Rohit heromoto CV (PROCESS QA)

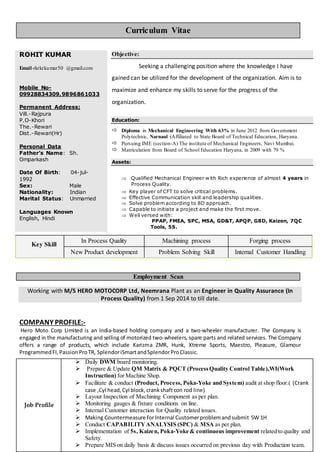

- 1. ROHIT KUMAR Email-rkrkrkumar50 @gmail.com Mobile No- 09928834309,9896861033 Permanent Address; Vill.-Rajpura P.O-Khori The.-Rewari Dist.-Rewari(Hr) Personal Data Father’s Name: Sh. Omparkash Date Of Birth: 04-jul- 1992 Sex: Male Nationality: Indian Marital Status: Unmarried Languages Known English, Hindi Objective: Seeking a challenging position where the knowledge I have gained can be utilized for the development of the organization. Aim is to maximize and enhance my skills to serve for the progress of the organization. Education: Diploma in Mechanical Engineering With 63% in June 2012 from Government Polytechnic, Narnaul (Affiliated to State Board of Technical Education, Haryana. Pursuing IME (section-A) The institute of Mechanical Engineers, Navi Mumbai. Matriculation from Board of School Education Haryana, in 2009 with 79 % Assets: Qualified Mechanical Engineer with Rich experience of almost 4 years in Process Quality. Key player of CFT to solve critical problems. Effective Communication skill and leadership qualities. Solve problem according to 8D approach. Capable to initiate a project and make the first move. Well versed with: PPAP, FMEA, SPC, MSA, GD&T, APQP, G8D, Kaizen, 7QC Tools, 5S. Working with M/S HERO MOTOCORP Ltd, Neemrana Plant as an Engineer in Quality Assurance (In Process Quality) from 1 Sep 2014 to till date. COMPANY PROFILE:- Hero Moto Corp Limited is an India-based holding company and a two-wheeler manufacturer. The Company is engaged in the manufacturing and selling of motorized two-wheelers, spare parts and related services. The Company offers a range of products, which include Karizma ZMR, Hunk, Xtreme Sports, Maestro, Pleasure, Glamour ProgrammedFI,PassionProTR, SplendoriSmartandSplendorProClassic. Curriculum Vitae Key Skill In Process Quality Machining process Forging process New Product development Problem Solving Skill Internal Customer Handling Employment Scan Job Profile Daily DWM board monitoring. Prepare & Update QM Matrix & PQCT (ProcessQuality Control Table),WI(Work Instruction) for Machine Shop. Facilitate & conduct (Product, Process, Poka-Yoke and System) audit at shop floor.( (Crank case ,Cyl head,Cyl block,crankshaftcon rod line) Layout Inspection of Machining Component as per plan. Monitoring gauges & fixture conditions on line. Internal Customer interaction for Quality related issues. Making Countermeasure forInternal Customerproblemandsubmit 5W 1H Conduct CAPABILITYANALYSIS (SPC) & MSA as per plan. Implementation of 5s, Kaizen, Poka-Yoke & continuous improvement related to quality and Safety. Prepare MIS on daily basis & discuss issues occurred on previous day with Production team.

- 2. PREVIOUS EMPLOYER:- Worked with Sona BLW Precision Forging LTD. Gurgaon as a Asst. Engineer in Process Quality from 18 jun 2012 to 25 Aug 2014.(Total 2 years 2 months) COMPANY PROFILE:- Sona BLWPrecision Forgings Limited is an ISO/TS 16949 and an ISO 14001:2004 company is a joint venture between Sona Holding and Mitsubishi Materials Corporation, Japan.Sona BLW Precision Forgings Ltd. was formed in 1995 and began commercial production in November 1996. The company is engaged in the manufacturing of Precision Forged (net shaped) Bevel Gears,Differential Case Assemblies and Synchroniser rings for Automotive and other applications Job Profile Take action & Closed Non-conformance found internal & external audit for IMS. Analysis data using 7 QC Tools to reduce in-house rejection. Red- Bin Analysis on daily basis. Analysis problem by using problem solving tool like 8D, 5-WHY, Seven step of Problem Solving. Analyze warranty components on monthly basis & Submitted market Failure Analysis report (MFAR) to warranty department. Ensuring safety of each and every team member who is working in respective area & Analysis daily near miss. As a mentor evaluate & Upgrade skill of the team members as per the requirement. Provide the short term training session of Quality related problems, instrument handling to the operators. Make monthlyQA InplantOPCOMand reviewedbyQualityhead. To conduct washingmachine Audit. Maintain & updating record & document in Machine Shop as per IMS requirement. Achievements Cyl block scoring warranty complaints reduced 40% from existence (Avg 50 component/month) Established Steel phase Machine shop department during Neemrana plant installation. Received two times Best Kaizen of the month award.(At Cyl block line) SuccessfulPrototype trial did of AAWA scooter line.(steel phase). Paper less working in STD room working as a team. Made inspectiontiming tostrengthen inspectionactivityonline. Special Project Cyl block scoring warranty Complaints as a team leader Washing machine Millipore valve achieved within Target (10 mg). Job Profile Conduct process capability study as per plan/requirement in machining line & take corrective action. Prepare component NG Record day to day with countermeasure report. Making Inspection report for new development part. Analysis Root cause & prepared CAPA,Analysis action plan. Maintaining record of monthly total rejection, % rejection & PPM. Knowledge of Customer complaint Handling and solve the complaint with effective counter measure. Analysis customer returns parts & give the countermeasure. If similar to other products then Horizontal deployment

- 3. TRAININGS:- 7 QC Tool. 5’S’ Techniques. KAIZEN. POKEYOKE. MSA, SPC,PPAP,APQP. ROOT CAUSE ANALYSIS. SUPERVISIORSKILLDEVLOPMENT. Advance Excel. Buildingeffective relationship. TPM(Total Productive Maintenance). Producttraining(Engine Crossfunctional partsinterrelationship.) One week ROBOTS trainingwith fanuc india ltd.BANGALORE, (About TOUCH UP & PROGRAMMING OF HANDLING TYPES ROBOT.) I hereby declare that all the details furnished above are true to the best of my knowledge. Date: (Rohit kumar) JOB PROFILE Responsible for giving countermeasure for Customer problems and submit to 5-W 1H Sheet & 8D. To conduct of Product & Process Audit as per Control Plan. Responsibility for lay out inspection of new development part. Analyze the In house Quality defect in machine shop. Analysis defect according to “PARATO” Analysis and Reduce in-house rejection. Responsible for Set-up approval when changover on line. Responsible for Inspection of Product as per Standard. Responsible for First off /Last Off and Patrolling inspection. Maintains and Prepare the documents like WORK INSTRUCTION,PROCESS PARAMETERS CHECKSHEET,INPROCESS INSPECTION STANDARD, Responsibility for maintain 5S. Pre dispatch Inspection of in house Product. Responsibility for given training to PDI Inspector Maintain MIR (Monthly Inspection Report) & submit to customer. Responsible for making PDI (Pre Dispatch Inspection) Report. Knowledge of Customer complaint Handling and solve the complaint with effective counter measure. Preparing NG information record. Maintain corrective & preventive action records of in House rejection. To conduct process and product audit as per plan. SPC study as per plan/requirement. Declaration: