WIRAJASA Waste Oil Burner

•

0 j'aime•1,074 vues

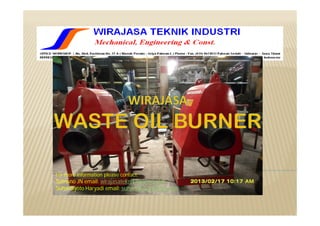

After the introduction of WIRAJASA Waste Oil Burner in 2008, this combustion device is now available in its third generation model. A technology that has entered into its maturity stages. A new design is also carrying an improvement in performance.

Signaler

Partager

Signaler

Partager

Recommandé

Recommandé

Contenu connexe

Tendances

Tendances (19)

Birkosit Sealing Compound for Steam and Gas Turbines

Birkosit Sealing Compound for Steam and Gas Turbines

Similaire à WIRAJASA Waste Oil Burner

Similaire à WIRAJASA Waste Oil Burner (20)

Opportunities of climate and energy efficiency co benefits

Opportunities of climate and energy efficiency co benefits

Plus de Suhardiyoto Haryadi

Plus de Suhardiyoto Haryadi (17)

Democracy and alternative political systems in Asia: After the Strong Men

Democracy and alternative political systems in Asia: After the Strong Men

Formulation of corporate strategy to get successful in rspo and ispo certific...

Formulation of corporate strategy to get successful in rspo and ispo certific...

Excellence in mechanical engineering, a profile of CV Wirajasa Teknik Industri

Excellence in mechanical engineering, a profile of CV Wirajasa Teknik Industri

Composting process and organic fertilizers production

Composting process and organic fertilizers production

Synthetic Asphalt or Bio-Asphalt Production Plant (Bahasa Indonesia)

Synthetic Asphalt or Bio-Asphalt Production Plant (Bahasa Indonesia)

Flowchart of composting and organic fertilizer production plants.

Flowchart of composting and organic fertilizer production plants.

Major equipment of organic fertilizer production plant.

Major equipment of organic fertilizer production plant.

Dernier

Enterprise Knowledge’s Urmi Majumder, Principal Data Architecture Consultant, and Fernando Aguilar Islas, Senior Data Science Consultant, presented "Driving Behavioral Change for Information Management through Data-Driven Green Strategy" on March 27, 2024 at Enterprise Data World (EDW) in Orlando, Florida.

In this presentation, Urmi and Fernando discussed a case study describing how the information management division in a large supply chain organization drove user behavior change through awareness of the carbon footprint of their duplicated and near-duplicated content, identified via advanced data analytics. Check out their presentation to gain valuable perspectives on utilizing data-driven strategies to influence positive behavioral shifts and support sustainability initiatives within your organization.

In this session, participants gained answers to the following questions:

- What is a Green Information Management (IM) Strategy, and why should you have one?

- How can Artificial Intelligence (AI) and Machine Learning (ML) support your Green IM Strategy through content deduplication?

- How can an organization use insights into their data to influence employee behavior for IM?

- How can you reap additional benefits from content reduction that go beyond Green IM?

Driving Behavioral Change for Information Management through Data-Driven Gree...

Driving Behavioral Change for Information Management through Data-Driven Gree...Enterprise Knowledge

Dernier (20)

2024: Domino Containers - The Next Step. News from the Domino Container commu...

2024: Domino Containers - The Next Step. News from the Domino Container commu...

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

Advantages of Hiring UIUX Design Service Providers for Your Business

Advantages of Hiring UIUX Design Service Providers for Your Business

Boost Fertility New Invention Ups Success Rates.pdf

Boost Fertility New Invention Ups Success Rates.pdf

HTML Injection Attacks: Impact and Mitigation Strategies

HTML Injection Attacks: Impact and Mitigation Strategies

Driving Behavioral Change for Information Management through Data-Driven Gree...

Driving Behavioral Change for Information Management through Data-Driven Gree...

From Event to Action: Accelerate Your Decision Making with Real-Time Automation

From Event to Action: Accelerate Your Decision Making with Real-Time Automation

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Understanding Discord NSFW Servers A Guide for Responsible Users.pdf

Apidays Singapore 2024 - Building Digital Trust in a Digital Economy by Veron...

Apidays Singapore 2024 - Building Digital Trust in a Digital Economy by Veron...

How to Troubleshoot Apps for the Modern Connected Worker

How to Troubleshoot Apps for the Modern Connected Worker

Apidays New York 2024 - The value of a flexible API Management solution for O...

Apidays New York 2024 - The value of a flexible API Management solution for O...

Axa Assurance Maroc - Insurer Innovation Award 2024

Axa Assurance Maroc - Insurer Innovation Award 2024

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

Strategies for Unlocking Knowledge Management in Microsoft 365 in the Copilot...

WIRAJASA Waste Oil Burner

- 1. For more information please contact: Sutrisno JN email: wirajasateknik@yahoo.com Suhardiyoto Haryadi email: suhardiyoto@gmail.com

- 2. DEVELOPED IN INDONESIA 4/30/2013WIRAJASA Waste Oil Burner 2 WIRAJASA Waste Oil Burner is designed and developed by an IndonesianWIRAJASA Waste Oil Burner is designed and developed by an Indonesian engineerengineer--entrepreneur.entrepreneur. The iThe inventor is Mr. Sutrisno Jono (picture above), the owner and Director of CV Wirajasa Teknik Industri.

- 3. SUBCRITICAL STEAM IS THE KEY 4/30/2013WIRAJASA Waste Oil Burner 3 WIRAJASA Waste Oil Burner is the first of its kind that applies superheated water or subcritical steam to boost combustion or oxidation of heavy oil. Key principle of this innovative device is basically founded on two essential points: preheating of waste oil and self-generated subcritical steam. One similarity with other waste oil burners developed in the USA and Europe is preheating of waste oil. Other features that distinguish WIRAJASA Waste Oil Burner from other devices include: Water is needed as the source of subcritical steam. Electric power requirement is low (only 8.6 kW). Air compression is required only at the start of operation.

- 4. PROVEN TECHNOLOGY 4/30/2013WIRAJASA Waste Oil Burner 4 The first generation has been in commercial production since 2008 Fabricated to the highest standards to ensure reliability and durability Adjustable operation in accordance with the heating requirements Reuse waste oil that may cause contamination in the environment Suitable for various thermal applications of industrial scale Automated operation by the application of control switchboard

- 5. TECHNICAL SPECIFICATIONS 4/30/2013WIRAJASA Waste Oil Burner 5 Fuel type: waste lubricating motor oil Typical calorific value: 9,600 kcal (compared to diesel oil: 9,000 kcal) Heating Capacity: Minimum 700,000 BTU per hour; Maximum 1,400,000 BTU per hour * Waste Oil Consumption: Minimum 19 liter per hour; Maximum 38 liter per hour Water Consumption: Minimum 5.7 liter per hour; Maximum 11.4 liter per hour Dimensional Sizes 220 L X 90 W X 170 H cm (completely assembled) Approximate weight: 700 kg (completely assembled) * Tentative figures; BTU= British thermal unit

- 6. SYSTEM FLOWCHART 4/30/2013WIRAJASA Waste Oil Burner 6 1 2 3 4 5 6 8 7 9 10 11 12 13 14 15 16 17 18 COMPONENTS 1. Oil inlet valve 2. Water supply 3. Reformer/Reactor Tank 4. Water inlet 5. Water preheating 6. Water level control 7. Steam inlet 8. Oil Inlet 9. Fuel additive 10. Oil valve 11. Steam trap 12. Injecting nozzle 13. Return oil 14. Combustion Chamber 15. Flames 16. Temperature control 17. Pressure gate 18. Safety valve 3rd Generation 1st Generation Compared to its predecessors the current model works on the same principles and accommodates some improvement in performance FLOWCHART

- 7. THE COMBUSTION PROCESS 4/30/2013WIRAJASA Waste Oil Burner 7 Phase 1: Preheating of water to achieve standard temperature of 180 º C. Water turns into a dry steam or sub-critical water and accumulate pressure that is stabilized at 3 bars. Waste oil absorbs heat from the heating water steam and reach a temperature of between 90 and 100º C. Phase 2: Injection or spray of heated, pressurized steam and mix it with heated waste oil mist through an injecting nozzle and shoot the mix into the combustion chamber. The mix of steam particles and heated oil mist will cause oxidation that is also known as combustion or burning and the temperature can reach as high as 400º C.

- 8. THE FIRST & SECOND GENERATION 4/30/2013WIRAJASA Waste Oil Burner 8 Commercial production of Waste Oil Burner was first started in 2008 A new model or the second generation device was introduced in 2010

- 9. THE THIRD GENERATION 4/30/2013WIRAJASA Waste Oil Burner 9 The latest (3rd generation) started commercial production in 2013

- 10. OUR COMMITMENTS 4/30/2013WIRAJASA Waste Oil Burner 10 For each unit delivered, we provide with it: Training of operators Standard Factory Guarantee After-sales services and spare- parts Contact us: CV Wirajasa Teknik Industri, Jalan Abdul Rachman No. 27 A, Pabean Sedati, Sidoarjo 61253, East Java, Indonesia. Telephone/Fax: +6231 8674933 DIRECTOR: Sutrisno JN email: wirajasateknik@yahoo.com Jakarta Representative: Suhardiyoto Haryadi email: suhardiyoto@gmail.com