Aerial/Boom Lift Operation Safety

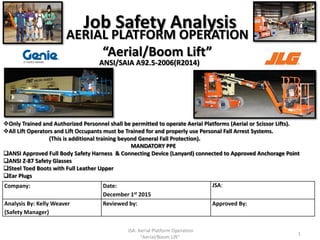

- 1. Job Safety Analysis Company: Date: December 1st 2015 JSA: Analysis By: Kelly Weaver {Safety Manager} Reviewed by: Approved By: MANDATORY PPE ANSI Approved Full Body Safety Harness & Connecting Device (Lanyard) connected to Approved Anchorage Point ANSI Z-87 Safety Glasses Steel Toed Boots with Full Leather Upper Ear Plugs 1 Only Trained and Authorized Personnel shall be permitted to operate Aerial Platforms (Aerial or Scissor Lifts). All Lift Operators and Lift Occupants must be Trained for and properly use Personal Fall Arrest Systems. (This is additional training beyond General Fall Protection). AERIAL PLATFORM OPERATION “Aerial/Boom Lift” ANSI/SAIA A92.5-2006(R2014) JSA: Aerial Platform Operation "Aerial/Boom Lift"

- 2. JSA: Aerial Platform Operation "Aerial/Boom Lift" 2 Documents to be kept on the Aerial Lift In a weather resistant storage compartment ANSI MANUAL OF RESPONSIBILITY Mfg. Make and Model specific Walk Around Inspection Form Manufacturer Operation and Safety Manual Fall Protection Inspection Checklist Any other documentation required by OSHA, ANSI, The Manufacturer, the Employer, or Site Specific Work Place. The owner of this card is to carry this card at all times when operating Aerial Lift Equipment This card expires in 3 years FWT , LLC Safety Management Danger Failure to obey the instructions and safety rules in this manual will result in death or serious injury. Do Not Operate Unless:

- 3. JSA: Aerial Platform Operation "Aerial/Boom Lift" 3 You learn and practice the principles of safe machine operation contained in this operator’s manual. 1 Avoid hazardous situations. {Know and understand the safety rules before going on to the next section}. 2 Always perform a pre-operation inspection. 3 Always perform function tests prior to use. 4 Inspect the workplace. 5 Only use the machine as it was intended. You read, understand and obey the manufacturer’s instructions and safety rules — safety and operator’s manuals and machine decals. You read, understand and obey employer’s safety rules and worksite regulations. You read, understand and obey all applicable governmental regulations. You are properly trained to safely operate the machine. DANGER Failure to obey the instructions and safety rules in this manual will result in death or serious injury. Do Not Operate Unless:

- 4. 4 Before use each day or at the beginning of each shift, the aerial platform shall be given a visual inspection and functional test including, but not limited to, the following: (1) Operating and emergency controls (2) Safety devices (3) Personal protective devices (4) Air, hydraulic and fuel system(s) leaks (5) Cables and wiring harness (6) Loose or missing parts (7) Tires and wheels (8) Placards, warnings, control markings and operating manual(s) (9) Outriggers, stabilizers, extendable axles and other structures (10) Guardrail systems (11) Items specified by the manufacturer ANSI /SAIA A92.5-2006 (R2014) Before the aerial platform is used and during use, the operator shall check the area in which the aerial platform is to be used for possible hazards such as, but not limited to: (1) Drop-offs or holes, including those concealed by water, ice, mud, etc. (2) Slope (s) (3) Bumps and floor obstructions (4) Debris (5) Overhead obstructions and electrical conductors (6) Hazardous locations and atmospheres (reference ANSI/NFPA 505-1987) 8.7 Workplace Inspection. “FAILURE TO COMPLY with your REQUIRED RESPONSIBILITIES in the use and operation of the Aerial Platform could result in DEATH OR SERIOUS INJURY” 8.3 Prestart Inspection. JSA: Aerial Platform Operation "Aerial/Boom Lift" Your Company USA

- 5. JSA: Aerial Platform Operation "Aerial/Boom Lift" 5 Step Sequence of Basic Job Step Hazards Recommended Action or Procedure PPE 1 Pre-start Inspection Vehicle components Proper fluid levels (oil, hydraulic, fuel and coolant); Leaks of fluids; Wheels and tires; Chemical penetration and burns to eyes and skin. Fire and Explosion Hazard. Carbon Monoxide Poisoning Always cover exposed skin, Nitrile Gloves Safety goggles. Avoid spilling or contacting fuel/fluids. Keep sparks and flames away from inspection area. Do not refuel with engine running. Do not start engine if you smell or detect fuel leaks. Refuel and operate in well ventilated area only. Prior to each work shift, conduct a pre-start inspection to verify that the equipment and all its components are in safe operating condition. Follow the manufacturer’s recommendations and include a check of:

- 6. JSA: Aerial Platform Operation "Aerial/Boom Lift" 6 Step Sequence of Basic Job Step Hazards Recommended Action or Procedure PPE 2 Pre-start Inspection Vehicle components Battery and charger; Lower-level controls; Horn, gauges, lights & backup alarms; Steering and brakes Acid Burn to eyes and skin Explosion Hazard while inspecting, or inspecting around Battery. Burns Electrocution Hazard Avoid spilling or contacting battery acid. Neutralize battery acid spills with baking soda. Do not use any battery or charger greater than 12V to jump start engine. Keep sparks and flames away from battery. Avoid contact with battery terminals. Prior to each work shift, conduct a pre-start inspection to verify that the equipment and all its components are in safe operating condition. Follow the manufacturer’s recommendations and include a check of:

- 7. JSA: Aerial Platform Operation "Aerial/Boom Lift" 7 Step Sequence of Basic Job Step Hazards Recommended Action or Procedure PPE 3 Pre-start Inspection Lift components Operating and emergency controls; Personal protective devices; Slips and Falls accessing Basket Use 3 Point contact, facing basket when Climbing in and out of basket. Prior to each work shift, conduct a pre-start inspection to verify that the equipment and all its components are in safe operating condition. Follow the manufacturer’s recommendations and include a check of: EMERGENCY STOP Ensure Platform and shoes are clean, dry, and oil free

- 8. JSA: Aerial Platform Operation "Aerial/Boom Lift" 8 Step Sequence of Basic Job Step Hazards Recommended Action or Procedure PPE 4 Pre-start Inspection Lift components Hydraulic, air, pneumatic, fuel and electrical systems; Fiberglass and other insulating components; Missing or unreadable placards, warnings, or operational, instructional and control markings; Mechanical fasteners and locking pins; Cable and wiring harnesses; Outriggers, stabilizers and other structures; Loose or missing parts; Guardrail systems. Chemical penetration and burns to eyes and skin. Fire and Explosion Hazard. Carbon Monoxide Poisoning Cuts and scrapes Slips and Falls Pinch Points from Engine Cowling Always cover exposed skin, Nitrile Gloves Safety goggles. Avoid spilling or contacting fuel/fluids. Keep sparks and flames away from inspection area. Keep hands clear of sharp objects and pinch points Prior to each work shift, conduct a pre-start inspection to verify that the equipment and all its components are in safe operating condition. Follow the manufacturer’s recommendations and include a check of: Missing or unreadable placards, warnings, or operational, instructional and control markings

- 9. JSA: Aerial Platform Operation "Aerial/Boom Lift" 9 PRIOR TO PUTTING THE MACHINE INTO SERVICE, ENSURE ALL THE FUNCTIONS ARE PROPERLY WORKING. At the ground controls: • Activate Emergency Stop • Activate each boom function • Test auxiliary controls At the platform controls: • Activate Emergency Stop • Test horn • Test foot switch • Test boom and platform functions • Test steering functions • Test the drive and braking • Test the drive enable system • Test drive speed limits • Test auxiliary controls Perform any additional test as prescribed by the manufacturer. PRE-OPERATION INSPECTION FUNCTIONAL TEST

- 10. JSA: Aerial Platform Operation "Aerial/Boom Lift" 10 “Equipment Tag Out” for Repair No aerial lift equipment is to be used until any deficiency(s) discovered during a Pre-Operation Inspection are corrected. If a hazardous deficiency is discovered during a Pre-Operation Inspection, the Operator alerts their Supervisor of the condition, who in turns contacts maintenance, who “Tags Out” the equipment from being used by controlling all keys for the vehicle, and placing a “Warning Tag” in the area near the controls with the following information: Name of Maintenance person who has “Tagged Out” the vehicle and has the keys in their possession as well as their contact information. Date vehicle was “Tagged Out”. Reason(s) for “Tagging Out” the vehicle including all noted deficiencies. (A photocopy of the completed inspection form may be taped to the basket or steering wheel if on a vehicle-mounted lift for this purpose.) Name and contact information for the Department's responsible person for implementation of this program. No repairs are made until the equipment and its components are blocked, tagged, locked out or otherwise made safe for repair work to commence according to applicable company Energy Control/LOTO Policy.

- 11. JSA: Aerial Platform Operation "Aerial/Boom Lift" 11 Step Sequence of Basic Job Step Hazards Recommended Action or Procedure PPE 5 Work Zone Inspections Inspect /Assess travel work site where Lift equipment will be operated and path of travel to and from Lift Designated storage area. NOAA: Fort Worth Current Weather Conditions http://www.srh.noaa.gov/fwd/ NOAA: Hicksville Current Weather Conditions http://www.crh.noaa.gov/iwx Drop-offs, holes, or unstable surfaces such as loose dirt Inadequate ceiling heights Slopes, ditches, or bumps; Debris and floor obstructions; Overhead electric power lines and communication cables Other overhead obstructions; Other hazardous locations and atmospheres; High wind and other severe weather conditions, such as ice; and The presence of others in close proximity to the work Inadequate Lighting Thoroughly examine the terrain prior to beginning travel for slopes, holes, slippery surfaces Assess all overhead structures for adequate height and energized electrical equipment Assess the worksite for housekeeping, including objects lying in the path of travel, overhead cranes, and other mobile equipment Obtain live weather forecast to determine wind, rain and or any other inclement conditions. Assess the amount and nature of work of personnel in the path of travel and work site.

- 12. JSA: Aerial Platform Operation "Aerial/Boom Lift" 12 November 2015 Fort Worth, TX Overhead Crane Maintenance {Crane Operator’s inattentiveness} caused Crane to collide with Scissor Lift while worker was in the lift. Worker held onto bridge to save his life Poor Housekeeping, Slippery and en-even surfaces cause TIP OVERS Ensure the work area is free of clutter and debris, and that the ground surface is solid, smooth, and stable

- 13. JSA: Aerial Platform Operation "Aerial/Boom Lift" 13 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 6 Fall Protection: REQUIRED Fall from heights Must be trained and certified to wear PFAS Ensure that access gates or openings are closed. Stand firmly on the floor of the bucket or lift platform. Do not climb on or lean over guardrails or handrails. Do not use planks, ladders, or other devices as a working position. Use a full body harness with a lanyard attached to the anchorage point in the bucket. Do not belt-off to adjacent structures or poles while in the bucket.

- 14. Step Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure 6b Inspect and Don Full Body Harness. Slips, Trips, and Falls from failure to inspect or wear harness. Breaks, Sprains, and ruptured organs from failure to ensure snug, comfortable fit. Inspect Harness, Lanyard, and Anchorage Harness Inspection Checklist. Ensure SNUG COMFORTABLE FIT. Carry Handle Handle Release Valve Oil Filler Plug Extension Screw Saddle Carrying Handle 14 JSA: Aerial Platform Operation "Aerial/Boom Lift" This Job Step requires “Authorized Training/Certification” for “Personal Fall Arrest Systems” Familiarization with JSA: “Personal Fall Arrest System” along with completing the: Sabre FWT“FALL PROTECTION INSPECTION CHECKLIST” PREPARE FOR SAFE OPERATION

- 15. JSA: Aerial Platform Operation "Aerial/Boom Lift" 15 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 7 Mounting / Dismounting the basket at ground level Slips, Trips and, Falls • Always use “three point contact” Leather, Nitrile , or Fabric gloves depending on conditions • Clean Steel Toe Work boots with full Leather Upper • Never use controls as handles • Never climb onto a moving machine • Never climb an elevated machine • Secure gates & chains before moving

- 16. JSA: Aerial Platform Operation "Aerial/Boom Lift" 16 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 8 Operation Traveling/Loading: Tip-Over, Ejections from the lift platform Contact with overhead structures Electric shock (electrocution), Collision with mobile equipment or stationary objects Striking Personnel After site inspection follow work plan. Observe for obstruction and other hazards Do not exceed the load-capacity limits. Take the combined weight of the worker(s), tools and materials into account when calculating the load. Do not use the aerial lift as a crane. Do not carry objects larger than the platform. Do not drive with the lift platform raised (unless the manufacturer’s instructions allow this). Do not operate lower level controls unless permission is obtained from the worker(s) in the lift (except in emergencies). Do not exceed vertical or horizontal reach limits. Do not operate an aerial lift in high winds above those recommended by the manufacturer. Do not override hydraulic, mechanical, or electrical safety devices. Travel at a safe speed Sound Horn when rounding corners and entering buildings

- 17. JSA: Aerial Platform Operation "Aerial/Boom Lift" 17 Watch for pedestrians and mobile equipment Watch for pedestrians and mobile equipment

- 18. JSA: Aerial Platform Operation "Aerial/Boom Lift" 18 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 9 Setting up at work site Personnel struck by Objects falling from lift Personnel struck by or caught between lift platform and stationary object Fall from elevated level, Objects falling from lift, Tip-Over, Ejection from the lift platform, Structural failures (collapse), Electric shock (electrocutions, Entanglement hazards, Contact with objects, and Contact with ceilings and other overhead objects. After site inspection follow work plan. Observe for obstruction and other hazards Caution affected personnel and place barricades or caution tape to keep persons out of the area. Do not lower the boom unless the area below is clear of personnel and obstructions.

- 19. JSA: Aerial Platform Operation "Aerial/Boom Lift" 19 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 10 Overhead Protection: Struck against Moving or stationary object such as Overhead Cranes or Structures Struck By Overhead Bridge Crane Contact with Power Lines may result in Shock or Electrocution (DEATH) Be aware of overhead clearance and overhead objects, including ceilings. Lock Out any Overhead Cranes that could make contact to the lift Do not position aerial lifts between overhead hazards if possible. Treat all overhead power lines and communication cables as energized, and stay at least 10 feet away. Ensure that the power utility or power line workers de-energize power lines in the vicinity of the work.

- 20. JSA: Aerial Platform Operation "Aerial/Boom Lift" 20 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 11 Stability in the Work Zone: Tip Over Unintended motion resulting in serious injury or death Set outriggers on pads or on a level, solid surface. Set brakes when/if outriggers are used. Use wheel chocks on sloped surfaces when it is safe to do so. Set up work zone warnings, such as cones and signs, when necessary to warn others. N Tip Over Hazards Operators need to be concerned about tip over hazards of two types, those due to the ground surface and those due to the operator 1. The condition of the surface on which the lift rests The surface must be level and solid. Many accidents are caused when the scissor lift is operated at too great a slope, or when the scissor lift hits a curb, hole on the ground or other irregularity in the surface while it is moving. 2. The behavior of the operator or user of the lift: If the operator leans too far out, stands on the guardrails, or uses the lift as a "freight elevator," exceeding safe load limits, tip over’s are likely to occur. Another possibility is running into some obstruction or entanglement that pushes the lift over. A further tip over danger comes from pushing or pulling against a fixed object, for example, when drilling into an adjacent wall surface.

- 21. JSA: Aerial Platform Operation "Aerial/Boom Lift" 21 Maintenance always makes sure the SCENE IS SAFE before conducting any Aerial Lift Operations

- 22. JSA: Aerial Platform Operation "Aerial/Boom Lift" 22 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 12 Work near Energized Electrical Equipment or Electrical Power lines Electric shock (electrocutions), Insulated aerial lifts offer protection from electric shock and electrocution by isolating you from electrical ground. However, an insulated aerial lift does not protect you if there is another path to ground (for instance, if you touch another wire). To maintain the effectiveness of the insulating device, do not drill holes in the bucket. Stay at least 10’ from overhead power lines. Lock Out any and all Overhead and Electrical Hazards while performing maintenance. Overhead Crane Guide Rail Copper Bus Bar Conductor System 600 V

- 23. JSA: Aerial Platform Operation "Aerial/Boom Lift" 23 Overhead Crane rails can be just as dangerous as a power line. Lift operators must maintain at least a 10’ clearance from these rails. If the work does not allow for clearance the rail must be locked out by an authorized employee. Never authorize an employee to work on or near live equipment.

- 24. JSA: Aerial Platform Operation "Aerial/Boom Lift" 24

- 25. JSA: Aerial Platform Operation "Aerial/Boom Lift" 25 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure PPE 13 Transferring to a Structure From the Platforms of Aerial Lift While Elevated Fall from elevated level Enter/exit through the gate only with the platform within 1 foot of a safe and secure structure 100% tie-off is required, utilizing two lanyards. One lanyard must be attached to the platform with the second lanyard attached to the structure. The lanyard connected to the platform must not be disconnected until such time as the transfer to the structure is safe and complete. 100% TIE OFF IS MANDATORY See JSA: “Personal Fall Arrest Systems”

- 26. JSA: Aerial Platform Operation "Aerial/Boom Lift" 26 Crushing Hazards Crushing hazards are most often related to raising the platform into a girder, ceiling, or joist. Problems may also arise from moving along the ground if the person on the platform is caught between the lift and some structure. Crushing hazards are also present in the lifting mechanism as the scissor mechanism moves.

- 27. JSA: Aerial Platform Operation "Aerial/Boom Lift" 27 Step Sequence of Basic Job Step Potential Hazards Recommended Action or Procedure 14 “Operator in Basket unable to safely operate lift” Operating Lift from Ground/Lower Controls Limited view of overhead Ensure clear line of site Use spotters if necessary Pushing E-Stop to stop all function and turn engine off Select “Ground Control” to override “Platform” and E-Stop Be sure both Ground and Platform E-Stop buttons are pulled out to restart engine Move and hold platform capacity select/function enable switch Move appropriate toggle function switch according to markings on control panel

- 28. JSA: Aerial Platform Operation "Aerial/Boom Lift" 28

- 29. JSA: Aerial Platform Operation "Aerial/Boom Lift" 29

- 30. JSA: Aerial Platform Operation "Aerial/Boom Lift" 30 SELF RESCUE: If the person working at heights has properly selected and used his or her fall protection equipment, 90% of workers will be able to perform a Self Rescue, which should include these steps: 1. Climbing back up to the level from which he fell (from a few inches to 2-3 feet). 2. Returning to the floor or ground to be evaluated for possible medical attention per OSHA. 3. Removing all components of fall arrest system impacted by the fall event from service and documenting (bag and tag) the components with name, date and activity at time of fall and giving the equipment to management. RESCUE PLAN A rescue plan must be a part of the Job Safety Analysis for any job that requires work at height. The rescue plan must include consideration of the following rescue types and circumstances:

- 31. JSA: Aerial Platform Operation "Aerial/Boom Lift" 31 ASSISTED SELF RESCUE WITH MECHANICALLY AIDED HAULING/ROPE SYSTEM If self-rescue is not possible, then an Assisted Self Rescue will be needed. The following guidelines should be used during a mechanically aided rescue: 1. An OSHA/ANSL compliant rescue and descent device will be secured to an anchor that is rated for at least 3,000 lbs. 2. The haul line may be swung over or lowered to the fallen worker, who will grab the rescue lifeline snap hook and secure it to the appropriate D-ring on his body support. A positive connection to the D-ring must be verified by one of the rescue team members. 3. The rescue team will raise or lower the fallen employee to the appropriate work platform or ground and provide medical aid as required by OSHA. 4. Remove all components of fall arrest system impacted by the fall event from service and document (bag and tag) the components with name, date and activity at time of fall and give the equipment to management.

- 32. JSA: Aerial Platform Operation "Aerial/Boom Lift" 32 1. The compliant rescue and descent device will be secured to an anchor that is rated for at least 3,000 lbs. 2. A rescue team member must attach the haul line to the worker’s fall arrest system. This can be performed by accessing the fallen worker and then attaching the rescue system directly to a D-ring on the worker’s harness, or by using a rescue pole for the attachment. The rescue team could also attach a rescue grab to the lanyard or vertical lifeline. 3. The rescue team must raise or lower the fallen worker to the appropriate work platform or ground and provide medical aid as required by OSHA. 4. Remove all components of fall arrest system impacted by the fall event from service and document (bag and tag) the components with name, date and activity at time of fall and give the equipment to management. If the worker’s injuries prevent the worker from attaching to the rescue system, both self-rescue and assisted self-rescue are not options, and a Fully Assisted Rescue is necessary: MECHANICALLY AIDED *(UNCONSCIOUS) with HAULING/ROPE SYSTEM

- 33. JSA: Aerial Platform Operation "Aerial/Boom Lift" 33 ASSISTED RESCUE WITH MECHANICALLY AIDED AERIAL LIFT Fully Assisted Rescue with 2nd Aerial Lift 1. A rescuer will get into the aerial lift and make sure there is a second fall protection device, such as a shock absorbing lanyard or self-retracting lifeline available for the fallen worker. {ENSURE 100% TIE OFF} 2. The aerial lift must be maneuvered into position (raised up underneath the fallen worker) so that the rescuer can perform the rescue. 3. Attach the second lanyard or self-retracting lifeline in the aerial lift to the fallen worker. 4. Disconnect the rescued worker from the impacted fall arrest equipment. 5. Lower the worker to the ground and provide medical aid as required by OSHA. 6. Remove all components of fall arrest system impacted by the fall event from service and document (bag and tag) the components with name, date and activity at time of fall and give the equipment to management.

- 34. JSA: Aerial Platform Operation "Aerial/Boom Lift" 34 Ground Controls Rescue plans should include steps to ensure that other personnel have been trained and familiarized to operate the machine from the ground controls and that a key is left in the ground controls during operation. Second AWP – Make sure your rescue plans include the availability of a second AWP along with operators trained to use it in the event an operator becomes incapacitated along with a method to transfer personnel in a way that prevents falling. Portable Lift – Certain situations will allow for a portable lift to be used as part of a rescue plan to aid in the rescue of incapacitated workers at height by providing the portability of a ladder but the benefit of an aerial work platform. Be sure personnel assigned to the lift in the rescue plan have been trained and familiarized.

- 35. JSA: Aerial Platform Operation "Aerial/Boom Lift" 35 Injured Worker Rescue/Removal/Care Normal first aid procedures should be performed as the situation arises. If the area is safe for entry, the first aid should be done by Company designated 1st Responders with American Heart Association Heart Saver Certification. ALL-CALL for Office Personnel: landline/phone no. Emergency All Call Radio Chanel Initiate Outside Emergency Services – Dial 911 Safety Manager / Primary 1st Responder: 1st Shift: 1st Aid Location: 2nd Shift: 1st Aid Location: Safety/First Aid Office Other: __________________ Location: ________________________ Rescue considerations. When personal fall arrest systems are used, the employer must assure that employees can be promptly rescued or can rescue themselves should a fall occur. The availability of rescue personnel, ladders, or other rescue equipment should be evaluated. In some situations, equipment that allows employees to rescue themselves after the fall has been arrested may be desirable, such as devices that have descent capability. Describe methods to be used for the removal of the injured worker(s): _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________

- 36. JSA: Aerial Platform Operation "Aerial/Boom Lift" 36 Company Trained/Certified 1st Responders Rescue / Care for Electrical Shock Victim 1. Separate the Person From Current's Source To turn off power: Unplug an appliance if plug is undamaged or shut off power via circuit breaker, fuse box, or outside switch. If you can't turn off power: Stand on something dry and non-conductive, such as dry newspapers, telephone book, or wooden board. Try to separate the person from current using non-conductive object such as wooden or plastic broom handle, chair, or rubber object. If high voltage lines are involved: The local power company must shut them off. Do not try to separate the person from current if you feel a tingling sensation in your legs and lower body. Hop on one foot to a safe place where you can wait for lines to be disconnected. 2. Perform CPR, if Necessary When you can safely touch the person, perform CPR if the person is not breathing or does not have a pulse. 3. Check for Other Injuries If the person is bleeding, apply pressure and elevate the wound if it's in an arm or leg. There may be a fracture if the shock caused the person to fall. 4. Wait for 911 to Arrive 5. Follow Up A doctor will check the person for burns, fractures, dislocations, and other injuries. An ECG, blood tests, CT scan, or MRI may be necessary. The person may be admitted to the hospital or a burn center.

- 37. JSA: Aerial Platform Operation "Aerial/Boom Lift" 37

- 38. JSA: Aerial Platform Operation "Aerial/Boom Lift" 38 After Each Use Park the machine on a firm, level surface, clear of obstruction and traffic. Retract and lower the boom to the stowed position. Rotate the turntable so that the boom is between the non-steer wheels. Turn the key to the off position and remove key to secure from unauthorized use Chock Wheels. Personal Fall Arrest Equipment (Safety Harness, Detachable Lanyards) MUST BE STORED IN A DESIGNATED , CLEAN, & DRY LOCATION & OUT OF THE WEATHER {DO NOT LEAVE PFAS IN THE BASKET OF THE LIFT, OR LYING IN THE SHOP OR OUTDOORS Standards that Apply OSHA Standards: 29 CFR 1910.67, 29 CFR 1910.269(p), 29 CFR 1926.21, 29 CFR 1926.453, 29 CFR 1926.502. American National Standards Institutes Standards: ANSI/SIA A92.2-1969; A92.3, ANSI/ASSE Z359.12-2009, ANSI Z359.2-6.1, Z259.16-04 (R2009) ASME A120.1ANSI Z359.4—2007 Safety Requirements for Assisted Rescue & Self-Rescue Systems, Subsystems & Components