Observation of the wastes in shipping and receiving - Continuous Improvement Suggestions

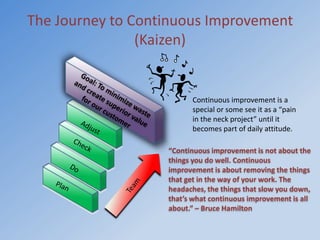

- 1. The Journey to Continuous Improvement (Kaizen) Continuous improvement is a special or some see it as a “pain in the neck project” until it becomes part of daily attitude. “Continuous improvement is not about the things you do well. Continuous improvement is about removing the things that get in the way of your work. The headaches, the things that slow you down, that’s what continuous improvement is all about.” – Bruce Hamilton

- 2. The Concept of Continuous Improvement (Kaizen) • The concept behind continuous improvement is: – Changes are made and continually improved upon – Although perfection will never be achieved, the goal is to continue reaching for it through small improvement – No idea is too small. No area should be untouched. No process is sacred Note: Problems are not scary, but the unknown problems that we can’t see.

- 3. First Step • Adjust • Plan Learn from what happens and turn that into further action • Check Hardest part Talk to the team, listen to them. Identify the problem (ask the 5 why) Closely monitor and analyze what is going on in the experiment Run the experiment • Do

- 4. Emotion vs. Fact • From time to time, when we don’t see the result we want or the process just isn’t what we plan for, we get emotional. I think it’s ok because we are human. But, sometimes it is difficult for us to interpret the fact when we get emotional. Maybe, it’s time for us to show the fact that based on the actual data. Lesson learned: Emotion gets us nowhere.

- 5. 100% customer satisfaction = deliver the right product to the right place at the right time. (JIT – just in time) customers nowadays don’t like to stock up their inventory; instead, they like to place small orders (LTL) with minimum lead times. Cost Saving 100% customer satisfaction Company’s goal: Increase revenue. Reduce cost (labor cost, material cost, transportation cost, operational cost, etc.) Company’s goal seems to be simple – cost reduction. How do we reach the goal with limited resources? Well, we might want to do things a little differently. We might need to focused on some issues we thought are to small to make an impact.

- 6. An example of preventable mistake that we should ask the 5 why 1. Why ship when it says customer pick up. 2. Why don’t you know (if the answer is “I don’t know) 3. Why wasn’t you trained? (If the answer is “Well, I wasn’t train to look at that part) 4. Why no one train you? (If the answer is “because nobody trained me”) 5. Why don’t they have time? (If the answer is “they don’t have time”) Stop right there and go get a trainer to train him!

- 7. Shipment Error When an error like this happened again although we have the help from the scanner reader, that raises a question: Is it the machine error or the human error? If it’s a machine error, it’s not that difficult to fix. But, if it’s a human error, that would be more questions to ask. If it is a lack of focus error, where the human focus is being used and reduce the need for that focus? In other words, there may be waste in the process requiring undo focus of the human that results in shipping errors.

- 8. Communication Flow Between Production Assistant and other departments Information such as Line Item Fill Rate, Shipment Completion, coming up promotions should be shared with shippers.

- 9. Training • • • • Reverse PGI Run the ATP without having TMS to link orders How to tell if orders are linked Actual GI Date MUST match Plan GI date (explain why it is important)

- 10. Standardize Processes Standardized work is the foundation of continuous improvement (Kaizen) • Should we identified locations for completed and incomplete paper work • Should the lead train shippers how to pick and load so we have an idea of the rate (time) to build a pallet • Should all shippers train for export loads so we don’t have to worry the door of the container won’t be able to close Note: It does sound like a pain, but when we do things the same way, I believe the process will be smoother.

- 11. Daily Huddle Constant incremental improvements – “I can do it” “Where does my daily work fit in the ‘big picture’?”

- 12. Week of November 19, 2012 44% is LTL not included the customer pickup. This information is from VL06, orders that PGI between Nov. 19 and Nov. 23. We have only three working days on that week. Continue…

- 13. Week of November 19, 2012 Based on the information on previous slide, this is what we need for the outbound loading ONLY. In these three days of working week, we have average of 13.3 TL and 13.3 LTL, not including customer pickup, and inbound delivery. Takt Time = available working time per day/required time per day (We use this in the production line for downtime, I believe) Assumed we had 6 shippers for these 3 working days. 480 (minutes per day) – (15*2) – (30) = 420 available per day * 6 = 2520 minutes 13.3 TL required 798 minutes (estimate) 13.3 LTL required 399 minutes (estimate Total for both TL and LTL per day = 1197 minutes Total available = 2520 minutes – 1197 (required) = 1323 minutes What do we do with the remaining of 1323 minutes? Average 3.675 hours per shipper Continue…

- 14. Shipping Warehouse Activities Mandatory or optional? If mandatory, need to do it everyday no matter how busy. • • • • 5 S – 30 minutes daily Cycle Count – 20 minutes (When needed) Huddle – 10 minutes daily Pallet Labels – 20 minutes per order (Napa, Walmart, Kmart, Amazon, OSH, Kubota, Sears, Carquest, just to name a few) • Plant Meeting – 1 hour (When needed) • Picking orders – Average 4 hours for a TL

- 15. 7 deadly wastes 1. Defects -- Data entry errors. 2. Overproduction – This is something we can’t control because we don’t decide what to produce. 3. Inventories – Our inventory is pretty good so far, not an issue. 4. Unnecessary motion of employees 5. Transport and handling of goods 6. Waiting 7. Confusion – missing or misinformation.

- 16. Input, Process and Output Input Off Picking loading 5 S 1. Demurrage Charges 2. Over Time 3. Shipment Errors might occurred 4. Messy warehouse 5. Frustrating employees Is the bottleneck avoidable? Maybe not. But, we might be able to minimize it, at least. 1. When we have less working days, plan ahead. 2. Minimize or no export loads when Holiday Seasons we have less working days Unplanned time off 3. Communicate with CSRs Unforeseen promotions 4. Determine how many orders can we do a day. 5. Determine how many workers we need. Output 6. Determine how many hours of OT needed. Process

- 17. Losing Orders From time to time, shippers won’t be able to locate an order that was given by the Production Assistant. How do we prevent this from happening again? •At the end of the day, production assistant should print out a report for all the orders created on that day and pass it to the lead in shipping department. This will make sure that the Production Assistant did print out the order. • When an order pass to a shipper for picking, it should be record on a piece of paper. That way, we clearly know who has which order. This will definitely help us to locate an order quickly.

- 18. As you can see the process takes a long time. But, if we could schedule the shipment and control the cut off date, I believe the lead time will be shorten.

- 19. Feb 4 – Feb 8 A glance of the regular 5 working days week.

- 20. Continue Feb 4 – Feb 8 35 34 35 30 25 Inbound Truck Load 20 17 16 Export LTL 15 Will Call UPS 10 4 3 5 0 Inbound Truck Load Export LTL Will Call UPS Note: We have two hours to load a truck. After that, we will be charged for waiting. UPS Freight is exception.