Contenu connexe Similaire à 966H Hydraulic Schematic RENR8828.pdf (20) Plus de JavierCarpio13 (14) 1. RENR8828

Preliminary

16

Page,

PRELIMINARY

PRELIMINARY

PRELIMINARY

RENR8828

November 2005

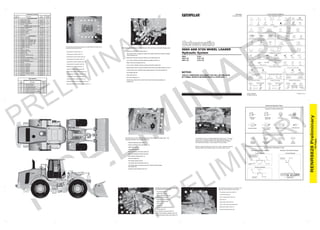

966H AND 972H WHEEL LOADER

Hydraulic System

966H:

A6D1-UP

A6G1-UP

972H:

A7D1-UP

A7G1-UP

©2005 Caterpillar

All Rights Reserved

Printed in U.S.A.

NOTICE:

THIS IS A TEMPORARY DOCUMENT THAT WILL BE REPLACED

BY FORMAL SERVICE INFORMATION AT A LATER DATE.

The following remote pressure taps are located inside the panel on the

front side of the service center:

- Transmission reverse clutch (1)

- Transmission forward clutch (2)

- Transmission fourth speed clutch (3)

- Transmission third speed clutch (4)

- Transmission second speed clutch (5)

- Transmission first speed clutch (6)

- Steering pump outlet pressure (7)

- Torque converter inlet pressure (8)

- Brake system accumulator pressure (9)

- Transmission lubrication pressure (10)

- Transmission pump outlet pressure (11)

- Torque converter outlet pressure (12)

- Steering cylinder rod end grease zerks (13)

- Rear axle oscillation bearing grease zerks (14)

ONE POSITION TWO POSITION THREE POSITION

VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

LINES CROSSING LINES JOINING

TWO-WAY THREE-WAY FOUR-WAY

SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

2-SECTION PUMP

MAIN AUX.

SPRING

(ADJUSTABLE)

VARIABILITY LINE RESTRICTION

(VARIABLE)

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

PRESSURE

COMPENSATION

PUMP: VARIABLE and

PRESSURE COMPENSATED

ENERGY TRIANGLES

HYDRAULIC PNEUMATIC

MEASUREMENT

PRESSURE TEMPERATURE FLOW

ROTATING SHAFTS

UNIDIRECTIONAL BIDIRECTIONAL

PUSH-PULL LEVER PEDAL

GENERAL MANUAL PUSH BUTTON SPRING

MANUAL CONTROL SYMBOLS

HYDRAULIC MOTORS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

HYDRAULIC PUMPS

FLUID STORAGE RESERVOIRS

CROSSING AND JOINING LINES

VALVE ENVELOPES VALVE PORTS

BASIC COMPONENT SYMBOLS

FLUID CONDITIONER

PUMP or MOTOR

FLUID POWER SYMBOLS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

VALVES

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

EXTERNAL RETURN INTERNAL RETURN

REMOTE SUPPLY PRESSURE

SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

ACCUMULATORS

SPRING LOADED GAS CHARGED

SOLENOID

or MANUAL

SOLENOID

and PILOT

SOLENOID and

PILOT or MANUAL

COMBINATION CONTROLS

SOLENOID SERVO THERMAL DETENT

HYDRAULIC AND PNEUMATIC CYLINDERS

DOUBLE ACTING

SINGLE ACTING

BASIC

SYMBOL

SPRING

LOADED

CHECK VALVES

TWO

POSITION

INFINITE

POSITIONING

FLOW IN ONE

DIRECTION

FLOW ALLOWED IN

EITHER DIRECTION

THREE

POSITION

CROSS

FLOW

PARALLEL

FLOW

INTERNAL PASSAGEWAYS

NORMAL POSITION

A B

P T

A B

P T

SHIFTED POSITION INFINITE POSITION

CONTROL VALVES

ATTACHMENT

MANUAL SHUTOFF

SHUTTLE PILOT

CONTROLLED

Hydraulic Symbols (Electrical)

Electrical Symbols Table

325-AG135 PK-14

Circuit Identification

Number

Wire Color Wire Gauge

Harness identification code

This example indicates

wire 135 in harness "AG".

325-PK-14

Wire Gauge

Wire Color

Circuit Number

Identification

Wire Number Identification Codes

Current Standard

Previous Standard

Electrical Schematic Example Hydraulic Schematic Example

325-PK

Wire Color

Circuit Number

Identification

B A

Wire

Wire

(EXAMPLE VALVE)

Current Standard

Transducer

(Fluid)

Transducer

(Gas / Air)

G

Generator

Electrical Wire

Pressure Switch

M

Electric Motor

Pressure Switch

(Adjustable)

Temperature Switch

T

Pressure

Symbol

Temperature

Symbol

Level

Symbol

Flow

Symbol

Electrical Symbols (Electrical)

Item

Number

Description

Part

Number

Schematic

Location

1 HAND METERING UNIT 230-4176 B-4

2 CONNECTOR - ORIFICE 108-2144 C-4

3 CYLINDER GP - STEER 133-1747 C-1

4 VALVE GP - NEUTRALIZER 146-7571 C-3, C-4

5 VALVE GP - STEER 142-3996 D-1

6 VALVE GP - NEUTRALIZER 8J-1553 E-2

7 VALVE GP - STEER 133-1728 F-1

8 CYLINDER GP - STEERING 133-1747 F-1, F-2

9 VALVE GP - CHECK 111-7775 E-3

10 VALVE GP - PILOT 164-4116 E-4

11 VALVE GP - SHUTTLE 8J-6875 E-3

12 SCREEN GP 154-2883 F-2

13 PUMP GP - STEERING 241-9157 A-6

14 PUMP GP - IMPLEMENT 254-4109 B-7

15 CYLINDER - TILT (STANDARD - 966) 242-4273 F-8

16 CYLINDER - TILT (STANDARD - 972) 244-8777 F-8

17 CYLINDER - TILT (HIGH LIFT - 966) 245-7484 F-8

18 CYLINDER - TILT (HIGH LIFT- 972) 245-7486 F-8

19 CYLINDER - LOGGER - 966 244-8777 F-8

20 CYLINDER - LIFT (LH) 242-4275 F-7

21 CYLINDER - LIFT (RH) 242-4274 F-7

22 VALVE 152-2646 D-9

23 VALVE GP - MANUAL 112-1817 E-9

24 ACCUMULATOR - PILOT 245-2975 F-5

25 PUMP GP - FAN 254-5147 B-8

26 MOTOR GP - FAN 161-8919 C-9

27 VALVE GP - COOLER BYPASS 142-8977 B-9

28 FILTER GP 244-1031 B-9

29 VALVE GP - FLOW DIVERTER 237-8180 A-9

30 FAN CONTROL-BRAKE CHARGE VALVE 242-1307 C-8

31 CASE DRAIN FILTER 249-2334 A-8

32 VALVE GP - BREAKER RELIEF 220-0814 A-8

33 TANK GP 237-2742 A-8

34 VALVE GP - DIVERTER 141-2597 B-5

35 PUMP GP - SUPP STEER 275-8543 A-5

36 VALVE GP - CONTROL 261-3945 D-9

37 VALVE GP - CONTROL 261-2337 D-9

38 VALVE GP - CONTROL 261-3972 D-9

39 VALVE GP - CONTROL 261-2338 D-9

40 VALVE GP - CONTROL 256-3644 D-9

41 ACCUMULATOR-RIDE CONTROL 245-2974 F-6

42 VALVE GP - CONTROL & RELIEF 263-5832 C-7

43 MOTOR GP 183-4077 C-6

Component Locations

COMMAND CONTROL STEERING CIRCUIT

HMU STEERING CIRCUIT

MAIN SCHEMATIC

Tap Locations

Pressure, Sampling, and Sensor

Tap

Number

Description

Schematic

Location

AA FAN PUMP PRESSURE A-9

BB TRUE LOAD SENSING E-9

CC SYSTEM PRESSURE PUMP E-9

DD LOAD SENSE PRESSURE B-7

EE STEERING SYSTEM PRESSURE B-7

FF STEERING LOAD SENSE B-4, D-4

HH HYDRAULIC FAN MOTOR PRESSURE B-8

JJ FAN PUMP LOAD SENSE B-9

The implement pump is a variable displacement piston pump. The pump

control valve (1) controls the angle of the swash plate (not shown). The

implement pump supplies oil flow for the implement hydraulic system,

the implement pilot system, and the optional CCS pilot system.

Maximum angle stop adjustment screw (2) is used to adjust the maximum

upstroke position of the actuator piston in the pump control valve (1).

1 2

1 2

3

4

5

6

7 8 9

10 11 12

13

14

This photo shows a front view of the implement control valve in the loader frame. The

following components can be seen in this view:

- Pressure differential relief valve (1)

- Head end solenoid valve (ride control) (2)

- Signal relief valve (3)

- Tilt anti-drift valve (4)

- Rod end solenoid valve (ride control) (5)

- Ride control balance solenoid valve (6)

- Pilot pressure reducing valve (7)

- Pilot accumulator (8)

- Pilot supply pressure tap (9)

- Lift cylinder head end pressure tap (10)

- Lift cylinder head end pressure sensor for Payload Control System

and Autodig (10)

- Hydraulic lockout solenoid valve (12)

11

10

9

1 2 3

4

5

6

12

8

7

The following components are located on the fan control and brake accumulator charging valve:

- Signal line to the fan and brake pump (1)

- Fan solenoid valve, an electronic output of the Engine ECM which controls the speed

of the cooling fan (2)

- Relief valve, limits the maximum pressure in the brake system (3)

- Cut-in valve, maintains minimum brake accumulator pressure (4)

- Return hose to the hydraulic tank (5)

- Cut-out valve, maintains maximum brake accumulator pressure (6)

- Brake pressure switch, warns the operator when brake accumulator pressure is low (7)

- Inverse shuttle valve, maintains equal charge pressure in both accumulators (8)

- Accumulator ports (9)

- Pump inlet port (10)

- Fan motor outlet port (11)

- Priority valve, blocks flow to the fan motor when the brake accumulators are

charging (12)

1

2

3

4 5

6

7

8

9

10

11

12

The following components can be seen from

the left rear of the control valve:

- Tilt anti-drift valve (1)

- Signal relief valve (2)

- Signal duplication valve (3)

- Return to tank port (4)

- Supply port from pump (5)

- Signal line to pump (6)

- Tank line (7)

- Screen (8)

- Tilt back pilot solenoid valve (9)

- Tilt back pilot (10)

- Tilt cylinder rod end line relief (11)

- Ride control balance solenoid valve (12)

- Rod end solenoid valve (ride control) (13)

1 2

3

4

5

6

7

8

9

10

11

12

13

The following components are located on the

right side of the implement control valve:

- Tilt cylinder rod end line relief (1)

- Lift anti-drift valve (2)

- Line to manual lower valve (3)

- Tank line (4)

- Ride control relief valve (5)

- Line to ride control accumulator (6)

- Raise pilot solenoid valve (7)

- Dump pilot solenoid valve (8)

1 2 3 4

5

6

7

8

2. RENR8828

Preliminary

30

Page,

Color

2

PRELIMINARY

DRAIN / RETURN LINE

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

IMPLEMENT PUMP OUTPUT

PRIMARY STEERING PUMP CIRCUIT

STEERING CIRCUIT

IMPLEMENT PILOT SUPPLY OIL

AUXILIARY CIRCUIT

LOAD SENSING

SUPPLY LINE

TILT CYLINDER CIRCUIT

LIFT CYLINDER CIRCUIT

SECONDARY STEERING CIRCUIT

BRAKE CHARGE VALVE AND FAN CONTROL CIRCUIT

A

B

C

D

E

F

A

B

C

D

E

F

2

3

4

5

6

7

8 2

3

4

5

6

7

8 1

2

3

4

5

6

7

8 2

3

4

5

6

7

8 1

1

A

C

D

E

F

B

C

D

E

F

B

9

9

Connection b1 only for Command Control Steering

THIS IS A TEMPORARY DOCUMENT THAT WILL BE REPLACED BY FORMAL SERVICE INFORMATION AT A LATER DATE.

6

9

3

HMU STEER AND 3PC IMPLEMENT

COMMAND CONTROL STEERING

AND 3PC IMPLEMENT ATTACHMENT

a1

a1

b1

b1

c1

c1

c1

d1

d1

d1

e1

4

2

e1

e1

CROSSOVER

RELIEF

SHUTTLE VLV

DIRECTIONAL SPOOL

MAKE UP

CHECK

BACK UP

RELIEF

PRESSURE

REDUCING

VALVE

PILOT PORT"A"

PILOT PORT"B"

REGULATED

PRESS. PORT

TO PILOT VALVE

TANK PORT

CYL PORT "A"

CYL PORT "B"

LOAD SENSING

PUMP PORT

8

8

7

12

10

11

34

35

B4 A4

CROSSOVER RELIEF

CYL PORT "A"

CYL PORT "B"

MAKE-UP CHECKS

DIRECTIONAL SPOOL

BACK-UP RELIEF

PUMP PORT

HMU SUPPLY PORT

PILOT PORT "B"

PILOT PORT "A"

PILOT CONTROL SPOOL

TILT

RACK

BACK

DUMP

RACK

BACK

HOLD

DUMP

LIFT

RAISE

LOWER/

FLOAT

RAISE

HOLD

LOWER

FLOAT

HOLD

HEAD

END

ROD

END

AUX

HEAD

END

ROD

END

LS DR

1

)(

R H

LS P T

F

PS

A1 A2

5

4

1

33

31

32

13

30

26

27

28

36

25

15 20 21

41

24

23

37 38

29

22

16

17

18

39

P

T

43

42

40

14

THIS SCHEMATIC IS FOR THE 966H AND 972H WHEEL LOADER

PART #: 242-0337 CHG 07

Components are shown installed on a fully operable machine with the key and engine

off and transmission shifter in neutral.

LINE PATTERNS

Drain / Return Lines

Component Group

Pilot / Load Sensing Pressure

Pressure Line

Attachment

Air Line

CALLOUTS

Taps (Pressure, Sampling,Sensor) by letter

Components by number

YY

52

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

AA

CC

BB

DD

EE

FF

FF

GG

HH

JJ

19