peter.fitzpatrick.cv.2016-2017

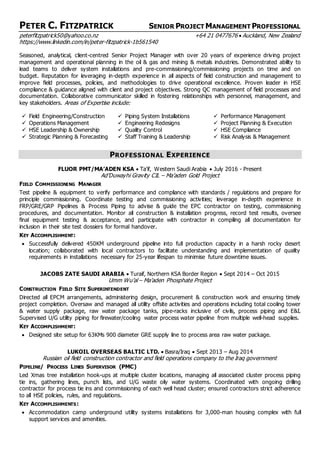

- 1. PETER C. FITZPATRICK SENIOR PROJECT MANAGEMENT PROFESSIONAL peterfitzpatrick50@yahoo.co.nz +64 21 0477676 Auckland, New Zealand https://www.linkedin.com/in/peter-fitzpatrick-1b561540 Seasoned, analytical, client-centred Senior Project Manager with over 20 years of experience driving project management and operational planning in the oil & gas and mining & metals industries. Demonstrated ability to lead teams to deliver system installations and pre-commissioning/commissioning projects on time and on budget. Reputation for leveraging in-depth experience in all aspects of field construction and management to improve field processes, policies, and methodologies to drive operational excellence. Proven leader in HSE compliance & guidance aligned with client and project objectives. Strong QC management of field processes and documentation. Collaborative communicator skilled in fostering relationships with personnel, management, and key stakeholders. Areas of Expertise include: Field Engineering/Construction Piping System Installations Performance Management Operations Management HSE Leadership & Ownership Engineering Redesigns Quality Control Project Planning & Execution HSE Compliance Strategic Planning & Forecasting Staff Training & Leadership Risk Analysis & Management PROFESSIONAL EXPERIENCE FLUOR PMT/MA’ADEN KSA Ta’if, Western Saudi Arabia July 2016 - Present Ad’Duwayhi Gravity CIL – Ma’aden Gold Project FIELD COMMISSIONING MANAGER Test pipeline & equipment to verify performance and compliance with standards / regulations and prepare for principle commissioning. Coordinate testing and commissioning activities; leverage in-depth experience in FRP/GRE/GRP Pipelines & Process Piping to advise & guide the EPC contractor on testing, commissioning procedures, and documentation. Monitor all construction & installation progress, record test results, oversee final equipment testing & acceptance, and participate with contractor in compiling all documentation for inclusion in their site test dossiers for formal handover. KEY ACCOMPLISHMENT: Successfully delivered 450KM underground pipeline into full production capacity in a harsh rocky desert location; collaborated with local contractors to facilitate understanding and implementation of quality requirements in installations necessary for 25-year lifespan to minimise future downtime issues. JACOBS ZATE SAUDI ARABIA Turaif, Northern KSA Border Region Sept 2014 – Oct 2015 Umm Wu’al – Ma’aden Phosphate Project CONSTRUCTION FIELD SITE SUPERINTENDENT Directed all EPCM arrangements, administering design, procurement & construction work and ensuring timely project completion. Oversaw and managed all utility offsite activities and operations including total cooling tower & water supply package, raw water package tanks, pipe-racks inclusive of civils, process piping and E&I. Supervised U/G utility piping for firewater/cooling water process water pipeline from multiple well-head supplies. KEY ACCOMPLISHMENT: Designed site setup for 63KMs 900 diameter GRE supply line to process area raw water package. LUKOIL OVERSEAS BALTIC LTD. Basra/Iraq Sept 2013 – Aug 2014 Russian oil field construction contractor and field operations company to the Iraq government PIPELINE/ PROCESS LINES SUPERVISOR (PMC) Led Xmas tree installation hook-ups at multiple cluster locations, managing all associated cluster process piping tie ins, gathering lines, punch lists, and U/G waste oily water systems. Coordinated with ongoing drilling contractor for process tie ins and commissioning of each well head cluster; ensured contractors strict adherence to all HSE policies, rules, and regulations. KEY ACCOMPLISHMENTS: Accommodation camp underground utility systems installations for 3,000-man housing complex with full support services and amenities.

- 2. PETER C. FITZPATRICK Page Two Fulfilled stringent HSE requirements related to H2S risk factors on Clusters 5, 6, 7, 8 & 10 well pads where drilling contractors continued in close proximity to ongoing construction installations and tie ins; installed GRE raw water supply pipe lines throughout village locations and high risk open range locations supported by armed security personnel. WORLEYPARSONS ARABIA Al-Jubail, Saudi Arabia Aug 2013 Tasnee Waste Heat Boiler Shutdown & Modifications CONSTRUCTION FIELD SUPERINTENDENT Incorporated on-site waste heat boiler ducting modifications for existing waste boiler feed ducts due to design failures. Assisted in an extensive engineering redesign to significantly improve supporting structural components that were failing under heat and stress loadings during operation. WORLEY PARSONS SAUDI ARABIA. Ras Al Khair Aug 2008 – June 2013 Ma’aden Ras Al Khair Phosphate Project, KSA - EPCM AREA FIELD ENGINEER Maintained, troubleshot, and repaired, cooling water supply systems, firewater ring main systems, potable water/ sewer, RTR/FRP, CPVC, carbon steel (all piping underground services), and road drainage systems. Managed specific ISBL/OSBL site contractors to resolve technical query documentation including civil / piping design issues resolutions, punch lists & closures staging, hydro testing and relevant flushings, JHA risk assessment documents, and field assembly sequencings for all U/G utilities. Monitored contractors and subcontractors for all piping assemblies, butt & wrap, laminations & O’ ring coupling joints on all large bore FRP seawater cooling lines through to client walk downs / handover. KEY ACCOMPLISHMENTS: Led management review on total cooling water system installations; enforced control over construction schedules; evaluated daily progress of road asphalting and paving contractor, road markings, and furniture. Oversaw PMC third party surveying contractor to verify quality, quantity and design change variations. Directed all the demobilisation of site contractors including camps and support facilities. CONSTRUCTION MANAGER (JULY 2012 – JUNE 2013) Administered the construction of Ammonia cooling water return stilling basin structure and accompanying FRP 2400NB associated piping system. Headed all the site civil works including 1100mt of reinforcing, 3853cm of fly- ash 45mpa marine grade concrete, 147LM of 2400NB FRP cooling water piping – U/G and AG spooling, ~17,000cm of layered compacted backfilling and its complete ND testing. Continually ensured conformance with HSE policies and guidelines. KEY ACCOMPLISHMENT: Guided the demobilisation of contractor’s construction camp facilities with full area reinstatement verification and formal handover back to client. FOSTER WHEELER OVERSEAS Jubail, Saudi Arabia March 2007 – July 2008 Sharuq U & O Project FIELD PIPING / CONSTRUCTION SUPERINTENDENT Assured PMC services to general contractors, timely completed all underground piping installation of RTR/FRP cooling water, firewater, waste/oily water systems, and stainless steel oxygen supply lines a per EPC contractor battery limits. Expedited FRP/RTR materials with vendor including Amiantit, Bondstrand Ltd - Al Khobar. KEY ACCOMPLISHMENT: Assured operational integrity of tie in systems to live plant facilities in pursuit of seamless plant operations through a dedicated integrated Construction & Operations Team.

- 3. PETER C. FITZPATRICK Page Three SAUDI ARABIAN BECHTEL COMPANY Khursaniyah Jan 2006 – March 2007 Khursaniyah Gas Project ~ Bechtel/Technip JV-EPCM, Client: Saudi Aramco LEAD FIELD PIPING & CONSTRUCTION SUPERINTENDENT Installed various piping systems including FRP, RTR, GRP & CS pip systems for various industrial applications with total quantity spanning over 185,000LM; under & over ground piping systems with ~2600LM of H2S supply/ waste return lines to Class 300 to three sulphur lock units (one per train). Sourced FRP/RTR materials from vendors including; Amiantit, Bondstrand - Al Khobar. BECHTEL-BSL/CSPC Daya Bay, PR China Sept 2004 – Dec 2005 Shell Nanhai Project FIELD CONSTRUCTION SUPERINTENDENT Managed all ISBL & OSBL and utilities installations; led underground and above ground piping installation projects as per EPC battery limits. Monitored and controlled cooling water, firewater, potable water, sewers, pipe rack process lines and utilities; carbon steel, low temp, SS, - GRP, FRP materials; underground and rack piping as applicable. Crafted punch lists, closed out systems, and facilitated client handover. BECHTEL AUSTRALIA Gladstone, QLD, Australia March 2003 – Jan 2004 Bechtel/Comalco Carr Project – Piping Supt Power Generation Steam Plant BOILER/PIPING CONSTRUCTION SUPERINTENDENT Systematically installed ~15,000LM - CS, chrome/Mo', SS piping boilers 1 & 2. Set up and ran site spool fabrication yard facilities directly on site minimizing transporting and handling requirements plus being able to directly coordinate and feed dedicated construction installation crews. KEY ACCOMPLISHMENT: Comalco considered this project to be one of their best-planned and executed Australian achievements. Piping Superintendent for Bechtel Inco Goro Nickel Project Piping & Construction Superintendent for Bechtel/Chevron Moran Oil & Gas Facilities Upgrades & Additions Piping Fabrication Shop Superintendent/Butanol Piping Site Superintendent for Bechtel Bina/Optimal UCC Butanol and Derivatives Project Piping Superintendent for Bechtel Malaysia, BASF/Petronas Acrylic Plant Work Permit Administrator for Bechtel/Texas Gas Utilities Project, direct hire project PMC Piping Superintendent for Bechtel Australia Pasminco Centry Zinc Project PMC Piping and Tankage Superintendent for Bechtel/Chevron Gobe Petroleum Project Boilermaker/Welding Supervisor for BHP New Zealand Steel, Power Generation Kilns Cogen Boiler Project Pipe Welding/Training Supervisor for Hicom Petro Pipes Ltd. Boilermaker/Welder for Baker Cranes Ltd., Humes Steel Pipes Ltd., Brenton Engineering & Services Ltd., Manro Engineering Ltd., United Marine Engineering Services Ltd., for Napier Engineering & Contractors Ltd., Ash Engineering Ltd., Carlos Verrisimo Ltd., McConnell Dowell Constructors Ltd., Bougainville Coppermine – Minenco Australia Ltd., and Price Norsteel Fabricators Ltd. EDUCATION, TRAINING & CERTIFICATIONS Otahuhu College, Auckland, New Zealand, Engineering to Fourth Form Level Manukau Technical Institute, Auckland, New Zealand, Boilermaking & Welding