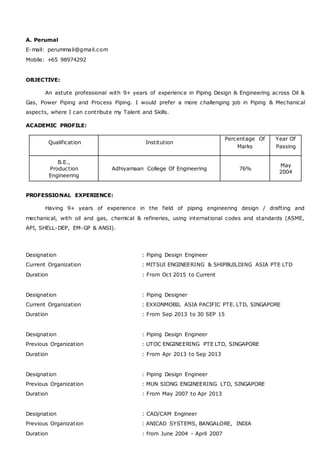

Perumal_CV_PD_Jan 2017

- 1. A. Perumal E-mail: perummail@gmail.com Mobile: +65 98974292 OBJECTIVE: An astute professional with 9+ years of experience in Piping Design & Engineering across Oil & Gas, Power Piping and Process Piping. I would prefer a more challenging job in Piping & Mechanical aspects, where I can contribute my Talent and Skills. ACADEMIC PROFILE: Qualification Institution Percentage Of Marks Year Of Passing B.E., Production Engineering Adhiyamaan College Of Engineering 76% May 2004 PROFESSIONAL EXPERIENCE: Having 9+ years of experience in the field of piping engineering design / drafting and mechanical, with oil and gas, chemical & refineries, using international codes and standards (ASME, API, SHELL-DEP, EM-GP & ANSI). Designation : Piping Design Engineer Current Organization : MITSUI ENGINEERING & SHIPBUILDING ASIA PTE LTD Duration : From Oct 2015 to Current Designation : Piping Designer Current Organization : EXXONMOBIL ASIA PACIFIC PTE. LTD, SINGAPORE Duration : From Sep 2013 to 30 SEP 15 Designation : Piping Design Engineer Previous Organization : UTOC ENGINEERING PTE LTD, SINGAPORE Duration : From Apr 2013 to Sep 2013 Designation : Piping Design Engineer Previous Organization : MUN SIONG ENGINEERING LTD, SINGAPORE Duration : From May 2007 to Apr 2013 Designation : CAD/CAM Engineer Previous Organization : ANICAD SYSTEMS, BANGALORE, INDIA Duration : from June 2004 - April 2007

- 2. SOFTWARE SKILL: ● Intergraph SmartPlant: 3D Piping & Equipment Modelling, GA, Isometric Generation, SPLM, I- Configure, Drafting. ● CADWorx: Piping & Equipment Modelling, P&ID, Isometric Generation, Drafting. ● Intergraph PDS: Piping & Equipment Modelling, MTO, Isometric extraction, GA Preparation. ● I-Sketch: Isometric Generation, I- Configure, Drafting. ● SmartPlant Review(SPR) & Navisworks. ● AutoCAD 2D/3D (2000-2014). ● Microstation. ● Unigraphics NX2. Solid Modelling, Drafting, Assembling the part models, CNC program. ● Catia v5: Solid Modelling, Drafting, Assembling the part models. ● Operating System: Windows/XP/Vista. ● MS office: Word, Excel, etc. CORE STRENGTHS: ● Possess extensive knowledge of 3D Piping Modelling using SmartPlant, PDS, & CADWorx. ● Possess 9+ years of professional experience in piping design. ● Development of 3D models with emphasis of P&ID, Equipment Layout, Plot Plan, Client specifications, economics, Safety of Piping systems and respect to operability, maintainability and support feasibility. ● Highly skilled in preparing material specifications, equipment layouts, piping GA and Isometric. ● Working knowledge of pipe specifications and their applications. ● Preparation of manpower time schedule for piping design projects. ● Preparation of Equipment & Piping GA Drawing. ● Preparation & checking of Isometric drawings. ● Preparations of Piping BOQ (MTO). ● Preparation of Piping Line List. ● Preparation of Line designation sheets, Data sheets, TIE-IN list & Valve list. ● Pipe thickness calculation based on ASME B31, ISO, DIN, DEP, GP standards. ● Collect and compile data from every discipline to create layouts and detailed piping design. ● Pipe span Calculation & Providing technical assistance for pipe support and details. ● If required Site Check for new pipe routing or existing routing modifications. ● Experience in cost effective designs and solutions to piping systems. ● Skilled in design piping systems in Oil & Gas, Refinery, Petrochemical. ● Excellent management and organizational skills. ● Good command over verbal and written communication skills. ● In-depth knowledge of Microsoft Office.

- 3. PROJECT HISTORY: 1. Aurora EOS Project for ExxonMobil & Mitsui Engineering & Shipbuilding Asia Pte Ltd at Jurong Island Singapore. ● Development of 3D models with emphasis of P&ID, Equipment Layout, Plot Plan, Client specifications, economics, Safety of Piping systems and respect to operability, maintainability and support feasibility. ● Checking the accuracy of Bill of Materials (MTO) in Piping Drawings. ● Creating piping reference data for SP3D using SPRD. ● Clash & model check & Resolving modelling issues related to SP3D. ● SPLM, SP3D, SPR installation Activities. ● Reporting to Project Manager and Piping Lead on daily basis about Piping drawing deliverables as per project standard, schedule, and budget. ● Co-ordinate with contractors, clients and consultants on daily design matters. ● Review & update piping field change request called FIN (Field Instruction Notice) to resolve piping queries. ● Coordinate and supervise the piping design engineering activities of the Projects to ensure the technical objectives are met within the approved scope, budget, schedule & compliance with projects specifications, relevant codes and standards. ● Monitoring and issuing Piping GA, Piping Support & Isometric drawings. ● Provide technical assistance and coordination with other discipline activities like (Project, Civil, Structural, Equipment, E&I, etc.) 2. ME5 PROJECT for JACOBS & Evonik Methionine Sea Pte Ltd at Jurong Island Singapore. ● Reporting to Project Manager and Project Engineer on a daily basis, with Design, drafting and drawing deliverable as per project scope, schedule, and budget. ● Working with Project Manager and Engineer to estimate quantities of piping drawings required for the project. ● Leads a team to produce complete piping design drawings required for fabrication. ● Checking team member’s work for accuracy and completeness. ● Able to train team members using company CAD tools. ● Customize the CAD tools as per project requirement. ● Utilize the Company Design tools to produce automated Bills of Material. ● Preparation and completion of isometric drawings, coordination with other design disciplines and squad check of vendor drawings and drawings from other disciplines. ● Detailing and issuing fabrication isometric drawings. ● Checking the accuracy of Bill of Materials. ● Possible work in the field to assist construction with carry-on engineering work and as-built work. ● Capable of gathering dimensional & technical data from an operating facility revamp or expansion work. ● Assisting with evaluation and development of company Design specifications and procedures & training. ● Ensures design practices, Quality Management System and Quality Assurance are followed.

- 4. 3. PO Transfer Pipeline TO CSL Plant Project for OilTanking Singapore Pte Ltd at Jurong Island Singapore. ● Responsible for production and checking of PFDs, P&IDs, GA, Piping modelling, plans & sections, isometric extraction & BOM (MTO). ● Handling Piping Packages like Pipe Rack Piping, Pump Piping, Tank Farm Piping, etc. ● To Perform Pipes Span Calculation, Pipe support selection & Special Support drawing. ● Pipe supporting, Support MTO & Special Support drawing preparation. ● Taking initiatives in coordinating with various disciplines like Civil, Electrical, Instrument, Project team. ● Responsible for underground pipe detail. ● Responsible to Provide the Design Engineering support while construction. ● Attending HAZOP, Internal & Client reviews/meeting. ● Preparation of Line designation sheets, Data sheets, TIE-IN list & Valve list. ● If required, go for site check to solve technical queries from project engineering. 4. Plant Change Request projects for Shell Seraya chemicals Ltd, Jurong Island Singapore. ● Preparation of PEFS, UEFS & Piping General Arrangement Drawings using SHELL DEP & ASME. ● CAD generated Isometric drawing & BOM preparation using PDS, CADWorx & SPOOLGEN. ● Preparation of Line designation sheets, Data sheets, TIE-IN list & Valve list. ● Pipe Span Calculation, Pipe support selection & details. ● If required Site Check for new pipe routing or existing routing modifications. ● MTO for all drawings as per client pipe class & ASME. ● Compile handover dossiers in formats agreed with Client. ● Structural drawing modifications for new platform design or existing platform extension. 5. Ethylene Cracker Complex Project for SHELL EASTERN ASIA LTD, Pulau Ular, Singapore client is CB&I Lummus Global J.V& TOYO Engg India Ltd. ● To setup design specification using I Configure, Intergraph Software. ● Generation of Spool Isometrics drawings on Intergraph-Spoolgen software. ● Implementing a plan to ensure efficient execution of engineering activities for assigned project. ● Coordination of engineering activities related to all of Design, Detailing, Fabrication and Erection. ● Co-ordinate with contractors, clients and consultants on daily design matters. ● Carry out all conceptual and detail design using Isometric, GA drawings & client technical documents define the construction & commissioning deliverable in the form systems & modules. ● Setup, populate & maintain the Work database system or other data base engineering information systems used to track progress & store handover data. ● Prepare weekly and monthly progress report & submit to project manager upon completion of drawings.

- 5. 6. MECHANICAL DECOKING MACHINE DESIGN: ● Mun Siong is the mechanical decoking contractor for Reliance Jamnagar Refinery. To use in refineries, we have designed and fabricated a new mechanical decoking machine. ● We finally succeeded in the fabrication of the new mechanical decoking machine after solving a number of tasks in due course. This was actually a team effort. This machine can be operated with a pump pressure up to max of 380 psi and the flow rate of 700-800 gallons/min at specific operating conditions. This comparatively has the same efficiency of our existing machine. It is also cost effective. And has the clearest live display monitoring with proper control of decoking which is in-built. Pigs are recorded and tracked in such a way which limits the likelihood of pigs becoming lodged or lost. 7. Bukom Refinery Modification Project for SHELL EASTERN ASIA LTD, Singapore; Client is Foster Wheeler Asia Pacific Pte Ltd, Pulau Bukom, Singapore. ● Working as an assistant engineer in piping & structural design team, involved in structural design and detailing activity of pipe rack modelling and detailing. ● Isometrics generation by using client GA, P&ID drawings. TRAINING & COURSES: ● QEHS MANAGEMENT SYSTEM INTERNAL AUDITOR TRAINING, at TUV SUD PSB Learning Pte Ltd, Singapore. PERSONAL PROFILE: Date of Birth : 12-06-1982 Language Known : English, Tamil, Kannada & Telugu Nationality : Indian Sex : Male FIN No : G8013504T Passport No : M8985627 Permanent Address : 5/86, Muthannappalli, Tirupathur, Vellore-635652. TN, India. Present Address : Block 518, #16-153, Jurong West St 52, Singapore - 640518. Email ID : perummail@gmail.com I hereby declare that the above particulars are true to the best of my knowledge and belief. PLACE : SINGAPORE Yours truly DATE: (A. PERUMAL)