil x x x x = x x x x 31.75 256.00 19.00 4ES 1 1/4" 31.75 0.90 mm 7/8" 22.23 220.00 23.00 3.00 3.00 3.00 + db X1 mm 186.50 196.50 169.55 4E 1 1/4" Ffu ≤ Øn x 2 0.6 x Fuplancha x 266.00 19.00 8ES tp x X1 tp ≥ 2 Øn 0.6 Fuplancha X1 TIPO Diametro bp tp pulg mm mm mm Ffu Øn bp = 256.00 mm tp 0.6 x x bpFyplancha x tp ANSI/AISC 358‐16 (6.8‐7) / Pag. 9.2‐30 tfviga mm 256.00 266.00 220.008ES 7/8" 22.23Ød 0.6 Fyplancha bp Ffu 171,066.87 360 12.7 360 12.7 ANSI/AISC 358‐16 Ffu ≤ Øn x Rn ANSI/AISC 358‐16 2 (6.8‐8) / Pag. 9.2‐28 TIPO Diametro pulg mm 4E 1 1/4" 31.75 4ES 1 1/4" 31.75 dbg : diametro del agujero Rn = 0.6 x Fuplancha x An An = tp x X1 X1 = bp ‐ 2 x ( +db + db ) Rn = 0.6 x Fuplancha x tp x X1 20.00 20.00 26.00 bp mm Ød 1.00 ANSI/AISC 358‐16 (2.4‐1) / Pag. 9.2‐7 Ffu ≤ 2 Ød x 0.6 x Fyplancha x bp x tp ≥ 2 Ffu 2 ≤ xØd Rn Rn = tp (6.8‐6) / Pag. 9.2‐30 14. Ffu = dviga tfviga Mf TIPO 4E 4ES 8ES Mf Kg x m 52,257.61 54,211.65 59,411.52 dviga mm 360 12.7 Ffu Kg 150,468.21 156,094.58 15. mm

- 17. RESUMEN PLANCHA EXTREMA SOLDADUDA ALAS DE LA VIGA x x x ‐ = x x = = x ‐ = SOLDADUDA ALMA DE LA VIGA = x x = = = ( ) 24.00 TIPO Ffu Kg 4E 150,468.21 4ES 156,094.58 8ES 171,066.87 =Fced viga 105,212.57 65,854.30 Kg Ffilete = Ffu Fced viga‐ Øw = 0.60 x Cpr Ry Ffilete 0.7071 ØFw Lv1;Lv2 31 Dfviga = 13.00 mm tp mm 45 Lv min 604 670 Øw 0.60 mm ‐ 8 Rwpenetración = 91,109.80 Kg RIGIDIZADOR ‐ 122 155 tp 10 Lst 18. ØFw 0.75 = 64,984.78 Øw = 167.30 mm Fyviga x bfviga x Lv1 = dviga 2 ‐ tfviga 11 13 150,468.21 Df3viga 4ES 8ES Ffu Kg 79,957.07 10 171,066.87 Ffu mm 59,358.41 FExx 1,899.00 Kg/cm2 Kg 26 64 50 64 58 Pfi = 98,320.86 Kg x Lef bfviga twviga Rwpenetración = 156,094.58 FExx x bfviga TIPO 4E tfviga = 91,109.80 Kg Rwpenetración mm Sxviga Fyviga dviga tfviga tfviga x Df1viga 16. Dfviga = 17. g bp mm mm 140 256 hplancha mm 604 mm 19.00 21.00 64.30 50.30 58 38 150 120 266 220 TIPO 4E 4ES 8ES 1 1/4" 31.75 Lef ØFw 0.75 Øw FExx 21,899.00 Kg/cm2 ‐ 212 269 mm hst mm 332.00 mm = Ffilete Kg 84,613.91 90,240.28 22.23 Pfo de mm 34.75 25.237/8" PERNO PLANCHA EXTREMA Diametro pulg mm 1 1/4" 31.75 mm 64.30 mm dbg 34.75

- 18. x x x x x x x x = ( ; ; ) PLANCHA EXTREMA Desgarramiento por los pernos = ( ; ) : : Desgarramiento por los pernos internos = ‐ = ( ; ) : TIPO Diametro pulg mm 4E 1 1/4" 31.75 4ES 1 1/4" 31.75 8ES 7/8" 22.23 Vu Kg Dw3viga mm 8 8 8 mm 8 32,260.06 32,174.65 32,097.68 8 Dw1viga mm 8 8 206.80 239.85 Dwviga 8 MaxDwviga Dw1viga Dw2viga Dw3viga 8 Vu Dw2viga = 0.9 Fyviga Ry twviga 1.5 ØFw 1.4142 Dw2viga mm 7 7 7 tp mm SOLDADURA MÍNIMA mm 167.30 167.30 167.30 Lv2 mm 206.80 Dw3viga Lv2 0.7071 ØFw Dw1viga = dperno ) 45 31 26 Lv mm 167.30 167.30 167.30 tfviga ‐ Lv1 ( Pfi + 2 x 4E 1 1/4" 31.75 4ES 1 1/4" 31.75 8ES 7/8" 22.23 Pfi mm 64.30 64.30 50.30 Lv2 = ‐dviga 2 x TIPO Diametro pulg mm Lc1 = de ‐ da 2 TIPO Diametro pulg mm Fup rno2 Kg 19. Vu < Øn x Rn = Øn x (ni) x rni + ANSI/AISC 358‐16 (6.8‐12.) / Pag. 9.2‐34 RESISTENCIA AL APLASTAMIENTO Y DESGARRAMIENTO POR CORTE DE LA PLANCHA Y EL ALA DE LA COLUMNA: rno 1 1/4" 31.75 4ES 1 1/4" 31.75 Øn x (no) x 96,377.76 56,583.07 rno Kg 89,505.00 61,659.00 32,317.27 rno 19.1. tp mm 45.00 31.00 26.00 = 1.2 x Lc1 x tp x Fup 8ES 7/8" 22.23 mm 58.00 58.00 19.1.1. 89,505.00 61,659.00 4E 19.1.2. Lc2 = x Lc2 x tp x Fuprni1 = 1.2 rni2 = 2.4Pfi + 32,317.27 Kg rno1 rno1 rno2 = 2.4 x db x tp x min rno1 rno2 rno1 rno2 Resistencia al aplastamiento Desgarramiento por los pernos 38.00 de da mm 34.75 34.75 25.23 Lc1 mm 40.63 40.63 25.39 139,903.20 Pfo + tfviga ‐ da x db x tp x Fup Lc3 Pb da Lc3 min Lc2 Lc3

- 19. = ( ; ) : : Chequeo por corte = ALA DE LA COLUMNA Desgarramiento por los pernos = ( ; ) : : Desgarramiento por los pernos internos x db x tp x Fup 8ES 7/8" 22.23 38.00 25.23 25.39 30.00 37,289.16 65,288.16 37,289.16 19.2.2. Lc2 = Pfi + Pfo + tfviga ‐ da rni1 = 1.2 x Lc2 x tp x Fup rni2 = 2.4 4E 1 1/4" 31.75 58.00 34.75 40.63 30.00 59,670.00 93,268.80 59,670.00 4ES 1 1/4" 31.75 58.00 34.75 40.63 30.00 59,670.00 93,268.80 59,670.00 TIPO Diametro de da Lc1 tfcolumna rno1 rno2 rno pulg mm mm mm mm mm Kg Kg Kg = 2.4 x db x x 2 rno min rno1 rno2 rno1 Desgarramiento por los pernos rno2 Resistencia al aplastamiento Fucolumna Fucolumnatfcolumna tfcolumna 19.2.1. Lc1 = de ‐ da rno1 = 1.2 x Lc1 x x rno2 64.30 rni2 rni Kg Kg 139,903.20 139,903.20 96,377.76 234,090.00 161,262.00 Lc4 mm 106.25 106.25 1 1/4" rni1 Kg Diametro pulg mm 31.75 1 1/4" 31.75 da mm 34.75 34.75 Pfi mm 19.1.3. 41.7850.30 Pfo mm 64 64 50 Lc2 mm 106.25 106.25 87.78 TIPO 4E 4ES 8ES 7/8" 22.23 25.23 64.30 Øn rni min rni1 rni2 rni1 rni2 Resistencia al aplastamiento Desgarramiento por los pernos internos x Rn = Øn x (ni) x rni + Øn x (no) x 96,377.76 53,177.90 56,583.07 53,177.90 < Øn x Rn Si Chequea Si Chequea Si Chequea Pb mm ‐ ‐ 67 Lc3 mm ‐ ‐ 41.775 TIPO Diametro pulg mm 4E 1 1/4" 31.75 4ES 2 2 4 (ni) (no) 19.2. Vu Kg 32,260.06 32,174.65 32,097.68 rno 2 2 4 Øn Rn Kg x 412,934.76 284,466.17 307,782.63 Vu 1 1/4" 31.75 8ES 7/8" 22.23 Øn 0.90 Vu < ANSI/AISC 358‐16 (6.8‐12.) / Pag. 9.2‐33

- 20. = ‐ = ( ; ) = ( ; ) : : Chequeo por corte = ALTURA "Yc" PARA 4E Y 4ES SIN RIGIDIZADOR DE ALA x (Tabla 6.5) / Pag. 9.2‐34 + C 4 ) + 54,211.65 Mf Kg x m 2,873.99 141 106.07 2,758.68 g mm 140 150 + g 2 1 1/4" 31.75 ( S 20. 4E 1 1/4" 31.75 32,260.06 2 2 275,289.84 h1 = dviga ‐ tfviga ‐ tfviga ‐ Pfi ANSI/AISC 358‐1620.1. tfviga Si Chequea 4ES 1 1/4" 31.75 32,174.65 2 2 275,289.84 Si Chequea 8ES 7/8" 22.23 32,097.68 4 4 355,133.81 Si Chequea (6.8‐12.) / Pag. 9.2‐33 Øn 0.90 TIPO Diametro Vu (ni) (no) Øn x Rn Vu < Øn x Rn pulg mm Kg Kg 8ES 7/8" 22.23 25.23 50.30 50 67 87.78 41.775 41.78 61,359.12 65,288.16 61,359.12 19.2.3. Vu < Øn x Rn = Øn x (ni) x rni + Øn x (no) x rno ANSI/AISC 358‐16 4E 1 1/4" 31.75 34.75 64.30 64 ‐ 106.25 ‐ 106.25 156,060.00 93,268.80 93,268.80 4ES 1 1/4" 31.75 34.75 64.30 64 ‐ 106.25 ‐ 106.25 156,060.00 93,268.80 93,268.80 rni2 Resistencia al aplastamiento TIPO Diametro da Pfi Pfo Pb Lc2 Lc3 Lc4 rni1 rni2 rni pulg mm mm mm mm mm mm mm mm Kg Kg Kg Lc3 Pb da Lc3 min Lc2 Lc3 rni min rni1 rni2 rni1 Desgarramiento por los pernos internos mm 141 + x h1 x ( 2 g S + 3 C 4 ) + = bfcol x h1 2 x ( ) 1 S + ho x ( ho x x bfcolC = Pfi Pfo C TIPO 4ES 1 1/4" 31.75 h1ho mmmm + Pfo 2 tfcolumna req mm 28.24 29.36 2 ho = dviga ‐ 277418 tfviga S Yc1 277418 102.47 Diametro pulg mm 4E + + S = 1 2 S Yc1 1 ) mm mm C2 2 x g 52,257.61

- 21. x x x = CON RIGIDIZADOR DE ALA = ‐ ‐ = x x x ALTURA "Yc" PARA 8ES SIN RIGIDIZADOR DE ALA x x xØd Fycolumna Yc (6.8‐13.) / Pag. 9.2‐34 120.00 113.00 94.87 3,641.87 Mf tfcolumna req Kg x m mm 59,411.52 26.75 C ) + g g 4 2 pb mm 67.00 S + S pb 2 + h3 x ( pb + C ) 2 tfcolumna req = 1.11 Mf ANSI/AISC 358‐16 + 2 x h1 x ( Pb + C ) + h2 x ( + S x h1 x ( 1 ) + h4 x ( 1 ) 2 S S + 2 xh4 = 1.11 Mf ANSI/AISC 358‐16 Ød Fycolumna Yc (6.8‐13.) / Pag. 9.2‐34 4ES 4,185.8264.30 64 + 21. 21.1. ANSI/AISC 358‐16 (6.8.) / Pag. 9.2‐35 Yc1 = bfcol 1 1/4" 31.75 418 277 150 141 106.07 Pfi Pfo mm mm 64.30 64 + 2 x h1 x ( S g TIPO Diametro ho g 52,257.61 23.10 54,211.65 23.84 tfcolumna req 4E 1 1/4" 31.75 418 277 140 141 102.47 4,297.09 psi ) + ho x psi Ød 1.00 ( 1 S + 1 ) pso ANSI/AISC 358‐16 (6.8‐13.) / Pag. 9.2‐33 64 64 63.85 64 63.85 64 ) + ho x 2 h1 Mf tfcolumna req Kg x m mm ANSI/AISC 358‐16 (6.8.) / Pag. 9.2‐34 Si psi > S Use psi S mm mm mm mmmm mm Yc2 pulg mm mm mm tfviga 2 psi = Pfi ‐ ts tfviga 20.2. ts1 ≤ tfcolumna ts 13.00 mm Pso Psi tfcolumna req = 1.11 Mf Ød Fycolumna Yc C S pso = Pfo ‐ ts Psi1 mm ( S + pso ) Yc2 = bfcol x h1 x ( 1 2 S + 1 mm mm mm mm 470.65 403.65 290.65 223.65 S Yc1 mm mm TIPO Diametro pulg mm g C mm mm 8ES 7/8" 22.23 h1 h2 h3 h4

- 22. CON RIGIDIZADOR DE ALA x x x RESUMEN ESPESOR DE ALA COLUMNA REQUERIDO. RESISTENCIA DE LAS ALAS DE LA COLUMNA ( ‐ ) RESISTENCIA A LA CEDENCIA LOCAL DEL ALMA DE LA COLUMNA = = = = = + x + x = =2 w mm 0.00 604.00 0.00 0.00 115.00 0.00 RIGIDIZADOR SIN DE ALA tfcolumna req mm 29.00 30.00 27.00 CON RIGIDIZADOR DE ALA tfcolumna req mm 24.00 24.00 22.00 Rigidizador ala columna A mm Diferencia mm 0.00 0.00 0.00 mm tral 0.00 0.00 0.00 h 59,411.52 21.22 Pfi Pfo Psi1 Pso Psi mm mm mm h3 x ( 1 ) Psi + h4 x ( 1 mm mm 50.30 50 50.15 49.85 50 x ( ) + 1 1/4" 31.75 4ES 1 1/4" 31.75 8ES 7/8" 22.23 tfcolumna mm 30.00 30.00 30.00 22. TIPO Diametro pulg mm 4E TIPO Diametro Yc2 Mf tfcolumna req pulg mm mm Kg x m mm + g 4 tfcolumna req = 1.11 Mf Ød Fycolumna Yc Pso Psi g + x h1 x ( 8ES 7/8" 22.23 5,790.52 (6.8‐13.) / Pag. 9.2‐33 + pb 2 ANSI/AISC 358‐16 21.2. ANSI/AISC 358‐16 (6.8.) / Pag. 9.2‐35 + ) + h3 x ( + pb ) 4 ( S 3 x pb 4 + ) S Yc2 = x h1 )+ h4 x 2 pb +S ) + h2 x ( 4 bfcol 1 1 3 x pb +h2 x ( ) 2 S Pso dcolumna N tfviga dcolumna Ct 0.50 So < Ct = 1.00 Ct 1.00 So ≥ ØdRn1 = dviga tfviga ØdMcf ANSI/AISC 358‐16 (6.8‐15.) / Pag. 9.2‐35 = 188,427.45 Kg Ffu = 150,468.21 Kg ANSI/AISC 358‐16 (6.8‐14.) / Pag. 9.2‐35 ØdMcf = Ød x Fycolumna x Yc1 x tfcolumna 2 = 6,544,085.48 Kg x cm 23. 24. So 3,700.00 mm 600.00 mmdcolumna tp2 Dfviga 13.00 mm38.70 mm

- 23. = + = = x ( x + + x ) x x x RESISTENCIA AL PANDEO DEL ALMA DE LA COLUMNA = ‐ x = = = = = x x x RESISTENCIA AL APLASTAMIENTO LOCAL DEL ALMA DE LA COLUMNA Cuando Ffu se aplica a una distancia mayor o igual a dcolumna / 2 desde el extremo de la columna "So" = = = x x 18.00 19.00 dcolumna N 8ES 7/8" 22.23 TIPO Diametro pulg mm 4E 25. ANSI/AISC 358‐16 (6.8‐17.) / Pag. 9.2‐37 h dcolumna Kc2 Ø Ct 1 1/4" 31.75 4ES Kc rcolumna tfcolumna 57.00 mm Ct 6 Kc N 2 tp Fycolumna twcolumna ØdØdRn2 1 1/4" 31.75 8ES 7/8" 22.23 tp mm 45.00 31.00 26.00 ØdRn Kg 209,682.61 187,722.21 179,879.21 Ct 0.50 So < dcolumna / 2 ØRn3 = x24 twcolumna 3 h E x Fycolumna = 100,531.29 Kg 26. 3,700.00 mm486.00 mm So Ct 1.00 So ≥ Ct = 1.00 TIPO Diametro pulg mm 4E 1 1/4" 31.75 4ES 1 1/4" 31.75 26.1. So ≥ dcolumna / 2 ØRn = Ø x 0.80 x twcolumna 2 x 1 + 3 x ( Fycolumna tfcolumna twcolumna N mm 102.70 74.70 64.70 So 3,700.00 mm dcolumna 600.00 mm Ø 0.75 Ø 0.75 Ffu Kg 150,468.21 156,094.58 171,066.87 Ffu Kg 150,468.21 156,094.58 171,066.87 dcolumna / 2 ANSI/AISC 358‐16 (6.8‐19.) / Pag. 9.2‐37 twcolumna req1 mm 18.00 E ANSI/AISC 358‐16 (6.8‐22.) / Pag. 9.2‐38 ) x twcolumna tfcolumna ( ) 1.5 x

- 24. Cuando Ffu se aplica a una distancia menor a dcolumna / 2 desde el extremo de la columna "So" y x x y x x mm t3rig mm 1.00 1.00 A UTILIZAR / RIGIDIZADOR DE ALMA DE COLUMNA 25.00 20.00 21.00 Vudp Kg 37,956.92 31,591.06 33,968.85 0.12 0.11 Ffu Kg 150,468.21 156,094.58 171,066.87 TIPO 4E 4ES 1 1/4" 31.75 102.70 87,026.71 Kg 12.00 150,468.21 55,892.48 25.00 204,913.03 18.00 156,094.58 104,134.05 20.00 124,503.52 19.00 171,066.87 110,758.89 22.00 141,545.32 twcolumna req3 Kg mm 64.70 79,367.73 86,244.07 128,906.10 19.00 171,066.87 115,366.80 ØdRn twcolumna req3 ØdRn twcolumna )1.5 x E Fycolumna tfcolumna tfcolumna twcolumna N > 0.20 dcolumna ( ) x ( dcolumna 18.00 156,094.58 21.00 137,098.02 twcolumna req1 Ffu 107,343.53 20.00 ØdRn twcolumna req3 ØdRn mm Kg Kg mm Kg twcolumna )1.5 x E Fycolumna tfcolumna tfcolumna twcolumna 12.00 150,468.21 56,255.65 25.00 208,196.89 twcolumna req1 Ffu twcolumna req2 mm 12.00 14.00 15.00 ØdRn Kg 112,511.29 140,420.63 155,077.88 ‐ twcolumna req1 mm 18.00 18.00 19.00 ØdRn Kg 226,589.76 214,687.06 230,733.61 Ffu Kg 150,468.21 156,094.58 171,066.87 174,053.421 1/4" 31.75 4ES 1 1/4" 31.75 8ES 7/8" 22.23 N mm 102.70 74.70 64.70 166,453.25 163,738.91 TIPO Diametro ØdRn Kg (6.8‐24.) / Pag. 9.2‐38 TIPO 8ES ANSI/AISC 358‐16 (6.8‐23.) / Pag. 9.2‐38 TIPO Diametro 31.75 102.70 87,026.71 4ES 1 1/4" 31.75 74.70 83,226.63 26.2. So < dcolumna / 2 ØRn = Ø x 0.40 x twcolumna 2 x 1 + 1 + 22.23 Diametro N ØdRn 4ES 1 1/4" 31.75 74.70 83,226.63 1 1/4" x twcolumna 2 x 31.75 102.70 Diametro N ØdRn pulg mm mm Kg 0.2 pulg mm mm 1 1/4" 31.75 74.70 81,177.30 ANSI/AISC 358‐16 dcolumna / 2 ØRn = Ø x 0.40 22.23 64.70 81,869.45 So < 7/8" dcolumna N ≤ 0.20 3 x ( N ) x pulg mm 4E 8ES 7/8" 22.23 Kg mm Kg 4E TIPO 4ES 8ES N ØdRn pulg mm mm Kg 8ES ØdRn4 4 x N 4E 4E 1 1/4" dcolumna 64.70 81,869.45 N/dcol 0.17 7/8" t2rig mm 10.00 10.00 10.00 trig mmKg 174,053.42 166,453.25 163,738.91 0.00 0.00 14.001.00 twcol req4 mm 12.00 14.00 15.00 twcol req5 mm 19.00 20.00 21.00 twcol req mm 19.00 20.00 21.00 mm t1rig 9.86 3.00 3.00 (

- 25. = x x x x = = ‐ x = ( ‐ ) + = ‐ = ‐ x x x x x x x ESPESOR RIGIDIZADOR DE ALA "ts" = = ‐ = = ( ; ; ; ) = ( ‐ ) = = x x x x x x x = = ( ; ; ) trigidizador mm 0.00 0.9 Dw2 : 1.5 ØFw 1.4142 TIPO Dw1 Dw2 Dw mm mm mm A mm 540.00 540.00 540.00 L mm Fyplancha ts 4E 0 6 6 4ES 0 6 6 8ES 8 6 8 0.00 14.00 Dw1 = t2rigidizardor = A L 90 = 9.86 mm ØdRn3 ØdRn4 ØdRn Kg 100,531.29 100,531.29 ts1 = W Fyplancha x x ( E ) 2 tfcolA L dviga tstwcolumna req twcolumna t1rigidizardor = 540.00 mmdcol 347.00 347.00 347.00 ØRn Ø 0.60 Fyplancha tw L Ø SOLDADURA MÍNIMA mm 4E = Fuplancha W Ø 2 Fsu 24.00 TIPO 1 1/4" 31.75 4ES ØdRn2 9.00 11.00 ts max ts3 ts4 ts5 ts2 = A = 12.70 mm ts3 = 13.00 mm Diametro pulg ts2 ) = ØRn min ØdRn1 = 9.00 mm 2,100,000.00 Kg/cm20.5 1.79 E W = bfcol 13.00100,531.29 Fsu Ffu ØRn Fsu Kg 49,936.93 55,563.30 70,535.59 ts4 = Fyplancha W Ø 0.9 Ø 27. 8ES 7/8" 22.23 30.00 27.00 22.00 12.00 Ffu Kg 150,468.21 156,094.58 171,066.87 max ( ts1 ; 0.75 U 0.75 ts5 mm 8.00 1 1/4" 31.75 30.00 30.00 8.00 9.00 29.00 30.00 24.00 mm 13.00 13.00 tstfcol mm ts4 mm tfcolumna req1 mm tfcolumna req2 mm U Ø 2 Fsu ts5 twcol 2 = 12.70 mm 140.00 mm L = dcol ‐ 2 x tfcol = 540.00 mm 2,530.00 Kg/cm2 2,530.00 Kg/cm2Fyplancha Fyviga = tfviga x Fyviga Fyplancha = t3rigidizardor A = 0.75 0.60 Fycol dcol Vudp = Vudp Vu ØRn 21

- 26. SOLDADURA A ALAS x x x x SOLDADURA A ALMA x x x Dw2a alma : SOLDADURA MÍNIMA ts Dw1a alas mm Dw2a alas mm = 0.9 Fyplancha mm TIPO 4E 4ES 540.00 TIPO Dw1a alma Dw2a alma Dwa alma mm mm mm 4E 0.00 14.00 Ancho Alto mm DIMENSIONES 4ES 7 6 7 8ES 7 6 7 8ES 13.00 Ancho SOLDADURA RIGIDIZADOR DE ALMA Dw mm 6.00 Cortemin mm 18.00 18.00 18.00 mm ALA 7 7 7 ALMA mm 140.00 140.00 140.00 Largo mm 540.00 540.00 7 7 7 mm 540.00 347.00 540.00 347.00 540.00 347.00 SOLDADURADIMENSIONES 6.00 8.00 RIGIDIZADOR DE ALAS t mm 0.00 ts mm 13.00 13.00 7 7 7 27.2. Dw1a alma = 0.6 Fyplancha ts ØFw 1.4142 4ES 8ES 7 7 7 6 6 6 7 6 7 1.5 ØFw 1.4142 27.1. Dw1a alas TIPO 4E : SOLDADURA MÍNIMA Dw2a alas Dwa alas mm

- 27. = = = = = = = Espesor de plancha 58140 256 64 10 RESUMEN UNIÓN "4E" 604 141 58 206 141 58 58 64 360 Viga Columna IPE360 HEB600 8 45.00 mm Calidad plancha ASTM ‐ A 36 Diametro del perno 1 1/4" Soldadura E60XX Calidad perno A325 Ambas alas iguales 8

- 28. = de Alas 2 0.00 604 Espesor de plancha 0.00 mm 347 540.00 25 25490 Espesor de plancha 0.00 mm RESUMEN UNIÓN "4E" Rigidizador de Alas 1 115 25 140 Espesor de plancha 13.00 mm 6 Rigidizador de Alma Borde a alas biselados HEB600 IPE360 540.00 Rigidizador

- 29. = = = = = = = = Diametro del perno 1 1/4" Calidad plancha ASTM ‐ A 36 Calidad perno 31.00 mm 25 187 RESUMEN UNIÓN "4ES" 266 58 150 58 Espesor de plancha 6 6 Viga IPE360 Columna HEB600 212 122 25 97 A325 604 58 141 64 360206 Ambas alas iguales 58 25 Soldadura E60XX 11 8 8 141 64 25 187 Espesor de plancha 8.00 mm

- 30. = Espesor de plancha 0.00 mm Rigidizador de Alas 2 115.00 0 Rigidizador de Alma Borde a alas biselados 6 0.00 mm Espesor de plancha 13.00 mm 25 25 490 25 IPE360 HEB600 540.00 347 540.00 Espesor de plancha 115 140 RESUMEN UNIÓN "4ES" Rigidizador de Alas 1

- 31. = = = = = = = = 10.00 mm 269 25 Espesor de plancha 13 8 8 26.00 mm 220 50 120 50 670 113 50 360 244 155 130 25 25 25 244 Espesor de plancha Calidad plancha ASTM ‐ A 36 IPE360 Columna HEB600 Calidad perno A325 Diametro del perno 7/8" Soldadura E60XX 113 50 38 67 Ambas alas iguales 8 8 RESUMEN UNIÓN "8ES" 38 67 67 67 100 Viga

- 32. = Rigidizador de Alas 2 0.00 Espesor de plancha 0.00 mm 25 490 25 RESUMEN UNIÓN "8ES" Rigidizador de Alas Rigidizador de Alma Borde a alas biselados 8 IPE360 HEB600 540.00 347 540.00 Espesor de plancha 115 140 14.00 mm Espesor de plancha 13.00 mm 25 0

- 33. Peso Total "Kg" Peso Total "Kg" Peso Total "Kg" COMPUTOS PERNOS RIGIDIZADOR ALA COLUMNA 2 0 7,850.00 0.00 UNIÓN 8ES COMPUTOS PLANCHAS DESCRIPCIÓN VOLUMEN PESO PESO ESPECIFICO m2 Kg/m3 Kg RIGIDIZADOR ALA COLUMNA 1 0.0039312 7,850.00 30.86 PLANCHA EXTREMA 0.0038324 RIGIDIZADOR ALA VIGA PLANCHA EXTREMA RIGIDIZADOR ALA VIGA 0.00 RIGIDIZADOR ALA COLUMNA 1 0.0039312 7,850.00 30.86 98.00 Peso Kg/ml 6.22 6.22 3.05 Peso total Kg 6.46 5.77 4.78 N° Pernos 8.00 8.00 16.00 0 7,850.00 0.00 7,850.00 30.08 0.0008339 7,850.00 6.55 0.00695808 7,850.00 54.62 0 7,850.00 RIGIDIZADOR ALMA COLUMNA 0.00524664 7,850.00 41.19 108.68 TIPO 4E 4ES 8ES Diametro pulg mm 1 1/4" 31.75 1 1/4" 31.75 7/8" 22.23 L1 mm 88.00 74.00 69.00 L2 mm 41.30 41.30 28.60 Ltotal mm 130.00 116.00 7,850.00 0.00 UNIÓN 4ES 39.10 Kg RIGIDIZADOR ALA COLUMNA 2 UNIÓN 4E COMPUTOS PLANCHAS DESCRIPCIÓN VOLUMEN PESO PESO ESPECIFICO m2 Kg/m3 Kg COMPUTOS PLANCHAS 73.21 RIGIDIZADOR ALA VIGA PLANCHA EXTREMA 0.000413824 7,850.00 3.25 RIGIDIZADOR ALA COLUMNA 1 0.0039312 7,850.00 30.86 RIGIDIZADOR ALMA COLUMNA 0 7,850.00 0.00 VOLUMEN DESCRIPCIÓN Kg/m3 7,850.00 m2 0.004980584 PESO ESPECIFICO PESO RIGIDIZADOR ALMA COLUMNA 0 7,850.00 0.00 85.48 RIGIDIZADOR ALA COLUMNA 2 0