Toyota 1KD Engine Repair Manual

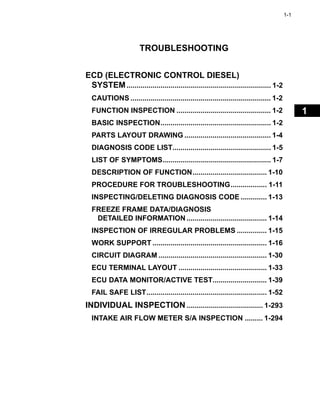

- 1. 1-1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 TROUBLESHOOTING ECD (ELECTRONIC CONTROL DIESEL) SYSTEM........................................................................ 1-2 CAUTIONS ...................................................................... 1-2 FUNCTION INSPECTION ............................................... 1-2 BASIC INSPECTION....................................................... 1-2 PARTS LAYOUT DRAWING ........................................... 1-4 DIAGNOSIS CODE LIST................................................. 1-5 LIST OF SYMPTOMS...................................................... 1-7 DESCRIPTION OF FUNCTION..................................... 1-10 PROCEDURE FOR TROUBLESHOOTING.................. 1-11 INSPECTING/DELETING DIAGNOSIS CODE ............. 1-13 FREEZE FRAME DATA/DIAGNOSIS DETAILED INFORMATION ........................................ 1-14 INSPECTION OF IRREGULAR PROBLEMS ............... 1-15 WORK SUPPORT ......................................................... 1-16 CIRCUIT DIAGRAM ...................................................... 1-30 ECU TERMINAL LAYOUT ............................................ 1-33 ECU DATA MONITOR/ACTIVE TEST........................... 1-39 FAIL SAFE LIST............................................................ 1-52 INDIVIDUAL INSPECTION ...................................... 1-293 INTAKE AIR FLOW METER S/A INSPECTION ......... 1-294 1KD_RM.book 1 ページ 2013年9月27日 金曜日 午後12時47分

- 2. 1-2 1KD_RM.book 2 ページ 2013年9月27日 金曜日 午後12時47分

- 3. 1-2 ECD (ELECTRONIC CONTROL DIESEL) SYSTEM CAUTIONS 1. Precautions for using the 'Engine Diagnostic Program' WARNING: • Read the 'Engine Diagnostic Program' instruction manual before using it. • In operating the machine with the 'Engine Diagnostic Program' connected, be careful of handling so that the cable of the 'Engine Diagnostic Program' does not hang on the pedal, the shift lever, or the steering wheel. • In operating the machine using the tool (such as performing a simulation test), to avoid operations while controlling the tool, two operators should always work and observe work rules. FUNCTION INSPECTION 1. Accelerator position sensor (potentiometer) (See the lift truck repair manual for the procedure.) 2. Intake air flow meter Caution: • Follow the procedure below to inspect the intake air flow meter S/A. • With the engine stopped, when a value of [MAF] from [Data monitor] does not meet the standard or when foreign matter is found in the platinum filament (heater) portion of the intake air flow meter S/A, the meter should be replaced. (1) Intake air quantity inspection SST 09111-36760-71 (09991-70201) Caution: • With the engine stopped, keep the machine horizontal and inspect these functions indoors. • Perform inspection with the intake air flow meter S/A mounted on the intake pipe (with the machine installed). • Do not suck air from the exhaust tail pipe in the exhaust duct. (a) Turn the ignition key switch on and wait for 30 seconds. (with the engine stopped) (b) According to the instruction of the 'Engine Diagnostic Program' screen, press [Data monitor] and monitor [MAF] and read a numerical value. Reference 1.2 g/sec (0.16 lb/min) or less (2) Sensor foreign matter adhesion inspection (a) Visually check the platinum filament (heater) portion in flow paths. Standard No foreign matter that can be visually checked Note: After checking that no foreign matter is found, return the intake air flow meter S/A to the machine. BASIC INSPECTION Note: When the location of a defect cannot be identified even after troubleshooting, it can be pinpointed through the basic inspection below. 1. Battery inspection (See the machine repair manual for the procedure.) 2. Cranking operation inspection (1) Inspect if the engine cranks. Note: If it does not crank, inspect relevant portions, referring to the LIST OF SYMPTOMS (See page 1-7 for the procedure.) 1KD_RM.book 2 ページ 2013年9月27日 金曜日 午後12時47分

- 4. 1-3 3. Engine start inspection (1) Inspect if the engine starts. NOTICE: • Engine should be cranked by two rotations at minimum when engine starting because ECD system electrically detects the fuel injected cylinder. • If it does not start, inspect relevant portions, referring to the LIST OF SYMPTOMS (See page 1-8 for the procedure.) 4. Air filter inspection (See the machine repair manual for the procedure.) 5. Idle speed inspection (1) Inspect idling. Reference: Refer to repair manual of the vehicle (after warm-up, during idling) 6. Fuel pressure inspection SST: 09240-36770-71 (1) According to the instruction of the screen, press [Data monitor] and monitor [Fuel Press] and measure fuel pressure. Reference: 30000 to 50000 kPa (after warm-up, during idling) 7. Fuel property Inspect if a proper fuel is used as described in the Operator's Manual. Diesel fuel For 8FD35U to 8FD80U model Use only ultra low-sulfur fuel defined by ASTM D0975 No.2-D S15. Refer to the following table for details. Detailed Requirement for ASTM D0975 No.2-D S15 Property Unit Value Distillation Temperature °C 90 % 282 to 338 Kinematic Viscosity mm2/s at 40 °C 1.9 to 4.1 Sulfur ppm (μ g/g) max 15 Cetane index -, min 40 Aromaticity %vol, max 35 Lubricity, HFRR μm, max 520 NOTICE: • Do not use bio-diesel fuel. Damage to engine will occur. • In cold weather, use winter diesel fuel to prevent clogging of the fuel filter caused by paraffin precipitation. In hot weather, do not use winter diesel fuel. Damage to engine will occur. • Do not use deteriorated fuel which has been stored for a long period of time or impure fuel in which foreign material, water and etc. is included. • If fuel is frozen or becomes wax-like substance in winter season, engine may be hard starting, rough idle after starting or engine rotation is impossible to increase. In that case, fuel for winter use should be used. Melt the wax generated in the fuel filter by warming.

- 5. 1-4 PARTS LAYOUT DRAWING Fuel pressure sensor Diesel turbo pressure sensor Common rail ASSY Intake air flow meter Glow plug ASSY Injector ASSY Water temperature sensor Inlet air temperature sensor Crank position sensor No. 2 Electric EGR control valve Oil pressure switch ASSY Crank position sensor Turbo charger S/A Suction control valve ASSY Fuel temperature sensor Pressure limiter 1KD_RM.book 4 ページ 2013年9月27日 金曜日 午後12時47分

- 6. 1-5 DIAGNOSIS CODE LIST ECD System Diagnosis code Diagnosis item Lamp on Code stored Page for reference P0046 Turbocharger boost control circuit range / performance 1-54 P0047 Turbocharger boost control solenoid circuit low 1-54 P0048 Turbocharger boost control solenoid circuit high 1-54 P007C Charge air cooler temperature sensor circuit low 1-59 P007D Charge air cooler temperature sensor circuit high 1-59 P0087 Fuel rail / system pressure - too low 1-65 P0088 Fuel rail / system pressure - too high 1-72 P0093 Fuel system leak detected - large leak 1-79 P0102 Mass air flow sensor circuit low 1-92 P0103 Mass air flow sensor circuit high 1-92 P0107 Manifold absolute pressure sensor circuit low 1-97 P0108 Manifold absolute pressure sensor circuit high 1-97 P0112 Intake air temperature sensor circuit Low 1-102 P0113 Intake air temperature sensor circuit high 1-102 P0115 Engine coolant temperature sensor circuit 1-108 P0117 Engine coolant temperature sensor circuit low 1-108 P0118 Engine coolant temperature sensor circuit high 1-108 P0180 Fuel temperature sensor "A" circuit 1-113 P0182 Fuel temperature sensor "A" circuit low 1-113 P0183 Fuel temperature sensor "A" circuit high 1-113 P0190 Fuel rail pressure sensor circuit 1-65 P0192 Fuel rail pressure sensor circuit low 1-65 P0193 Fuel rail pressure sensor circuit high 1-65 P0201 Injector circuit / open - (Cylinder 1) 1-118 P0202 Injector circuit / open - (Cylinder 2) 1-118 P0203 Injector circuit / open - (Cylinder 3) 1-118 P0204 Injector circuit / open - (Cylinder 4) 1-118 P0299 Turbocharger underboost 1-131 P0335 Crankshaft position sensor circuit 1-133 P0339 Crankshaft position sensor circuit intermittent × 1-133 P0340 Camshaft position sensor circuit 1-137 P0405 Exhaust gas recirculation sensor circuit low 1-141 P0406 Exhaust gas recirculation sensor circuit high 1-141 P042E Exhaust gas recirculation control stuck open 1-146 P0489 Exhaust gas recirculation control circuit low 1-151 P0490 Exhaust gas recirculation control circuit high 1-151 P0560 System voltage 1-154 P0606 ECM / PCM processor 1-157 P060A Internal control module monitoring processor performance 1-157 P060B Internal control module A/D processing performance 1-157 P0617 Starter relay circuit high 1-159 1KD_RM.book 5 ページ 2013年9月27日 金曜日 午後12時47分

- 7. 1-6 P0627 Fuel pump control circuit / open 1-162 P062D Fuel injector driver circuit performance 1-118 P062F Internal control module EEPROM error 1-166 P1229 Fuel pump system 1-169 P1251 Motor for turbocharger control circuit (Intermittent) 1-173 P2120 Pedal position sensor "D" circuit 1-180 P2121 Pedal position sensor "D" circuit range / performance 1-188 P2122 Pedal position sensor "D" circuit low 1-180 P2123 Pedal position sensor "D" circuit high 1-180 P2125 Pedal position sensor "E" circuit 1-180 P2127 Pedal position sensor "E" circuit low 1-180 P2128 Pedal position sensor "E" circuit high 1-180 P2138 Pedal position sensor "D" / "E" voltage correlation 1-180 P2226 Barometric pressure circuit 1-191 P2228 Barometric pressure circuit low 1-191 P2229 Barometric pressure circuit high 1-191 P2564 Turbocharger boost control position sensor "A" circuit low 1-193 P2565 Turbocharger boost control position sensor "A" circuit high 1-193 U0101 Lost communication with can × 1-197 Diagnosis code Diagnosis item Lamp on Code stored Page for reference 1KD_RM.book 6 ページ 2013年9月27日 金曜日 午後12時47分

- 8. 1-7 LIST OF SYMPTOMS ECD System Symptom Portion to be inspected Page for reference Does not crank Battery - Starter 5-2 Starting relay - Shift lever position - Fast idling rough Fuel filter - Injector ASSY 1-118 Starter system 1-199 Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Intake air flow meter 1-294 Fuel property 1-3 Water temperature sensor 1-295 Fuel piping (blocking from the tank to the supply pump) - Idle speed high Troubleshooting of rough idle and large vibration 1-270 Injector ASSY 1-118 Starter system 1-199 Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Water temperature sensor 1-295 Accelerator position sensor (potentiometer) - Idle speed low Troubleshooting of rough idle and large vibration 1-270 Injector ASSY 1-118 Electric EGR control valve 1-296 Compression 2-79 Valve clearance 2-78 Fuel piping - Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Idle unstable Troubleshooting of rough idle and large vibration 1-270 Injector ASSY 1-118 Fuel piping - Electric EGR control valve 1-296 Compression 2-79 Valve clearance 2-78 Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Fuel property 1-3 Power steering system - Alternator ASSY (external accessory) 7-4 1KD_RM.book 7 ページ 2013年9月27日 金曜日 午後12時47分

- 9. 1-8 Hunting Injector ASSY 1-118 ECU power supply system 1-290 Compression 2-79 Fuel piping - Valve clearance 2-78 Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Fuel property 1-3 Power steering system - Alternator ASSY (external accessory) 7-4 White smoke is discharged Electric EGR control valve 1-296 Injector ASSY 1-118 Fuel filter - Engine control computer - Suction control valve ASSY 1-296 Fuel pressure sensor 1-296 Preheating control circuit system 1-206 Fuel property 1-3 Compression 2-79 Turbo charger oil leak and white smoke 1-234 White smoke 1-224 Black smoke is discharged Troubleshooting of black smoke 1-249 Electric EGR control valve 1-296 Injector ASSY 1-118 Exhaust system clogging - Hard starting, engine stalling Troubleshooting of hard starting and engine stalling 1-212 Starter system 1-199 Preheating control circuit system 1-206 Fuel property 1-3 ECU power supply system 1-290 VC power supply system 1-284 Battery - Lack of power, hesitation, surge (hesitation) Troubleshooting of lack of power, hesitation, and surge (hesi- tation) 1-260 Rough idling, large vibration Troubleshooting of rough idle and large vibration 1-270 ID code writing abnormality 1-16 Knocking, abnormal noise Troubleshooting of knocking and abnormal noise 1-277 Turbo charger S/A noise 1-243 Symptom Portion to be inspected Page for reference 1KD_RM.book 8 ページ 2013年9月27日 金曜日 午後12時47分

- 10. 1-9 Abnormal engine noise, or noisy engine Note: It is not abnormal phenomenon engine noise becomes higher when engine revolution is decreased to idle state after engine revolution increased higher. And this noise tend to become higher at low temperature, but it is not abnormal phenomenon. Engine status where noise is often heard Example of sound Probable cause NOTE: During idling Rasping sound Water pump bearing defect Put a sound scope on the water pump body to check. • Remove the V-ribbed belt and try to rotate by hand. If the turning feels rough or bumpy to the hand, then the bearing is defective. Squealing sound Squeaking sound Oil seal squeal Apply engine oil from outside the seal, or spray an anti-squealing agent. • The sound gets smaller or stops. Hissing noise Air suction sound Inspect the intake manifold and air cleaner for appropriate installation. • Try plugging the place where the air gets in with engine oil, grease or cloth. Certain engine speed Squealing sound Belt slipping The sound occurs on sudden accelera- tion from idle. • Check if the indicator mark of the V- ribbed belt tensioner ASSY is in the range of the standard value. (See page 2-77 for the procedure.) • Inspect the V-ribbed belt for wear, cracks and adhered oil. Knocking sound Piston side knock Heard from the lower part of the engine. Knocking sound of the connecting rod bearing Knocking sound of the crankshaft bearing Piston pin knocking sound Whistling sound Turbo charger S/A Sound volume and pitch are propor- tional to the turbo charger S/A or engine speed. Whole engine speed Clicking sound Clattering sound Excess valve clearance or faulty contact Adjust the valve clearance. (See page 2-77 for the procedure.) A "raspberry" sound A "put-put" sound Exhaust leak Check by blocking with a wet cloth the likely location of the leak in the exhaust system. • The noise becomes louder when the engine speed is increased. 1KD_RM.book 9 ページ 2013年9月27日 金曜日 午後12時47分

- 11. 1-10 Excessive engine oil consumption DESCRIPTION OF FUNCTION 1. What is the ID code (compensation code)? (1) For the optional injection characteristic of the injector ASSY, the engine control computer performs different injection period compensation for each injector ASSY. This compensation data is punched as a 30-digit alphanumeric ID code on the head of the injector ASSY. The ID code should be written when the injector ASSY or the engine control computer is replaced. (See page 1-16 for the procedure.) Caution: Improper writing of the ID code can cause rough idling or abnormal noise. Cause Inspection or adjustment areas NOTE: Leaking to the exterior of the engine PCV Engine unit Turbo charger S/A (See page 1-234 for the procedure) Leaking to the interior of the engine Cylinder head S/A Cylinder block S/A Head gasket Oil loss via the piston ring A lot carbon build-up will be visible around the top of the piston. Oil loss via the valve guide Determined by the condition of the carbon adhered to the intake valve cap and the top of the piston, and by the wetness of the valve cap caused by oil. Turbo charger S/A (See page 1-234 for the procedure) Injector ASSY ID code Order in which the ID code is read or written No.1 cylinder No.2 cylinder No.3 cylinder No.4 cylinder 1KD_RM.book 10 ページ 2013年9月27日 金曜日 午後12時47分

- 12. 1-11 PROCEDURE FOR TROUBLESHOOTING Next 1. Check diagnosis codes and freeze frame data (See page 1-14 for the procedure.) 2. Delete diagnosis codes and freeze frame data (See page 1-13 for the procedure.) 3. Check diagnosis codes again (See page 1-13 for the procedure.) Result A 1. Check the list of diagnosis codes (See page 1-5 for the procedure.) Result 1. Check the list of symptoms (See page 1-7 for the procedure.) Result B 1 Making diagnosis and checking symptoms (See page 6-12 for the procedure.) 2 Checking diagnosis codes Result Go to A code was output. A A code was not output. B B Go to step 4. 3 List of diagnosis codes (main inspection portions) or troubleshooting for each code Result Go to A faulty section was identified. A A faulty section was not identified. B A Go to step 9. B Go to step 6. 4 List of symptoms Result Go to A faulty section was identified. A A faulty section was not identified. B A Go to step 9. 1KD_RM.book 11 ページ 2013年9月27日 金曜日 午後12時47分

- 13. 1-12 Result B 1. Perform [Data monitor] and [Active test] Result B Next Next Next Next 5 Basic inspection (See page 1-2 for the procedure.) Result Go to A faulty section was identified. A A faulty section was not identified. B A Go to step 9. 6 Inspecting with 'Engine Diagnostic Program' Result Go to A faulty section was identified. A A faulty section was not identified. B A Go to step 9. 7 Inspecting ECU terminal voltage and circuits (See page 1-33 for the procedure.) 8 INSPECTION OF IRREGULAR PROBLEMS (See page 1-15 for the procedure) 9 Repairing defective parts 10 Checking diagnosis codes (See page 1-5 for the procedure.) End 1KD_RM.book 12 ページ 2013年9月27日 金曜日 午後12時47分

- 14. 1-13 INSPECTING/DELETING DIAGNOSIS CODE Note: • Read the 'Engine Diagnostic Program' instruction manual before using it. • 'Engine Diagnostic Program' enables you to select not only the normal mode but the check mode. In the check mode, abnormality detection sensitivity can be improved, compared to the normal mode. • Perform inspection in the check mode when normal codes are output in the normal mode despite of possible abnormalities in a signal system of each sensor. 1. Preparation before inspection (1) Put the shift position to N. (2) Disable all of outside loads. 2. Inspecting diagnosis codes (reading with 'Engine Diagnostic Program') (1) To Use check mode, according to the instruction of the 'Engine Diagnostic Program', press [Utility] select [Check mode]. (2) According to the instruction of the 'Engine Diagnostic Program' screen, press [Trouble code] and check the diagnosis code. 3. Deleting diagnosis code memory (using 'Engine Diagnostic Program') (1) According to the instruction of the 'Engine Diagnostic Program' screen, press [Trouble code] press [Clear], to delete the diagnosis code. SST 09111-36760-71 (09991-70201) Caution: • If it cannot be deleted, turn the ignition key switch OFF and then delete it again. • Do not delete diagnosis codes with 'Engine Diagnostic Program' before making diagnosis and checking symptoms. 4. Deleting diagnosis codes (by removing fuse) (1) Remove the EFI2 fuse (10 A), and in 15 seconds or more connect the fuse. Caution: • Be sure to delete diagnosis code memory after inspecting and repairing the ECD system. Then, check that normal codes are output. • Do not delete diagnosis codes by clearing the battery (removing the fuse) before making diagnosis and checking symptoms. 5. Checking diagnosis results (using 'Engine Diagnostic Program') SST 09111-36760-71 (09991-70201) Note: After repairing the faulty system with the output diagnosis code or when performing a recreation test after deleting the diagnosis code, check output diagnosis codes. (1) Use 'Engine Diagnostic Program' to delete the diagnosis code. (2) Perform a test for checking diagnosis results. (3) According to the instruction of the 'Engine Diagnostic Program' screen, press [Trouble code]. (4) Check diagnosis code results. 1 2 Engine room relay block EFI2 fuse 1KD_RM.book 13 ページ 2013年9月27日 金曜日 午後12時47分

- 15. 1-14 FREEZE FRAME DATA/DIAGNOSIS DETAILED INFORMATION 1. Checking freeze frame data (reading with 'Engine Diagnostic Program') With 'Engine Diagnostic Program', according to the instruction of the screen, press [Trouble code]. Indicates existance of freeze frame data with a mark in [FED], press the mark. SST 09111-36760-71 (09991-70201) (1) Turn the ignition key switch ON. (2) Press [Trouble code]. Indicates existance of freeze frame data with a mark in [FED], press the mark. (3) In the screen displaying the diagnosis code, detected diagnosis codes appear. (4) Select a diagnosis code for which freeze frame data is checked. 2. Checking chronological freeze frame data (1) In the screen displaying freeze data, select an item for which chronological freeze frame data is checked. Note: • Chronological freeze frame data also includes ECU data recorded at the occurrence of a diagnosis code and around that point. • Chronological freeze frame data can be checked when press a mark in [FED], ' '. • For chronological freeze frame data, a total number of five points (including a diagnosis detection point, three points before detection, one point after detection) can be displayed. 3. List of freeze frame data DTC detection point Freeze frame data recording point 0.5 sec. 0.5 sec. 0.5 sec. 1 2 3 4 Item name Engine Speed Actual VN Position Calculate Load VN Position Sensor Out MAF VN Motor Duty Atmosphere Pressure VN Close Learn Value MAP VN Close Learn Status Coolant Temp Initial Engine Coolant Temp Intake Air Initial Intake Air Temp Engine Run Time Engine Start Time Starter Signal Engine Speed (Starter Off) Injection Volume Starter Count Pilot 1 Injection Period Electric Duty Feedback Value Pilot 2 Injection Period Intake Air Temp (Turbo) Main Injection Period Battery Voltage After Injection Period Engine Speed of Cyl #1 Pilot 1 Injection Timing Engine Speed of Cyl #2 Pilot 2 Injection Timing Engine Speed of Cyl #3 Main Injection Timing Engine Speed of Cyl #4 After Injection Timing Av Engine Speed of All Cyl 1KD_RM.book 14 ページ 2013年9月27日 金曜日 午後12時47分

- 16. 1-15 INSPECTION OF IRREGULAR PROBLEMS 1. Inspecting irregular problems (this can be done only when 'Engine Diagnostic Program' is used) Note: Follow the procedure below to change the mode. This allows improvement of disconnection detection sensitivity and more reliable detection of irregular defects. (1) Delete diagnosis codes. (See page 1-13 for the procedure and notes.) (2) Set the check mode. (See page 1-13 for the procedure and notes.) (3) Perform a simulation (recreation) test. (See page 0-16 for the procedure and notes.) (4) Visually inspect the connector and each terminal, and inspect the connection condition. (See page 0-11 for the procedure and notes.) (5) Inspect the wire harness and connector for excessive force. (See page 0-13 for the procedure and notes.) (6) Use a cooling method for inspection. (See page 0-16 for the procedure and notes.) 2. Checking wire harness and connector instantaneous interruption Note: If a defective system is found based on an output diagnosis code at the inspection of diagnosis codes (check mode), its location should be pinpointed in the following way: (1) After reading the diagnosis code in the check mode, delete diagnosis code memory. (See page 1-13 for the procedure and notes.) (2) Select the check mode, and start the engine. (See page 1-13 for the procedure and notes.) (3) With the engine idling, shake the wire harness and the connector of the defective system where the diagnosis code was output at the inspection of diagnosis codes (check mode). (See page 0-16 for the procedure and notes.) (4) After the wire harness and the connector are shaken, when the engine check indicator turns on, the connection of them may be poor. Injector Memory Error Time after DTC Cleared Target Common Rail Pressure Warmup Cycle Cleared DTC Fuel Press TC and TE1 Fuel Temperature Isochronous Control Target Speed Target Pump SCV Current Isochronous Control Proportional Term Pump SCV Learning Value Isochronous Control Integral Term Accel Position Total Operation Hours Accel Sens. No.1 Volt % Total Number of Rotations Accel Sens. No.2 Volt % Total Injection Volume Target EGR Pos. Pre Glow Actual EGR Valve Pos. After Glow EGR Close Lrn. Val. Target Idle Engine Speed EGR Close Lrn. Status Adjustment Volume Mode Status Value after Confirmation EGR Operation Prohibit Target Booster Pressure Fuel Return Temp VN Turbo Command EGR Motor Duty #1 Item name 1KD_RM.book 15 ページ 2013年9月27日 金曜日 午後12時47分

- 17. 1-16 WORK SUPPORT 1. List of work support steps When parts requiring initialization and writing have been replaced, initialize and write them by following the steps in the list below in numerical order. Note: The ID code represents 'Engine Diagnostic Program' saved in the engine control computer (injector compensation code). 2. Initializing the supply pump ASSY learned value Caution: Be sure to perform this precedure (initialization) after replacing the pump ASSY or the engine control computer. Note: If an error occurs during the initialization, do it again from <Procedure 1/4>. Work support item Replacement Reading and Saving the injector compensation code Initializing the supply pump ASSY leaned value Writing the injector compensation code Supply pump ASSY (1) Engine ASSY (1) Injector ASSY (1) Supply pump ASSY + engine ECU (1) (2) (3) Injector ASSY + engine ECU (1) (2) (3) Engine ASSY + engine ECU (1) (2) (3) Engine ECU (with old data) (1) (2) (3) Engine ECU (without old data) (1) (2) <Procedure 1/4> Select [Supply Pump Initialization] Initialization Cancel <Procedure 2/4> Press [Next] to proceed <Procedure 3/4> Check the initial conditions, then press [Next] <Procedure 4/4> Supply Pump Initialization is complete, press [Exit] 1KD_RM.book 16 ページ 2013年9月27日 金曜日 午後12時47分

- 18. 1-17 (1) Turn the ignition key switch ON. According to the instruction of the 'Engine Diagnostic Program', press [Utility]. Caution: Do not start the engine. (2) <Procedure 1/4> Select [Supplt Pump Initialization], then press [Select]. (3) <Procedure 2/4> Press [Next] to proceed. (4) <Procedure 3/4> After check the initial conditions, then press [Next]. Caution: Preform this procedure, the ignition key switch turned on and the engine stopped. 1KD_RM.book 17 ページ 2013年9月27日 金曜日 午後12時47分

- 19. 1-18 (5) <Procedure 4/4> Supply Pump Initialization is complete, press [Exit]. (6) Start up the engine for warm up. Caution: Do not perform racing immediately after the engine is started. Note: • If the Engine does not start, do it again <procedure 1/4>. • The engine warm-up state shall be acondition water temperature is 60 °C (140 °F) or more and fuel temperature is 20 °C (68 °F) or more. (a) To check water temperature, in the 'Engine Diagnostic Program' select [Data monitor] and monitor [Coolant Temp] Reference 60 °C (140 °F) or more (b) To check fuel temperature, in the 'Engine Diagnostic Program' Select [Data monitor] and monitor [Fuel Temperature] Reference 20 °C (68 °F) or more • When fuel temperature does not increase due toan environment to be measured, increase engine speed litlle by little until it reaches NMR (No load Maximum Revolution), make it the steady state, and then increase the temperature. Do not perform racing rapidly. (7) Run at idle for one minute or more in the state after engine warm-up. (8) The initializatin is now completed. 1KD_RM.book 18 ページ 2013年9月27日 金曜日 午後12時47分

- 20. 1-19 3. Reading and Saving the injector compensation code In this procedure, read codes (injector compensation codes) from the engine control computer, and save compensation codes to the 'Engine Diagnostic Program'. Note: • Due to the defective engine control computer or wire harness, or poor connection of the diagnostic connector, a writing abnormally may occur. Inspect and check the connection of the wire harness or the diagnostic connector. When they are normal, the engine control computer may be defective. • For replacement ECU, need to write the compensation codes of each cylinder. Use this saving compensation codes function to avoid error, writing incorrect compensation code, install another cylinder No. • This saving function can save one latest data of each cylinder. • If using saved data, confirm the saved compensation code and cylinder number, and compensation code of the top of the injector ASSY are right. <Procedure 1/6> Select [Injector compensation] Cancel Read Compensation Code In case of reading another cylinder compensation code Save Replace <Procedure 2/6> <Procedure 3/6> Select a function [Read Compensation Code] <Procedure 4/6> Select a Cylinder number <Procedure 5/6> Appears Cylinder No and Compensation Code <Procedure 6/6> Press [Replace] or [Save] (In case of there is no compensation code) (In case of there is previous compensation code) Next 1KD_RM.book 19 ページ 2013年9月27日 金曜日 午後12時47分

- 21. 1-20 (1) Turn the ignition key switch ON. According to the instruction of the 'Engine Diagnostic Program', press [Utility]. Caution: Do not start the engine. (2) <Procedure 1/6> Select [Injector Compensation], then press [Select]. (3) <Procedure 2/6> Press [Next] to proceed, read <NOTICE> message, then press [Next]. (4) <Procedure 3/6> Select a function [Read Compensation Code], then press [Next]. 1KD_RM.book 20 ページ 2013年9月27日 金曜日 午後12時47分

- 22. 1-21 (5) <Procedure 4/6> Select a Cylinder number from No.1 to 4, then press [Next]. (6) <Procedure 5/6> Note: Appears selected cylinder No. and compensation code. To save the compensation code, press [Save]. If there is previous saved data, and need to save new compensation data, press [Replace]. If there is no previous saved data, and need to save new compensation data, press [Save]. Caution: This saving function can save one latest data of each cylinder. Confirm the cylinder number, and saved date and time to use this saved data, in case of writing a compensation code to replaced engine control computer. If you need all cylinder compensation codes, repeat this procedure same times as cilynder numbers. 1KD_RM.book 21 ページ 2013年9月27日 金曜日 午後12時47分

- 23. 1-22 (7) <Procedure 6/6> To read another Cylinder’s injector compensation code, press [Next] and repeat this procedure from <Procedure 4/6>. To exit this function, press [Cancel]. 1KD_RM.book 22 ページ 2013年9月27日 金曜日 午後12時47分

- 24. 1-23 4. Writing the injector compensation code In this procedure, write codes (injector compensation codes) to the engine control computer. • Use saved compensation codes in the 'Engine Diagnostic Program'. • Input manual compensation codes. Note: • Due to the defective engine control computer or wire harness, or poor connection of the diagnostic connector, a writing abnormally may occur. Inspect and check the connection of the wire harness or the diagnostic connector. When they are normal, the engine control computer may be defective. • In case of replacement ECU, need to write the compensation codes of each cylinder. Use saved codes or input manually. If using saved data, confirm the saved compensation code and cylinder number, and compensation code of the top of the injector ASSY are right. Program can save one latest data of each cylinder. • In case of replacement ECU, injector ASSY, or engine, need to write the compensation codes of each cylinder. Input the compensation codes manually. Confirm the cylinder number and compensation code of the top of the injector ASSY are right. <Procedure 1/6> Select [Injector compensation] Cancel Replacement 1)engine control computer Use saved compensation codes Input manual compensation codes <Procedure 2/6> <Procedure 3/6> Select a function [Set Compensation Code] <Procedure 4/6> Select a Cylinder number <Procedure 5-a/6> Press [Open] <Procedure 6/6> Writing is complete Writing compensation codes <Procedure 5-b/6> Press [Input] Writing compensation codes Replacement 1)engine control computer 2)injector ASSY 3)engine 1KD_RM.book 23 ページ 2013年9月27日 金曜日 午後12時47分

- 25. 1-24 Note: If you use the directly read the compensation code, read the code (30-digit alphanumerical characters) punched on the head of the injector ASSY. (1) Turn the ignition key switch ON. According to the instruction of the 'Engine Diagnostic Program', press [Utility]. Caution: Do not start the engine. (2) Select [Supplt Pump Initialization], then press [Select]. (3) <Procedure 1/6> Select [Injector Compensation], then press [Select]. (4) <Procedure 2/6> Press [Next] to proceed, read <NOTICE> message, then press [Next]. Code Injector ASSY 1KD_RM.book 24 ページ 2013年9月27日 金曜日 午後12時47分

- 26. 1-25 (5) <Procedure 3/6> Select a function [Set Compensation Code], then press [Next]. (6) <Procedure 4/6> Select a Cylinder number from No.1 to 4, then press [Next]. Use a saved compensation code: go to (8) Input a manual compensation code: go to (9) (7) <Procedure 5-a/6> Use a saved compensation code, press [Open] Confirm [Cylinder Number] and [Saved Date], then press [Open] press [Next] to write the saved data. Caution: Confirm the saved compensation code, cylinder number, and compensation code of the top of the injector ASSY are right. Program can save one latest data of each cylinder. If the compensation code writing error occurs, write again. go to (9) 1KD_RM.book 25 ページ 2013年9月27日 金曜日 午後12時47分

- 27. 1-26 (8) <Procedure 5-b/6> Input a manual compensation code, press [Input] Using a key to input the code, then press [OK] press [Next] to write the data. Caution: Confirm the cylinder number, compensation code of the top of the injector ASSY, input compensation code are right. If the compensation code writing error occurs, write again. If the inputted code is incorrect, 'Error Injector Compensation' occurs, input compensation code correctly. go to (9) (9) <Procedure 6/6> Injector compensation writing is complete. Press [Next] to continue writing code of the other cylinder, press [Cancel] to exit this function. (10) After completing writing, delete the diagnosis code. 1KD_RM.book 26 ページ 2013年9月27日 金曜日 午後12時47分

- 28. 1-27 5. Fuel System inspection Perform this procedure, to air bleeding after fuel system parts replacement, or to check fuel system malfunction. Note: • Engine revolution rises, confirm the vehicle not moving. • Operate acceleration pedal according to the 'Engine Diagnostic Program' screen. <Procedure 1/8> Select [Fuel System Check] Cancel <Procedure 2/8> Start the engine <Procedure 3/8> Warm up the engine <Procedure 4/8> Rise the engine revolution over 1400rpm <Procedure 5/8> Check completed <Procedure 6/8> Save data (in case of fuel system malfunction check) <Procedure 7/8> Repeat 5 times the procedure <Procedure 8-a/8> Keep Idling <Procedure 8-b/8> Data analysis Checking the Fuel System Fuel system parts replacement Fuel system malfunction check 1KD_RM.book 27 ページ 2013年9月27日 金曜日 午後12時47分

- 29. 1-28 (1) Turn the ignition key switch ON. According to the instruction of 'Engine Diagnostic Program', press [Utility]. (2) <Procedure 1/8> Select [Fuel System Check], then press [Select] Until the water temperature becomes 70degC (158degF) or higher, can not proceed. (3) <Procedure 2/8> Read the message, and start the engine, keep idling, then press [Next] (4) <Procedure 3/8> Warm up the engine. The water temperature (engine coolant temperature) is 70 °C (158 °F) or higher, then press [Next]. Note: Until the water temperature becomes 70 °C (158 °F) or higher, can not proceed. 1KD_RM.book 28 ページ 2013年9月27日 金曜日 午後12時47分

- 30. 1-29 (5) <Procedure 4/8> Open the acceleration pedal, rise the engine revolution over 1400rpm, then press [Next]. Fuel system check starts automatically, needs 15sec, check is completed. Caution: Open the acceleration pedal until the check is completed. Note: Fuel system check can proceed under the condition that the engine revolution is over 1400rpm. If the condition is not satisfied, the check stops. The engine revolution automatically keep 1400rpm while the check is proceeding. The combustion noise becomes louder while the check is proceeding, this phenomena is not malfunction. (6) <Procedure 5/8> Fuel System Check is completed, close the acceleration pedal, press [Exit]. (7) <Procedure 6/8> In case of fuel system malfunction check, press [Save]. Input the file name if necessary. (8) <Procedure 7/8> Repeat 5 times from <Procedure 1/8>. Fuel system parts replacement: go to (9) Fuel system malfunction check: go to (10) (9) <Procedure 8-a/8> Keep idling over 3min. (10) <Procedure 8-b/8> At <Procedure 1/8> screen, press [Proj info]. Select the saved data in 'Fuel System Check' folder, in Individual data list window. Display and confirm the graph from saved data. 1KD_RM.book 29 ページ 2013年9月27日 金曜日 午後12時47分

- 31. 1-30 CIRCUIT DIAGRAM Ignition switch Glow plug Turbo charger S/A Starter Accelerator position sensor Battery GLOW GLOW GREL AM1 IGSW STA ST STA EFI2 EFI BATT VNM+ VNM- EDU VNVC MAIN VNA VNE2 +B2 +B MREL VCPA VPA EPA VCP2 VPA2 EPA2 A B Parking brake switch ECU-IG Neutral start relay ST T/C shift switch MAIN 1KD_RM.book 30 ページ 2013年9月27日 金曜日 午後12時47分

- 32. 1-31 Fuel pressure sensor Suction control valve ASSY Injector driver Injector ASSY (No.1) Injector ASSY (No.2) Injector ASSY (No.3) Injector ASSY (No.4) Intake air flow meter Fuel filter pool switch Crank position sensor Crank position sensor No.2 Electric EGR control valve A B EDU IJ1+ IJ1- IJ2- IJ2+ IJ3- IJ3+ IJ4- IJ4+ GND +B #10 #20 #30 #40 INJF VCS1 PCR1 E2S1 PCV+ PCV- EGM+ EGM- VCEG EGRA EEGL NE+ NE- G+ G- IREL #1 #3 #2 INJ1 #4 E2G VG THA ETHA P 1KD_RM.book 31 ページ 2013年9月27日 金曜日 午後12時47分

- 33. 1-32 Inlet air temperature sensor Water temperature sensor Fuel filter clogging switch Alternator Fuel temperature sensor Diesel turbo pressure sensor Combination meter ASSY SAS/OPS controller Atmospheric pressure sensor THF ALT ETHF CAN+ FPSW PIM VCPM EPIM EC CAN- THIA ETHI THW ETHW W GIND THWO W3 TC CANH CANL E02 E01 E1 ME01 OBD Diagnostic connector TC E 1KD_RM.book 32 ページ 2013年9月27日 金曜日 午後12時47分

- 34. 1-33 ECU TERMINAL LAYOUT Reference Terminal number [Terminal symbol] Input Output Measurement condition Reference value B53 - B56 [VPA - EPA] Input Accelerator fully closed 0.5 to 1.1 V Accelerator fully opened 2.6 to 4.5 V B54 - B58 [VPA2 - EPA2] Input Accelerator fully closed 1.2 to 2.0 V Accelerator fully opened 3.4 to 5.0 V B43 - A109 [STA - E1] Input During cranking 6 V or more B32 [EC] - Engine ground Ground Always Less than 1 Ω B12 - A109 [W - E1] Output When the engine check indicator turns on (Ignition key switch ON) 0 to 3 V During idling (When the engine check indicator does not turn on) 11 to 14 V A B A B 1 2 3 20 21 22 4 5 6 12 13 14 23 24 25 7 8 9 15 16 17 26 27 28 11 10 18 19 29 30 4 5 6 7 8 9 11 10 12 13 14 15 16 17 18 19 1 2 3 24 25 26 27 28 29 30 20 21 22 23 55 37 36 35 34 33 32 31 53 52 51 50 49 48 47 54 39 38 61 60 59 58 57 56 63 62 40 41 42 43 44 45 46 31 32 33 50 51 52 34 35 36 42 43 44 53 54 55 37 38 39 45 46 47 56 57 58 41 40 48 49 59 60 67 68 69 70 71 72 74 73 75 76 77 78 79 80 64 65 66 87 88 89 90 91 92 93 118 100 99 98 97 96 95 94 116 115 114 113 112 111 110 117 102101 124123122121120119 126125 103 81 82 83 84 85 86 104 105 106 107 108 109 #4 #3 #2 #1 INJ1 ALT P GREL FPSW CAN+ CAN- E01 E02 VNM- VNM+ PCV+ VCS1 THIA ETHI E2S1 THF ETHF PCR1 THW ETHW VG THA ETHA E2G VCEG VNE2 EPIM PIM VNVC VNA VCPM EGRA EEGL PCV- NE+ NE- G+ G- E1 EGM+ EGM- ME01 +B EC BATT +B2 EPA MREL VCPA IREL VPA2 STA VPA TC IGSW W3 CANH CANL W EPA2 VCP2 THWO GIND 1KD_RM.book 33 ページ 2013年9月27日 金曜日 午後12時47分

- 35. 1-34 B2 - A109 [BATT - E1] Input Always 11 to 14 V B1 - A109 [+B - E1] Input Engine stop Ignition key switch ON 11 to 14 V B20 - A109 [+B2 - E1] Input Engine stop Ignition key switch ON 11 to 14 V B55 - B56 [VCPA - EPA] Output Engine stop Ignition key switch ON 4.5 to 5.5 V B57 - B58 [VCP2 - EPA2] Output Engine stop Ignition key switch ON 4.5 to 5.5 V B45 - A109 [MREL - E1] Output Engine stop Ignition key switch ON 11 to 14 V Engine stop 10 seconds or more elapsed after igni- tion key switch turns off 0 to 1.5 V B44 - A109 [IREL - E1] Output During idling 0 to 1.5 V B38 - A109 [THWO - E1] Output During idling Pulse generation (Waveform 1) B30 - A109 [GIND - E1] Output Ignition key switch ON, While the glow indicator turns on 0 to 3 V After warm-up, during idling 11 to 14 V B26 - A109 [TC - E1] Input Ignition key switch ON 11 to 14 V Short-circuit between the terminals TC and E of the diagnostic connector 0 to 1.5 V B25 - A109 [IGSW - E1] Input Engine stop Ignition key switch ON 11 to 14 V B7 - A109 [CANH - E1] Input and output Engine stop Ignition key switch ON Pulse generation (Waveform 2) B6 - A109 [CANL - E1] Input and output Engine stop Ignition key switch ON Pulse generation (Waveform 3) A113 - A90 [THIA - ETHI] Input Intake temperature 0 to 80 °C (32 to 176 °F) (during warm-up) 0.5 to 3.4 V A112 - A89 [THF - ETHF] Input Ignition key switch ON (when cool) 0.5 to 3.4 V Fuel temperature 20 °C (68 °F) 2.0 to 2.7 V A111 - A88 [THW - ETHW] Input Cooling water temperature 60 to 120 °C (140 to 248 °F) (during warm-up) 0.2 to 1.0 V A110 - A87 [THA - ETHA] Input Intake temperature 0 to 80 °C (32 to 176 °F) (during warm-up) 0.5 to 3.4 V A67 [E2S1] - Engine ground Ground Always Less than 1 Ω A68 - A67 [VCS1 - E2S1] Output Engine stop Ignition key switch ON 4.5 to 5.5 V A66 - A67 [PCR1 - E2S1] Input After warm-up, during idling 1.7 to 2.2 V A65 - A64 [VG - E2G] Input After warm-up, during idling Pulse generation A64 [E2G] - Engine ground Ground Always Less than 1 Ω A51 - A109 [INJ1 - E1] Input After warm-up, during racing Pulse generation (Waveform 4) A50 - A109 [#1 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) A49 - A109 [#2 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) A48 - A109 [#3 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) A47 - A109 [#4 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) Terminal number [Terminal symbol] Input Output Measurement condition Reference value 1KD_RM.book 34 ページ 2013年9月27日 金曜日 午後12時47分

- 36. 1-35 Terminal number [Terminal symbol] Input Output Measurement condition Reference value B2 - A109 [BATT - E1] Input Always 11 to 14 V B1 - A109 [+B - E1] Input Engine stop Ignition key switch ON 11 to 14 V B20 - A109 [+B2 - E1] Input Engine stop Ignition key switch ON 11 to 14 V B55 - B56 [VCPA - EPA] Output Engine stop Ignition key switch ON 4.5 to 5.5 V B57 - B58 [VCP2 - EPA2] Output Engine stop Ignition key switch ON 4.5 to 5.5 V B45 - A109 [MREL - E1] Output Engine stop Ignition key switch ON 11 to 14 V Engine stop 10 seconds or more elapsed after ignition key switch turns off 0 to 1.5 V B44 - A109 [IREL - E1] Output During idling 0 to 1.5 V B38 - A109 [THWO - E1] Output During idling Pulse Generation (Waveform 1) B30 - A109 [GIND - E1] Output Ignition key switch ON, While the glow indicator turns on 0 to 3 V After warm-up, during idling 11 to 14 V B26 - A109 [TC - E1] Input Ignition key switch ON 11 to 14 V Short-circuit between the terminals TC and E of the diagnostic connector 0 to 1.5 V B25 - A109 [IGSW - E1] Input Engine stop Ignition key switch ON 11 to 14 V B7 - A109 [CANH - E1] Input and output Engine stop Ignition key switch ON Pulse generation (Waveform 2) B6 - A109 [CANL - E1] Input and output Engine stop Ignition key switch ON Pulse generation (Waveform 3) A113 - A90 [THIA - ETHI] Input Intake temperature 0 to 80 °C (32 to 176 °F) 0.5 to 3.4 V A112 - A89 [THF - ETHF] Input Ignition key switch ON (when cool) 0.5 to 3.4 V Fuel temperature 20 °C (68 °F) 2.0 to 2.7 V A111 - A88 [THW - ETHW] Input Cooling water temperature 60 to 120 °C (140 to 248 °F) 0.2 to 1.0 V A110 - A87 [THA - ETHA] Input Intake temperature 0 to 80 °C (32 to 176 °F) 0.5 to 3.4 V A67 [E2S1] - Engine ground Ground Always Less than 1 Ω A68 - A67 [VCS1 - E2S1] Output Engine stop Ignition key switch ON 4.5 to 5.5 V A66 - A67 [PCR1 - E2S1] Input After warm-up, during idling 1.7 to 2.2 V A65 - A64 [VG - E2G] Input After warm-up, during idling Pulse Generation A64 [E2G] - Engine ground Ground Always Less than 1 Ω A51 - A109 [INJ1 - E1] Input After warm-up, during racing Pulse Generation (Waveform 4) A50 - A109 [#1 - E1] Output After warm-up, during idling Pulse Generation (Waveform 5) A49 - A109 [#2 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) A48 - A109 [#3 - E1] Output After warm-up, during idling Pulse generation (Waveform 5) A47 - A109 [#4 - E1] Output After warm-up, during idling Pulse generation (Waveform 5)

- 37. 1-36 1. Oscilloscope waveform (1) Waveform 1 Note: Depending on cooling water temperature, A changes. (2) Waveform 2 (3) Waveform 3 (4) Waveform 4 Note: As the engine speed increases, the waveform cycle gets shorter. GND A A Item Description Measurement terminals THWO - E1 Gauge set 5 V/DIV, 100 ms/DIV Conditions During idling Water temperature A 30 °C (86 °F) 16 ms 90 °C (194 °F) 278.5 ms 120 °C (248 °F) or more 385 ms GND Item Description Measurement terminals CANH - E1 CAN+ - E1 Gauge set 1 V/DIV, 10 ms/DIV Conditions Engine stop Ignition key switch ON GND Item Description Measurement terminals CANL - E1 CAN- - E1 Gauge set 1 V/DIV, 10 ms/DIV Conditions Engine stop Ignition key switch ON GND Item Description Measurement terminals CH1: INJ1 - E1 Gauge set 2 V/DIV, 1 ms/DIV Conditions After warm-up, during racing 1KD_RM.book 36 ページ 2013年9月27日 金曜日 午後12時47分

- 38. 1-37 (5) Waveform 5 Note: As the engine speed increases, the waveform cycle gets shorter. (6) Waveform 6 (7) Waveform 7 Note: • As the engine speed increases, each amplitude becomes larger. • As the engine speed increases, the waveform cycle gets shorter. (8) Waveform 8 GND GND GND GND CH1 CH3 CH4 CH2 Item Description Measurement terminals CH1: #1 - E1 CH2: #2 - E1 CH3: #3 - E1 CH4: #4 - E1 Gauge set 5 V/DIV, 20 ms/DIV Conditions After warm-up, during idling GND Item Description Measurement terminals ALT - E1 Gauge set 5 V/DIV, 5 ms/DIV Conditions During idling GND GND CH1 CH2 Item Description Measurement terminals CH1: NE+ - NE- CH2: G+ - G- Gauge set 5 V/DIV, 20 ms/DIV Conditions After warm-up, during idling GND GND CH1 CH2 Item Description Measurement terminals CH1: PCV+ - E1 CH2: PCV- - E1 Gauge set CH1: 10 V/DIV, 5 ms/DIV CH2: 500 mv/DIV, 5 ms/DIV Conditions After warm-up, during idling 1KD_RM.book 37 ページ 2013年9月27日 金曜日 午後12時47分

- 39. 1-38 (9) Waveform 9 Note: The waveform depends on operations of the turbo charger S/ A. (10) Waveform 10 Note: The waveform depends on operations of the turbo charger S/ A. Item Description Measurement terminals VNM+ - E1 Gauge set 5 V/DIV, 20 ms/DIV Conditions After warm-up, during idling Item Description Measurement terminals VNM- - E1 Gauge set 5 V/DIV, 50 ms/DIV Conditions After warm-up, during idling 1KD_RM.book 38 ページ 2013年9月27日 金曜日 午後12時47分

- 40. 1-39 ECU DATA MONITOR/ACTIVE TEST 1. List of ECU data monitor (1) With SST, according to the instruction of the screen, display [Data monitor] to inspect computer data. Note: • To check the standard, unless otherwise specified, completely warm up the engine, disable all of outside loads, select the N range, and power off each accessory. • Results of the inspection in the actual machine are reference values, so actual values may be different depending on regions or weather. SST 09111-36760-71(09991-70201) Item name Description/ Display range Reference Remarks Engine Speed • Indicates engine speed. • Display range: 0 to 6000 r/min • 50 to 400 r/min: During cranking • 700 to 800 r/min: After engine warm- up, during idling • It displays a value output from the crank position sensor No.2. • If the crank position sensor No.2 does not oper- ate properly, the engine speed becomes about 0 r/min or is remarkably different from the actual engine speed. Calculate Load • Indicates engine load. • Display range: 0 to 100% 13 to 25%: After engine warm-up, during idling (Disable all of outside loads, N range) • It displays a value calculated by the engine con- trol computer. • Engine load value = (Actual fuel injection amount/Maximum fuel injec- tion amount in the current engine speed) x 100 MAF • Indicates intake air quantity. • Display range: 0 to 655.35 g/sec (0 to 86.69 lb/min) • 16 to 24 g/sec (2.12 to 3.17 lb/min): After engine warm- up, during idling • 40 to 65 g/sec (5.29 to 8.60 lb/min): For engine speed NMR (No Load Max- imum Revolution) Note: It changes depend- ing on the amount of EGR. • It displays a value output from the intake air flow meter S/A. • Based on intake air quantity, the engine control computer controls fuel injection amount, injection timing, EGR, and others. • When intake air quantity is always about 0 g/sec (0 lb/min): - The power circuit of the intake air flow meter S/ A is disconnected. - The VG circuit is disconnected or short-cir- cuited. - The EVG circuit is disconnected. Symptoms when outside the reference: Rough idling Atmosphere Pressure • Atmospheric pres- sure value. • Display range: 0 to 250 kPa Actual atmospheric pressure • With ignition key switch turned on, when a differ- ence between a value of the atmospheric pres- sure sensor and that of the intake manifold pressure sensor is 10 kPa or more, either sensor has an abnormality. • With ignition key switch turned on, when atmo- spheric pressure is 0 kPa or 140 kPa, the sensor circuit is abnormal. • Standard atmospheric pressure: 101 kPa • Atmospheric pressure decreases by 1 kPa with each lifting of 100 m (328 ft). This changes depending on weather (high or low atmospheric pressure). • The atmospheric pressure sensor is contained in the engine control computer. 1KD_RM.book 39 ページ 2013年9月27日 金曜日 午後12時47分

- 41. 1-40 ECU DATA MONITOR/ACTIVE TEST 1. List of ECU data monitor (1) With 'Engine Diagnostic Program', according to the instruction of the screen, display [Data monitor] to inspect computer data. NOTICE: • To check the reference, unless otherwise specified, completely warm up the engine, disable all of outside loads, select the N range, and power off each accessory. • Results of the inspection in the actual machine are reference values, so actual values may be different depending on regions or weather. SST: 09240-36770-71 Item Name Description/ Display Range Reference Remarks Engine Speed • Indicates engine speed • Display range: 0 to 6000 rpm • 50 to 400 rpm: During cranking • Refer to repair manual of the vehicle: After engine warm-up, during idling • It displays a value output from the crank position sensor No. 2. • If the crank position sensor No. 2 does not operate properly, the engine speed becomes about 0 rpm or is remarkably different from the actual engine speed. Calculate Load • Indicates engine load. • Display range: 0 to 100% 10 to 30%: After engine warm-up, during idling (disable all of outside loads, N range) • It displays a value calculated by the engine control computer. • Engine load value = (Actual fuel injection amount/Maximum fuel injection amount in the current engine speed) x 100 MAF • Indicates intake air quantity. • Display range: 0 to 655.35 g/sec (0 to 86.69 lb/min) • 6 to 25 g/sec (0.79 to 3.17 lb/min): After engine warm- up, during idling • 30 to 80 g/sec (3.96 to 10.6 lb/min): For engine speed NMR NOTE: It changes depending on the amount of EGR. • It displays a value output from the intake air flow meter S/A. • Based on intake air quantity, the engine control computer controls fuel injection amount, injection timing, EGR, and others. • When intake air quantity is always about 0 g/sec (0 lb/min): -The power circuit of the intake air flow meter S/A is disconnected. -The VG circuit is disconnected or short-circuited. -The EVG circuit is disconnected. Symptoms when outside the reference: -Rough Idling Atmosphere Pressure • Atmospheric pressure value. • Display range: 0 to 255 kPa Actual atmospheric pressure • With ignition key switch turned on, when a difference between a value of the atmospheric pressure sensor and that of the intake manifold pressure sensor is 10kPa or more, either sensor has an abnormality. • With ignition key switch turned on, when atmospheric pressure is 0kPa or 140 kPa, the sensor circuit is abnormal. • Standard atmospheric pressure: 101 kPa • Atmospheric pressure decreases by 1 kPa with each lifting of 100 m (328 ft). This changes depending on weather (high or low atmospheric pressure). • The atmospheric pressure sensor is contained in the engine control computer.

- 42. 1-41 Item name Description/ Display range Reference Remarks MAP • Indicates absolute pressure of the internal intake manifold. • Display range: 0 to 255 kPa • 90 to 110 kPa (depending on atmospheric pressure): During idling • 115 to 160 kPa: For engine speed NMR • With ignition key switch turned on or during idling, intake manifold pressure and atmospheric pressure are almost the same (standard atmospheric pressure = 101 kPa). • With the accelerator fully opened, when intake manifold pressure is 20 kPa lower than target supercharging pressure for five seconds or more, you may feel insufficient output. • It displays a value output from the diesel turbo pressure sensor. Symptoms when outside the reference: Insufficient output Coolant Temp • Indicates engine cooling water tem- perature. • Display range: -40 to 140 °C (-40 to 284 °F) 70 to 90 °C (158 to 194 °F): After engine warm-up • When engine cooling water temperature is -40 °C (-40 °F) or 140 °C (284 °F), the sensor circuit is disconnected or short-circuited. • After it is left for a long time, engine cooling water temperature, intake air temperature, and ambient temperature become almost the same. • It displays a value output from the water temper- ature sensor. Symptoms when outside the reference: Difficulty in starting the engine when cool, rough idling, black smoke, insufficient output Intake Air • Indicates intake air temperature. • Display range: -40 to 140 °C (-40 to 284 °F) A value equal to tem- perature in the posi- tion where the intake air flow meter S/A is mounted • After it is left for a long time, engine cooling water temperature, intake air temperature, and ambient temperature become almost the same. • When intake air temperature is -40 °C (-40 °F) or 140 °C (284 °F), the sensor circuit is disconnected or short-circuited. • It displays a value output from the inlet air tem- perature sensor contained in the intake air flow meter S/A. Engine Run Time • Indicates rotating time after the engine starts. • Display range: 0 to 65535 sec Rotating time after the engine starts • Indicates elapsed time after the engine starts. Starter Signal • Indicates starter signals. • Display range: ON/ OFF ON: During cranking Ignition switch (STA) output: • ON: Indicates that the engine is cranking. • OFF: Indicates that the engine is not cranking Although STA is turned off, the starter continues to operate. The STA signal abnormality (P0617) is stored. Injection Volume • Indicates fuel injec- tion amount. • Display range: 0 to 1279.98 mm3/ st 5 to 15 mm3/st: During idling (Disable all of outside loads, N range) • It displays fuel injection amount for each combus- tion. • For the injector ASSY clogging, low fuel quality, fuel filter element clogging, or increased engine friction, fuel injection amount will increase. • For abnormalities such as low intake manifold pressure or a small quantity of intake air, fuel injection amount is limited, which causes insuffi- cient output. • It displays a value calculated by the engine con- trol computer.

- 43. 1-42 Item Name Description/Display Range Reference Remarks Pilot 1 Injection Period Indicates pilot 1 injection period. Display range: 0 to 65535 µs 200 to 300 µs: During idling (water temperature is less than 60 °C (140 °F), disable all of outside loads, N range) For symptoms such as knocking, poor drivability, or white smoke, check pilot 1 injection period. (with or without pilot injection) It displays a value calculated by the engine control computer Symptoms when outside the reference: knocking, poor drivability, white smoke Pilot 2 Injection Period Indicates pilot 2 injection period. Display Range: 0 to 65535 µs 200 to 350 µs: During idling (complete warm-up, disable all of outside loads, N range) For symptoms such as knocking, poor drivability, or white smoke, check pilot 2 injection period. (with or without pilot injection) It displays a value calculated by the engine control computer. Symptoms when outside the reference: knocking, poor drivability, white smoke Main Injection Period Indicates main injection period. Display range: 0 to 65535 µs 300 to 600 µs: During idling (complete warm-up, disable all of outside loads, N range) When fuel pressure becomes 15000 kPa or less, main injection period becomes 0 µs. For engine hard starting, check main injection period. (with or without injection) When P0093, P0627 or P062D is output, the engine stop request is output. In this case, main injection period becomes 0 µs. NOTICE: After the engine check indicator turns on, in about one minute the engine stops. Therefore, inspection cannot be performed with freeze frame data. It displays a value calculated by the engine control computer After Injection Period Indicates after injection period. Display range: 0 to 65535 µs 0 to 400 µs: During idling (complete warm-up, disable all of outside loads, N range) For symptoms such as black smoke and poor drivability, check after injection period. (with or without after injection) It displays a value calculated by the engine control computer. Pilot 1 Injection Timing Indicates pilot 1 injection timing. Display range: -70 to 20 °CA -14 to -5 °CA: Water temperature is less than 60 °C (140 °F), during idling, and the machine is in the range of usual atmospheric pressure It displays a value calculated by the engine control computer. Pilot 2 Injection Timing Indicates pilot 2 injection timing. Display range: -50 to 20 °CA -10 to -2 °CA: After engine warm-up, during idling, and the machine is in the range of usual atmospheric pressure. It displays a value calculated by the engine control computer. Main Injection Timing Indicates main injection timing. Display range: -90 to 90 °CA -3 to 1 °CA: After engine warm-up, during idling, and the machine is in the range of usual atmospheric pressure. For symptoms such as poor drivability, black smoke, or white smoke, check main injection timing. It displays a value calculated by the engine control computer. After Injection Timing Indicates after injection timing. Display range: -10 to 50 °CA It displays a value calculated by the engine control computer.

- 44. 1-43

- 45. 1-44 Item Name Description/ Display Range Reference Remarks Fuel Press Indicates fuel pressure Display Range: 0 to 655350 kpa 30000 to 50000kPa: during idling (complete warm-up, disable all of outside loads, N range) Fuel pressure means the actual common rail fuel pressure. Inspect fuel pressure, comparing to common rail target fuel pressure. In the stable condition (during idling after warm- up) fuel pressure is within 5000 kPa of target value. The engine control computer uses fuel pressure to perform feedback control of common rail target fuel pressure. Fuel injection amount is determined based on injection timing and fuel pressure. Injection patterns are also selected based on fuel pressure. Starting the engine requires a minimum of 25000 kPa fuel pressure. (note that when fuel pressure is about to reach its target, a delay is introduced even in the normal state) When fuel pressure is lower than 25000 kPa, rough idling may occur. When fuel pressure decreases from common rail target fuel pressure by 20000 kPa, output may be insufficient. When the actual fuel pressure is 40000 kPa higher than common rail target fuel pressure, P1229 is output. When fuel pressure is lower than a target value, insufficient output will occur without DTC output. When fuel pressure is higher than 250000 kPa, DTC P0088 is output. It displays a value output from the fuel pressure sensor (common rail assy) Symptoms when outside the reference: Difficulty starting the engine, poor drivability, insufficient output, knocking. Fuel Temperature Indicates fuel temperature Display range: - 40 to 215°C (-40 to 419°F) Actual fuel temperature When the engine is completely cooled, fuel temperature is equal to ambient temperature. It displays a value output from the fuel temperature sensor. Target Pump SCV Current Indicates a target value of final pump current. Display range: 0 to 8192 mA 1600 to 2000 mA: during idling (complete warm-up, disable all outside loads, N range) It displays a calculated value by the engine control computer for target current for driving the suction control valve assy and controls a target value of solenoid current. When high fuel pressure is required, a target value of solenoid current is higher. Typically, a target value of solenoid current is in the range of 800 to 2500 mA. When the target value remains a 3000mA or more, it indicates that the pump is defective. (such as a defect due to deposit) If it is not in the standard, even when the pump operates actively, the actual fuel pressure does not match common rail fuel pressure. Symptoms when outside the reference: Difficulty in starting the engine, insufficient output, or rough idling.

- 46. 1-45 Target EGR Pos. Indicates EGR valve target opening degree. Display range: 0 to 100% 0 to 90%: After engine warm-up, during idling (com- plete warm-up, dis- able all of outside loads, N range) • EGR valve fully opened: 100% • EGR valve fully closed: 0% • Inspect it comparing to the actual EGR opening degree #1. • EGR target opening degree displays a calculated value by the engine control computer based on sensor output values (such as the intake air flow meter S/A, inlet air temperature sensor (con- tained in the intake air flow meter S/A), diesel turbo pressure sensor). Symptoms when outside the reference: • When EGR target opening degree is not in the standard and near 0%, the intake air flow meter S/A may be abnormal, or an intake or exhaust system may get clogged. • When EGR target opening degree is not in the standard and near 100%, the EGR pipe may get clogged. Actual EGR Valve Pos. • Indicates EGR valve actual open- ing degree. • Display range: 0 to 100% 0 to 90%: After engine warm-up, during idling (complete warm-up, disable all of outside loads, N range) • EGR valve fully opened: 100% • EGR valve fully closed: 0% • It is effective to judge if the EGR valve is stuck. • Inspect it comparing to EGR target opening degree. • In the active test, check operations of the EGR valve. • When the EGR valve becomes abnormal around a certain temperature, refer to engine cooling water temperature and outside temperature which are reference in case of an abnormality. • The valve position displays a calculated value output from the EGR valve position sensor. Symptoms when outside the reference: • EGR valve stuck open: Hard starting (no engine stalling), black smoke, white smoke, insufficient output • EGR valve stuck close: Increase of turbo super- charging sound EGR Close Lrn. Val. • Indicates an EGR fully-closed posi- tion learned value. • Display range: 0 to 5.00 V 0 to 1 V • An EGR fully-closed position learned value is output voltage from the EGR valve position sen- sor. • When the EGR fully-closed position learned value becomes the upper or lower limit of the nor- mal range, foreign matter may be involved in the EGR valve. • The lower limit of the EGR fully-closed position learned value is 0 V, and the upper 1 V. When this value is fixed to either limit, the valve position sensor may be abnormal, or the valve position may be misplaced (with foreign matter). Item name Description/ Display range Reference Remarks 1KD_RM.book 45 ページ 2013年9月27日 金曜日 午後12時47分

- 47. 1-46 EGR Close Lrn. Status • Indicates a state of EGR fully-closed position learning. • Display range: Completed/Not completed Completed • Completed: It means that fully-closed position learning is normally completed. • Not completed: It means that the learned fully- closed position may not in the correct range. • When it is not completed, foreign matter may be involved in the EGR valve. Note: After the battery cable is disconnected and then connected, when the ignition key switch is never turned off, learning may not be com- pleted. Results of inspection in the actual machine: Ignition key switch ON: Completed EGR Operation Prohibit • Indicates that oper- ations of EGR are prohibited. • Display range: OK/ NG OK: In the active test, EGR target opening degree bank 1 can be per- formed. • OK: In the active test, EGR target opening degree bank 1 can be performed. • NG: In the active test, EGR target opening degree bank 1 cannot be performed. Target Booster Pressure • Indicates target pressure of super- charging pressure. • Display range: 0 to 639.98 kPa - • Inspect it comparing to intake manifold pressure. • With the accelerator fully opened, when intake manifold pressure is 20 kPa lower than target supercharging pressure for five seconds or more, you may feel insufficient output. • It displays a value calculated by the engine con- trol computer. Boost Pressure Deviation • Indicates super- charging pressure deviation. • Display range: -320 to 320 kPa - It displays a difference between target supercharg- ing pressure and intake manifold pressure. VN Turbo Command • Indicates VN turbo motor target open- ing degree. • Display range: 0 to 100% 0 to 100% • VN turbo target opening degree is a command of the engine control computer. • 0%: The nozzle vane is fully opened. (The actuation rod is contracted) • 90% or more: The nozzle vane is fully closed(The actuation rod is extended) • When VN turbo target opening degree is large, the turbo operates effectively. • The command of the engine control computer controls nozzle vane opening degree. Actual VN Position • Indicates actual VNT opening degree. • Display range: 0 to 127.5% 0 to 100% • When movement of the nozzle vane becomes slow and it is stuck, a difference between this opening degree and VN turbo target opening degree is larger, and VN turbo output (duty) also becomes large. • VNT actual opening degree is controlled to suit VN turbo target opening degree. VN Position Sensor Out • Indicates VNT opening sensor output voltage. • Display range: 0 to 4.99 V 1 to 3 V: After engine warm-up, during idling It displays a value output from the nozzle vane opening degree sensor. VN Motor Duty • Indicates the VNT motor drive duty ratio. • Display range: 0 to 127.5% 2 to 88% When movement of the nozzle vane becomes slow, output (duty) increases to the direction of 100%. Item name Description/ Display range Reference Remarks 1KD_RM.book 46 ページ 2013年9月27日 金曜日 午後12時47分

- 48. 1-47 VN Close Learn Value • Indicates a VNT fully-closed learn- ing voltage value. • Display range: 0 to 4.99 V 1.0 to 2.0 V - VN Close Learn Status • Indicates a VNT fully-closed posi- tion learning his- tory. • Display range: ON/ OFF ON When VN Close Learning is not completed, the performance of the machine may decrease. (low engine output) VN Turbo Operation Prohibit • Indicates that the VN turbo active test is prohibited. • Display range: Allowed/Prohibited Allowed: VN turbo opening degree can be per- formed in the active test. When it is prohibited, the engine control computer does not allow performing the active test for VN turbo opening degree. Initial Engine Coolant Temp • Indicates engine cooling water tem- perature at start- up. • Display range: -40 to 120 °C (-40 to 248 °F) Engine cooling water temperature at start- up • With freeze frame data, you can determine if an abnormality occurred at start-up when cool, or after the engine warm-up. • It displays a value output from the water temper- ature sensor at engine start-up. Initial Intake Air Temp • Indicates initial intake air tempera- ture. • Display range: -40 to 120 °C (-40 to 248 °F) Intake air tempera- ture at engine start-up It displays a value output from the intake air flow meter S/A (intake temperature sensor) at engine start-up. Engine Start Time • Indicates engine start time. • Display range: 0 to 267386 ms - It displays the time required by engine start-up. Engine Speed (Starter Off) • Indicates engine speed when the starter is turned off. • Display range: 0 to 1593 rpm - It displays engine speed immediately after the engine starts. Starter Count • Indicates how many times the starter has been turned on. • Display range: 0 to 255 - It displays how many times the starter has been turned on since ignition key switch was turned on. Electric Duty Feedback Value • Indicates an electri- cal load feedback value. • Display range: 0 to 39.8 mm3 /st 0 to 5 mm3 /st After electrical load is turned off and then on, ISC electrical load correction amount increases. Item name Description/ Display range Reference Remarks 1KD_RM.book 47 ページ 2013年9月27日 金曜日 午後12時47分

- 49. 1-48 Intake Air Temp (Turbo) • Indicates intake air temperature after the inter cooler is passed. • Display range: -40 to 190 °C (-40 to 374 °F) During idling 70 °C (158 °F) or less • Indicates intake air temperature of the intake manifold (after the inter cooler ASSY is passed). • Intake air temperature after turbo charging is set to 170 °C (338 °F) while the fail safe function is operating. • When intake air temperature after turbo charging becomes high, turbo supercharging pressure is suppressed, which may cause insufficient output. • It displays a value output from the inlet air tem- perature sensor. Check Mode • Indicates the check mode state. • Display range: Check/Normal Check mode state: Check Check mode: A particular DTC can be easily detected at a high sensitivity. Battery Voltage • Indicates battery voltage. • Display range: 0 to 15 V 11 to 14 V: Ignition key switch ON When it is 11 V or less, characteristics of electronic parts will be changed. Symptoms when outside the reference: When it is 5 V or less, it is difficult to start the engine. Alternate Duty Ratio • Indicates the alter- nator power gener- ation duty ratio. • Display range: 0 to 100% - • It is used to output alternator power generation duty and to decide electrical load. • When injection amount during idling is larger than normal, it is used to determine if there are electri- cal load or other causes. • In the state where Alternate Duty Ratio is not high (low electrical load), when idling injection amount is large, injection amount of the injector ASSY may decrease, or engine friction may be large. • It is used to judge a power generation request state due to an abnormal electrical system. • Whether or not accessories (such as A/C or the heater) operate, when Alternate Duty Ratio is always the maximum value, an abnormality occurs in the electrical system (such as battery deterioration). • It displays a duty value from the ALT terminal. Engine Speed of Cyl #1 Engine Speed of Cyl #2 Engine Speed of Cyl #3 Engine Speed of Cyl #4 • Indicates cylinder engine speed. • Display range: 0 to 51199 rpm The engine speed of all cylinders are almost the same: Normal • It is output only when the engine speed is mea- sured for each cylinder in the active test. • Indicates engine speed for each cylinder during cranking. Example: - When compression of the No.1 cylinder is low, Engine Speed of Cyl #1 is about 300 rpm, Engine Speed of Cyl #2, #3, and #4 is about 200 rpm. - When compression of the No.2 cylinder is low, Engine Speed of Cyl #2 is about 300 rpm, Engine Speed of Cyl #1, #3, and #4 is about 200 rpm. - When compression of the No.3 cylinder is low, Engine Speed of Cyl #3 is about 300 rpm, Engine Speed of Cyl #1, #2, and #4 is about 200 rpm. - When compression of the No.4 cylinder is low, Engine Speed of Cyl #4 is about 300 rpm, Engine Speed of Cyl #1, #2, and #3 is about 200 rpm. Symptoms when outside the reference: When the engine speed of all cylinders is not the same, idling is not stable. Item name Description/ Display range Reference Remarks 1KD_RM.book 48 ページ 2013年9月27日 金曜日 午後12時47分

- 50. 1-49 Av Engine Speed of All Cyl • Indicates the aver- age engine speed of all cylinders. • Display range: 0 to 51199 rpm - • It is output only when the engine speed is mea- sured for each cylinder in the active test. • Indicates the average engine speed of all cylin- ders during cranking. Time after DTC Cleared • Indicates elapsed time after DTC is deleted. • Display range: 0 to 65535 min Time after DTC is deleted It displays elapsed time after DTC is deleted (or shipped from the factory). Warm-up Cycle Cleared DTC • Indicates warm-up count after DTC is deleted. • Display range: 0 to 255 - • It displays engine warm-up count after DTC is deleted. • (Warm-up Cycle Cleared DTC of data list is deleted) - (Warm-up Cycle Cleared DTC of freeze frame data is deleted) = Warm-up count after an abnormality occurs TC and TE1 • Indicates the con- nection condition between TC and TE1 in the active test. • Display range: ON/ OFF - When the TE1/TC terminals are turned on in the active test, the system operates as if the TC termi- nal and E terminal of the diagnostic connector are connected. Isochronous Control Target Speed • Indicates the Isoch- ronous Control Tar- get Speed. • Display range: 0 to 12800 r/min 700 to 800 r/min: After engine warm-up, during idling It displays a value calculated by the engine control computer. Isochronous Control Proportional Term • Indicates the Isoch- ronous Control Proportional Term. • Display range: -50 to 120 mm3 /st - It displays a value calculated by the engine control computer. Isochronous Control Integral Term • Indicates the Isoch- ronous Control Integral Term. • Display range: -80 to 79.997 mm3 / st - It displays a value calculated by the engine control computer. Total Operation Hours • Indicates the Total Operation Hours. • Display range: 0 to 4500000000 sec - It displays a value calculated by the engine control computer. Total Number of Rotations • Indicates the Total Number of Rota- tions. • Display range: 0 to 4290000000 Rotations - It displays a value calculated by the engine control computer. Total Injection Volume • Indicates the Total Injection Volume. • Display range: 0 to 33554432 L (0 to 8864147 gal) - It displays a value calculated by the engine control computer. Item name Description/ Display range Reference Remarks 1KD_RM.book 49 ページ 2013年9月27日 金曜日 午後12時47分

- 51. 1-50 Item name Description/ Display range Reference Remarks Av Engine Speed of All Cyl • Indicates the aver- age engine speed of all cylinders. • Display range: 0 to 51199 rpm - • It is output only when the engine speed is mea- sured for each cylinder in the active test. • Indicates the average engine speed of all cylin- ders during cranking. Time after DTC Cleared • Indicates elapsed time after DTC is deleted. • Display range: 0 to 65535 min Time after DTC is deleted • It displays elapsed time after DTC is deleted (or shipped from the factory). Warm-up Cycle Cleared DTC • Indicates warm-up count after DTC is deleted. • Display range: 0 to 255 - • It displays engine warm-up count after DTC is deleted. • (Warm-up Cycle Cleared DTC of data list is deleted) - (Warm-up Cycle Cleared DTC of freeze frame data is deleted) = Warm-up count after an abnormality occurs TC and TE1 • Indicates the con- nection condition between TC and TE1 in the active test. • Display range: ON/ OFF - • When the TE1/TC terminals are turned on in the active test, the system operates as if the TC ter- minal and E terminal of the diagnostic connector are connected. Isochronous Control Tar- get Speed • Indicates the Isoch- ronous Control Tar- get Speed. • Display range: 0 to 12800 r/min • It displays a target engine speed with the re- quest of vehicle is taken. Refer to repair manual of the vehicle After engine warm-up, during idling Isochronous Control Proportional Term • Indicates the Isoch- ronous Control Proportional Term. • Display range: -50 to 120 mm3/st - • It displays a value calculated by the engine con- trol computer. Isochronous Control Integral Term • Indicates the Isoch- ronous Control Integral Term. • Display range: -80 to 79.997 mm3/ st - • It displays a value calculated by the engine con- trol computer. Total Operation Hours • Indicates the Total Operation Hours. • Display range: 0 to 4500000000 sec - • It displays a value calculated by the engine con- trol computer. Total Number of Rotations • Indicates the Total Number of Rota- tions. • Display range: 0 to 4290000000 Rotations - • It displays a value calculated by the engine con- trol computer. Total Injection Volume • Indicates the Total Injection Volume. • Display range: 0 to 33554432 L (0 to 8864147 gal) - • It displays a value calculated by the engine con- trol computer.

- 52. 1-51 Item name Description/ Display range Reference Remarks Accel Sensor Out No.1 (Accurate) • Indicates the Accel Sensor Out No.1 (Accurate). • Display range: 0 to 5.000 V IG-ON: 0.75 to 0.95 V (Accel pedal: Close) - Accel Sensor Out No.2 (Accurate) • Indicates the Accel Sensor Out No.2 (Accurate). • Display range: 0 to 5.000 V IG-ON: 1.35 to 1.55 V (Accel pedal: Close) - Pre Glow • Indicates the Pre Glow. • Display range: ON/OFF - Pre Glow demand: ON After Glow • Indicates the After Glow. • Display range: ON/OFF - After Glow demand: ON Target Idle Engine Speed • Indicates the Tar- get Idle Engine Speed. • Display range: 0 to 10000 r/min • It displays a target value of the engine individual • Check "Isochronous Control Target Speed" because it is not sometimes match with engine speed, while still installed on the vehicle. Fuel Return Temp • Indicates the Fuel Return Temp. • Display range: -40 to 215 °C (-40 to 419 °F) - • It displays a value calculated by the engine con- trol computer. EGR Motor Duty #1 • Indicates the EGR Motor Duty #1 • Display range: 0 to 127.5 % 0 to 100% • It displays a value calculated by the engine con- trol computer. 2. Active test (1) With 'Engine Diagnostic Program', according to the instruction of the screen, display the [Active test] screen to perform the active test. SST: 09240-36770-71 Item name Description Constraint condition Control the Select Cylinder Fuel Cut Stop fuel injection of each cylinder #1/ #2/#3/#4 (Injection of multiple cylinders cannot be stopped.) With the machine stopped, during engine rotating Check the Cylinder Compression Stop fuel injection of all cylinders. Measure engine speed during cranking. With the machine stopped, when the crank position sensor and sensor No.2 are in the normal state Control the EGR Step Position Increase or decrease EGR opening degree. When the test is started, opening degree shall be 0. It can be increased or decreased in the range of 0 to 100% by 1%. With the machine stopped, Ignition key switch ON (Engine stop) Activate the EGR Valve Close Forced closed of the EGR valve With the machine stopped, during engine rotating after warm-up