RAMKAMAL

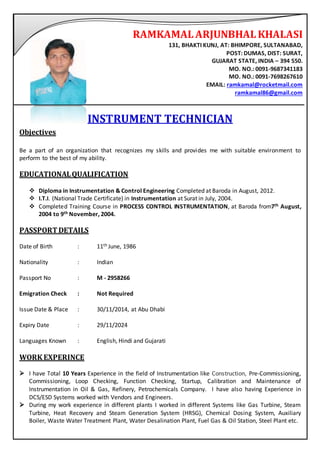

- 1. RAMKAMAL ARJUNBHAL KHALASI 131, BHAKTI KUNJ, AT: BHIMPORE, SULTANABAD, POST: DUMAS, DIST: SURAT, GUJARAT STATE, INDIA – 394 550. MO. NO.: 0091-9687341183 MO. NO.: 0091-7698267610 EMAIL: ramkamal@rocketmail.com ramkamal86@gmail.com INSTRUMENT TECHNICIAN Objectives Be a part of an organization that recognizes my skills and provides me with suitable environment to perform to the best of my ability. EDUCATIONALQUALIFICATION Diploma in Instrumentation & Control Engineering Completed at Baroda in August, 2012. I.T.I. (National Trade Certificate) in Instrumentation at Surat in July, 2004. Completed Training Course in PROCESS CONTROL INSTRUMENTATION, at Baroda from7th August, 2004 to 9th November, 2004. PASSPORTDETAILS Date of Birth : 11th June, 1986 Nationality : Indian Passport No : M - 2958266 Emigration Check : Not Required Issue Date & Place : 30/11/2014, at Abu Dhabi Expiry Date : 29/11/2024 Languages Known : English, Hindi and Gujarati WORK EXPERINCE I have Total 10 Years Experience in the field of Instrumentation like Construction, Pre-Commissioning, Commissioning, Loop Checking, Function Checking, Startup, Calibration and Maintenance of Instrumentation in Oil & Gas, Refinery, Petrochemicals Company. I have also having Experience in DCS/ESD Systems worked with Vendors and Engineers. During my work experience in different plants I worked in different Systems like Gas Turbine, Steam Turbine, Heat Recovery and Steam Generation System (HRSG), Chemical Dosing System, Auxiliary Boiler, Waste Water Treatment Plant, Water Desalination Plant, Fuel Gas & Oil Station, Steel Plant etc.

- 2. Employment History Company : AL SHIRAH RECRUITMENT SERVICES EST. Client : AbuDhabi PolymersCompany.(BOROUGE),UAE Position : InstrumentControl Technician(Maintenance) Duration : 8th July2012 to till date Company : AL MELEHY TRADING CO. Client : Utility,Train1 & 2 Shutdown,ADGAS,DasIsland,UAE Position : Instrument Technician (Shutdown& Startup) Duration : 25th March 2012 to 14th May, 2012 Company : KENTECH INTERNATIONAL ABU DHABI LTD. Client : OAG PlantShutdown,ADGAS,DasIsland,UAE Position : Instrument Technician (Shutdown& Startup) Duration : 27th October2011 to 29th November,2011 Company : COMSIPAL A’ALI Co.W.L.L. Client : The Bahrain PetroleumCo.(BAPCO),atBahrain Position : Instrument Technician (Shutdown,Startup& Maintenance) Duration : 15th February,2011 to 25th September,2011 Company : MIRAJ INSTRUMENTATION PVT. LTD. Client : Reliance Infrastructure Ltd,Goapowerstation Position : Instrument Technician (Shutdown,Startup& Maintenance) Duration : 17th September,2010 to 17th December,2010 Company : BRUNEL INDIA PVT. LTD. Client : CAIRN EnergyIndiaPvt.Ltd.,at Barmier,Rajasthan Position : Instrument Technician (Commissioning& Startup) Duration : 15th January,2010 to 30th June,2010 Company : CONSOLIDATED CONTRACTORS CO. W.L.L. Client : Khursaniyah Gas Plant Project, at Saudi Arabia Position : Instrument Technician (Commissioning & Startup) Duration : 20th August, 2008 to 6thJanuary, 2010 Company : DODSAL ENG.& CONTS. PTE. LTD. Client : Ras Gas Onshore Expansionproject- II(RGX-II),atQatar Position : Instrument Technician (Construction& Commissioning) Duration : 19th June 2007 to 24th July,2008 Company : TYCO ENGINEERING & CONSTRUCTIONPVT. LTD. Client : Essar Power Ltd., at Hazira, surat Position : Instrument Technician (Construction& Commissioning) Duration : 25th January,2006 to 14th June,2007 Company : MAYUINSTRUMENTATION Client : Oil &Natural Gas Corporation Ltd., O.N.G.C.,atHazira, surat Position : Instrument Technician (Calibration& Maintenance) Duration : 1st December,2004 to 8th January,2006

- 3. NATURE OF WORK Good knowledge of Preventive, Predictive, Corrective and breakdown maintenance. Flushing and zero check of pressure and DP type transmitters. Good knowledge of calibration, Repair, and Troubleshooting of all type Transmitter Like pressure, flow, level, temperature etc. Transmitter Make: - Rosemount, Yokogawa, Honeywell, ABB, Kent, Foxboro, Endress+Hauser etc. Good knowledge of all type switches calibration like Pressure, Flow, Level and Temperature. Good knowledge of all type of control valve calibration like PV, FV, LV, TV etc. Control valve Calibration, Maintenance, Overhauling and Troubleshooting of Control Valve like Globe Valve, Ball Valve, Butterfly Valve, Angle Valve, Three way Valve, Safety Relief Valve, Gate Valve, Motor Operated Valve(MOV), Non Return Valve etc. Different types of Valve Positioners Make:- Fieldveu Smart Positioners Fisher (DVC-6000, 6005, 6010, 6015, 6020, 6025, 6030, 6035,6200), Siemens, Foxboro, Samson 3730, SMC, Voltak, Rotex, Kinston, Siemens, Flow Serve, Dembla, Yamatek, Masoneilan India etc. Over speed test for gas and steam turbine using Woodward and also check turbine electronic and mechanical vibration trip set point. Vibration is Measure in Terms of Displacement, Frequency, Velocity, Acceleration and Keyphasor etc. Also used Vibration Calibrator TK3 for radial and axial vibration probe sensitivity check. Recording and maintaining data sheets, technical calibration sheet and records. I worked in the Lead Man of All instrument Installation, Loop Checking, Pre-Commissioning, Commissioning, Function Checking, Troubleshooting and Startup of the plant. Bypassing by forcing on DCS and ESD system before proceeding in troubleshooting and maintenance of industrial process in running plant. Able to replace damaged safety barriers, power supply module (PS), Input Output Cards, HPM Cards and also Checking of busted fuse, fan and light condition in DCS/ESD cabinets. Good knowledge in field bus instrument and calibration. Instrument cable pulling, laying, Glanding, Trashing and Termination to Junction box, Field instrument and marshalling panel. OTHERS I/P & P/I converters, Solenoid Valves, Cascade Control System, Split Range, Open loop, Close loop, Safety Berries, Proximity & Limit Switches, Controller, Recorders, Scanners, All types Orifice, Ventured Tube, Anubar, Variable Area Flow Meter, Temperature Sensors (RTD) (Types: PT 50, 100, 200, 500, 1000, Thermocouple (Types: T,E,J,K,R,S,B,N), Level Transmitter like D.P. type, Air Purge &Bubbler type, Radar etc. KEY ACCOMPLISHMENT Flexible work attitude. Can work independently. A good team player. Having good knowledge of plant safety rules and regulations. Good knowledge about permit to work (PTW), electronic permit to work (EPTW) system and kinds of permits like cold work permit, hot work permit category A & B, excavation permit and Confine space entry permits. Executed daily operations of co-coordinating day to day maintenance of plant, received job order to determine work priorities. Co-ordination with all maintenance department Computer knowledge of Windows OS like XP, Vista, Win-7, Win-8, MS office 2010, Photoshop, Internet & e-mail operations with latest versions.

- 4. ESD TATA HONEYWELL TDC 3000 SAFTEY MANGER (SM) R145.2 SOFTWARE (SAFETY BUILDER) YOKOGAWA, BLUE STAR PLC & YASKAWA SCU 84 PLC ALLEN BRADLEY SERIES PLC DCS TATA HONEYWELL TDC 3000 TATA HONYWELL EXPERION PKS R300 YOKOGAWA DCS CENTUM CS3000R3 SIEMENS TELEPERMXP SPPA - T 2000 FIRE & GAS SYSTEM FIRE & GAS INSTRUMENTS like Manual Alarm Call Point, Smoke Detectors, Toxic (H2S) Gas Detectors, Flame Gas Detectors, Heat Detectors, UV/IR Flame Detector, Open Path Gas Detector, Infrared Gas Detector, Horn, Fusible Plug Loops etc. I Also Involved in Fire and Gas System Maintenance, Calibration and Commissioning. DUTIES AND RESPONSIBILTIES I have knowledge of Calibrating Different types of Transmitters like Pressure, Flow, Level & Temperature; Converters, Controllers, Switches, Gauges & Different types of Valves such as Control Valves, Governor valve Throttle trip valve (TTV), Diaphragm Valves, Three Way Valves, Globe Valves, ON/OFF Valves, ESD Valves etc. I have knowledge of Bench & Field Calibration by using Druck (DPI-610 IS Pressure Calibrator, UPS-III-IS Loop Calibrator), DBC 150 Temperature Calibrator, TRX-II OCEI 424 Temperature Calibrator), Hart Communicator (Model 475, 375, 275), YHC4150X Hart Communicator (Yokogawa), Scandura B20/IS Calibrator, Fluke 718 & 707EX Calibrator, Fluke 724 Temperature Calibrator, Ametek Pressure & Temperature Calibrators, Ronan Model x86 Calibrator, Bentley Nevada TK3 Vibration Calibrator, WOODWARD, MA Source (OCEI 501,503), Dead Weight Tester & Multimeter etc. I can Operate DCS and ESD in Loop Checking, Pre-Commissioning and Commissioning of all Analog and Digital Signals including Loop Configurations, Controller Action & Functionality and Ranges etc. Installation of all Process Control Instruments, Junction Boxes, Cable Routing, Cable Lying, Gladding and Termination in Accordance whit the documents & drawing Loop checking from field bus Devices to the monitoring device and simulation through Hart Communicator for DCS system. I used to confirm all Loop Details are Correct against all project, Vendor Information, P&ID, I/O schedule, Data Sheet, Instrument Index on Database, Alarms and Trip Schedule Including Rack, Slot, Channel location for I/O Devices. I can interpret with P& ID Drawings, Instrument HOOK-UP Drawings, INSTRUMENT SEGMENT Diagrams, LOGIC & INTERLOCK Diagrams, ILD’S Drawings, Cause & Effect, Plot Plant Diagramand Internal Wiring Diagrams for Construction & Commissioning and Startup Work. My Responsibilities includes Pre-Commissioning, Commissioning, Loop Checking, Function Checking, Startup, Maintenance, Troubleshooting of Interlock System and Maintain all the Calibration Records of Master Instruments. I hope that you will consider my application and give me a chance to serve under your company. Thanking you in anticipation for hearing kind and early response. ___________________ RAMKAMAL KHALASI