OvenA3

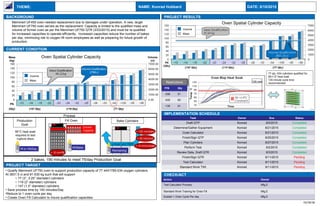

- 1. BACKGROUND PROJECT RESULTS THEME: NAME: Konrad Hubbard DATE: 8/10/2015 CURRENT CONDITION 10/19/16 PROJECT TARGET CHECK/ACT Memmert UF450 oven needed replacement due to damages under operation. A new, larger Memmert UF750 oven serves as the replacement. Capacity is limited to the qualified mass and volume of former oven as per the Memmert UF750 QTR (3/23/2015) and must be re-qualified for increased capacities to operate efficiently. Increased capacities reduce the number of bakes per day, minimizing risk to oxygen fill room employees as well as preparing for future growth of production. • Qualify Memmert UF750 oven to support production capacity of 77 4441785-034 oxygen cylinders. At 3831.5 ci and 91.630 kg such that will support o 77 (3”, 3.25” diameter) cylinders o 119 (2” diameter) cylinders o 147 (1.5” diameter) cylinders. • Save process time by 140 minutes/Day •Reduce to 1 oven cycle per day • Create Oven Fill Calculator to insure qualification capacities. IMPLEMENTATION SCHEDULE Process Excess Capacity 45/Bake + 10 min/fill Fill Oven + 10 min/unload Unload and Refill Remaining + 30 min/cool + 120 min/bake Bake Cylinders 2 bakes, 190 minutes to meet 75/day Production Goal 75 to 105/Day Production Goal 85°C heat soak required to test rupture discs Oven Spatial Cylinder Capacity Volume (ci) Mass (kg) PN Volume Qualification: 2799 ci (147 Qty) (119 Qty) (77 Qty)(Qty) -034 -034 -034 Volume Mass Volume Mass Task Owner Due Status Draft QTP Konrad 8/5/2015 Completed Determine/Gather Equipment Konrad 8/21/2015 Completed Code Calculator Konrad 8/21/2015 Completed Finish/Sign QTP Konrad 8/25/2015 Completed Plan Cylinders Konrad 8/27/2015 Completed Perform Test Konrad 9/2/2015 Completed Review Data, Draft QTR Konrad 9/3/2015 Completed Finish/Sign QTR Konrad 9/11/2015 Pending Test Calculator Konrad 9/11/2015 Pending Standard Work TWI Konrad 9/11/2015 Pending Action Owner Test Calculator Process Mfg.E Standard Work Training for Oven Fill Mfg.E Sustain 1 Oven Cycle Per day Mfg.E Mass Qualification: 91.63 kg Volume Qualification 3831.52 ci (147 Qty) (119 Qty) (77 Qty) PN (Qty) Oven Spatial Cylinder Capacity RestrictionsRestrictions P/N Qty -036 51 -035 60 -135 61 85 +/-2ºC Constraint 77 qty -034 cylinders qualified for 85+/-2º heat soak 135 minute cycle time recommended 120 min