LPG specifications for candidates

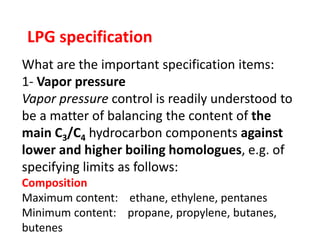

- 1. LPG specification What are the important specification items: 1- Vapor pressure Vapor pressure control is readily understood to be a matter of balancing the content of the main C3/C4 hydrocarbon components against lower and higher boiling homologues, e.g. of specifying limits as follows: Composition Maximum content: ethane, ethylene, pentanes Minimum content: propane, propylene, butanes, butenes

- 2. LPG specification What are the important specification items: 2- non volatile residue: Rust & dirt elemental sulphur the lighter ends (C5's, C6's)

- 3. LPG specification What are the important specification items: 2- Water Free or entrained : non visible during test Dissolved: maximum content For full protection: water content 10 ppm wt for propanes water content 20 ppm wt for butanes

- 4. LPG specification What are the important specification items: 2- Water Or adding anti-freezing agent like methanol Methanol content: • minimum content is usually 0.05 vol % (to prevent under-dosing) • maximum content (to avoid contamination problems) according to the user application

- 5. LPG specification What are the important specification items: 3- Toxicity & odour control is a matter of minimizing the content of hydrogen sulphide but allowing, in commercial grades, a very small proportion of certain volatile sulphur compounds such as ethyl mercaptans or dimethyl sulphide to impart a detectable odour

- 6. LPG specification What are the important specification items: odour control Regulatory codes : it is readily detectable, by a distinct odor, at one-fifth of the lower limit of flammability of the gas in the air. Research and experience have shown that ethyl mercaptan inject data rate of 1.0 lb per 10,000 gal Of liquid LP Gas will meet this requirement under normal conditions. It is customary practice to inject 1.5 lb or more (preferable) to ensure an adequate warning agent concentration when conditions may be less than ideal.

- 7. LPG specification What are the important specification items: 4- Corrosion By presence of : H2S Sulfur compounds Water Oxygen Caustic alkali

- 8. LPG specification What are the important specification items: 4- Corrosion One is to specify the degree of corrosion which is allowable under standardized test conditions, namely a slight discoloration of a copper strip immersed in liquid LPG for a specified time and at a prescribed temperature (e.g. 1 hr, 37.8°C). Copper is chosen because it is the most sensitive of metals likely to be encountered by LP gases in ordinary process equipment.

- 9. LPG Test & analyzers LPG test considerations: - Sample point from life stream or storage - The moment of sample taking related to the operations - Cylinder size compared to the tested quantity - Sample taking period of cylinder purge - Leaks in sampling cylinders - The analyzer calibration - The analyzer cleaning from previous sampling

- 10. LPG Test & analyzers LPG test considerations: - LPG recycling before sampling from Bullet or sphere is recommended due to stratification of hydrocarbons in large vessel

- 11. LPG cylinders in gas plant

- 12. LPG cylinders in gas plant 'Bombs' are sometimes fitted with outage or ‘ ullage' tubes to ensure at least a 20% volume free vapour space to allow for liquid expansion with temperature rise. In sampling refrigerated propane, the ullage space should be increased to 30% for increased safety.

- 13. LPG Volatility test The volatility test (ASTM D 1837) is used with a maximum of (-38.3°C) for the 95% evaporation temperature in the case of propanes and (+2.2°C) for butanes. Correlation work shows that the(-38.3°C) temperature is met if the content of 'C4's+ are not more than 2.5%; if the butanes content in propane were 10% for example (as is allowed in B.S. 4250), the evaporation temperature would rise to (-23.9°C)

- 15. Egyptian LPG specification after 2012

- 16. Egyptian LPG specification after 2012

- 17. Egyptian LPG specification before 2012

- 18. Egyptian LPG specification before 2012

- 20. LPG loading

- 21. LPG filling capacity The maximum LPG capacity of a vessel depends on its size and on the highest temperature specified for its size range, in accordance with the following equation. where S.G. is the liquid specific gravity, t° is the highest temperature and cf is the correction factor

- 23. LPG storage capacity Capacities of LPG pressure vessels usually installed on industrial users' premises range from 0.5 to 100 ton. The vessels themselves are cylinders with hemispherical or dished ends and can be mounted. Above about 100 ton vessel capacity, a spherical shape becomes more economical for LPG pressure vessels.

- 24. LPG storage vessel types Sphere Bullet

- 25. LPG vessel commissioning 1. pressure testing : 1.5 times the maximum working pressure using water for 30 minutes without pressure loss 2- Leak test: nearly 90 % of the design pressure 50-90 psi for butanes 105-200 psi for propanes 3- Purging: by inert gas (nitrogen)

- 26. LPG safety precautions 1. LPG is stored, normally, as a liquid under pressure 2. Leakage, especially of liquid, may release large volumes of flammable gases 3 . LPG vapour is heavier than air and may flow along the ground or through drains and be ignited at a considerable distance from the source of leakage 4. Because of its low boiling temperature, liquid LPG will cause skin burning 5. Ignition of a gas cloud will begin many yards distant downwind of the leakage point 6. The released gas can cause suffocation