4. Jyrki Heino: Jätemuovi – haitallisesta hiilipohjaisesta materiaalista arvokkaaksi metallurgisen koksin, koksaamokaasun, vedyn ja hiilivetypohjaisen öljyn raaka-aineeksi

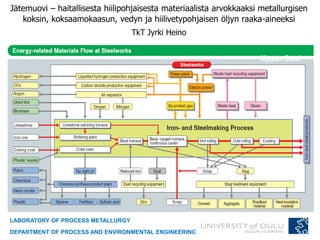

- 1. Jätemuovi – haitallisesta hiilipohjaisesta materiaalista arvokkaaksi metallurgisen koksin, koksaamokaasun, vedyn ja hiilivetypohjaisen öljyn raaka-aineeksi TkT Jyrki Heino Nippon Steel LABORATORY OF PROCESS METALLURGY DEPARTMENT OF PROCESS AND ENVIRONMENTAL ENGINEERING

- 2. The history of Harjavalta industrial area 1944 Copper factory is moved from Imatra to Harjavalta. 1945 The start up of the Outokumpu copper factory

- 3. The history of Harjavalta industrial area 1945 The start up of the Outokumpu copper factory 1947 The start up of the Kemira sulphuric acid plant Year 1950

- 4. 1949 Start up of first Outokumpu copper flash smelter 1956 First licensed Outokumpu copper flash smelter starts up in Ashio, Japan 1959 Start up of first Outokumpu nickel flash smelter 1995 Start up of AGA hydrogen plant 1995 Start up of Direct Outokumpu Nickel (DON) process 1999 Outokumpu out sources industrial maintenance, transport, sanitation, industrial sanitation and guarding to partnership companies

- 5. Type II industrial system Concentrate, silica sand FLOW SHEET OF COPPER SMELTER Feed mixture Flue dust Bag filter Oxygen and air SCREENING AND GRINDING Bag filter Steam CONCENTRATE DRYING WHB FLASH SMELTING FURNACE PRESSURE FILTER Slag concentrate Slag Matte Scrap, anode scrap THICKENER Silica sand, coke, reverts SLAG GRINDING WHB EP CONVERTER Ni drying HEAT EXCHANGER Ni Electric furnace bins ANODE CASTING Propane, air ANODE FURNACE Waste slag Bag filter Air and oxygen SLAG COOLING Blister SLAG CONCENTRATOR Acid plant EP Cu-ANODE

- 6. = More than 55 licences in five continent The first ever copper flash smelting process started in Harjavalta, Finland at 1949 Outotec 2012

- 7. Copper and nickel flash smelters as an important part of Harjavalta industrial eco-park YARA SUOMI OY MAINTENANCE KEMIRA OYJ Mainpartner Oy GAS PRODUCTION Insta Automation Oy SECURITY Air Liquide Finland Oy ABB Oy Services ISS Security Oy Oy AGA Ab POWER SUPPLY Suomen Teollisuuden Energiapalvelut STEP Oy BOLIDEN HARJAVALTA OY PLANNING AND PROJECTS Outotec (Finland) Oy Insta Automation Oy NORILSK NICKEL HARJAVALTA OY CANTEEN Amiga and Fazer VR CARGO THE PORI PORT OY HACKLIN LTD Boliden Harjavalta Oy CLEANING OF FACILITIES SOL Palvelut Oy INDUSTRIAL CLEANING Lassila & Tikanoja Oyj WASTE WATER TREATMENT Aquflow Oy Oy INTERNAL TRANSPORTATION Valtasiirto Oy 16.12.2013 LUVATA PORI OY OUTOTEC (FINLAND) OY 7 Boliden Harjavalta Oy 2012)

- 8. The product and company diversity progress 1945 - 2013 YEAR COMPANY PRODUCTS 1945 Outokumpu Anode copper 2013 Boliden Harjavalta Oy Anode copper, nickel matte, sulphuric acid, and sulphuric dioxide in smelters of Harjavalta plant. Cathode copper, gold, silver, platinum and palladium concentrate, copper sulphate, nickel sulphate, copper telluride, and selenium in electrolysis of Pori plant Norilsk Nickel Harjavalta Oy Nickel cathodes, nickel briquettes, nickel powders, nickel fine powder, nickel solutions, nickel chemicals, ammonium sulphate, copper sulphide, and cobalt sulphate solution SP Minerals Oy Screened granulated nickel slag for sand blasting and roofing felt production Kemira Oyj Aluminium sulphate YARA Urea phosphate, different kinds of fertilizers, urea AGA Gaseous oxygen, hydrogen and nitrogen, liquid oxygen, nitrogen, and argon STEP Oy Process steam, high temperature steam, process energy, district heating energy, raw water, salt-free and precipitated water, electric energy, and compressed air

- 9. Material and energy change of Harjavalta Industrial Eco Park STEP ADVANTAGES NN Environmental and recycling benefits YARA Better energy efficiency Better product diversity when different companies can concentrate to their own core know-how areas Marketing and logistic benefits Improved safety activity NN = Norilsk Nickel Imago factors Positive co-operation factor based on cultural differences

- 11. Environmental load of Finnish ferrous and nonferrous metallurgical industry – Future challenges In ferrous industry main raw materials are oxide ores and in nonferrous industry sulphide ores Earlier sulphur dioxide was main problem in nonferrous metal manufacture; now the main problem is a huge amount of unutilised solid wastes High electric energy demand in electrolysis of copper, nickel and zinc and ferrochromium and stainless steel manufacture The main problem of ore based ferrous industry is CO2 emissions Specific CO2 emissions (tons per produced ton of steel) of Finnish steel industry are one of the lowest in the world The major problem when using more steel scrap as a raw material will be the contamination of steel by tramp elements Utilisation of some dusts, slimes and sludge from ferrous industry is waiting for economical solutions

- 12. Harjavalta industrial park as an example of an industrial ecosystem when developing environmental friendliness of carbon steel Basic principle: “The primary production chain of the ore based steel making is not disturbed (Pöyliö et al. 2002)” => So, there is ahead a mega jump in technological, economic and ecological efficiency by totally eliminating waste streams and fully exploiting synergies with other related industrial technologies. (Szekely 1996) Heino 2006

- 13. Industrial ecology applied to carbon steel manufacture More efficient use of own iron residues (dusts, scales and sludge = waste oxides) Use of iron residues from other industries (Scrap, slags, roasting residues) Use of secondary or bio based energy sources and reducing agents (Plastics, tar, heavy oil, tyres, wood, etc.) More efficient use of slags in cement industry, in road construction and agriculture to replace virgin raw materials Low heat energy utilization in district heating, in greenhouses or somewhere else in the surrounding community. Coke oven gas can be converted into H2, which can be fed into fuel cell battery for automobile or chemical industry Utilisation of carbon monoxide as a raw material of formic acid manufacture Better energy efficiency with the aid of energy integration included pinch technology, etc.

- 14. EFFICIENT FUEL FOR A BLAST FURNACE (EFBF) 01.09.2011 - 31.08.2015 T. Fabritius, S. Gornostayev, J. Heino., S. Huttunen, T. Kokkonen, and R. Mattila INTRODUCTION Natural reserves of coking coal are limited and the standards for blast furnace iron making are becoming increasingly strict, encouraging steel producers to implement environmentally friendly and economical processes. The production of high quality coke requires a better control of its properties (e.g., reactivity and strength) as well as sustainable and economic management of coke oven gases (H2 ~ 58.5% and CH4 ~ 23.8% as a main utilisable components). Because of the limited source of coking coal, it must be found new ways to substitute the virgin raw material with other appropriate renewable or secondary organic compounds. Without large investments costs to extra treatment plant twaste plastics charged in coke ovens can be used as a secondary source of hydrogen, a fuel, a reductant, a carburization agent and a structural support used in a BF thus substituting virgin coal and thus decreasing carbon dioxide emissions. LABORATORY of PROCESS METALLURGY DEPARTMENT of PROCESS and ENVIRONMENTAL ENGINEERING

- 15. INTRODUCTION TO PLASTIC COKE RESEARCH IN EFBF Without large investments costs to extra treatment plant waste plastic can be processed in coke ovens to be used in blast furnace as structural support, carbon based reductant, carburization agent, and fuel for the hot iron metal. By-products of coking process (H2, hydrocarbon oil, and CH4) can be used in other more valuable purposes. Virgin coal will be substituted and CO2 emissions reduced.

- 16. PLASTIC COKE RESEARCH To study how coking process proceeds when coking coal without and with varying amounts of plastics. To investigate coking process when changing the amount of the plastics among the coking coal. To produce different type of plastic-free and plastic-bearing coke for analysing and testing. To investigate how plastics and their amount affect the porosity and strength of the coke and to define is there any maximum limit to the amount of the plastics. To measure the coke gas composition when coking coal without and with varying amounts of plastics.

- 17. The coal-to-coke transformation takes place as follows: The heat is transferred from the heated brick walls into the coal charge with the following consequences: 1. From about 375°C to 475°C, the coal decomposes to form plastic layers near each wall. 2. At about 475°C to 600°C, there is a marked evolution of tar, and aromatic hydrocarbon compounds, followed by resolidification of the plastic mass into semi-coke. 3. At 600°C to 1100°C, the coke stabilization phase begins. This is characterized by contraction of coke mass, structural development of coke and final hydrogen evolution. 4. When the plastic layers have met at the center of the oven, the entire mass has been carbonized. Source: Shelton Iron and Steel Co

- 19. Plastic as a secondary raw material of coke Source: Nippon Steel

- 21. EXPERIMENTAL Metallurgical coke was prepared in laboratory scale coke ovens by coking three common coals (RI, EV and BU) without and with most widely used plastic polyethylene (HDPE, (C2H4)n). Plastics and coals were grinded to < 5 mm. In mini coking process samples were warmed up to 1200 ºC. Coke compression strength was measured by Zwick 100 kN Tensile test machine. Image analysis by optical microscopy was performed to study textures and porosity of coke. ASAP 2020 Pore size analyser was used to measure porosity and surface area (BET) of coke

- 22. Laboratory scale coke oven battery with nine coke ovens

- 23. Tools and methods for advanced studies of coke Optical microscopy and image analysis Digital camera Recognition of textures (mosaic, isotropic, banded) and pores. Mattila O., Salmi P. Wavelet-based image analysis method to study the properties of coke (2008) Scanmet III Conf., Sweden, p. 237-244.

- 24. Cold compression strength (kN/m2) of coke as a function of PE plastic 0 – 12,5 % addition in RI coal

- 25. RESEARCH RESULTS No significant changes were observed in the cold strength results from 0 up to 5% of HDPE plastics addition to the three different coals BU, EV and RI. Below 5% HDPE plastics addition in RI coal the increase of mosaic texture at the expense of isotropic texture compensates for the weakening effect of increased porosity. Also rounded macro pores observed in texture analysis, decrease the weakening effect. Mosaic carbon texture in coke is usually less reactive with carbon dioxide compared to isotropic carbon texture, thus improving the CRI and CSR values of coke to be used in blast furnace. The cold compression strength results of coke manufactured by adding the most common plastic (HDPE) to Riverside coal were very encouraging. Estimations are both coal-specific and plastic-specific and should be made

- 26. Eco-efficient features of Finnish metallurgical industry Conservation of energy and intelligent use of non-fossile energy sources and minimizing the impact on the environment; air, water, soil ASM Historical Landmark Award for the Outokumpu Flash Smelting Process in 2002 About 50 % of the World copper and 30 % of nickel is produced by Flash Smelting method developed in Harjavalta Finland by Outokumpu (nowadays Outotec) 13 BAT´s = Best Available Technologies developed by Outotec rated by the EU to their energy-efficiency and low emissions Ruukki as a leader in the Dow Jones Sustainability index among carbon steel manufactures (Cleantechfinland 2011) Outokumpu Tornio Stainless steel plant having the lowest carbon footprint of world stainless steel manufactures (Outokumpu 2010) Mäkinen 2006 and Outotec 2012

- 27. Pekka Tervonen, TkT, eMBA Johtaja Puh: +358 40 6739519 pekka.tervonen@oulu.fi

- 28. Centre for Environment and Energy (CEE) 1. CEE:n toiminnan painopisteet ovat ilma, vesi, energia ja resurssitehokkuus sekä edellisiä poikkileikkaavana teemana mittaustekniikka. 2. Visiona on olla ekoinnovatiivisten ratkaisujen haluttu yhteistyökumppani. 3. Strategiana on kehittää ympäristö- ja energia-alaa yhdistävä osaamiskeskittymä, joka yhdistää nopeasti alan huippuosaamisen tutkimus-, kehitys- ja innovaatiotoiminnan hankkeisiin, yhteistyöverkostot ja rahoituskanavat. 4. CEE yhdistää läpinäkyvästi valitun alan huippututkimuksen ja yritysosaamisen Oulussa ja yhteistyöverkkojen kautta valtakunnallisesti ja kansainvälisesti. Tämä luo kestävän pohjan tutkimus- ja yritysyhteistyölle. 5. Toimintafilosofia on ohjelmapohjainen verkostomalli, mikä mahdollistaa nopean ja proaktiivisen tutkimusyhteisöjen ja yritysten yhteistyön.

- 29. CEE – yritysosaamisen ja huippututkimuksen integraatio

- 30. CIRU –platform/CEE (Juha.roininen@oulu.fi) CIRU – Platform auttaa teollisuusyrityksiä kehittämään prosessejaan ja hyödyntämään niissä syntyviä sivuainevirtoja. Asiantuntemuksemme perustuu tieteelliseen tutkimukseen termodynamiikan, minerologian, kemiallisten analyysien, reaktiokinetiikan ja virtausmallinnuksen alueilla. Voimavaroinamme on koko tekninen osaaminen ja erityisenä tavoitteenamme on yhdistää toimintaamme myös tuotteistaminen kaikkine osa-alueineen. Tässä työssä huomioimme myös yhteiskunnallisen vaikuttamisen, josta esimerkkinä on muotoilu aspektin tuominen mukaan aliarvostettujen materiaalivirtojen tuotteistamiseen yhtenä työkaluna hyväksyttävyyden saavuttamiseksi ekologisille toimintamalleille. Toimintamme peruslähtökohtia on tarpeiden tunnistaminen, avoimuus, yhteistyö sekä innovaatioiden edistäminen tutkimuksen avulla. Yhteistyö suurteollisuuden ja julkisten toimijoiden kanssa toimii erinomaisesti Työmme tavoite on lisätä toimijoiden kannattavuutta ja ekologisuutta korkealaatuisella tieteellisellä osaamisella ja erityisesti PK sektorin toimijat ovat erittäin toivottuja osallistumaan tähän yhteistyöhön. Tule mukaan parantamaan maailmaamme ja ota yhteyttä meihin tulevaisuuden tekijöihin.

- 31. Sources of information CENTRE FOR ENVIRONMENT AND ENERGY (2013) <http://www.oulu.fi/english/CEE> Cleantechfinland (2011) <http://www.cleantechfinland.com/news/ruukki_achieves_industry leader_position_in_ dow_jones_ sustainability_indexes/>. 21.9.2011 Heino, J. (2006) Harjavalta industrial park as an example of an industrial ecosystem when developing environmental friendliness of carbon steel. Doctoral dissertation. Acta Universitatis Ouluensis, C Technica 254. 163 p. (In Finnish) Heino, J., Gornostayev, S., Kokkonen, T. Huttunen, S. Fabritius, T. Waste plastic – From harmful carbon based material to valuable raw material of metallurgical coke, coke oven gas, hydrogen, and hydrocarbon oil. Annual World Conference on Carbon, 17-22 June, 2012, Krakow, Poland. Oral presentation and paper in conference proceedings. Heino, J., Gornostayev, S., Kokkonen, T., Turpeinen, E., Huuhtanen, M., Suopajärvi, H., Huttunen, S. Fabritius, T. & Keiski, R. (2013) Waste plastic as an additional raw material of metallurgical coke to produce hydrogen as by-product. Poster in 2nd International Symposium of Green Chemistry 2013 in France. Kawasaki Steel. <URL:http://www.kawasaki-steel-21st-cf.or.jp/chapter_2/index.html> 24.10.2002 Mäkinen, J. (2006) Eco-efficient Solutions in the Finnish Metallurgical Industry. Challenges of Eco-efficiency seminar. Outokumpu. (2010) The energy and low-carbon programme. Outokumpu leading the way. <URL:http://www.outokumpu.com/51623.epibrw/> 8 p. Outotec (2012) <URL:http ://www.outotec.com/pages/Page____40893.aspx?epslanguage=EN> Nippon Steel news June 2004 Pöyliö, E., Makkonen, H., Laitila, L., Heino, J., Hiltunen, A. & Härkki, J. (2002) Optimal recycling of the iron based steelmaking dusts, scales and sludge. Recycling and waste treatment in mineral and metal processing: Technical and economic aspects. Luleå, 16.6 – 20.6.2002. Luleå University of Technology, MEFOS and the Mineral, Metals & Materials Society. Volume 2, pp. 129 –137. Szekely, J. (1996) Steelmaking and industrial ecology - Is steel a green material? ISIJ International 36(1996)1, pp. 121 - 132. Yonesawa K. Longitudinal vision of steelmaking industries from an environmental standpoint in Japan through course 50 project. SCANMET III 3rd International Conference on Process Development in Iron and Steel making, 8-11, June 2008, Luleå, Sweden, vol. 1, pp. 49-58.