Ijrdtvlis26 1426106

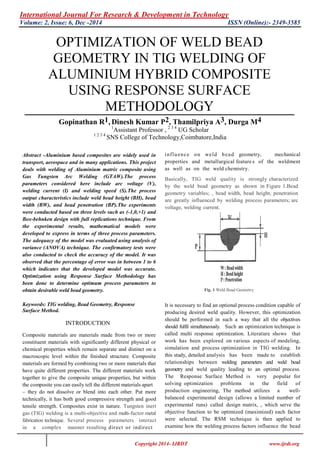

- 1. International Journal For Research & Development in Technology Volume: 2, Issue: 6, Dec -2014 ISSN (Online):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY Gopinathan R1, Dinesh Kumar P2, Thamilpriya A3, Durga M4 1 Assistant Professor , 2 3 4 UG Scholar 1 2 3 4 SNS College of Technology,Coimbatore,India Abstract -Aluminium based composites are widely used in transport, aerospace and in many applications. This project deals with welding of Aluminium matrix composite using Gas Tungsten Arc Welding (GTAW).The process parameters considered here include arc voltage (V), welding current (I) and welding speed (S).The process output characteristics include weld bead height (BH), bead width (BW), and bead penetration (BP).The experiments were conducted based on three levels such as (-1,0,+1) and Box-behnken design with full replications technique. From the experimental results, mathematical models were developed to express in terms of three process parameters. The adequacy of the model was evaluated using analysis of variance (ANOVA) technique. The confirmatory tests were also conducted to check the accuracy of the model. It was observed that the percentage of error was in between 1 to 6 which indicates that the developed model was accurate. Optimization using Response Surface Methodology has been done to determine optimum process parameters to obtain desirable weld bead geometry. Keywords: TIG welding, Bead Geometry, Response Surface Method. INTRODUCTION Composite materials are materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct on a macroscopic level within the finished structure. Composite materials are formed by combining two or more materials that have quite different properties. The different materials work together to give the composite unique properties, but within the composite you can easily tell the different materials apart – they do not dissolve or blend into each other. Put more technically, it has both good compressive strength and good tensile strength. Composites exist in nature. Tungsten inert gas (TIG) welding is a multi-objective and multi-factor metal fabrication technique. Several process parameters interact in a complex manner resulting direct or indirect influence on weld bead geometry, mechanical properties and metallurgical feature s of the weldment as well as on the weld chemistry. Basically, TIG weld quality is strongly characterized by the weld bead geometry as shown in Figure 1.Bead geometry variables; , bead width, bead height, penetration are greatly influenced by welding process parameters; arc voltage, welding current. Fig. 1 Weld Bead Geometry It is necessary to find an optional process condition capable of producing desired weld quality. However, this optimization should be performed in such a way that all the objectives should fulfil simultaneously. Such an optimization technique is called multi response optimization. Literature shows that work has been explored on various aspects of modeling, simulation and process optimization in TIG welding. In this study, detailed analysis has been made to establish relationships between welding parameters and weld bead geometry and weld quality leading to an optimal process. The Response Surface Method is very popular for solving optimization problems in the field of production engineering, The method utilizes a well- balanced experimental design (allows a limited number of experimental runs) called design matrix, , which serve the objective function to be optimized (maximized) each factor were selected. The RSM technique is then applied to examine how the welding process factors influence the bead

- 2. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org geometry; bead width (BW), bead height (BH), penetration (P). An o p ti mal p ar amet er co mb i nat io n w a s t h e n obtained. Through analyzing the design matrix, the most influential factors for individual quality targets of TIG welding process can be identified. Additionally, the analysis of variance (ANOVA) was also utilized to examine the most significant factors for the bead geometry in TIG welding process. RESPONSE SURFACE METHODOLOGY Engineers often wish to determine the values of the process input parameters at which the responses reach their optimum. RSM is one of the optimization techniques currently in widespread use in describing the performance of the welding process and finding the optimum of the responses of interest. When all independent variables are measurable, controllable and continuous in the experiments, with negligible error, the response surface can be expressed by y = f (x1, x2… xk) ______________________(1) k is the number of independent variables. To optimize the response „„y‟‟, it is necessary to find an appropriate approximation for the true functional relationship between the independent variables and the response surface. Usually a second-order polynomial Eq. (2) is used in RSM . y = bo +∑biXi +∑biiX2ii+∑bijXiXj+ --------------- (2) The test was designed based on a three factors-three levels central box-behnken design with full replication. The TIG welding input variables are arc voltage (V), welding current (I), welding speed (S) as shown below in Table 1. Table 1 Parameters and level Parameter Notation Units Factor levels -1 0 1 Arc Voltage V Volts 25 30 35 Welding Current I Amps 90 120 150 Welding Speed S Cm/min 24 36 48 A Box-Behnken design matrix shown in table 2 consisting of15 sets of coded conditions was selected to conduct the experiments. Table 2 Box-Behnken design matrix Exp.No. Arc Voltage (V) Welding Current (A) Welding Speed (m/min) 1 -1 -1 0 2 1 -1 0 3 -1 1 0 4 1 1 0 5 -1 0 -1 6 1 0 -1 7 -1 0 1 8 1 0 1 9 0 -1 -1 10 0 1 -1 11 0 -1 1 12 0 1 1 13 0 0 0 14 0 0 0 15 0 0 0 EXPERIMENTAL SETUP In this project Al 2024 matrix composite, Aluminium alloy 2024 consists of mainly copper and magnesium as the alloying elements. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is not weldable, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al- 1Zn for protection, although this may reduce the fatigue strength For welding, the material was made into specimens with the dimensions of 140×25×6mm RESULT AND DISCUSSION The objective of the present study is to establish relationships between the process parameters (inputs) and process responses (outputs) in GTAW welding; using the statistical regression analysis carried out on the data collected as per Response surface method design of experiments (DOE). The most important process parameters in GTAW are the arc voltage (V); welding current (I); and welding speed (S). The process response characteristics considered are bead height (BH), Bead Width (BW), Bead Penetration (BP). The levels for each of the input parameters are given in Table 1. Therefore, 15 combinations of input process parameter are shown.

- 3. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org Table 3 Experimental design matrix and results Exp.No. Arc Voltage (V) Welding Current (A) Welding Speed (m/min) Bead Width (BW) (mm) Bead Height (BH) (mm) Bead Penetration (BP) (mm) 1 25 90 0.36 5.843 1.193 3.284 2 35 90 0.36 8.178 1.856 3.375 3 25 150 0.36 8.760 1.870 3.196 4 35 150 0.36 8.146 1.874 3.210 5 25 120 0.24 7.236 1.437 2.986 6 35 120 0.24 9.660 2.179 2.680 7 25 120 0.48 5.894 1.582 3.125 8 35 120 0.48 6.265 1.101 3.653 9 30 90 0.24 9.147 1.815 3.394 10 30 150 0.24 7.580 1.455 3.128 11 30 90 0.48 6.168 1.308 3.720 12 30 150 0.48 8.946 1.657 2.607 13 30 120 0.36 6.480 1.749 2.990 14 30 120 0.36 6.125 1.535 2.721 15 30 120 0.36 6.192 1.712 2.680

- 4. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org Different regression functions (Linear, Linear plus square and quadratic model) are fitted to the above data a n d t h e coefficients values are calculated using regression analysis. The best model is the most fitted function to the experimental data. Such a model can accurately represent the actual GTAW process. Therefore In this research, the adequacies of various functions have been evaluated using analysis of variance (ANOVA) technique. The model adequacy checking includes test for significance of the regression model and test for significance on model coefficients .The ANOVA results recommend that the curvilinear model is the best fit in this case. The Stepwise elimination process removes the insignificant terms to adjust the fitted quadratic model. The final proposed models are presented below: The associated P-value for this model is lower than 0.05; i.e. α=0.05 or 95% confidence level. This illustrates that the model is statistically significant. Quadratic regression equations for bead width, bead height, bead penetration are given below: Bead Width, BW = 25.987 + 0.08715 × (V) 0.2324 × (I) - 47.82 × (S) + 0.0153 × (V2) + 0.0012 × (I2) + 42.589 × (S2 ) - 0.00491 × (V) × (I) - 0.855 × (V) × (S) + 0.3017 × (I )× (S) Bead Height, BH = -6.258 + 0.279 × (V) + 0.0158 × (I) + 13.841 × (S) + 0.000978× (V2) + 0.000009 × (I2) - 7.989 × (S2 ) - 0.00109× (V) × (I) - 0.509 × (V) × (S) + 0.0492 × (I )×(S) Bead Penetration, BP = 16.1319- 0.54312 × (V) - 0.05784 × (I) – 8.911 × (S) + 0.00736 × (V2) + 0.000316 × (I2) + 9.0277 × (S2 ) - 0.000128 × (V) × (I) + 0.3475× (V) ×(S) - 0.0588 × (I )× (S) From the above equation, V = Arc Voltage I = Welding Current S = Welding Speed Correlation factor (R2) for each term of the three models. Based on ANOVA, the values of R2 in quadratic model are over 75% for all weld bead characteristics. This means that this model provides an excellent representation of the actual process in terms of BH, BW and BP responses equation. Figure 2 shows TIG welding specimen. After welding, specimen cut into required dimensions of 50 x 10 x 6 mm. for analysis of weld bead geometry using profile projector (Mitutoyo PJ-A3000). Weld bead specimen shows in Fig 3. Fig. 2 TIG Welding specimen Fig. 3 After welded specimen

- 5. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org Table 4 Experimental Results & Predicted Results Exp.No. Bead Width (mm) Predicted Bead Width (mm) Bead Height BH (mm) Predicted Bead Height (mm) Bead Penetration BP (mm) Predicted Bead Penetration (mm) 1 5.843 5.918 1.193 1.332 3.284 3.410 2 8.178 8.522 1.856 1.893 3.375 3.530 3 8.760 8.417 1.870 1.832 3.196 3.040 4 8.146 8.071 1.874 1.735 3.210 3.083 5 7.236 6.979 1.437 1.307 2.986 3.164 6 9.660 9.135 2.179 2.151 2.680 2.828 7 5.894 6.418 1.582 1.609 3.125 2.976 8 6.265 6.521 1.101 1.230 3.653 3.475 9 9.147 9.328 1.815 1.805 3.394 3.089 10 7.580 8.179 1.455 1.621 3.128 3.105 11 6.168 5.568 1.308 1.141 3.720 3.742 13 6.480 6.265 1.749 1.665 2.990 2.797 14 6.125 6.265 1.535 1.665 2.721 2.797 15 6.192 6.265 1.712 1.665 2.680 2.797

- 6. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org R-Sq(adj) 0.624 0.584 Fratio (calculated) 16.06 3.37 Fratio (from table) (3,2,0.05) 19.16 19.16 19.16 Whether the model is adequate? Yes Bead width (BW) First-order terms Sum of 9.6867 0.3577 0.4514 Degrees of freedom (dof) Mean square (MS) 3.2289 0.1192 0.1504 Second-order terms Sum of 13.5681 0.662 0.7875 Degrees of freedom (dof) Mean square (MS) 2.2614 0.1103 0.1312 Error terms Sum of 0.07172 0.02616 0.05671 Degrees of freedom (dof) Mean square (MS) 0.0356 0.01308 0.02836 Lack of fit Sum of 1.7144 0.1322 0.3737 Degrees of freedom (dof) Mean square (MS) 0.5715 0.04407 0.1246 0.929 0.866 0.742 ANALYSIS OF VARIANCE The purpose of analysis of Variance is to investigate which welding parameters significantly affect the performance characteristics. This is accomplished by separating the total variability of the grey relational grades, which is measured by the sum of the squared deviations from the total mean of the grey relational grade, into contributions by each welding parameters and the error. In addition, the F test was used to determine which welding parameters have a significant effect on the performance characteristic. Usually, the change of the welding parameter has a significant effect on the performance characteristic when the F value is large. ANOVA results for overall weld bead geometry is shown in Table 5 Table 5 ANOVA test results Result of the ANOVA indicates that the welding speed is the most effective parameter on the responses under the multi criteria optimization (higher penetration, lower bead width, bead height). The percent contributions of other parameters are arc voltage and current not more effective compare than welding speed. For illustrative purpose, the distributions of real data around regression lines for quadratic model are illustrated in Fig. to. These figures demonstrate a good conformability of the developed models t the real process. Fig. 4 Predicted values for BW vs. actual values

- 7. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org Bead Width 6.422 mm Bead Height 1.238 mm Penetration 3.464 mm Fig. 5 Predicted values for BH vs. actual values Fig. 6 Predicted values for BP vs. actual values OPTIMIZED PARAMETER From the above design of experiment results using MINITAB software and the experimental values of the response (Bead geometry characteristics) the optimized parameter can be shown in Table 5 and 6. Table 6 Optimized process parameter Arc Voltage 35 Volts Welding Current 120 Amps Welding Speed 48 c/min Table 7 Optimized bead parameter The optimized parameter given above can be the best parameter condition for TIG welding of copper matrix composite. CONCLUSION Response surface method (RSM) can be effectively used to find optimum condition for TIG welding copper matrix composite. Essential requirements for all types of welding are deep penetration, lower bead width and bead height for reducing weld metal consumption. This study has concentrated on the application of response surface method for solving multi criteria optimization problem in the field of tungsten inert gas welding process. The optimum condition of process parameter is found to be V=35 Volts, I=120 Amps, S=48 cm/min. The optimum condition of weld bead parameter is found to be BW=6.422 mm, BH=1.238mm, BP= 3.464 mm. REFERENCES [1]. Jiang Qjnglei, Li Yajiang “Microstructure characteristics in TIG welded joint of Mo-Cu composite and 18-8 stainless steel” Int. Journal of Refractory Metals & Hard Materials 28(2010), Page no.(429-433). [2]. Wang Xi-he, Niu Ji-tai “Investigation on TIG welding of SICp-reinforced aluminium-matrix composite using mixed shielding gas and Al-Si filler” Materials science and Engineering A 499 (2009), Page no.(106-110). [3]. Ugur Esme , Melih Bayramoglu “Optimization of weld bead geometyin TIG welding process using grey relation analysis and taguchi method” Original scientific article MTAEC9 ,43(3) (2009), Page no. (143-149). [4]. A.Kokangul,M.Bayramoglu “Mathematical modeling for prediction and optimization of TIG welding pool geometry” METABK 48(2) (2009), Page no. (109-112). [5]. Manoj Singla, Dharinder Singh “Parametric optimization of gas metal arc welding processes bu using factorial design approach ” Journal of Minerals & Materials Characterization & Engineering, Vol.9,No.4, (2010), Page no. (353-363). [6]. P.K.Palani, N.Murugan “Selection of parameters of pulsed current gas metal arc welding”, Journal of Materia; Processing Technology, Vol.No. 172, (2006), Page no.(1-10) [7]. Jianjun WU, Guobin LI “Copper Matrix Composites Reinforced with Nanometer Alumina Particle” Journal of Materials science and Technology, Vol.15 No.2 (1999) Page no. (143-146).

- 8. International Journal For Research & Development in Technology Paper Title:- OPTIMIZATION OF WELD BEAD GEOMETRY IN TIG WELDING OF ALUMINIUM HYBRID COMPOSITE USING RESPONSE SURFACE METHODOLOGY (Vol.2, Issue-6) ISSN(O):- 2349-3585 Copyright 2014- IJRDT www.ijrdt.org [8]. JIANG Long-tao, WU Gao-hui “Fabrication and characterization of high dense Mo/Cu composites for electronic packaging applications” Trans.Nonferrous Met.Soc. China 17(2007) Page no. (580-583). [9]. A. Włodarczyk-Fligier, L.A. Dobrzański “Manufacturing of aluminium matrix composite materials reinforced by Al2O3 particles” Journal of Achievements in Materials and Manufacturing Engineering, Vol.27 (2008) Page no. (99-102). [10]. Viseslava Rajkovic, Dusan Bozic “Effect of copper and Al2O3 particles on characteristics of Cu-Al2O3 composites” Materials and Design 31(2010) Page no. (1962- 1970)