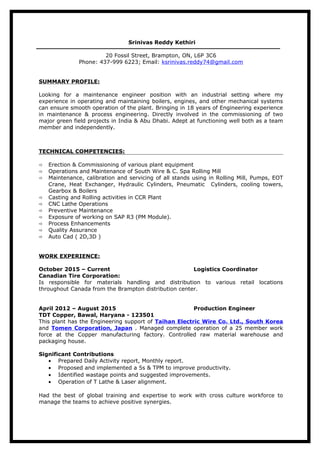

Resume of Srinivas

- 1. Srinivas Reddy Kethiri 20 Fossil Street, Brampton, ON, L6P 3C6 Phone: 437-999 6223; Email: ksrinivas.reddy74@gmail.com SUMMARY PROFILE: Looking for a maintenance engineer position with an industrial setting where my experience in operating and maintaining boilers, engines, and other mechanical systems can ensure smooth operation of the plant. Bringing in 18 years of Engineering experience in maintenance & process engineering. Directly involved in the commissioning of two major green field projects in India & Abu Dhabi. Adept at functioning well both as a team member and independently. TECHNICAL COMPETENCIES: Erection & Commissioning of various plant equipment Operations and Maintenance of South Wire & C. Spa Rolling Mill Maintenance, calibration and servicing of all stands using in Rolling Mill, Pumps, EOT Crane, Heat Exchanger, Hydraulic Cylinders, Pneumatic Cylinders, cooling towers, Gearbox & Boilers Casting and Rolling activities in CCR Plant CNC Lathe Operations Preventive Maintenance Exposure of working on SAP R3 (PM Module). Process Enhancements Quality Assurance Auto Cad ( 2D,3D ) WORK EXPERIENCE: October 2015 – Current Logistics Coordinator Canadian Tire Corporation: Is responsible for materials handling and distribution to various retail locations throughout Canada from the Brampton distribution center. April 2012 – August 2015 Production Engineer TDT Copper, Bawal, Haryana - 123501 This plant has the Engineering support of Taihan Electric Wire Co. Ltd., South Korea and Tomen Corporation, Japan . Managed complete operation of a 25 member work force at the Copper manufacturing factory. Controlled raw material warehouse and packaging house. Significant Contributions • Prepared Daily Activity report, Monthly report. • Proposed and implemented a 5s & TPM to improve productivity. • Identified wastage points and suggested improvements. • Operation of T Lathe & Laser alignment. Had the best of global training and expertise to work with cross culture workforce to manage the teams to achieve positive synergies.

- 2. August 2008 – April 2012 Maintenance Technician Union Copper Rod Factory, Abu Dhabi Was responsible for 8mm copper rod supplied in coils on pallets, for use in the cable industry. The Construction Industry of Middle East has to be fed from planned plant Management to undertake timely execution in compliance with global standards of both American and British ASTM-B49 and BS: EN 1977 Significant Contributions • Merit of having increased Roll Life • Received Cash Reward for reducing IPA Consumption. • Balancing and condition monitoring • Have a clear understanding of Engineering Failure Management Expertise of both Failure Mode and Effects Analysis FMEA and Failure Reporting, Analysis, and Corrective Action System FRACAS May 1997 – July 2008 Senior Process Controller Sterlite Industries India Ltd., India Started my career at Sterlite Industries India Ltd as Process Engineer. Was part of the team for Hot & Cold Commissioning for New CCR Plant & Cooling Tower for Refinery Plant at Tuticorin. In Continuous Catalytic Regeneration (CCR) plant we have faced a corrosion problem at the downstream of regeneration section which was caused by chloride ion contained vent gas. Did the trouble shooting and resolved in a time frame without the plant shut down. Made it operative at 98.7% peak operation Significant Contributions • Efficiently lead Hot & Cold Commissioning for New CCR Plant & Cooling Tower Commissioning for Refinery Plant at Tuticorin in May’05. • Played a vital role in improving CCR plant availability from 95.7% to 98.7% during 2006-2007. Received financial appreciation from the management for the same. • Successfully headed Heat Exchanger Commissioning for CCR. • As Zone Leader for maintenance team, implemented 5S and TPM. • Successfully executed TQM and Continual Improvement Projects in CCR. • LPG Reduction. • Plant Engineering Spare Reduction by 15 % in TPM Project Key Functional Areas: Maintenance Operations Handling the routine preventive maintenance and troubleshooting activities to achieve high productivity by reducing breakdown time. Analyzing each process and machinery involved regarding their specified safety parameters to ensure a safe working environment. Conducting enquiries and investigations of machinery failures, monitoring all the processes involved to take corrective action. Identifying areas and opportunities of improvement, recommending process modifications. Arranging resource requirements such as manpower, machinery, materials and ensuring their optimum utilization. Conduct regular quality inspections for preservation of engineering equipment and stores.

- 3. Project Management Spearheading project activities involving erection & commissioning of various plant equipment and machinery Coordinating projects for the set up standards with accountability for strategic utilization & deployment of available resources to achieve organizational objectives. Planning PMI for machineries as well as ensuring strict adherence to the PMI schedule. Detail Engineering Analysing and producing the technical requirements and specifications & recommending design modifications based on requirements. Monitoring of design, necessary modifications during project engineering stage prior to equipment finalisation for procurement/ erection/ commission in the application. Writing technical documentation and describing the specifications/usage of products. Quality Assurance Developing quality systems by streamlining system procedures, practices and approach, and formulating SOPs and controls for acquiring and maintaining ISO 9000 standards. Conducting regular internal audits, root cause analysis, troubleshooting and reviews to ensure adherence to highest standards. Training and guiding teams towards identifying factors critical to quality, reducing process variation, improving capabilities & increasing stability Administration Planning of daily work schedule and major maintenance and allocation of manpower. Coordinating with other departments to streamline the activities to ensure proper workflow. Ensuring safety of personnel and equipment at working places. Maintaining necessary documentation and preparing reports for analyzing the various processes. Motivating and training the subordinate team members and monitoring their performances Education Graduate from Ambedkar University, India in June 2008 Diploma in Materials Management, All India Council for Management Studies, 1998 ITI Fitter, from Pavan Institute, India in 1994. Second class boiler certificate in October 2002 LANGUAGES: • Telugu Mother tongue • English Fluent • Hindi Fluent • Tamil ,Marathi Basic Reference: Will provide upon Request