SUMER_MECH_Er

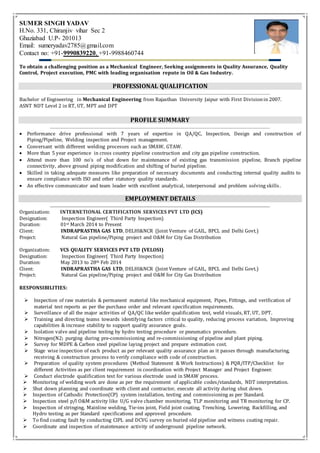

- 1. SUMER SINGH YADAV H.No. 331, Chiranjiv vihar Sec 2 Ghaziabad U.P- 201013 Email: sumeryadav2785@gmail.com Contact no: +91-9990839220, +91-9988460744 To obtain a challenging position as a Mechanical Engineer, Seeking assignments in Quality Assurance, Quality Control, Project execution, PMC with leading organisation repute in Oil & Gas Industry. PROFESSIONAL QUALIFICATION Bachelor of Engineering in Mechanical Engineering from Rajasthan University Jaipur with First Divisionin 2007. ASNT NDT Level 2 in RT, UT, MPT and DPT PROFILE SUMMARY Performance drive professional with 7 years of expertise in QA/QC, Inspection, Design and construction of Piping/Pipeline, Welding inspection and Project management. Conversant with different welding processes such as SMAW, GTAW. More than 5 year experience in cross country pipeline construction and city gas pipeline construction. Attend more than 100 no’s of shut down for maintenance of existing gas transmission pipeline, Branch pipeline connectivity, above ground piping modification and shifting of buried pipeline. Skilled in taking adequate measures like preparation of necessary documents and conducting internal quality audits to ensure compliance with ISO and other statutory quality standards. An effective communicator and team leader with excellent analytical, interpersonal and problem solving skills. EMPLOYMENT DETAILS Organization: INTERNETIONAL CERTIFICATION SERVICES PVT LTD (ICS) Designation: Inspection Engineer( Third Party Inspection) Duration: 01st March 2014 to Present Client: INDRAPRASTHA GAS LTD, DELHI&NCR (Joint Venture of GAIL, BPCL and Delhi Govt.) Project: Natural Gas pipeline/Piping project and O&M for City Gas Distribution Organization: VCS QUALITY SERVICES PVT LTD (VELOSI) Designation: Inspection Engineer( Third Party Inspection) Duration: May 2013 to 28th Feb 2014 Client: INDRAPRASTHA GAS LTD, DELHI&NCR (Joint Venture of GAIL, BPCL and Delhi Govt.) Project: Natural Gas pipeline/Piping project and O&M for City Gas Distribution RESPONSIBILITIES: Inspection of raw materials & permanent material like mechanical equipment, Pipes, Fittings, and verification of material test reports as per the purchase order and relevant specification requirements. Surveillance of all the major activities of QA/QC like welder qualification test, weld visuals, RT, UT, DPT. Training and directing teams towards identifying factors critical to quality, reducing process variation, Improving capabilities & increase stability to support quality assurance goals. Isolation valve and pipeline testing by hydro testing procedure or pneumatics procedure. Nitrogen(N2) purging during pre-commissioning and re-commissioning of pipeline and plant piping. Survey for MDPE & Carbon steel pipeline laying project and prepare estimation cost. Stage wise inspection of each product as per relevant quality assurance plan as it passes through manufacturing, receiving & construction process to verify compliance with code of construction. Preparation of quality system procedures (Method Statement & Work Instructions) & PQR/ITP/Checklist for different Activities as per client requirement in coordination with Project Manager and Project Engineer. Conduct electrode qualification test for various electrode used in SMAW process. Monitoring of welding work are done as per the requirement of applicable codes/standards, NDT interpretation. Shut down planning and coordinate with client and contractor, execute all activity during shut down. Inspection of Cathodic Protection(CP) system installation, testing and commissioning as per Standard. Inspection steel p/l O&M activity like U/G valve chamber monitoring, TLP monitoring and TR monitoring for CP. Inspection of stringing, Mainline welding, Tie-ins joint, Field joint coating, Trenching, Lowering, Backfilling, and Hydro testing as per Standard specifications and approved procedure. To find coating fault by conducting CIPL and DCVG survey on buried old pipeline and witness coating repair. Coordinate and inspection of maintenance activity of underground pipeline network.

- 2. Checking bill of material, material reconciliation and certify RA bill. Daily progress reports preparation and reporting to management. Conducting regular internal audits and reviews to ensure pre-set norms. An effective communicator with excellent relationship management skills and strong analytical, problem solving. Aware of piping Standards, Codes, and procedures for fabrication, Erection & Welding of plant piping work, International design Codes/Standards such as ASME B31.3, B 31.4, IIC, B31.8, B16.5, API-5L and API 1104 etc. PREVIOUS EXPERIENCE Organization: KALPATARU POWER TRANSMISSION LTD. EPC company in Infrastructure (Oil & Gas Sector / Railways / Building & Factories) and Power Designation: Senior Engineer QA/QC Duration: April 2012 to May 2013 Client: INDIAN OIL CORPORATION LTD Project: Paradip Raipur Ranchi Pipeline Project 14’’&10’’ P/L RESPONSIBILITIES: Entrusted with overall responsibility to manage quality control functions as well as inspection and testing. Job order review, site visiting, Material requisition, controlling manpower & equipment& eventual execution of job in a safe manner. Involved in monitoring as well as ensuring the smooth execution of projects involving vendor evaluation Quality aspects, coordination, etc. Defining quality systems, procedures & work schedules and ensuring strict compliance. Ensure that the subcontractors are qualified as per contract specification and standards to carry out specific jobs activities on site. Study of P&ID and extracted line list, Fabrication and erection of equipment according to the drawings. Monitoring welding activity are done as per the requirement of applicable code/standard. Inspect pipe fit-ups, Alignment and visual inspection of welding. NDT, interpretation of Radiography test films and conduct DPT tests. Organize hydrostatic test (mechanical clearance, header design approval, calibration of test instrument, pigging, gauging, thermal stabilization, pressurization, air volume calculation, leak test during hold period, depressurization, dewatering, swabbing). Preparation of QC documents and method of statements for job execution. Qualify WPS and prepare PQR record as per required by client and conduct WQT. Reviewing all the job procedures, WPS, PQR, ITP, QAP, QCP, IR, according to codes, standards & specifications. To prepare DPR, monthly quality report and updating the Pipe book and Tie-in chart. Activities pertaining to construction of cross-country pipeline like ROU acquisition, visual welding inspection and NDT, lowering, Bending, Tie-in Joints, Field joint coating etc. Organization: INDRAPRASTHA GAS LIMITED ( JOINT VENTURE OF GAIL, BPCL AND DELHI GOVT), Delhi Designation: Project Engineer Duration: March 2010 to April 2012. Projects: Project and O&M of Natural Gas P/L- City Gas Distribution in Delhi & Delhi NCR RESPONSIBILITIES: Station piping Hook-up work for the compressor inlet at CNG station as line layout, to prepare GAD and Isometric, welding inspection, & assembly. P/L locating to third party agency and monitoring third party execution work in vicinity of buried gas pipeline. Survey for new pipeline and design required pipeline diameter as per consumption or looping. Shutdown/ Hot tapping planning and coordination for new pipeline branch. Performing O&M Activity on underground steel pipeline(high pressure gas) and above ground piping of CNG station throughout network(total 570 km), FRS maintenance and set outlet pressure. TLP (Test lead point) and TR installation for Cathodic protection of pipeline, monitoring for Cathodic protection. CAT(current attenuation test) survey for underground P/L for assessing the coating health. Liaising with the authority and third party on matters related to excavation Coordination with contractor and consultant/TPI To moderate Tender document/SOR, Checking RA bill and verify it. Preparation of isometrics, Extraction of MTOs & Preparation of BOM. Isometrics of all lines, Isometrics of Pipe Spools for Fabrication from Layouts, Revision and Updating of Drawings And Documents.

- 3. February 2008 to July 2009 Worked with United Poly Engineering Pvt Ltd, Okhla, New Delhi As Assistant Engineer Responsibilities: Prepare production planning and control(PPC) plan and review production floor Managing the Tool room and Production floor. Die designing for new product and die maintenance supervision. Supervision of manpower and monitoring of machines. CAREER ACHIEVEMENT Completed 14’’x130km and 10’’x160km Cross country pipeline project as a Senior Engineer QA/QC. Laying, testing and commissioning of city gas pipeline diameter 4’’,6’’,8’’,12’’,16’’ in Delhi &NCR. Handled city gas distribution high pressure CS pipeline network over 600KM and perform O&M activity. Attend more than 100nos shut down for gas pipeline shifting dia.4’’ to 18’’ CS pipeline and completed successfully. Gas reconciliation and minimize gas loss. Construction of oil terminal and Inspection of piping fabrication work. WPS qualify for API 5L X70 grade and API 5L X 60 grade Technical Preview: API 1104 (Welding of Pipelines & Related Facilities) API 5L (Specification For Line Pipe) ASME Sec IIC (Specifications for Welding Electrodes and Filler Metals-Materials) ASME Sec V (Non-destructive Examination) ASME Sec VIII (Hydro testing) ASME B16.5 (Pipe, Flanges and Flanged Fittings) ASME B31.3(Process Piping) & ASME B31.8 (Gas Transmission and Distribution Piping Systems) EN 12068:1999 - Cathodic protection. External organic coatings for the corrosion protection of buried or immersed steel pipelines used in conjunction with Cathodic protection. Tapes and shrinkable materials. IT SKILLS Proficient in AutoCAD 2007, Operating Windows XP / Vista & 7, MS Office and Internet Applications PERSONAL DETAILS Name : Sumer Singh Yadav Father’s Name : Shri Balbir Singh Yadav Address : Village + Post- Tofapur, Tehsil- Mawana, District -Meerut, Uttar Pradesh, Pin-250401 Date of Birth : 27 August 1985 Languages Known : English and Hindi Notice Period : One Month DECLARATION I herby affirm that the information in the document is accurate and true to best of my knowledge Date : Sumer Singh Yadav