12 Years E&I Inspector seeks new role

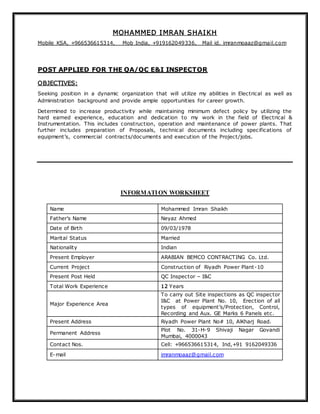

- 1. MOHAMMED IMRAN SHAIKH Mobile KSA, +966536615314, Mob India, +919162049336, Mail id. imranmoaaz@gmail.com POST APPLIED FOR THE QA/QC E&I INSPECTOR OBJECTIVES: Seeking position in a dynamic organization that will utilize my abilities in Electrical as well as Administration background and provide ample opportunities for career growth. Determined to increase productivity while maintaining minimum defect policy by utilizing the hard earned experience, education and dedication to my work in the field of Electrical & Instrumentation. This includes construction, operation and maintenance of power plants. That further includes preparation of Proposals, technical documents including specifications of equipment’s, commercial contracts/documents and execution of the Project/jobs. INFORMATION WORKSHEET Name Mohammed Imran Shaikh Father’s Name Neyaz Ahmed Date of Birth 09/03/1978 Marital Status Married Nationality Indian Present Employer ARABIAN BEMCO CONTRACTING Co. Ltd. Current Project Construction of Riyadh Power Plant-10 Present Post Held QC Inspector – I&C Total Work Experience 12 Years Major Experience Area To carry out Site inspections as QC inspector I&C at Power Plant No. 10, Erection of all types of equipment’s/Protection, Control, Recording and Aux. GE Marks 6 Panels etc. Present Address Riyadh Power Plant No# 10, AlKharj Road. Permanent Address Plot No. 31-H-9 Shivaji Nagar Govandi Mumbai, 4000043 Contact Nos. Cell: +966536615314, Ind,+91 9162049336 E-mail imranmoaaz@gmail.com

- 2. EDUCATIONAL QUALIFICATIONS: Diploma engineering 3year Electronics & Communication technology Board of Maharashtra, TOTAL EXPERIENCE: 12 Years,whichis having11 yearsin Abroadand 1 Year inIndia. EXPERIENCE SYNOPSIS DESIGNAT ION: QC Inspector, E&I I am currently working as QC Inspector E&I in Arabian BEMCO Contracting Co. Ltd. at Power Plant #10. (PP10, 4000 MW) Riyadh, Saudi Arabia. “It would be the World’s Largest Combined Cycle Power Plant”. MAJOR JOB RESPONSIBILIT IES ARE SUMMARIZED BELOW : 1. To prepare ITP’s and Checklists 2. To monitor all construction activities which can affect the quality of job 3. Comprehensive monitoring of all on-going site works 4. To make it sure that all DCN’s/FCN’s are being implemented on site 5. Responsible to verify the execution of construction activities according to approved drawings & applicable project specifications 6. To raise NCR’s and WDR’s 7. To coordinate with site engineers to close client letters, NCR’s/WDR’s. 8. To verify the construction areas prior to final client’s engineers inspection 9. Responsible to attend scheduled inspections & comply with the comments issued by client’s Engineer 10. To conduct site inspections prior to submit RFIWs to client. 11. To Inform Site engineer for any dispute or difference of opinion with client’s Engineer for further clarification 12. To Verify, inform, & advise to site engineer for any job defect / deficiency, in order to initiate the required preventive or corrective actions 13. To Confirm with site engineer that only the latest revision of documents & drawings available for inspection 14. To Prepare and fill all inspection formats / checklist indicated on latest revision of applicable site inspection test plans 15. To Inform site engineer of any site modification/change for implementation of 'mark-up' drawing as it is recommended on Quality Plan, PRESENT PROFESSIONAL EXPERIENCE: ERECT ION WORK ACT IVIT IES: Inspection of Installation Duct banks, Inspection of Installation 62.5 MW GE Mark VIe Gas Turbines, Generator, Turbine accessory compartment & GE Mark VIe & AC & DC MCC’s, Inspection of Installation GSU & distribution transformers(13.8kV,4.16kV,480 V) MCC’s-GE Mark & 13.8kV segregated bus duct, AC/DC, DB’s,

- 3. Inspection of Installation TCP,GCP, LCP, PLC & DCS Panels, Inspection of Installation All Aux. System motors, & Cooling water Fan Motors, GNAC and GLAC & Cooling Water modules & Wash Water skids CO2 Skids, Battery charger and discharger & Grounding grid Generator and GSU transformer protection & control panels, Inspection and installation of Ladder and Cable trays Inspection and installation of conduits (RGS, EMT & PVC coated RGS) Installation and inspection of Lighting fixtures, wiring and Lux measurement Inspection of Pit, network, joint (CAD welding) equipment’s Inspection of Installation all kids of Devices like, PT,TT,FT & LT Transmitters and Switches and all types of Junction Boxes, Inspection of All types of Cables Pulling , like Power, Control, Instruments, Fiber Optics & Communications Cables, Inspection of Witness IR Test, Meggering Like, Power, Control & Instruments cables, Testing of Pit resistance, network resistance, joint resistance, Ensuring compliance of works with applicable codes, standards, contract specifications, identify any non-conformance & coordinating suitable corrective action, Inspection of Witness All Types of Termination like, Power, Control, Instruments, Fiber Optic & Communication Cables, Energization of all types of equipment’s-(Transformers, Panels etc.) Witnessing the IR and Energization of Motors and dry type Transformers To supervise and witness the changes implementation in panels and red-mark drawings, T EST ING ACT IVIT IES: Inspection and testing for all instruments. Witnessing the IR and Energization of Motors and dry type Transformers Witness Installation Cable terminations and instrument loop checks as per ITPs and international standards, for Steam Turbine & Gas Turbine Marks Vie system. 62.5 MW GE make Gas Turbines based generator units & GE- Generator Units GSU & distribution transformers (13.8kV,4.16kV,480 V) & MCC’s-GE Make Non-segregated Bus Ducts, TCP and GCP-(Turbine and Generator Control Panels) All Aux. System motors, Cooling water and Fan Motors Cooling Water modules & Wash Water skids Water Treatment Areas, Tank Farm Areas, Main Control Building & All BOP’s Online/Offline/Stability and Sensitivity Tests Solo Run and Couple Run Test for LV & MV motors of different systems. Loop and functional testing related to DCS, Cold Loop and Hot Loop checks from HMI to field instruments as per the projects specifications. Also for safety and interlocking test for the Marks Vie control system. LOW CURRENT SY ST EM: Witness Installations and Commissioning of Fire Alarm Detection and fire fighting. Witness Installation and commissioning of Public Address system equipment’s and control panels it includes Siren System. Witness Installation and commissioning activities of BMS systems all around the project Technical and Non Technical Buildings.

- 4. Witness Installation and Commissioning of Telephone and Data system all around the project Technical and Non Technical Buildings. Witness Pulling, Splicing and OTDR test for all Fiber Optic Cables all around the project Technical and Non Technical Buildings. PREVIOUS PROFESSIONAL EXPERIENCE: Witness Installation of all types Panel, like PLC, DCS, and Switchgear Panel, JB’s, Network Cabinets and all types of Devices like PT, TT, LT, & FT Transmitter & Switches. Witness all type of Cable pulling & meggering like, Power, Control, and Instruments. Communication & Fiber Optic cables, Witness Termination like Power, Control, and Instruments. Communication & Fiber Optic cables, Installation and commissioning of Fire Alarm System, Public Address system & Telephone & Data system, Witness Cold loops and Hot loops check, PROFILE SUMMARY : Implement the QA/QC program and follow the duly approved ITP’s and conduct the inspections with client and follow up until the final approvals. Proactive during constructions and provide full support to avoid any major violations. Issue nonconformance report upon any non conformity and report to QC Managers. To prepare ITP’s and Checklists To monitor all construction activities which can affect the quality of job Comprehensive monitoring of all on-going site works To make it sure that all DCN’s/FCN’s are being implemented on site Responsible to verify the execution of construction activities according to approved drawings & applicable project specifications To raise NCR’s and WDR’s To coordinate with site engineers to close client letters, NCR’s/WDR’s. To verify the construction areas prior to final client’s engineers inspection Responsible to attend scheduled inspections & comply with the comments issued by client’s Engineer Witness calibration of instruments and assist during construction and pre- commissioning Assist in the preparation review and updating of company’s Quality control manual & operation procedure in accordance with the ISO 9000 Quality System Co- ordinates and raising RFI with client project inspection unit for project inspection & stage wise activities for witness/hold point. Co-ordination with client, Engineers, Staffs, site workers, and checking of site activities of work progress, EXPERIENCE PROFILE: From April 2009 to July 2016 (7 Y ears) Company : ARABIAN BEMCO Project : Power Plant No. 10 Client : Saudi Electricity Company (RIYADH KSA) Position : I&C QC Inspector From Dec ember 2006 to Dec ember 2008(02 Y ears): Company : DODSAL PTE LTD

- 5. Project : CCWP-2 QP Ras Laffan (DOHA QATAR) Client : QATAR PETROLEUM Position : E & I QC Inspector From January 2005 to Dec ember 2006(01 year & 11 months) Company : TARIQ AL GHANIM ALMEN (KUWAIT) Project : KOC & KNPC Projects Client : KOC Position : E & I QC Inspector WORK EXPERIENCE IN INDIA: From Jan 2004 to Dec 2004(11 Months) Company : BST Engineering & Construction Co. LTD (INDIA) Project : Panipath Refinery Position : E&I Supervisor QUALIFICAT ION: Diploma Engineering in Electronics & Communication, in the year 1999. COMPUT ER PROFICIENCY MS Office (Outlook, Word, Excel, Power Point,) REFERENCES Will Be Furnished Upon Demand PERSONNEL INFORMAT ION: Nationality : Indian Date of Birth : 09/03/1978 Marital Status : Married Pass Port No. H4194726 : Expire Date. 22-03-2019 Issue Date 23-03-2009 : Issue Place Mumbai I am fully confident and all the above said are true to the best of my knowledge. Best Wishes & Regards Mohammad Imran Shaikh