CHECKLIST CT210M (1978) CIAC 2020.pdf

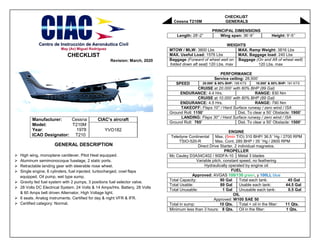

- 1. CHECKLIST Revision: March, 2020 Manufacturer: Cessna Model: T210M Year: 1978 ICAO Designator: T210 CIAC’s aircraft YVO182 GENERAL DESCRIPTION High wing, monoplane cantilever. Pitot Heat equipped. Aluminum semimonocoque fuselage, 2 static ports. Retractable landing gear with steerable nose wheel. Single engine, 6 cylinders, fuel injected, turbocharged, cowl flaps equipped. Oil pump, wet type sump. Gravity fed fuel system with 2 pumps, 3 positions fuel selector valve. 28 Volts DC Electrical System. 24 Volts & 14 Amps/Hrs. Battery, 28 Volts & 60 Amps belt driven Alternator, High Voltage light. 6 seats. Analog instruments. Certified for day & night VFR & IFR. Certified category: Normal. CHECKLIST Cessna T210M GENERALS PRINCIPAL DIMENSIONS Length: 28’-2” Wing span: 36’-9’’ Height: 9’-5’’ WEIGHTS MTOW / MLW: 3800 Lbs MAX. Ramp Weight: 3816 Lbs MAX. Useful Load: 1576 Lbs MAX. Baggage load: 240 Lbs Baggage (Forward of wheel well on folded down aft seat) 120 Lbs. max Baggage (On and Aft of wheel well) 120 Lbs. max PERFORMANCE Service ceiling: 28.500’ SPEED 20.000’ & 80% BHP: 198 KTS 10.000’ & 80% BHP: 181 KTS CRUISE at 20.000’ with 80% BHP (89 Gal) ENDURANCE: 4.4 Hrs. RANGE: 830 Nm CRUISE at 10.000’ with 80% BHP (89 Gal) ENDURANCE: 4.5 Hrs. RANGE: 790 Nm TAKEOFF: Flaps 10° / Hard Surface runway / zero wind / ISA Ground Roll: 1150’ Dist. To clear a 50’ Obstacle: 1900’ LANDING: Flaps 30° / Hard Surface runway / zero wind / ISA Ground Roll: 765’ Dist. To clear a 50’ Obstacle: 1500’ ENGINE Teledyne Continental TSIO-520-R Max. (5min T/O) 310 BHP/ 36.5´´Hg / 2700 RPM Max. Cont. 285 BHP / 35´´Hg / 2600 RPM Direct Drive Starter, 2 individual magnetos. PROPELLER Mc Cauley D3A34C402 / 90DFA-10 Metal 3 blades Variable pitch, constant speed, no feathering Hydraulically operated by engine oil FUEL Approved: AVGAS 100/130 green, y 100LL blue Total Capacity: 90 Gal Total each tank: 45 Gal Total Usable: 89 Gal Usable each tank: 44.5 Gal Total Unusable: 1 Gal Unusable each tank: 0.5 Gal OIL Approved: W100 SAE 50 Total in sump: 10 Qts. Total + oil in the filter: 11 Qts. Minimum less than 3 hours: 8 Qts. Oil in the filter: 1 Qts.

- 2. CHECKLIST Cessna T210M INDEX 1 1 CONTENT PAGE SPEEDS ………………….................................................. 2 PRE-FLIGHT INSPECTION ….......................................... 3 INSPECCIÓN INTERIOR ……………………...…………… 4 EXTERIOR INSPECTION …............................................. 5 NORMAL PROCEDURES BEFORE STARTING ENGINE ……..……………………… 7 STARTING ENGINE ………………………………………… 8 BEFORE TAXIING .....………………………………………. 8 BEFORE TAKEOFF…………..……………………………... 9 ENGINE RUN-UP………….………………………………… 10 NORMAL TAKEOFF ………………………………………… 10 SHORT FIELD TAKEOFF ………...……………………….. 11 MAXIMUM PERFORMANCE TAKEOFF …………………. 11 NORMAL CLIMB .……..…………………………………….. 12 CRUISE ………………………………………………………. 12 DESCENT ……………………..…………………….……….. 12 BEFORE LANDING ……………..…………………………... 13 NORMAL LANDING ……………….…………….………….. 13 SHORT FIELD LANDING ………….…………….…………. 13 BALKED LANDING ………...…………….………………….. 14 AFTER LANDING ……….…………….…………….……….. 14 SECURING THE AIRPLANE ……………………………….. 14 CHECKLIST Cessna T210M V SPEEDS 2 V SPEEDS (AIRSPEED INDICATOR) KIAS Maximum Demonstrated Crosswind Velocity 21 * VR “ROTATE” 60-70 VS0 Beginning of WHITE arc 55 VS Beginning of GREEN arc 68 VFE End of white arc 115 10° Flaps 150 VNO Beginning of YELLOW arc 165 VNE RED line 195 Short field Takeoff, Flaps 10º, Speed at 50´ 75 VX 80 Normal climb out 80-90 VY To 17.000´ 24.000´ 97 93 Normal enroute climb, flaps and gear up. 100 120 VLE Max. Landing gear Extended speed 195 VLO Max. Landing gear Operating speed 140 Normal approach, Flaps UP 90-80 Normal approach, Flaps 30º 80-70 Short Field approach, Flaps 30° 71 Balked Landing: Maximum Power, Flaps 20° 70 ENGINE FAILURE after takeoff Flaps UP Flaps DOWN 85 80 MAXIMUM GLIDE (3800 Lbs) (3400 Lbs) (3000 Lbs) 85 80 75 VA Maximum Recommended Turbulent Air Penetration Speed (3800 Lbs) (3200 Lbs) (2600 Lbs) 119 110 98

- 3. CHECKLIST Cessna T210M PRE-FLIGHT INSPECTION 3 FIGURE 1 -1 NOTE Visually check airplane for general conditions during Walk Around inspection. In cold weather: remove even small accumulations of frost, ice or snow from wings, tail, and control surfaces. Also, make sure that control surfaces contain no internal accumulations of ice or debris. Prior to flight, check that pitot heater (if installed) is warm to touch within 30 seconds with battery and pitot heat switches on. If a night flight is planned: check operation of all lights, and make sure a flashlight is available. WARNING: When Turning “ON” the Master Switch using an external power source, or pulling the propeller through by hand, treat the propeller as if the Ignition Switch were “ON”, do not stand, nor allow anyone else to stand, within the arc of the propeller, since a loose or broken wire, or a component malfunction, could cause the propeller to rotate. CHECKLIST Cessna T210M PRE-FLIGHT INSPECTION 4 INTERIOR INSPECTION: CABIN: a) Aircraft Flight Manual ----------------------------------------------------- AVAILABLE b) Flight Book ----------------------------------------------------------------------- CHECK: I. Airplane keys, Fuel card, maintenance and reports book (Check remaining hours to next inspection) II. Logbooks: Fuselage, Engines, and Propellers. III. Certificates: (Check Current) Airworthiness. Registration. Insurance policy. Acoustic homologation. Radio station certificate. Weight and Balance. c) Weight and Balance manifest ------------------------------------------------ CHECK d) Parking Brake ------------------------------------------------------------------------- SET e) Control Wheel Lock ----------------------------------------------------------- REMOVE f) Landing Gear Handle ------------------------------------------------------------ DOWN g) Auxiliary Fuel Pump ----------------------------------------------------------------- OFF h) Ignition Switch ------------------------------------------------------------------------ OFF i) Beacon --------------------------------------------------------------------------------- ON j) Master Switch ---------------------------------------------------------- ON and Check: I. Fuel Quantity ------------------------------------------------------ CHECKED II. Landing Gear position lights ------------------- ON, and Press to Test III. Avionics Master -------------------------------------------------------------ON Check radios´ Fan operative, then OFF IV. Courtesy lights --------------------------------------- ON, Check then OFF V. Beacon ------------------------------------------------------------------------ ON VI. Stall Warning ------------------------------------------------------------- Check VII. Pitot Heat --------------------- ON, Check operative then ----------- OFF k) Master Switch ------------------------------------------------------------------------- OFF l) Fuel Selector Valve --------------------------------------------------- ON Fuller Tank m) Cowl Flaps ------------------------------------------------------------------ FULL OPEN n) Mixture -------------------------------------------------------------------------- CUT-OFF o) Propeller ---------------------------------------------------------------------- FORWARD p) Throttle -------------------------------------------------------------------------------- IDLE q) Static Pressure Alternate Source Valve (if installed) ----------------------- OFF r) Radar (If installed) ------------------------------------------------------------------ OFF s) Oxygen Supply Pressure (If installed) ------------------------------------ CHECK t) Oxygen Masks (If installed) -------------------------------------------- AVAILABLE u) Fire Extinguisher and survival equipment -------------------------- AVAILABLE

- 4. CHECKLIST Cessna T210M PRE-FLIGHT INSPECTION 5 EXTERIOR INSPECTION: a) Static Source Openings (both sides of fuselage) – CHECK for stoppage. EMPENNAGE: b) Baggage Door -------------------------------------------------- CHECK for security c) Rudder Gust Lock ---------------------------------------------------------- REMOVE d) Control Surfaces --------------- CHECK freedom of movement and security RIGHT WING trailing edge: 1. Aileron ------------------------ CHECK for freedom of movement and security 2. Fuel Tank Vent at Wing Tip Training Edge ------------- Check for stoppage RIGHT WING: 1. Wing Tie Down -------------------------------------------------------- DISCONNECT 2. Main Wheel Tire --------------------------------------- CHECK for proper inflation 3. Cabin Step --------------------------------------- CHECK for security cleanliness, and retraction well for cleanliness. 4. Before first flight of the day and after each refueling, use sampler cup and drain small quantity of fuel from fuel tank sup quick-drain valve to check for water, sediment, and proper fuel grade. 5. Fuel quantity ------------------------------- CHECK VISUALLY for desired level 6. Fuel filler cap ----------------------------------- SECURE and vent unobstructed NOSE: 1. Propeller and Spinner -------------- CHECK for nicks, security and oil leaks. 2. Air inlets --- CHECK, engine induction air (left) and heater air (right) for restrictions. 3. Landing and Taxi lights ---------------- CHECK for condition and cleanliness 4. Nose Wheel Strut and Tire ----------- CHECK for condition and cleanliness 5. Nose Tie Down ------------------------------------------------------ DISCNONNECT 6. Engine Oil level --- CHECK, do not operate with less than seven (7) quarts. Fill to ten (10) quarts for extended flight. 7. Before first flight of the day and after each refueling, pull out strainer drain knob for about four seconds to clear fuel strainer of possible water and sediment. Check strainer rain closed. If water is observed, the fuel system may contain additional water, and further draining of the system at the strainer, fuel tank sumps, and fuel reservoir drain valves will be necessary. CHECKLIST Cessna T210M PRE-FLIGHT INSPECTION 6 LEFT WING: 1. Main Wheel Tire ----------------------------------------- Check for proper inflation 2. Before first flight of the day and after each refueling, use sampler cup and drain small quantity of fuel from fuel tank sup quick-drain valve to check for water, sediment, and proper fuel grade. 3. Fuel Quantity ------------------------------- CHECK VISUALLY for desired level 4. Fuel Filler Cap ---------------------------------- SECURE and vent unobstructed LEFT WING Leading edge: 1. Pitot Tube Cover ---------------- REMOVE and check opening for stoppage 2. Stall Warning Vane -----------------------– CHECK for freedom of movement 3. Wing Tie Down ------------------------------------------------------- DISCONNECT LEFT WING trailing edge: 1. Fuel Tank Vent at Wing Tip Trailing Edge ------------ CHECK for stoppage 2. Aileron ------------------------ CHECK for freedom of movement and security

- 5. CHECKLIST Cessna T210M NORMAL PROCEDURES 7 BEFORE STARTING ENGINE: 1. Doors --------------------------------------------- CLOSE and LOCK 2. Seats, Belts, Harnesses ------------------ ADJUST and LOCK 3. Parking Brake ----------------------------------------------------- SET 4. Fuel Selector Valve ------------------------------- FULLER TANK 5. Cowl Flaps --------------------------------------------- FULL OPEN 6. Trims ------------------------------------------------------------- Neutral 7. Landing Gear Lever ----------------------------------------- DOWN 8. Throttle ------------------------------------------------------------ IDLE 9. Propeller ------------------------------------- HIGH RPM (Forward) 10.Mixture ------------------------------------------------------ CUT-OFF 11.Flaps ------------------------------------------------------------------- UP 12.Avionics Master Switch --------------------------------------- OFF 13.Master Switch ----------------------------------------------------- OFF 14.Auxiliary Fuel Pump -------------------------------------------- OFF 15.Ignition Switch --------------------------------------------------- OFF CAUTION: The AVIONICS MASTER SWITCH must be “OFF” during engine start to prevent possible damage to avionics. 16.Electrical equipment ------------------------------------------- OFF 17.Beacon --------------------------------------------------------------- ON 18.Circuit Breakers ---------------------------------------- CHECK IN 19.Radios -------------------------------------------------------------- OFF CHECKLIST Cessna T210M NORMAL PROCEDURES 8 STARTING ENGINE: 1. Mixture ------------------------------------------------------------ RICH 2. Propeller ------------------------------------ HIGH RPM (Forward) 3. Throttle ------------------------------------------------------ CLOSED 4. Master Switch ----------------------------------------------------- ON 5. Auxiliary Fuel Pump -------------------------------------------- ON 6. Throttle ------------ ADVANCE to obtain 50-60 PPH Fuel Flow Then RETURN to IDLE Position 7. Auxiliary Fuel Pump ------------------------------------------- OFF 8. Propeller Area ----------------------------------------------- CLEAR 9. Ignition Switch ---------------------------------------------- START Release when engine starts 10.Throttle -------------------------- RESET to desired IDLE speed Check Oil Pressure 11.Avionics Master Switch ---------------------------------------- ON 12.Radios --------------------------------------------------------------- ON BEFORE TAXIING: 1. Taxi Clearance ---------------------------------------------- OBTAIN 2. Taxi Light ----------------------------------------------------------- ON 3. Taxi Area ------------------------------------------------------- CLEAR 4. Parking Brake -------------------------------------------- RELEASE

- 6. CHECKLIST Cessna T210M NORMAL PROCEDURES 09 BEFORE TAKEOFF: 1. Throttle ---------------------------------------------------- 1.000 RPM 2. Parking Brake ---------------------------------------------------- SET 3. Taxi Light ---------------------------------------------------------- OFF 4. Window ----------------------------------------- CLOSE and LOCK 5. Flight Controls --------------------------- FREE and CORRECT 6. TRIMS ------------------------------------------------------- TAKEOFF 7. Flaps ---------------------------------- CHECK 10°; 20°; 30°; & 0° Set for TAKEOFF 8. Fuel Selector Valve ------------------------------ FULLER TANK 9. Cowl Flaps --------------------------------------------- FULL OPEN 10.Mixture ----------------------------------------------------------- RICH 11.Propeller ------------------------------------ HIGH RPM (Forward) 12.Cabin Air ------------------------------------------------- As required 13.Instruments & Radios ----------------------------------- CHECK 15. ENGINE RUN-UP: a. Throttle ----------------------------------------------------- 1.700 RPM Check Engine Instruments in Green Arc. b. Magnetos ------ Move Ignition Switch first to “R” and check max. Drop do not exceed 150 RPM, move the Switch back to “BOTH”, then to “L” and check max. Drop do not exceed 150 RPM, move the switch back to “BOTH” There should not be a differential greater than 50 RPM between magnetos. NOTE: If there is a doubt concerning operation of the ignition system, RPM checks at higher engine speeds will usually confirm whether a deficiency exists. c. Propeller ----- CYCLE from high to low RPM; return to high RPM (full forward) I. RPM --------------------------------- DROPS II. Manifold Press ------------------- CONSTANT III. Oil Pressure ----------------------- DROPS IV. Propeller -------------------------- HIGH RPM (Forward) CHECKLIST Cessna T210M NORMAL PROCEDURES 10 e. Engine Instruments & Ammeter ------------------------ CHECK f. Suction Gage -------------------------------- CHECK in Green Arc. g. Throttle ---------------------------------------------------- 1.000 RPM 16. Autopilot (If installed) ----------------------------------------- OFF 17. Beacon, Navigation, Strobe Lights ------- ON as Required 18. Takeoff clearance ----------------------------------------- OBTAIN 19. Parking Brake ------------------------------------------- RELEASE TAKEOFF NORMAL TAKEOFF: 1. Flaps ----------------------------------------------------------- 0° - 10° 2. Power ---------------------- 36.5´´Hg / 2700 RPM (5 min limit) 3. Mixture -------------------------------- ADJUST to 178-186 PPH 4. Elevator control ---------------------- Rotate at 60 to 70 KIAS NOTE: When the nose wheel is lifted, the gear motor may run 2-3 seconds to restore hydraulic pressure. 5. Climb Speed ----------------------------------------- 80 – 90 KIAS 6. Brakes ----------------------- Apply momentarily when airborne 7. Landing Gear ---------------------------- RETRACT in climb out 8. Flaps ------------------------------------------------------- RETRACT

- 7. CHECKLIST Cessna T210M NORMAL PROCEDURES 11 SHORT FIELD TAKEOFF: 1. Flaps ------------------------------------------------------------------ 10º 2. Brakes ---------------------------------------------------------- APPLY 3. Power ------------------------ 36.5´´Hg / 2700 RPM (5 min limit) 4. Mixture -------------------------------- ADJUST to 178-186 PPH 5. Brakes ----------------------------------------------------- RELEASE 6. Elevator control --------------------------------- Slightly Tail Low 7. Climb Speed -------- 75 KIAS until all obstacles are cleared 8. Landing Gear ------- RETRACT after obstacles are cleared 9. Flaps ------------------------ RETRACT after reaching 80 KIAS NOTE: Do not reduce power until wing flaps and landing gear have been retracted MAXIMUM PERFORMANCE CLIMB: 1. Airspeed ------------------------------------------------------- 97 KIAS 2. Power ------------------------------------------- 35´´Hg / 2600 RPM 3. Mixture ---------------------------------------- ADJUST to 162 PPH NOTE: See power and fuel flow placard for maximum continuous power manifold pressure and fuel flow above 17.000´. Refer to section 5 for airspeed above 17.000´ NOTE: On hot days at higher altitudes, be alert for fuel vapor indications. If fuel flow fluctuations are observed or if desired fuel flows cannot be maintained turn the AUX. FUEL PUMP “ON” and reset the mixture as required. 4. Cowl Flaps ----------------------------------------------- FULL OPEN NOTE: On hot days turn AUX. FUEL PUMP “ON” momentarily if switching tanks in climb CHECKLIST Cessna T210M NORMAL PROCEDURES 12 NORMAL CLIMB: 1. Airspeed ------------------------------------------- 100 --- 120 KIAS 2. Power -------------------------------------------- 30” Hg / 2500 RPM 3. Mixture -------------------------------------------- LEAN to 120 PPH NOTE: On hot days, it may be necessary to utilize the AUX. FUEL PUMP to maintain 120 PPH 4. Cowl Flaps ---------------------------------------- OPEN as required CRUISE: 1. Power -------------------------------- 15-30” Hg / 2200-2500 RPM 2. Mixture ------------------------------------------------------------- LEAN NOTE: On hot weather at high altitudes, be alert for fuel vapor indications. If fuel flows fluctuations are observed place the AUX. FUEL PUMP switch in the “ON” position and reset mixture control as desired. The AUX: FUEL PUMP should be turned off when fuel flows will remain steady. 3. Cowl Flaps ---------------------------- CLOSED (open if required) NOTE: On hot days, turn AUX. FUEL PUMP “ON” momentarily if switching tanks within 30 minutes of cruise. DESCENT: 1. Power -------------------------------------------------------- As desired 2. Auxiliary Fuel Pump -------------------------------------------- OFF 3. Mixture ---------------------------- ADJUST for smooth operation (Full RICH for IDLE power) 4. Cowl Flaps --------------------------------------------------- CLOSED

- 8. CHECKLIST Cessna T210M NORMAL PROCEDURES 13 BEFORE LANDING: 1. Seats, Belts, Shoulder Harnesses -------------------- SECURE 2. Fuel Selector Valve -------------------------------- FULLER TANK 3. Mixture -------------------------------------------------------------- RICH 4. Propeller ---------------------------------------------------- HIGH RPM 5. Landing gear - EXTEND (below 140 KIAS) and Check Down 6. Landing Lights ----------------------------------------------------- ON 7. Auxiliary Fuel Pump --------------------------------------------- OFF 8. Flaps ------------------------------------------------------ AS DESIRED (10° below 150 KIAS, 20° or 30° below 115 KIAS) 9. Autopilot (if installed) ------------------------------------------- OFF NORMAL LANDING: 1. Flaps ------------------------- As Desired (Flaps Down preferred) 2. Airspeed -------------------------------- 80 - 90 KIAS (Flaps Up) 70 - 80 KIAS (Flaps Down) 3. Touchdown -------------------------------- MAIN WHEELS FIRST 4. Landing Roll ------------------------ Lower nose wheel GENTLY 5. Braking ------------------------------------- MINIMUM REQUIRED SHORT FIELD LANDING 1. Flaps ----------------------------------------------- FULL DOWN (30°) 2. Airspeed -------------------------------------------------------- 71 KIAS 3. Power ---------------- REDUCE to IDLE after clearing obstacle 4. Touchdown ---------------------------------- MAIN WHEEL FIRST 5. Brakes ----------------------------------------------- APPLY HEAVILY 6. Wing Flaps -------------------------------------------------- RETRACT CHECKLIST Cessna T210M NORMAL PROCEDURES 14 BALKED LANDING (GO AROUND) 1. Power -------------------------- 36.5´´Hg / 2700 RPM (5 min limit) 2. Flaps ------------------------------ RETRACT to 20° (Immediately) 3. Climb Speed --------------------------------------------------- 70 KIAS 4. Flaps --------------------------------------------- RETRACT SLOWLY (After reaching safe altitude and 75 KIAS) 5. Cowl Flaps -------------------------------------------------------- OPEN AFTER LANDING 1. Flaps --------------------------------------------------------- RETRACT 2. Cowl Flaps ------------------------------------------------------- OPEN 3. Radar (if installed) ----------------------------------------------- OFF SECURING AIRPLANE: 1. Throttle -------------------------------------------- Adjust 1000 RPM 2. Parking brake ----------------------------------------------------- SET 3. External Lights (Except Beacon) ---------------------------- OFF 4. Radios --------------------------------------------------------------- OFF 5. Avionics Master -------------------------------------------------- OFF 6. Mixture---------------------- IDLE CUT-OFF (PULL FULL OUT) (Wait for the propeller to stop) 7. Ignition Switch ---------------------------------------------------- OFF 8. Master Switch ----------------------------------------------------- OFF

- 9. CHECKLIST Cessna T210M INDEX 2 15 CONTENT PAGE EMERGENCY PROCEDURES ENGINE FAILURES: DURING TAKEOFF RUN …………………..……………….. 16 IMMEDIATELY AFTER TAKEOFF …………………………. 16 DURING FLIGHT ……….……………………………………. 17 FORCED LANDINGS: EMERGENCY LANDING WITHOUT ENGINE POWER … 17 PRECAUTIONARY LANDING WITH ENGINE POWER … 18 DITCHING …..………………………………………………… 18 FIRES: DURING START ON GROUND ……………....................... 19 ENGINE FIRE IN FLIGHT ……….………………………..… 19 ELECTRICAL FIRE IN FLIGHT ……………..……….…….. 20 CABIN FIRE …………………………………….…………….. 20 WING FIRE ……….………………………………………..…. 20 LANDING GEAR MALFUNCTION: LANDING GEAR FAILS TO RETRACT ……….…………… 21 LANDING GEAR FAILS TO EXTEND……..……….………. 21 GEAR UP LANDING ……………....………………….……... 21 LANDING WITHOUT POSITIVE INDICATION OF GEAR LOCKING ……………………………………..…….… 22 LANDING WITH A DEFECTIVE NOSE WHEEL OR FLAT NOSE TIRE) ………………………………..…….……. 22 LANDING WITH A FLAT MAIN TIRE ……………..……..… 22 OTHER: OVER-VOLTAGE LIGHT ILUMINATES ……………………. 23 AMMETER SHOWS DISCHARGE …………………………. 23 STATIC SOURCE BLOCKAGE ……………………………... 23 ICING ……………..……………………………………………. 24 CHECKLIST Cessna T210M EMERGENCY PROCEDURES 16 ENGINE FAILURES: ENGINE FAILURE DURING TAKEOFF RUN: 1. Throttle -------------------------------------------------------------- IDLE 2. Brakes -------------------------------------------------------------- Apply 3. Flaps ---------------------------------------------------------- RETRACT In case of runway excursion: 4. Secure the aircraft: a) Mixture ------------------------------------------ IDLE CUT-OFF b) Fuel Selector Valve ----------------------------------------- OFF c) Ignition Switch ------------------------------------------------ OFF d) Auxiliary Fuel Pump ---------------------------------------- OFF e) Master Switch ------------------------------------------------ OFF ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF: 1. Airspeed -------------------------------------- 85 KIAS (Flaps Up) 80 KIAS (Flaps Down) 2. Area for landing ----------------------------------------- Search for 3. Re-Start -------------------------------------- If able due to situation 4. Secure the aircraft: a) Mixture ------------------------------------------ IDLE CUT-OFF b) Fuel Selector Valve ---------------------------------------- OFF c) Ignition Switch ----------------------------------------------- OFF d) Auxiliary Fuel Pump --------------------------------------- OFF 5. Flaps -------------------------- As Required (30° Recommended) e) Master Switch ----------------------------------------------- OFF

- 10. CHECKLIST Cessna T210M EMERGENCY PROCEDURES 17 ENGINE FAILURES: ENGINE FAILURE DURING FLIGHT: 1. Airspeed ------------------------------------------------------- 85 KIAS 2. Area for landing ------------------------------------------ Search for 3. Re-Start --------------------------------------- I able due to situation a) Fuel Selector Valve ------------------- FULLER TANK b) Mixture ------------------------------------------------ RICH c) Auxiliary fuel pump ----------------------------------- ON (For 3-5 seconds with throttle open 1/2 open then OFF) d) Ignition Switch -------------------------------------- BOTH (Or START if propeller is stopped) e) Throttle ------------------------------- ADVANVE Slowly FORCED LANDINGS: EMERGENCY LANDING WITHOUT ENGINE POWER: 1. Airspeed ------------------------------------ 90 KIAS (Flaps UP) 80 KIAS (Flaps Down) 2. Secure the aircraft: a) Mixture ------------------------------------- IDLE CUT-OFF b) Fuel Selector Valve ----------------------------------- OFF c) Ignition Switch ------------------------------------------ OFF d) Auxiliary Fuel Pump ---------------------------------- OFF 3. Landing Gear ------------------------------------------------- DOWN (UP if terrain is rough or soft) 4. Flaps ---------------------------- As required (30º recommended) 5. Doors ------------------------------ UNLATCH prior to touchdown e) Master Switch ------------------------------------------ OFF 1. Brakes -------------------------------------------- APPLY HEAVILY CHECKLIST Cessna T210M EMERGENCY PROCEDURES 18 PRECAUTIONARY LANDING WITH ENGINE POWER: 1. Airspeed ------------------------------------------------------------ 85 KIAS 2. Flaps -------------------------------------------------------------------------10º 3. Select a field, FLY OVER noting terrain and obstructions, then RETRACT FLAPS upon reaching a safe altitude and airspeed. 4. Electrical Switches --------------------------------------------------- OFF 5. Landing Gear -------------------------------------------------------- DOWN (UP if terrain is rough or soft) 6. Flaps ---------------------------------------------- 30° (on final approach) 7. Airspeed ------------------------------------------------------------ 75 KIAS 8. Doors ------------------------------------ UNLATCH prior to touchdown 9. Avionics Master Switch --------------------------------------------- OFF 10. Master Switch ---------------------------------------------------------- OFF 11. Brakes --------------------------------------------------- APPLY HEAVILY DITCHING: 1. Airspeed --------------------------------------------------------------- 75 KIAS 2. Seat belts ------------------------------------------------------------- Adjusted 3. Life vests ---------------------------------------------------------------- Put on 4. Heavy objects ------------------------------------------- Secure or jettison 5. Survival equipment --------------------------------------------- Keep near 6. Landing Gear --------------------------------------------------------------- UP 7. Flaps -------------------------------------------------------------------------- 30° 8. Power --------------------------- Stablish 300 FPM descent at 75 KIAS NOTE: If no power is available: Approach at 85 KIAS with FLAPS UP or at 80 KIAS with FLAPS 10° 9. Approach: a) High winds, Heavy seas ------------------------------------- Into the wind b) Light winds, Heavy swells ----------------------------- Parallel to swells 10. Secure the aircraft: a) Mixture ------------------------------------------- IDLE CUT-OFF b) Fuel Selector Valve ----------------------------------------- OFF c) Ignition Switch ------------------------------------------------ OFF d) Auxiliary Fuel Pump ---------------------------------------- OFF 11. DOORS ----------------------------------- UNLATCH prior to touchdown e) Master Switch -------------------------------------------------- OFF 12. Touchdown ------------------------------------------- LEVEL ATTITUDE

- 11. CHECKLIST Cessna T210M EMERGENCY PROCEDURES 19 FIRES: FIRE DURING START ON GROUND: 1. Ignition Switch --- START (continue cranking to obtain start) 2. Auxiliary Fuel Pump -------------------------------------------- OFF If engine starts: 2. Power -------------------------------- 1700 RPM for a few minutes 3. Engine ------------------- SHUTDOWN and inspect for damage If engine fails to start: 2. Throttle --------------------------------------------------- FULL OPEN 3. Mixture ------------------------------------------------ IDLE CUT OFF 4. Ignition Switch --------------------- Continue cranking (START) 5. Secure the aircraft: a) Mixture ------------------------------------------ IDLE CUT-OFF b) Fuel Selector Valve ---------------------------------------- OFF c) Ignition Switch ----------------------------------------------- OFF d) Auxiliary Fuel Pump --------------------------------------- OFF e) Master Switch ----------------------------------------------- OFF 6. Fire extinguisher -------------------------------------------------- Use 7. Fire damage ---------- Inspect, repair, or replace components ENGINE FIRE IN FLIGHT: 1. Mixture ------------------------------------------------ IDLE CUT-OFF 2. Fuel sector valve ------------------------------------------------- OFF 3. Master Switch ----------------------------------------------------- OFF 4. Cabin Heat & Cabin Air ------------------------------------ CLOSE Except overhead vents. 5. Airspeed ------------------------------------------------ 120 KIAS or + (If fire is not extinguished, increase Glide speed to find and airspeed which will provide an incombustible mixture) 6. Forced Landing ------------------------------------------ EXECUTE CHECKLIST Cessna T210M EMERGENCY PROCEDURES 20 ELECTRICAL FIRE IN FLIGHT: 1. Master Switch ----------------------------------------------------- OFF 2. Avionics Master -------------------------------------------------- OFF 3. All other switches (except IGNITION SWITCH) --------- OFF 4. Vents, Cabin Heat & Cabin Air -------------------------- CLOSE Except overhead vents. 5. Fire Extinguisher ----------------------- ACTIVATE (if available) If fire appears out and electrical power is necessary for continuance of flight: 6. Master Switch ------------------------------------------------------- ON 7. Circuit Breakers ------- Check for faulty circuit, do NOT reset 8. Switches de radios ----------------------------------------------- OFF 9. Avionics Master ---------------------------------------------------- ON 10. Radio / Electrical Switches ----------------- ON, one at a time With delay after each until sort circuit is localized 11. Vents, Cabin Heat & Cabin Air -------------------------- OPEN When it is ascertained that fire is completely extinguished CABIN FIRE: 1. Master Switch ----------------------------------------------------- OFF 2. Vents, Cabin Heat & Cabin Air -------------------------- CLOSE 3. Fire Extinguisher ----------------------- ACTIVATE (if available) 4. Land the airplane as soon as possible to inspect for damage WING FIRE: 1. Navigation, Beacon & Strobe Lights ---------------------- OFF 2. Pitot Heat Switch ------------------------------------------------- OFF 3. Radar (if installed) ----------------------------------------------- OFF 4. Perform a sideslip to keep the flames away from the fuel tank and cabin, and land as soon as possible NOTE: If an oxygen system is available, occupants should use oxygen masks until smoke and discharging dry powder clears. After discharging an extinguisher within a closed cabin, ventilate the cabin.

- 12. CHECKLIST Cessna T210M EMERGENCY PROCEDURES 21 LANDING GEAR MALFUNCTION: LANDING GEAR FAILS TO RETRACT: 1. Master Switch ------------------------------------------------------ ON 2. Landing Gear Lever ----------------------- Check (lever full UP) 3. LDG GEAR & GEAR PUMP circuit breakers -------------- IN 4. Gear UP light (amber) -------------------------------------- CHECK 5. Landing Gear Lever -------------------------------------- RECYLE 6. Gear Motor ---------- CHECK operation (ammeter and noise) LANDING GEAR FAILS TO EXTEND: 1. Landing Gear Lever ----------------------------------------- DOWN 2. Emergency Hand Pump ----- EXTEND HANDLE and PUMP (About 65 cycles) 3. Gear DOWN Light (green) -------------------------------------- ON 4. Emergency Hand Pump ------------------------------------ STOW NOTE: It takes about 55 cycles (110 strokes) to extend the gear (light on) and about 10 more (until resistance becomes heavy) to close the gear doors. NOTE: If the landing gear does not extend, attempt another manual extension with the Avionics Power and Master Switches turned OFF to eliminate any possible electrical malfunctions. After extension, turn the Avionics Power and Master Switches back ON to check that the gear-down indicator light is illuminated. GEAR UP LANDING: 1. Landing Gear Lever ------------------------------------------------ UP 2. LDG GEAR & GEAR PUMP circuit breakers --------------- IN 3. Runway or area for landing ----------------------------- SELECT 4. Flaps ------------------------------------------------------ 30° (On Final) 5. Airspeed ------------------------------------------------------- 75 KIAS 6. Doors ------------------------------- UNLATCH prior to touchdown 7. Avionics Master & Master Switch -------------------------- OFF (When landing is assured) 8. Touchdown --------------------------------------- Slightly TAIL LOW 9. Mixture ------------------------------------------------ IDLE CUT-OFF 10. Ignition Switch -------------------------------------------------- OFF 11. Fuel Selector Valve -------------------------------------------- OFF 12. Airplane ------------------------------------------------- EVACUATE CHECKLIST Cessna T210M EMERGENCY PROCEDURES 22 LANDING WITHOUT POSITIVE INDICATION OF GEAR LOCKING: 1. Before Landing Checklist ------------------------ COMPLETED 2. Approach --------------------------------------- Normal (Full Flaps) 3. LDG GEAR & GEAR PUMP circuit breakers -------------- IN 4. Landing ------------------------------ As SMOOTHLY as possible 5. Brakes -------------------------------------------- MINIMUM required 6. Taxi ------------------------------------------------------------- SLOWLY 7. Engine --------------------- SHUTDOWN before inspecting gear LANDING WITH A DEFECTIVE NOSE GEAR: (Or flat nose tire) 1. Movable load --------------------- TRANSFER to baggage area 2. Passengers ------------------------------------- MOVE to rear seat 3. Before Landing Checklist ------------------------ COMPLETED 4. Runway ------------------- HARD SURFACE or SMOOTH SOD 5. Flaps ------------------------------------------------------------------- 30° 6. Doors ------------------------------ UNLATCH prior to touchdown 7. Avionics Master & Master Switch -------------------------- OFF (When Landing is assured) 8. Touchdown -------------------------------------- Slightly TAIL LOW 9. Mixture ------------------------------------------------ IDLE CUT-OFF 10. Ignition Switch -------------------------------------------------- OFF 11. Fuel Selector Valve -------------------------------------------- OFF 12. Elevator Control - Hold nose off ground as long as possible 13. Airplane -------------------------------------------------- EVACUATE LANDING WITH A FLAT MAIN TIRE: 1. Approach ---------------------------------------- Normal (Full Flaps) 2. Touchdown ---------------------------------------- GOOD TIRE first 3. Directional Control -------------------------------------- MAINTAIN

- 13. CHECKLIST Cessna T210M EMERGENCY PROCEDURES 23 OTHERS: OVER-VOLTAGE LIGHT ILLUMINATES AMMETER SHOWS DISCHARGE: 1. Avionics Master -------------------------------------------------- OFF 2. Master Switch ------------------------------------ OFF (Both sides) 3. Master Switch ------------------------------------------------------ ON 4. OVER-VOLTAGE light ------------------------------------------ OFF 5. Avionics Master --------------------------------------------------- ON If OVER-VOLTAGE light illuminates again: 6. Alternator ----------------------------------------------------------- OFF 7. Nonessential Radio / Electrical Equipment ------------- OFF 8. Flight -------------------------- TERMINATE as soon as practical STATIC SOURCE BLOCKAGE: (Erroneous Instrument Reading Suspected) 1. Alternate Static Source Valve ------------------------- PULL ON 2. Airspeed -- Climb 2 knots faster and approach 7 knots faster Than normal or consult appropriate table 3. Altitude ---------------------------------------CRUISE 150 Ft higher And APPROACH 70 Ft higher than normal CHECKLIST Cessna T210M EMERGENCY PROCEDURES 24 ICING: (INADVERTENT ICING ENCOUNTER) 1. Pitot Heat -------------------------------------------------------------- ON 2. Turn back or change altitude to obtain an OAT that is less conducive to icing 3. Cabin Heat & Defroster ---------------------------------------- OPEN 4. Increase engine speed to minimize ice build-up on propeller blades. If excessive vibration is noted, momentarily reduce engine speed to 2200 RPM with the propeller control, and then rapidly move the control full forward. 5. Watch for signs of induction air filter ice and regain manifold pressure by increasing the throttle setting. 6. Plan a landing at the nearest airport. 7. With an ice accumulation of ¼ inch or more on the Wing leading edges, be prepared for a significantly higher power requirement, approach speed, stall speed, and landing roll. 8. Open the window and, if practical, scrape ice from a portion of the windshield for visibility in the landing approach. 9. Use 10° to 20° landing flap setting for ice accumulations of 1 Inch or less. With heavier ice accumulation, approach flaps retracted to ensure adequate elevator effectiveness in the approach and landing. 10. Approach at 85-95 KIAS (Flaps 20°) and 95-105 KIAS (flaps 10° or 0°) depending upon the amount of ice accumulation. If ice accumulation is unusually large, decelerate to the planned approach speed while in the approach configuration (landing gear and flaps down) at a high enough altitude which would permit recovery in the event that a stall buffet is encountered.

- 14. CHECKLIST Cessna T210M 25 CHECKLIST Cessna T210M 26 PROCEDIMIENTOS DE FALLA DE COMUNICACIONES VFR: Si no se puede hacer contacto de radio con el ATC: 1. Asegúrese de que está usando la frecuencia correcta, si es posible trate de utilizar otra frecuencia disponible. 2. Compruebe el volumen del radio. 3. Chequee la posición del Switch en el panel de control de audio. 4. Verifique si el micrófono está propiamente enchufado y que usted tiene puesto los audífonos y que tanto las cornetas como el micrófono están bien enchufados en toda su extensión. 5. Trate de usar el micrófono de mano si se tienen puestos los audífonos. 6. Si su avión está equipado con más de un radio trate de alternar el Transreciver. 7. Si se encuentra dentro de su extensión llame al último control de ATC donde haya efectuado contacto y pida asistencia. Si aún no se ha podido hacer contacto con el ATC: 8. Transponder 7600. 9. Permanecer fuera del espacio aéreo clase D hasta haber determinado el flujo y dirección del tránsito; Incorporarse al patrón de tránsito. 10. Al hacer contacto visual con las luces del controlador alabear varias veces consecutivas, encender las luces externas y acatar las instrucciones emitidas por las luces.