LAWSON RESUME

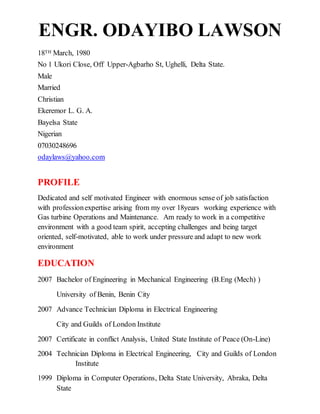

- 1. ENGR. ODAYIBO LAWSON 18TH March, 1980 No 1 Ukori Close, Off Upper-Agbarho St, Ughelli, Delta State. Male Married Christian Ekeremor L. G. A. Bayelsa State Nigerian 07030248696 odaylaws@yahoo.com PROFILE Dedicated and self motivated Engineer with enormous sense of job satisfaction with professionexpertise arising from my over 18years working experience with Gas turbine Operations and Maintenance. Am ready to work in a competitive environment with a good team spirit, accepting challenges and being target oriented, self-motivated, able to work under pressure and adapt to new work environment EDUCATION 2007 Bachelor of Engineering in Mechanical Engineering (B.Eng (Mech) ) University of Benin, Benin City 2007 Advance Technician Diploma in Electrical Engineering City and Guilds of London Institute 2007 Certificate in conflict Analysis, United State Institute of Peace (On-Line) 2004 Technician Diploma in Electrical Engineering, City and Guilds of London Institute 1999 Diploma in Computer Operations, Delta State University, Abraka, Delta State

- 2. 1996 Senior Secondary SchoolCertificate, Government College, Ughelli, Delta State 1990 First SchoolLeaving Certificate, Itive Primary School, Oteri, Ughelli, Delta State WORK HISTORY 1. TRANSCORPUGHELLI POWER LIMITED POSITION: Mechanical Maintenance Staff DURATION: 1ST November2013 till date DUTIES AND RESPONSIBILITIES INSTALLATION, MAINTENANCE AND SERVINCING OF GAS TURBINE POWER PLANT GE FRAME 9E MACHINES Carryout Combustion Inspection, Hot Gas path Inspection and Major Inspection Overhauling Installation/maintenance of accessorycompartment component to include, cranking motor, torque converter and accessory gear box Replacement of gear box main shaft Calibration of inlet guide vain controlactuator Compressor washing Turbine accessorycompartment alignment Installation and repair of Cooling Water Pumps Installation of stages 1,2 and 3 turbine buckets and Nozzles Removal of Generator Rotorfor rehabilitation Servicing of accessoryshaft Maintenance and servicing of CompressorBleed Valves Regulation of lube oil pressure valve, cooling water header regulatory valve Installation of Static Compressorblades Installation of stages 1,2 and 3 turbine buckets and Nozzles Rotorclearance on GE Gas turbine frames

- 3. TP set back, X1&X2/R1&X1. Bearing 1, 2 & 3 Clearances Inspection and maintenance of Air Inlet system Inspection and maintenance of Exhaust plenum and stalk. Rigging ON SITE TECHNICAL PATNERS THOMASSEN HOLDING LIMITED, DUBAI Rehabilitation and Major Inspection E & B TURBINE SERVICES, HOLLAND Rehabilitation and Major Inspection HITACHI H25 MACHINES Carrying Combustion Inspection, Hot Gas path Inspection, Major Inspection Overhauling Installation and maintenance of Detroit Diesel Engine Installation of Torque Converters and Charge pumps Installation and alignment of Torque converter, AccessoryGear Box, Reduction Gear, Turbine Accessorycompartment and Generator Alignment Installation of bothDiesel and Lube oil lines Footvalves Re-calibration of inlet Guide Vane Installation of stage 1,2 and 3 Turbine buckets and Turbine Nozzles Carry out of BoroscopeInspection Maintenance of Mist Separator Servicing of Air Pulsation System compressors Servicing of Accessoryand Load coupling shafts Servicing of INGERSOLL RAND Compressors forAir Pulsation System Servicing of GREENFIELD Compressorfor ABB Hydrogen Plant Servicing of Holman mobile compressors 2. POWER HOLDING COMPANYOF NIGERIA UGHELLI POWER PLC

- 4. POSITION: System ElectricalOperator DURATION: 1stSeptember 1998 – 30th October2013 DUTIES AND RESPONSIBILITIES CONTROL, MONITORING AND OPERATIONOF GAS TURBINE GENERATOR Control, Monitor and operation of GE FRAME 9E gas Turbine Generators and HITACHI 25 gas turbine and SIEMENS generators STARTING, RUNNING AND SYNCHRONISATION OF GAS PLANTS Run-up of gas turbine generators, monitor startup/run-up conditions and synchronize same to National grid using Human Machine Interface (HMI) or Backup Operator Interface (BOI) MONITORING, CONTROLSTABILIZATION OF SYSTEM FREQUENCY Monitoring, control and stabilization of system condition and frequency by varying the Gas turbine output to match customer demand/consumption in other to prevent system collapse, and restoration of same in the case of a collapse OPERATIONOF 132KV/33KV/3.3KV/415 SWITCHGEARS Operation of 132KV/33KV/3.3KV/415KV high to low voltage switch gears, for unit Power ControlCenter and Motor controlCenter. Powering cranking motors and other unit auxiliary motors PRODUCTIONOF HYDROGEN Running and operation of ABB Hydrogen plant for the production of hydrogen used for the cooling of GE Generator stators winding ISSUANCE AND ACCEPTANCE OF WORKPERMIT Creating safe work condition for workmen, issuing work permits to workmen after isolation of equipment and accepting surrounding of permits upon successfuljob completion LOGGING AND REPORTING

- 5. Operation event/activities, hourly machine readings are logged timely and are relay to National ControlCentre and Area Control Centre for system analysis INSPECTION Carrying out of unit and station Inspection. Startup inspection and Routine Inspection INSPECTION/OPERATIONOF 330KV/132KV SWITCHYARD Operation of 330KV/132KV switch yard equipment to cover, breakers, Isolators, CTs and PTs, Grounding switches ACHIEVEMENTS REHABILITATION OF GAS TURBINE (GT19) GE FRAME 9E Execution of Compressorbellmouth, Compressorforward and aft casing upper half opening Performance of laser casing alignment due casing change Replacement of Damaged CompressorRotor Replacement of Bearing Nos 1, 2 and 3 Labyrinth Seal Replacement of Bearing Nos1, 2 and 3 Combustion Liners and Nozzles replacement done Replacement of Stages 1, 2 and 3 turbine Nozzles and Stages 1, 2 and 3 Shrewd Blocks Stages 1, 2 and 3 Turbine Buckets replacement done Execution of Exhaust plenum repair Execution of Compressorand Exhaust Bellows repair and replacement Unit was restored to service generating 100mw full capacity REPAIR OF GT16 GE FRAME 9E OIL SPILL FROM ACCESSORYGEAR BOX SHAFT BEARING Opened up AccessoryGear Box after separation of bothcoupling (forward and after) Replacement of AccessoryGear Box Main Shaft with a new one

- 6. Replacement of both Accessaryand Turbine side Bearings and Labyrinth seals Alignment of AccessoryGear Box to No1 Bearing, AccessoryGear Box to Torque Converter and Torqueconverter to Cranking Motor. Unit was restored back to service with the oil leakage/spill stopped GAS TURBINE (GT6) HITACHI H25 REHABILITATION Removal of Combustion components and opening up of Turbine casing Installation of stage 1 turbine buckets Installation of stages 1 and 2 turbine Nozzles Installation of 10Nos transition pieces Boxing up Alignment of Generator to Reduction gear, Reduction gear to No 2 Bearing. Alignment of turbine compartment to AccessoryCompartment Application of packing on one side of bearing No2 housing resulting from bad turbine clearance of the turbine rotor Addition of 350g of weight on load coupling shaft to balance the rotor for correction of high vibration of 25mm/s to 6mm/s Unit fired generating 20mw COURSES ATTENDED PHCN Two years system operator’s course (Portharcourt) PHCN In -Plant/On -the-job Training System Operator’s Refresher Courses Siemens Gas Power Plant on-the-site Training ( Ajaokuta, Nigeria) Siemens V94.2 GTPP Simulation Training (Erlange, Germany) PROFESSIONAL MEMBERSHIP Member, Nigeria Institute of Mechanical Engineers (MNiMechE) Member, The Nigerian Society of Engineers (MNSE)

- 7. Registered with the Council for the Regulation of Engineering in Nigeria (COREN) NYSC Exempted (Exemption Certificate available) REFEREES PastorEngr . Onokurhefe Blessed Head Mechanical Transcorp Ughelli Power Ltd. 08037744021 Engr. P. O. Olagbegi Head of Department Mechanical Department Faculty of Engineering University of Benin, Benin City 07039547375