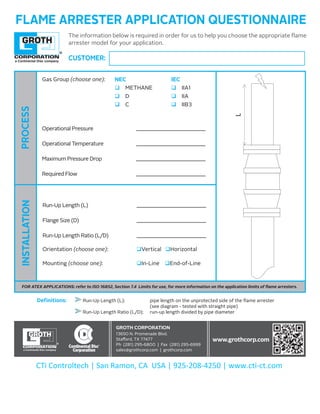

Flame Arrester Application Questionnaire

•

1 j'aime•861 vues

Deflagration Flame Arresters are fire safety devices used to protect stored or process media from deflagrations. A deflagration flame arrester can be used on the top of a tank in certain conditions, as an in-line safety device where combustible gases are transported through low pressure pipe lines.

Signaler

Partager

Signaler

Partager

Télécharger pour lire hors ligne

Recommandé

Contenu connexe

Tendances

Tendances (20)

Flowseal MS Series - Triple Offset Butterfly Valves

Flowseal MS Series - Triple Offset Butterfly Valves

ISTEC Aquametro Chemical Flowmeter - Domino Series

ISTEC Aquametro Chemical Flowmeter - Domino Series

Industrial Boiler and Burner Limit Control Switches

Industrial Boiler and Burner Limit Control Switches

Trunnion Mount Ball Valves For Industrial Pipelines

Trunnion Mount Ball Valves For Industrial Pipelines

Severe Service Control & Isolation Valves in the Refining Industry

Severe Service Control & Isolation Valves in the Refining Industry

Hytork Pneumatic Actuators for Industrial Process Control

Hytork Pneumatic Actuators for Industrial Process Control

Similaire à Flame Arrester Application Questionnaire

Similaire à Flame Arrester Application Questionnaire (20)

IRJET- CFD Analysis of Flow through Integral Orifice Plate Assemblies Under D...

IRJET- CFD Analysis of Flow through Integral Orifice Plate Assemblies Under D...

40 CFR 98 Tier 4 Greenhouse Gas Reporting with Stack Emissions Flow Meter

40 CFR 98 Tier 4 Greenhouse Gas Reporting with Stack Emissions Flow Meter

Pressure piping thickness and flange rating calculation 2

Pressure piping thickness and flange rating calculation 2

Comparative Study Between Cross Flow Air To Air Plate Fin Heat Exchanger With...

Comparative Study Between Cross Flow Air To Air Plate Fin Heat Exchanger With...

IRJET- A Case Study: In-Situ Weld Repair of Steel Casting of Grade C12A AST...

IRJET- A Case Study: In-Situ Weld Repair of Steel Casting of Grade C12A AST...

Plus de CTi Controltech

Plus de CTi Controltech (20)

Flowserve Valve, Actuation and Instrumentation Portfolio

Flowserve Valve, Actuation and Instrumentation Portfolio

Electric Control Valve Actuators for Industrial Process Applications

Electric Control Valve Actuators for Industrial Process Applications

Integrated Flame Scanner For Commercial and Industrial Combustion Operations

Integrated Flame Scanner For Commercial and Industrial Combustion Operations

Controlling Cavitation in Industrial Control Valves

Controlling Cavitation in Industrial Control Valves

Seven recommendations for bolstering industrial control system cyber security

Seven recommendations for bolstering industrial control system cyber security

Digital valve positioner for industrial process control valves

Digital valve positioner for industrial process control valves

Victory Energy Firetube Boiler for extreme duty - Frontier Series

Victory Energy Firetube Boiler for extreme duty - Frontier Series

Trunnion Mount Ball Valve Double Block and Bleed Assembly

Trunnion Mount Ball Valve Double Block and Bleed Assembly

Dernier

College Call Girls Nashik Nehal 7001305949 Independent Escort Service Nashik

College Call Girls Nashik Nehal 7001305949 Independent Escort Service NashikCall Girls in Nagpur High Profile

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur EscortsCall Girls in Nagpur High Profile

Dernier (20)

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

College Call Girls Nashik Nehal 7001305949 Independent Escort Service Nashik

College Call Girls Nashik Nehal 7001305949 Independent Escort Service Nashik

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

Introduction to IEEE STANDARDS and its different types.pptx

Introduction to IEEE STANDARDS and its different types.pptx

Structural Analysis and Design of Foundations: A Comprehensive Handbook for S...

Structural Analysis and Design of Foundations: A Comprehensive Handbook for S...

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Isha Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Isha Call 7001035870 Meet With Nagpur Escorts

(MEERA) Dapodi Call Girls Just Call 7001035870 [ Cash on Delivery ] Pune Escorts![(MEERA) Dapodi Call Girls Just Call 7001035870 [ Cash on Delivery ] Pune Escorts](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![(MEERA) Dapodi Call Girls Just Call 7001035870 [ Cash on Delivery ] Pune Escorts](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

(MEERA) Dapodi Call Girls Just Call 7001035870 [ Cash on Delivery ] Pune Escorts

result management system report for college project

result management system report for college project

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

(ANJALI) Dange Chowk Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...![(ANJALI) Dange Chowk Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![(ANJALI) Dange Chowk Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

(ANJALI) Dange Chowk Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...

VIP Call Girls Service Kondapur Hyderabad Call +91-8250192130

VIP Call Girls Service Kondapur Hyderabad Call +91-8250192130

Sheet Pile Wall Design and Construction: A Practical Guide for Civil Engineer...

Sheet Pile Wall Design and Construction: A Practical Guide for Civil Engineer...

Flame Arrester Application Questionnaire

- 1. FLAME ARRESTER APPLICATION QUESTIONNAIRE Definitions: Run-Up Length (L): pipe length on the unprotected side of the flame arrester (see diagram - tested with straight pipe) Run-Up Length Ratio (L/D): run-up length divided by pipe diameter The information below is required in order for us to help you choose the appropriate flame arrester model for your application.NEC Methane D C B A IEC IIA1 IIA IIB1 IIB2 IIB3 IIB IIC Pre-Ignition Pressure Pre-Ignition Temperature Maximum Pressure Drop Required Flow Max Allow Working Pressure Run-Up Length (L) Flange Size (D) L / D : OMER: Gas Group (circle one) L Groth in-line deflagration flame arresters must be installed at or within 10 pipe diameters of the source of ignition and are only approved for gas groups IIA1 / Methane, pre-ignition pressures at or below 15.7 psia, and pre-ignition temperatures at or below 140°F. Groth end-of-line deflagration flame arresters must be installed at or within 10 pipe diameters of the end of a vent pipe and are only approved for gas groups IIA / D, pre-ignition pressure at or below 14.7 psia (atmospheric), and pre-ignition temperatures at or below 140°F. Orientation (circle one) HorizontalVertical Location (circle one) In-Line End-of-Line 10/5/2011 PROCESSINSTALLATION Gas Group (choose one): NEC IEC q METHANE q IIA1 q D q IIA q C q IIB3 Operational Pressure ________________________ Operational Temperature ________________________ Maximum Pressure Drop ________________________ Required Flow ________________________ Run-Up Length (L) ________________________ Flange Size (D) ________________________ Run-Up Length Ratio (L/D) ________________________ Orientation (choose one): qVertical qHorizontal Mounting (choose one): qIn-Line qEnd-of-Line CUSTOMER: FOR ATEX APPLICATIONS: refer to ISO 16852, Section 7.4 Limits for use, for more information on the application limits of flame arresters. GROTH CORPORATION 130 N. Promenade Blvd. Stafford, TX Ph (281) 2-800 | Fax (281) 2- sales@grothcorp.com | grothcorp.com THE NETHERLANDS Energieweg 20 2382 NJ Zoeterwoude-Rijndijk The Netherlands Ph +(31) 1 12221 | Fax +(31) 1 131 cdcnl@contdisc.com CHINA Room 10, Tower B, COFCO Plaza No. 8 JianGuoMenNei Avenue Beijing (10000), P.R. China Ph +(86) 10 22 88 | Fax +(86) 10 22 288 cdcchina@contdisc.com INDIA 23/P/1, Mahagujarat Industrial Estate, Moraiya, Sarkhej-Bavla Road, Ahmedabad (GJ) 382213 INDIA Ph +(1) 21 1 333 | Fax +(8) 10 22 288 gcmpl@contdisc.com www.grothcorp.com Continental Disc Corporation reserves the right to alter the information in this publication without notice. // © 2012 Groth Corporation Reproduction without written permission is prohibited. LIT1083 // 0812 CTi Controltech | San Ramon, CA USA | 925-208-4250 | www.cti-ct.com