Borkay Kataloglar Asly Yng

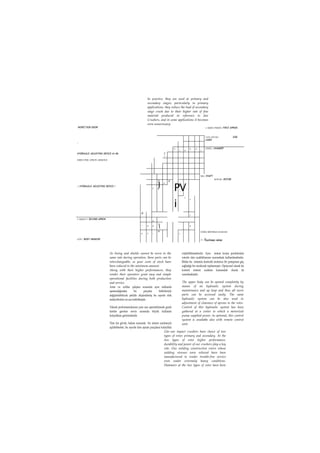

- 1. In practice, they are used at primary and secondary stages; particularly in primary applications, they reduce the load of secondary stage crush due to their higher rate of fine material produced in reference to Jaw Crushers, and in some applications it becomes even unnecessary. INSPECTION DOOR 1. KIRICI PERDE / FIRST APRON YAN ASTAR / SIDE LINER / • 0 0 0 CEKİÇ / HAMMER o © o HYDRAULIC ADJUSTING DEVICE At Mk 7 / KIRICI PER/ APRON ARMOUR MiL/ SHAFT ROTOR / ROTOR 0 d J PV © / / HYDRAULIC ADJUSTING DEVICE / 0 l i 1 0 O a 2. KIRICI P SECOND APRON ■ - ■ ■ ■ 0 CEKİÇ SIRTIRMA KAMASI/ O 0 c o GÖV / BODY ARMOUR — TIGHTENING WEDGE As lining and shields cannot be worn in the erişilebilinmektedir. Aynı sistem kırma perdelerinin same rate during operation, these parts can be rotorla olan uzaklıklarının ayarındada kullanılmaktadır. interchangeable, so your costs of stock have Bütün bu sistemin kontrolü motorize bir pompanın güç been reduced to the minimum amount. sağladığı bir merkezde toplanmıştır. Opsiyonel olarak bu Along with their higher performances, they kontrol sistemi uzaktan kumandalı olarak da render their operators great easy and simple sunulmaktadır. operational facilities during both production and service. The upper body can be opened completely by Astar ve zırhlar çalışma sırasında aynı miktarda means of an hydraulic system during aşınmadığından bu parçalar birbirleriyle maintenance and up keep and thus all worn değiştirilebilecek şekilde düşünülmüş bu sayede stok parts can be accessed easily. The same maliyetleriniz en aza indirilmiştir. hydraulic system can be also used in adjustment of clearance of aprons to the rotor. Yüksek performanslarının yanı sıra operatörünede gerek Control of this hydraulic system has been üretim gerekse servis sırasında büyük kullanım gathered at a center to which a motorized kolaylıkları getirmektedir. pump supplied power. As optional, this control system is available also with remote control Tüm üst gövde, bakım sırasında bir sistem yardımıyla unit. açılabilmekte, bu sayede tüm aşınan parçalara kolaylıkla Gür-san impact crushers have choice of two types of rotor; primary and secondary. At the two types of rotor higher performance, durability and power of our crushers play a key role. Our welding construction rotors whose welding stresses were relieved have been manufactured to render trouble-free service even under extremely heavy conditions. Hammers at the two types of rotor have been

- 2. designed to be used as reverse and plain; and at primary type rotors, to be replaced both from side and top. Primary type rotors can accommodate hammer of higher chromium alloy in order to break abrasive material at the same time. Surfaces of hammer which leaned against rotor have been ground for full contact and tightly fixed to the rotor by key tightening system. This reduce breakage risk of hammer down to minimum and make it possible to produce rather harder materials. IMPACT CRUSHERS Armour plates at the opposite surfaces to which rotor threw material have been fixed on surfaces of body with key inserts, which facilitates use of approximately entirety of the armour and additionally ensures disassembly- reassembly operations are completed within shortest possible time. Gür-san impact crushers have been equipped with protection system against pieces of metal that may be found in the fed material in order to render fault-free and uninterrupted service. SJH

- 3. This protection system, in case of entering any unbreakable material into the crusher, causes automatically remove away aprons from rotor and allow such unbreakable materials to pass through without causing damage to the machine; and upon completion of the operation it allows aprons to turn back their originally adjusted position and continues its fault-free operation. DARBELİ KIRICILAR GRADASYON TABLOSU IMPACT CRUSHERS GRADATION CHART Aşağıdaki tablo, kalker malzemenin kırımında birinci kırıcı perde 50 mm, ikinci kırıcı perde 25 mm açıklığında ayarlandığı durumda değişik rotor hızlarındaki gradasyon dağılımlarını göstermektedir. The chart at below approximate gradation at various when braker plate settings of 50 mm and 25 mm. ÜRÜN BOYUTU ROTOR HIZI ROTOR SPEED PRODUCT SIZE 20m/s (3900 fpm) 27m/s (3900 fpm) 33m/s (6500 fpm) 41m/s (3900 fpm) Gradation will vary depending on particle size of feed, rate of feed, hardness of rock and natural breaking characterictics. T E K N İ K Ö Z E L L İ K L E R / SPECIFICATIONS K34/K34P A 1040 mm 41" B 884 mm 35" C 3135 mm 10'-3" D 1905 mm 75" E 1435 mm 57" F 3280 mm 10'-9" G 1044 mm 41" H 2470 mm 8'-1" J 1520 mm 60" K37/K37P

- 4. GLRSAN............................................................................4 GLRSAN..........................................................................14 GLRSAN..........................................................................25 GLRSAN...............................................................................69 GURSAN........................................................................109 RI^h âti....................................................................................118 S'ESİFİKASYONLAR SPECIFICATIONS INLET WIDTH INLET HIGHT ROTOR DIAM. ROTOR WIDTH POWER K34 1040 mm 41" 880 mm 35" 01250 mm 49" 1000mm 39" 220 HP 160 KW K34/P 1040 mm 41" 880 mm 35" 01250 mm 49" 1000mm 39" 220 HP 160 KW K37 1290 mm 51" 880 mm 35" 01250 mm 49" 1250mm 49" 270 HP 200 KW K37/P 1290 mm 51" 890 mm 35" 01250 mm 49" 1250mm 49" 270 HP 200 KW K39 1540 mm 61" 890 mm 35" 01250 mm 49" 1500mm 59" 350 HP 250 KW K40 2040 mm 80" 890 mm 35" 01250 mm 49" 2000mm 78" 2x270 HP 2x200 KW K38 1540 mm 61" 1350 mm 53" 01400 mm 55" 1500mm 59" 2x180HP 2x132 KW K41 2040 mm 80" 1600 mm 63" 01600 mm 63" 2000mm 78" 2x270 HP 2x200 KW MAX. FEED SIZE CAPACITY QUANTITY OF WEIGHT OF THE STANDART IMPACT BARS IMPACT BARS ROTOR RPM K34 550 mm 22" 140-200 mtph 150-220 4 160 kg 353 LBS 550 RPM stph K34/P 700 mm 26" 140-350 mtph 155-385 4 295 kg 650 LBS 550 RPM stph K37 550 mm 22" 160-250 mtph 180-275 8 100 kg 220 LBS 550 RPM stph K37/P 700 mm 26" 160-500 mtph 180-550 4 365 kg 805 LBS 550 RPM stph K39 550 mm 22" 250-350 mtph 275-385 8 120 kg 265 LBS 550 RPM stph K40 550 mm 22" 350-600 mtph 385-660 8 160 kg 353 LBS 550 RPM stph K38 1000 mm 39" 250-600 mtph 275-660 4 580 kg 1280 LBS 490 RPM stph K41 1300 mm 51" 600-900 mtph 660-990 4 900 kg 1985 LBS 430 RPM stph GLRSAN İNŞAAT MAKİNALARI SANAYİ LTD. ŞTİ. / CONSTRUCTION MACHINES INDUSTRY LTD. CO. Küçük Sanayi 3. Cadde No: 101 06930 Sincan - ANKARA / TURKEY Tel: +90. 312 269 20 23 - 269 32 67 • Fax: +90. 312 269 32 38 w e b : w w w . g u r - s a n . c o m . t r • e-mail: i n f o @ g u r - s a n . c o m . t r

- 5. ÇENECrKlRİCİtAR/ JAW CRUSHERS GÜRSAN çeneli kırıcıları yumuşak kalker den, en sert GÜRSAN Jaw Crushers have been designed so as bazalt'a kadar her türden malzemeyi kıra bilmek üzere to be capable of crushing all kinds of materials tasarlanmışlardır. ranging from soft limestone to hardest basalt. We have 9 different types of Primary and 150 x 100 mm (6"x4") labrotuar tipinden 1300 x 1100 mm Secondary type Jaw Crushers from laboratory (51"x43") ağız açıklığına kadar 9 ayrı tipde Primer ve type with 150 x 100 mm (6"x4") feed opening to Sekonder tip çeneli kırıcımız bulunmaktadır. 1300 x 1100 mm (51"x43")jaw gap. Our Jaw Crushers' high flywheel speeds, jaw Çeneli kırıcılarımızın yüksek volan hızları, çene kapma grabbing angles, pitmans' toggle plates and rear açıları, pitmanlarmm emniyet plakaları ve arka blokları ile blocks as well as their higher performances based olan özel geometrilerinin getirdiği yüksek performansları, on their special geometry, their durability and güvenilirlikleri, dayanıklılıkları ve kullanıcı dostu ayar user friendly adjustment mechanisms provide mekanizmaları kullanıcılarına eşsiz işletme avantajları their users great and unique operational sağlamaktadır. advantages. BESLEME OLUĞU / feed box . VOLAN / fly wheel PİTMAN RULMANI / pitman koruma astarı / __ PITMAN FACE PROTECTION PITMAN BEARING PLATE SEYYAR CENE KAMASI / TIGHTENING WEDGE OF SWINGING JAW sabit cene kaması / TIGHTENING WEDGE OF FIXED JAW SIKTIRMA YAYI / TIGHTENING SPRING SABİT CENE ÜST KAMA SAPLAMASI / fixed jaw upper tightening bolt R SABİT CENE / fixed jaw O EGZANTRİKMİL / ECCENTRIC SHAFT SEYYAR CENE ÜST kaması saplaması / SWINGING JAW LOWER TIGHTENING BOLT SIKTIRMA YAYI / tightening spring PİTMAN / pitman AYAR PLAKASI / adjusting shims AYAR PİSTONU / yan üst astar / UPPER CHEEK PLATE ADJUSTMENT PISTON yan alt astar / LOWER CHEEK PLATE GERGİ SAPLAMASI YAYI / tension spring seyyar cene / SWINGING JAW ayar bloğu / ^ADJUSTING BLOCK DESTEK MAKARALARI GERGİ SAPL. / TENSION ROD SABİT ÇENE ALT KAMASI / SEYYAR ÇENE MESNET PLAKASI SUPPORTING PULLEYS

- 6. FIXED JAW LOWER TIGHTENING BOLT alt kaması / TOGGLE PLATE SWINGING JAW GERGİ SAPLAMASI / UPPER TIGHTENING TENSION ROD BOLT All GÜRSAN Jaw Crushers have been equipped with hydraulic assistant adjustment mechanism. This system facilitates easy and fast adjustment of discharge setting according to the product curve which you wish to obtain. Adjustment of discharge setting may be done by inserting or removing of adequate number and thickness of adjustment plates to and from the behind of the adjustment block which pushed forward by means of hand pump hydraulic system. This system provides possibility to make adjustment in larger intervals and is much more safe compared to other adjustment mechanisms. On the other hand stationary and mobile jaws are manufactured from manganese steel so as to be used up and down and furthermore their rear surfaces have been machined in order to prevent them to spoil surfaces on which they will lean and to prevent breakages throughout their service life due to contraction. Prestress with leaf springs has been given onto clamping studs of key locks fixing the jaws against break loose that may occur due to impacts and surface crushes. Flywheel hubs of our large jaw crushers (CK 07 1100 x 900 (43"x35") and CK 08 1300 x 1100) (51"x43") have been equipped with special tightening system which connects flywheels to eccentric shaft. While this system ensures that the flywheel can hold the shaft safely and tightly in case of excessive stresses occurring at the time of restarting, caused by pieces of rock retained at the mouth of jaw as the result of stopping of the machine because of any reason, it has been facilitating disassembly-reassembly operation which may become necessary for both maintenance and transportation. Crusher's shafts have been manufactured from forged steel and provided with spherical oscillating roller bearing. Roller bearings are of grease lubricated, which have been protected with labyrinth felts against external effects. As optional unit, crushers have been equipped with automatic lubrication system. Diameters of outer bearing and inner bearing are equal with one another, and for facilitating assembly and disassembly operation of outer bearings are of taper type with hole, which are fitted on the shaft with taper sleeve; inner bearings however can be easily dismantled by means of hydraulic disassembly system through hydraulic canal in the shaft. "Pitman" has been manufactured from cast steel and designed to resist against stressed loads even under the severest conditions. Toggle plates (safety plates) of machines have been manufactured pig cast iron against materials fed and pieces of iron which might slip unintentionally and their geometry has been so designed as to break easily under overload with out causing damage by such pieces of iron onto other components of the machine. Houses of the toggle plates are of non-lubricating type and so designed that they could be easily replaced.

- 7. KAPASİTELER CAPACITIES T E K N İ K Ö Z E L L İ K L E R / SPECIFICATIONS TEKNİK SPESİFİKASYONLAR TECHNICAL SPECIFICATIONS

- 8. T E K N İ K Ö Z E L L İ K L E R / SPECIFICATIONS

- 9. ÇENELİ KIRICILAR GRADASYON TABLOSU / JAW CRUSHERS GRADIATION CHART KIRICI AYAR AÇIKLIGI / CRUSHER CLOSED SIDE SETTING 19mm 25mm 38mm 45mm 50mm 57mm 64mm 70mm 76mm 89mm 102mm 127mm 152mm 179mm 203mm 229mm 254mm 3/4" 1" 1-1/2" 1-3/4" 2" 2-1/4" 2-1/2" 2-3/4" 3" 3-1/2" 4" 5" 6" 7" 8" 9" 10" +254 mm + 10" 100 100 100 100 100 254 mm 10" 94 82 73 66 60 229 mm 9" 100 88 76 68 61 55 203 mm 8" 93 80 69 61 55 50 179 mm 7" 100 83 72 62 54 48. 5 44 152 mm 6" 100 100 90 74 63 54 47. 5 42. 5 38. 5

- 10. 127 mm 5" 100 100 96 87 78 64 54 47 41 36 32 102 mm 4" 95 90 84 74 65 54 46 40 34 30 27 89 mm 3-1/2" 100 89 81 76 66 58 48 41 35. 5 30. 5 26. 5 23. 5 76 mm 3" 100 93 80 72 67 58 52 43 36. 5 31. 5 27 23. 5 20. 5 71 mm 2- 3/4" 100 96 88 75. 5 67. 5 62. 5 54 48. 5 40 34 29. 5 25 21. 8 19 64 mm 2-1/2" 96 91 82 70 62. 5 58 50 45 37 31. 5 27 23 20 17. 5 Q 57 mm 2-1/4" 100 93 85 76 65 58 53. 5 46. 5 41. 5 34 29 25 21. 3 18. 3 16 < 50 mm 2" 100 95 87 79 69 57 53 49 42. 5 38 31 26. 5 23 19. 5 16. 5 14. 4 m

- 11. m Z" 45 mm 1-3/4" 98 90 80 72 62 52 48 44 38. 5 34. 5 28 24 20. 5 17. 5 14. 7 12. 6 £O 38 mm 1-1/2" 100 92 82 71 62 54. 5 45 42 38. 5 34 30. 5 24. 5 21 18 15 13 11 LU 32 mm 1-1/4" 97 86 75 62. 5 55 48 40 37 34 30 27 22 18. 5 15. 9 13. 2 11. 3 9. 6 N 25 mm 1" 90 73 62 52 46 40 33. 5 31 28. 5 25 22. 5 18. 5 15. 5 13. 4 11. 2 9. 5 7. 9 V 22 mm 7/8" 86 66 56 46. 5 41. 5 36 30 28 26 22. 5 20. 1 16. 5 14 11. 9 10 8. 4 7 3 b Q 19 mm 3/4" 75 55 47 39 34. 5 30. 5 25. 5 22. 5 22 19 17. 3 14 12 10. 2 8. 5 7 5. 8 g 16 mm 5/8" 67 49. 5 42. 5 35. 2 31 27. 2 22. 5 21 19. 5 17 15. 5 12. 5 10. 8 9. 1 7. 6 6. 3 5. 2 Q_ 12 mm 1/2" 56 41. 5 35. 5 29. 8 26 23 19. 4 18 16. 5 14. 8 13. 3 10. 8 9. 2 7. 8 6. 5 5. 3 4. 3

- 12. 10 mm 3/8" 42 31 27 22. 5 19. 5 17. 5 14. 6 13. 7 12. 7 11. 2 10. 2 8. 2 7 5. 9 4. 8 3. 9 3. 1 8 mm 5/16" 38 28 24 20 17. 6 15. 7 13. 2 12. 3 11. 3 10 9. 1 7. 4 6. 3 5. 2 4. 3 3. 5 2. 8 6. 4 mm 1/4" 31. 5 23 20 17 14. 8 13 11. 2 10. 3 9. 7 8. 6 7. 8 6. 3 5. 3 4. 4 3. 6 2. 9 2. 3 4. 8 mm 4M 24 17. 5 15 12. 5 11. 2 10 8. 5 8 7. 4 6. 0 5. 9 4. 8 4 3. 4 2. 7 2. 2 1. 7 2. 4 mm 8M 13. 5 9. 9 8. 5 7. 3 6. 4 5. 7 4. 9 4. 6 4. 3 3. 8 3. 4 2. 8 2. 4 2. 0 1. 6 1. 2 1 1. 5 mm 10 M 11. 4 8. 3 7. 2 6. 2 5. 4 4. 8 4. 1 3. 9 3. 7 3. 2 2. 9 2. 4 2. 0 1. 7 1. 4 1 .8 1. 2 mm 16 M 6. 8 5 4. 4 3. 8 3. 3 2. 9 2. 5 2. 4 2. 3 2 1. 8 1. 5 1. 3 1 .9 .7 .5 0. 6 mm 30 M 3. 8 2. 9 2. 5 2. 2 1. 9 1. 7 1. 5 1. 4 1. 3 1. 2 1. 1 .9 .8 .6 .6 .4 .3 0. 42 mm 40 M 2. 9 2. 1 1. 9 1. 7 1. 4 1. 3 1. 2 1. 2 1. 1 1. 0 .9 .7 .6 .5 .5 .3 . 24

- 13. 0. 3 mm 50 M 2. 3 1. 6 1. 4 1. 3 1. 1 1 1 1 .9 .8 .8 .6 .5 .4 .4 .2 .2 0. 15 mm 100 M 1. 3 1 .8 .7 .6 .5 .5 .5 .5 .4 .4 .3 .3 .2 .2 .1 .1

- 14. GLRSAN İNŞAAT MAKİNALARI SANAYİ LTD. ŞTİ. / CONSTRUCTION MACHINES INDUSTRY LTD. CO. Küçük Sanayi 3. Cadde No: 101 06930 Sincan - ANKARA / TURKEY Tel : +90. 312 269 20 23 - 269 32 67 • Fax : +90. 312 269 32 38 w e b : w w w . g u r - s a n . c o m . t r • e-mail: i n f o @ g u r - s a n . c o m . t r

- 15. Gijr-San has redesigned its great capacity screens in order to meet its end users' increasing demands and to provide the best sifting solution to them and manufactured its EP series screens of brand new generation. While designing these screens Gür-San has used the most advanced technology in addition to its approximately 25 year experience and knowledge feedback. Designs have been executed through 3 dimensional CAD computer program, and critical components have been subjected to stress analysis against severe conditions under a computer program operating by integration to this program. ELIPTICAL FORWARD MOTION ACCELERATES MATERIALDİK ELİPTİK HAREKET ELEK ÜZERİNDE KALAN MALZEMENİN FORWARD WHICH CAUSES UNIFORM DISTRIBUTION, BEKLETİLEREK ELEK ÖLÇÜSÜNE } YAKIN MALZEMENİN DAHA FINES PASS THROUGH THE MESH ETKİLİ ^ AYRIŞTIRILMASIN! SAĞLAR.

- 16. Jt UPHILL ELLIPTICAL MOTION DECELARATESTHE MATERIAL FOR ^^ TO ACHIVE ACCURATE SEPARATION OF THE NEAR SIZE Vibration system has been contemplated to rise at higher revolutions required by effective screening and to be adjustable easily according

- 17. to different conditions, and designed to permit easy and rapid replacement of defective components in case of maintenance. This system which provides effective oscillation consists of twin right hand side and left hand side vibration units and interim cardan shaft which makes to operate these two vibrators in synchronization and transmits the power coming from the motors to another. Disassembly and reassembly of these vibrator units take only several hours. Modular vibrator which required to be replaced due to whatever reason may be replaced either by its spare kept in your stock or by any spare vibrator available at the stocks of Gür-San. Dismantled defective vibrator may be sent to Gür-San and thus

- 18. you may have it to be maintained and repaired under one year warranty and under Gür-San's Quality Assurance. Thus, you would be capable of avoiding loss of time due to suspension at the Work Site and non-guarantied maintenance to be carried out at your Work Site in a dirty and inconvenient environment. These vibrators are grease lubricated and may be equipped with automatic lubrication system optionaly. All screens have been equiped with vibration dampers for eliminating excessive oscillation occurring at the time of starts and stops. During design of EP Series screens safety of users and operational facility have been also taken into consideration. For this purpose a lot

- 19. of details have been observed at the Work Site and eventual solutions have been brought. Safe guards of eccentric weights, V-Belts transmitting power of motors and cardan shaft have been so designed that they may be easily dismantled and reassembled and in perfect protection. Suspension springs have been protected with rubber hoses for safety and against materials that may be jammed therein. In order to be able to replace sieves of screen easily, the spaces between decks have been kept high; on the other hand the fact that vibration unit is located at the top of the screen ensured both making maintenance of the unit easily and spaces between decks become rather comfortable.

- 20. Effective washing system has been also integrated into the screens; when requested, all of these models may be supplied complete with the said effective washing system. Another feature which has been taken into consideration however is that decks are manufactured optionally according to both wire sieves of different types and modular polyurethane sieves to be used for abrasive materials. Precaution has been taken on surfaces against wearing by coating rubber on which abrasive materials may contact. EP SERIES VIBRATING SCREENS SPECIFICATIONS EP 04 (8 m2) and EP 05 (12 m ) screens are 2 available on mobile chasis also. Both models are designed to set up at the site easly and rapidly.

- 21. Their inspection platforms, stair cases and sliding front chutes are as practical as stationary ones.

- 22. E L E K L E R / S C R E E N S TİPİ ÖLÇÜLER' EP04 M 5'-3" x EP05 M 6'-7" x 16'-5" 19'-8 A 12'-5" 12'-5" 12'-5" 13'-9" 13'-9" 13'-9" B 32'-7" 32'-7" 33'-4" 32'-7" 32'-7" 32'-7" C 20' 20' 20'-6" 20'-7" 20'-7" 20'-7" D 39" 39" 39" 39" 39" 39" E 34" 34" 34" 36" 36" 4'-4"

- 23. F 13'-5" 13'-5" 13'-11" 13'-11" 13'-11" 14'-9" G 36'-3" 36'-3" 36'-9" 36'-3" 36'-3" 34'-1" H 9'-4" 9'-4" 9'-4" 10'-8" 10'-8" 10'-8" TYPE DIMENSIONS EP04 M EP05 M 1600x5000 2000x6000 A 3780 mm 3780 mm 3780 mm 4200 mm 4200 mm 4200 mm B 9920 mm 9920 mm 10. 170 mm 9920 mm 9920 mm 9920 mm C 6090 mm 6090 mm 6250 mm

- 24. D 1000 mm 1000 mm 1000 mm 1000 mm 1000 mm 1000 mm 6270 mm 6270 mm 6270 mm E 850 mm 850 mm 850 mm 920 mm 920 mm 1320 mm 11. 050 mm 11. 050 mm 11. 390 mm F 4100 mm 4100 mm 4250 mm 4250 mm 4250 mm 4500 mm G 11. 040 mm 11. 040 mm 11. 200 mm

- 25. GLRSAN İNŞAAT MAKİNALARI SANAYİ LTD. ŞTİ. / CONSTRUCTION MACHINES INDUSTRY LTD. CO. Küçük Sanayi 3. Cadde No: 101 06930 Sincan - ANKARA / TURKEY Tel: +90. 312 269 20 23 - 269 32 67 • Fax: +90. 312 269 32 38 w e b : w w w . g u r - s a n . c o m . t r • e-mail: i n f o @ g u r - s a n . c o m . t r

- 26. Gür-sarı Primer units are the products of our research and development program using the state-of-art technology, engineering and equipment. 3 dimensional CAD design program has been used during design of Units; a software program where stresses to exert effect on critical parts so designed were analyzed within a computer environment has been used.

- 27. Taking into consideration the requirements of end user the following targets have been selected on design of products: Higher productivity, Easy and simple operation, Durability, Reliability, Easy transportation, Easy and rapid installation. Gür-sarı Primer units have been built around Giirsan Jaw and Impact Crushers which proved themselves on all kinds of materials for many years.

- 28. Jaw Crushers which are placed at the heart of our Jaw Primary units have been designed and manufactured for the purpose of using them in the first stage crushing of all types of materials ranging from soft limestone rock to the hardest basalt These crushers have been providing unique and exclusive operational advantages to their users with their high flywheel speeds, jaw grabbing angles, safety plates of their pitmans and their rear blocks as well as their superior performances based on their geometry, reliabilities, durability and their user friendly adjustment mechanisms.

- 29. If the material to be crushed is soft or semi-hard, lower abrasive, then capacity and crushing rate will be much more higher, cubical values will be perfect; therefore our primer unit with impact crusher has been recommended as alternative. In the course of numerous applications finish product can be produced without need for secondary crusher, eventually investment costs could be reduced. Several of numerous superior features of our user friendly impact crushers are: Hammers which can be easily replaced and presented also as chromium alloy, used reverse and plain, heavy-duty rotor, completely cable- controlled and hydraulic controlled adjustment

- 30. system, primary apron preventing clogging, hydraulically opened upper body. Another significant feature in our Impact Crushers is that they are equipped with a protection system against pieces of metal which might be present within the material fed to the Crusher. This protection system ensures that in case of entering of any material which is impossible to be crushed into crusher such material may pass through the machine without causing damage by removal of aprons automatically from rotor, and that the crushed should continue its trouble free operation by returning aprons to their adjusted original

- 31. position after such unbreakable material left the machine. Our Mobil Primer facilities have been provided with hydraulic legs in order to be able to carry out installation easily and quickly at the Work Site. This System makes it possible as soon as possible that the unit be lifted to studs at the Work Site. Hydraulic power unit which supply power to this system controls the system which adjusts the discharge setting, if the crusher on the facility has jaw. Adjustment of the crusher can be made easily by moving adjustment block to and front by means of pistons available at the rear of the crusher and by inserting or removing shim plates.

- 32. If the crusher is of impact type this system provides assistance in making adjustment the clearance between the aprons and rotor and crusher plates and easy and rapid maintenance for armour, inings, rotor and hammers by opening upper body of the crusher. Our Mobile primer units have been designed and manufactured as heavy duty type in so much as stationary units; both their hopper capacities and feeder structures are of capacity and structure which could be fed by heavy rock trucks. These feeding systems, depending on the request, are capable of feeding the material automatically without need for operator to the crusher as much

- 33. as it needed, ensuring that the facility is to be fed in optimum capacity according to hardness of the material, adjustment position of the crusher. Another a unique feature involved in our facilities however is the pre-screening system which has been solved at our feeders as compact. Thanks to this system fine material which is unnecessary to be fed to the crusher can be by-passed directly to the crusher's conveyor belt; and in the mean time however the unwanted soil in the fine material is separated and conveyed to the soil conveyor belt. This unique system, whose duty has been performed by most companies by employing an

- 34. extra screen, increases both capacity and production quality of your plant. Our Primary Plants, in addition to standard features mentioned above, include according to demands of end users optional attachments such as hydraulic rock crushers, operator cabins, drive systems with diesel engine and generator, dust dumping system, finger grid by- pass sieve, magnetic separators on outlet conveyor belt and hoppers with larger volume capacity, etc. In addition to all of foregoing features and specifications our primer units have been also manufactured EC Directives on Machine

- 35. accepted by the European Community (CE Sign) like all other products of Gür-San.

- 36. ÇENELİ KIRICILI SEYYAR PRİMER KIRMA TESİSLERİ MOBILE PRIMARY CRUSHING PLANTS WITH JAW CRUSHER STANDART STANDART P02 P06 P08 P10 P12 P16 EKİPMAN EQUIPMENT 1 BESLEYİCİ FEED HOPPER BUNKERİ 5 m3 6. 5 yd 3 15 m3 20 yd 3 20 m3 26 yd 3 35 m3 46 yd 3 30 m3 40 yd 3 50 m3 65 yd 3 2 BESLEYİCİ GRIZZLY FEEDER G10 G11 G12 G14 G13 G16 GENİŞLİK WIDTH 600 mm 24" 900 mm 35" 1000 mm 39" 1100 mm 43" 1100 mm 43" 1370 mm 54" UZUNLUK LENGTH 2500 mm 8' - 2" 3200 mm 10' - 6" 4000 mm 13' - 2" 3170 mm 10' - 5" 4000 mm 13' - 2" 3920 mm 12' - 10" TAHRİK DRIVE 10 HP 7, 5 KW 15 HP 10 KW 20 HP 15 KW 2x10 HP 2x7 KW 20 HP 15 KW 2x10. 5 HP 2x7. 5 KW 3 IZGARALI ELEK SCLAPINGS GENİŞLİĞİ GRIZZLY 1100 mm 43" 1370 mm 54" WIDHT

- 37. IZGARALI ELEK SCLAPINGS UZUNLUĞU GRIZZLY 2150 mm 7' 2150 mm 7' LENGTH TAHRİK DRIVE 2x15 HP 2x3. 8 KW 2x6 HP 2x4. 3 KW 4 ÇENELİ KIRICI JAW CRUSHER K04 K06 K06 K07 K07 K08 AĞIZ GENİŞLİĞİ INTAKE WIDTH 610 mm 24" 900 mm 35" 900 mm 35" 1100 mm 43" 1100 mm 43" 1300 mm 51" AĞIZ INTAKE DERİNLİĞİ DEPTH 380 mm 15" 650 mm 26" 650 mm 26" 800 mm 35" 900 mm 35" 1100 mm 43" TAHRİK DRIVE 40 HP 30 KW 125 HP 90 KW 125 HP 90 KW 180 HP 132 KW 180 HP 132 KW 220 HP 160 KW 5 BOŞALTMA DISCHARGE BANDI CONVEYOR B02 C4 B02 D6 B02 D6 B02 D7 B02 D7 BAND GENİŞLİĞİ BELT WIDTH 600 mm 24" 750 mm 30" 750 mm 30" 1000 mm 39" 1000 mm 39" UZUNLUĞU LENGTH 4000 mm 13'-1" 6000 mm 19'-8" 6000 mm 19'-8" 7000 mm 23' 7000 mm 23' TAHRİK DRIVE 4 HP 3 KW 7. 5 HP 5. 5 KW 7. 5 HP 5. 5 KW 10 HP 7. 5 KW 10 HP 7. 5 KW

- 38. 6 YAN BAND SIDE CONVEYOR B04/6. 5/2. 1 BAND GENİŞLİĞİ BELT WIDTH 650 mm 26" UZUNLUĞU LENGTH 2100 mm 6'-9" TAHRİK DRIVE 2 HP 1. 5 KW OPSİYONEL OPTIONAL EKİPMAN EQUIPMENT P02 P06 P08 P10 P12 P16 7 BOŞALTMA DISCHARGE BANDI CONVEYOR B02 C6 B02 D12 B02 D12 B02 F14 B02 F14 BAND GENİŞLİĞİ BELT WIDTH 600 mm 24" 750 mm 30" 750 mm 30" 1000 mm 39" 1000 mm 39" UZUNLUĞU LENGTH 6000 mm 19'-8" 12000 mm 39'-4" 12000 mm 39'-4" 14000 mm 46' 14000 mm 46' TAHRİK DRIVE 3 HP 2. 2 KW 7. 5 HP 5. 5 KW 7. 5 HP 5. 5 KW 10 HP 7. 5 KW 10 HP 7. 5 KW

- 39. 8 MANYETİK MAGNETIC AYIRICI SEPERATOR OPTION OPTION OPTION OPTION OPTION 9 TOZ DUST İNDİRGEME REDUCTION OPTION OPTION OPTION OPTION OPTION OPTION SİSTEMİ SYSTEM 10 KUMANDA CONTROL PANOSU CABIN OPTION OPTION OPTION OPTION OPTION OPTION 11 OTOMATİK OTOMATIC BESLEME FEEDING OPTION OPTION OPTION OPTION OPTION OPTION 12 KIRICI İÇİN OTOMATIC OTOMATİK LUB. OF THE OPTION OPTION OPTION OPTION OPTION OPTION YAĞLAMA CRUSHER 13 IZGARA ALTI FINGER SCREEN OPTION UNDER PARMAK ELEK GRIZZLY OPTION OPTION OPTION OPTION OPTION

- 40. DARBELİ KIRICILI SEYYAR PRİMER KIRMA TESİSLERİ MOBILE PRIMARY CRUSHING PLANTS WITH IMPACT CRUSHER STANDART STANDART P14 P18 P20 EKİPMAN EQUIPMENT 1 BESLEYİCİ FEED HOPPER 40 m3 52 yd3 35 m3 46 yd3 20 m3 26 yd3 BUNKERİ 2 BESLEYİCİ FEEDER G15 G14 G12 GENİŞLİK WIDTH 1370 mm 54" 1100 mm 43" 1000 mm 39" UZUNLUK LENGTH 3170 mm 10'-5" 3170 mm 10'-5" 4000 mm 13'-2" TAHRİK DRIVE 2x10 HP 2x7KW 2x10 HP 2x7 KW 20 HP 15 KW

- 41. 3 IZGARALI ELEK SCLAPINGS GRIZZLY 1370 mm 54" 1100 mm 43" GENİŞLİĞİ WIDTH IZGARALI ELEK LENGTH 2150 mm 7' 2150 mm 7' UZUNLUĞU TAHRİK DRIVE 2x6 HP 2x4. 3KW 2x5 HP 2x3. 8 KW 4 DARBELİ KIRICI IMPACT CRUSHER K38 K37 P K34 P AĞIZ GENİŞLİĞİ INTAKE WIDTH 1540 mm 61" 1290 mm 51" 1040 mm 41" AĞIZ YÜKSEKLİĞİ INTAKE HEIGHT 1350 mm 53" 884 mm 35" 884 mm 35" ROTOR ÇAPI ROTOR DIAMETER 1400 mm 55" 1250 mm 49" 1250 mm 49" TAHRİK DRIVE 2x180 HP 2x132 KW 270 HP 200 KW 220 HP 160 KW

- 42. 5 BOŞALTMA BANDI DISCHARGE B02G7 B02F7 B02D6 CONVEYOR BAND GENİŞL İĞİ BELT WIDTH 1200 mm 47" 1000 mm 39" 750 mm 30' UZUNLUĞU LENGTH 7000 mm 23' 7000 mm 23' 6000 mm 19'-8" TAHRİK DRIVE 15 HP 11 KW 10 HP 75 KW 7. 5 HP 5. 5 KW OPSİYONEL OPTIONAL P14 P18 P20 EKİPMAN EQUIPMENT 7 BOŞALTMA BANDI DISCHARGE B02/D/15 CONVEYOR

- 43. BAND GENİŞLİĞİ BELT WIDTH 750 mm 30" UZUNLUĞU LENGTH 1500 mm 49' TAHRİK DRIVE 10 HP 7. 5 KW 8 MANYETİK MAGNETIC OPTION OPTION OPTION AYIRICI SEPERATOR 9 TOZ DUST OPTION OPTION OPTION İNDİRGEME REDUCTION SİSTEMİ SYSTEM 10 KIRICI ALTI VIBRATING FEEDER OPTION OPTION OPTION BESLEYİCİ (BELOW CRUSHER) 11 IZGARA ALTI FINGER SCREEN OPTION OPTION OPTION

- 44. PARMAK ELEK UNDER GRIZZLY ÇENELİ KIRICILI SEYYAR PRIMER KIRMA TESİSLERİ MOBILE PRIMARY CRUSHING PLANTS WITH JAW CRUSHER STANDART EKİPMAN PERFORMANCE P02 P06 P08 EN BÜYÜK BESLEME FEED SIZE, UP TO 350 mm 14" 600 mm 24" 600 mm 24" EBADI EN BÜYÜK ÜRÜN PRODUCT SIZE, UP TO 150 mm 6" 200 mm 8" 200 mm 8" EBADI EN YÜKSEK KAPASİTE CAPACITY, UP TO 130 TPH 145 STPH 300 TPH 330 STPH 300 TPH 330 STPH ANA ÖLÇÜLER MAIN DIMENSIONS UZUNLUK LENGTH (L) 8935 mm 29'-4" 10400 mm 34'-1" 11090 mm 36'-5" GENİŞL İK WIDTH (W) 2350 mm 7'-9" 3850 mm 12'-8" 4270 mm 14' YÜKSEKLİK HEIGHT (H) 3860 mm 12'-8" 5180 mm 17' 5040 mm 16'-6"

- 45. AĞIRLIK WEIGHT 16 TON 35200 LBS 27 TON 59500 LBS 30 TON 66000 LBS BESLEME YÜKSEKLİĞİ LOADING HEIGHT (A) 3860 mm 12'-8" 5180 mm 17' 5040 mm 16'-6" BOŞALTMA DISCHARGE HEIGHT 1500 mm 4'-11" 1500 mm 4'-11" 1500 mm 4'-11" YÜKSEKLİĞİ (B) BY-PASS BOŞALTMA DISCHARGE HEIGHT 1100 mm 43" 1100 mm 43" YÜKSEKLİĞİ BY- PASS CHUTE (C) NAKİL ÖLÇÜLERİ TRANSPORT DIMENSION S NAKİL GENİŞL İĞİ TRANSPORT WIDTH 1850 mm 6' 2720 mm 8'-11" 2720 mm 8'-11" NAKİL TRANSPORT LENGHT 7870 mm 25'-10" 9900 mm 32'-6" 10830 mm 35'-6" UZUNLUĞU (E) NAKİL YÜKSEKLİĞİ TRANSPORT HEIGHT 3030 mm 9'-11" 4270 mm 14' 4200 mm 13'-9" (F) NAKİL AĞIRLIĞI TRANSPORT WEIGHT 16 TON 35200 LBS 27 TON 59500 LBS 30 TON 66000 LBS BUNKER AĞIRLIĞI HOPPER WEIGHT STANDART EKİPMAN PERFORMANCE P10 P12 P16

- 46. EN BÜYÜK BESLEME FEED SIZE, UP TO 800 mm 31" 800 mm 31" 1000 mm 39" EBADI EN BÜYÜK ÜRÜN PRODUCT SIZE, UP TO 300 mm 12" 300 mm 12" 300 mm 12" EBADI EN YÜKSEK KAPASİTE CAPACITY, UP TO 900 TPH 990 STPH 900 TPH 990 STPH 1200 TPH 1320 STPH ANA ÖLÇÜLER MAIN DIMENSIONS UZUNLUK LENGTH (L) 13900 mm 45'-7" 12900 mm 42'-4" 14350 mm 47" GENİŞL İK WIDTH (W) 5270 mm 17'-4" 4200 mm 13'-9" 5500 mm 18' YÜKSEKLİK HEIGHT (H) 6600 mm 21'-8" 6150 mm 20'-2" 7550 mm 24'-9" AĞIRLIK WEIGHT 75 TON 165000 LBS 60 TON 132000 LBS 110 TON 242500 LBS BESLEME YÜKSEKLİĞİ LOADING HEIGHT (A) 6560 mm 21'-6" 6150 mm 20'-2" 7550 mm 24'-9" BOŞALTMA DISCHARGE HEIGHT 1475 mm 4'-10" 1475 mm 4'-10" 1200 mm 47" YÜKSEKLİĞİ (B) BY-PASS BOŞALTMA DISCHARGE HEIGHT 950 mm 37" 950 mm 37" 1000 mm 39" YÜKSEKLİĞİ BY- PASS CHUTE (C) NAKİL ÖLÇÜLERİ TRANSPORT DIMENSION S

- 47. NAKİL GENİŞL İĞİ TRANSPORT WIDTH 2880 mm 9'-5" 2880 mm 9'-5" 3150 mm 10'-4" NAKİL TRANSPORT LENGHT 13300 mm 43'-8" 12300 mm 40'-4" 13700 mm 45' UZUNLUĞU (E) NAKİL YÜKSEKLİĞİ TRANSPORT HEIGHT 4300 mm 14'-1" 4300 mm 14'-1" 4300 mm 14'-1" (F) NAKİL AĞIRLIĞI TRANSPORT WEIGHT 55 TON 121000 LBS 50 TON 110000 LBS 85 TON 187500 LBS BUNKER AĞIRLIĞI HOPPER WEIGHT 14 TON 31000 LBS 10 TON 22000 LBS 25 TON 55000 LBS

- 48. DARBELİ KIRICILI SEYYAR PRİMER KIRMA TESİSLERİ MOBILE PRIMARY CRUSHING PLANTS WITH IMPACT

- 50. PERFORMANS PERFORMANCE P14 P18 P20

- 51. 1000 mm 39" 600 mm 24" 600 mm 24" EN BÜYÜK FEED SIZE, UP TO

- 52. EN BÜYÜK BOYUTU 200 mm 8" 150 mm 6" 150 mm 6" ÜRETİLEN MALZEME PRODUCT SIZE, UP

- 53. 800 TPH 880 STPH 300 TPH 330 STPH 250 TPH 275 STPH EN YÜKSEK CAPACITY, UP TO

- 54. ANA ÖLÇÜLER MAIN DIMENSIONS

- 55. 14500 mm 47'-7" 14500 mm 47'-7" 14200 mm 46'-7" UZUNLUK LENGTH (L)

- 56. 5500 mm 18' 5270 mm 17'-4" 4100 mm 13'-5" GENİŞLİK WIDTH (W)

- 57. 6600 mm 21'-8" 6300 mm 20'-8" 5860 mm 19'-3" YÜKSEKLİK HEIGHT (H)

- 58. 80 TON 176400 LBS 63 TON 139000 LBS 30 TON 66100 LBS AĞIRLIK WEIGHT

- 59. 6600 mm 21'-8" 6300 mm 20'-8" 5860 mm 19'-3" BESLEME YÜKS. LOADING HEIGHT

- 60. 1450 mm 57" 1480 mm 57" 1450 mm 57" BOŞALTMA DISCHARGE

- 61. YÜKSEKLİĞİ HEIGHT (B)

- 62. DISC. HEIGHT BY-PASS 970 mm 38" 970 mm 38" 970 mm 38" CHUTE (C) BY-PASS

- 63. NAKİL ÖLÇÜLERİ TRANSPORT DIMENSIONS

- 64. 3150 mm 10'-4" 2500 mm 8'-2" 2200 mm 7'-3" NAKİL GENİŞLİĞİ TRANSPORT WIDTH

- 65. 13700 mm 45' 13700 mm 45' 13550 mm 44' NAKİL TRANSPORT

- 66. 4300 mm 14'-1" 4000 mm 13'-1" 4000 mm 13'-1" NAKİL TRANSPORT

- 67. 60 TON 132300 LBS 49 TON 108000 LBS 20 TON 44100 LBS NAKİL AĞIRLIĞI TRANSPORT

- 68. 20 TON 44100 LBS 14 TON 31000 LBS 10 TON 22000 LBS BUNKER HOPPER WEIGHT

- 69. GLRSAN İNŞAAT MAKİNALARI SANAYİ LTD. ŞTİ. / CONSTRUCTION MACHINES INDUSTRY LTD. CO. Küçük Sanayi 3. Cadde No: 101 06930 Sincan - ANKARA / TURKEY Tel: +90. 312 269 20 23 - 269 32 67 • Fax: +90. 312 269 32 38 w e b : w w w . g u r - s a n . c o m . t r • e-mail: i n f o @ g u r - s a n . c o m . t r

- 70. Belt conveyors are the group of products designed by GURSAN as a result of its experiences acquired at field and in production for many years. In the design of belt conveyors, ease of installation at field, inspection and transportation are taken into consideration. They are designed modularly to a width of 500 mm, 600 mm, 750 mm, 800 mm, 1000 mm and 1200 m such that they would readily adapt to changes of the customer's requirements in time. This modular design includes three main groups: Drive module, intermediate modules, and tail module.

- 71. The drive module is, as may be understood from its name, a module containing a motor and a reducer that enable the conveyor operation. The bearing, the group of drums and the reducer included in this section are selected a size larger than what is required and are designed to give a problem-free service for many years. TAHRİK TAMBURU

- 72. #

- 73. LTMA OLUĞU WRGE CHUTE SAKIM PLATFORMU (TAHRİK MODULI INSPECTION PLATFORM (DRIVE MOD D BACK MODÜL BACK FOOT All drum cores are fitted on the drum shaft with conical shrink sleeves and the drive drum is coated ivith rubber to avoid skidding in rainy weather. Belts longer than 15 m are equipped: ivith a locking system at the other end dpitie drum shaft to prevent the wound belt from sliding back. Surface of the belt that carries the goods should be scraped well at the discharge point, which is very important for purposes of both the cleaning of the plant and the service life of other operating components. To this end, underside of the drive drum is fastened to the body with wear-resistant, replaceable rubber holders and equipped with scraper knives. Intermediate modules are manufactured to three different sizes: 2 m, 4 m, and 6 m. They are highly strong against buckling owing to their box structure. Since they are assembled

- 74. in the form, they are fully compatible with one another. Thus, it is possible to shorten or lengthen the belt in time or to use with the module in this belt, another belt of the same width. Tail modules are manufactured to two different sizes: î m and 2 m. With belts longer than 40 m, the tail drum is stationary and a weighted tension module to tension the belt. There is a triangular scraper in front of the tail drum, bedded from the tail drum shaft, to clean the back side of the belt and prevent the belt from getting particles in between and damage the belt rubber. Other important parts on a belt

- 75. conveyor are the feed hopper and the discharge chute. Particularly the feed hopper design is highly important for purposes of the life of the belt rubber. In order that the material fed onto the belt from the hopper can be loaded on the conveyor without inflicting any damage to the belt rubber especially when big materials are fed thereunto, this section of the entire belt is supported with the hopper base. At this section, no idlers are used and the belt is bedded on polyamide skidding boards. Owing to this system, the impact load transferred to the hopper base is damped by

- 76. means of rubber blocks that fasten the hopper to the belt body thereunder. Legs are in such a shape as to occupy less space in transportation and be installable fast and easily on the construction site. In stock belts, legs are inclined the same as the stock. In revolving stock belts, V-legs are equipped with rubber wheels and a motor reducer to drive them. /Is with all GURSAN products, ease of maintenance has been one of the prominent design criteria for our conveyor systems. For this purpose, inspection platforms are provided along the entire conveyor length and three sides of the drive unit for ease of

- 77. access to parts to be inspected. Conveyor belts can also be provided with a covering system fur purposes of both environmental protection and for keeping aggregates away from external effects. Safety measures are taken on all our conveyor belts as specified by CE norms. S P E S İ F İ K A S Y O N L A R / SPlüiflEAJIB^S

- 78. AÇIKLAMA / DESCRIPTION BAND GENİŞLİĞİ BELT WIDHT 500 mm 600 mm 650 mm 26" 750 mm 800 mm 1000 mm 1200 mm 20" 24" 30" 32" 39" 47" BAND HIZI / BELT SPEED 1, 3 - 1, 8 (nv's) TAHRİK / POWER 4-11 <kw) 5. 4-60 (kw) 5. 5 82 (hp) 7. 5 - 90 (kw) 10125 (hp) 515 (hp)

- 79. ARAÇ MODÜL ÖLÇÜLERİ BOY 2000 mm - 4000 mm - 6000 mm 6'7'/13'11/2" /19'8" INTERMEDIATE MODULE LENGTH DIMENSIONS GENİŞLİK 746 mm 846 mm 33" 896 mm 996 mm 1046 mm 1246 mm 49" 1446 mm WIDTH 29" 35" 39" 41" 57" YÜKSEKLİK 585 mm 585 mm 585 mm 585 mm 585 mm 585 mm 585 mm HEIGTH 23" 23" 23" 23" 23" 23" 23" KUYRUK MODÜL BOY 1000 mm - 2000 mm 39" !6'7' ÖLÇÜLERİ LENGTH TAIL MODULE GENİŞLİK 780 mm 31" 880 mm 930 mm 1030 mm 41" 1080 mm 1280 mm 50" 1480 mm 58" DIMENSIONS WIDTH 35" 37" 43" YÜKSEKLİK 585 mm 585 mm 585 mm 5S5 mm 23" 585 mm 23" 585 mm 5S5 mm HEIGTH 23" 23" 23" 23" 23"

- 80. TAHRİK MODÜL BOY 1000 mm ÖLÇÜLERİ LENGTH 39" DRIVE MODULE GENİŞLİK 750 mm 850 mm 900 mm 1000 mm 39" 1050 mm 41" 1250 mm 1450 mm DIMENSIONS WIDTH 30" 33" 35" 49" 57" YÜKSEKLİK 1140 mm 1140 mm 45" 1140 mm ■ 1140 mm 1140 mm 1140 mm 1140 mm HEIGTH 45" 45" 45" 45" 45" 45" BESLEME HAZNESİ UZUNLUK 1500 mm 1500 mm 59" 1500 mm 59" 1500 mm 59" 1500 mm 59" 1500 mm 59" 1500 mm FEED HOPPER LENGTH 59" 59" GENİŞLİK 700 mm 800 mm 850 mm 950 mm 1000 mm 1200 mm 47" 1400 mm 55" WIDTH 28" 32" 33" 37" 39"

- 81. KUYRUK TAMBURU ÇAP 0 280 mm 0 280 mm 0 280 mm 0 280 mm 0 280 mm 0 280 mm 0 280 mm 11" TAIL DRUM DIAMETRE 11" 11" 11" 11" 11" 11" GENİŞLİK 540 mm 640 mm 690 mm 790 mm 31" 840 mm 1040 mm 1240 mm 49" WIDTH 21" 25" 27" 33" 40" TAHRİK TAMBURU ÇAP 0 400 mm 0 400 mm 0 400 mm 0 400 mm 0 400 mm 0 400 mm 0 400 mm 16" DRIVE DRUM DIAMETRE 16" 16" 16" 16" 16" 16" GENİŞLİK 540 mm 640 mm 690 mm 27" 790 mm 840 mm 1040 mm 40" 1240 mm 49" WIDTH 21" 25" 31" 33" MAKSİMUM İKİ AYAK PLATFORMLU 16m ARASI MESAFE WITH WALKWAYS 52'6" MAX. CLEARENCE PLATFORSUZ 22 m 72'-2" BETWEEN FOOTS WITHOUT WALKWAYS

- 82. TAŞIYICI RULOLAR ÇAP DIAMETRE 0 89 mm CARRYING IDLERS 4" GENİŞLİK 170 mm 200 mm 220 mm 250 mm 10" 270 mm 11" 330 mm 13" 400 mm WIDTH 7" 8" 9" 16" DÖNÜŞ RULOLAR ÇAP 0 89 mm 4" RETURN IDLERS DIAMETRE GENİŞLİK 520 mm 620 mm 670 mm 770 mm 820 mm 102ft mm 1220 mm 48" WIDTH 20" 24" 26" 30" 32" i RULO MIL ÇAPI 0 20 mm SHAFT DIAMETRES OF IDLERS 4/5"

- 83. İSTASYONLAR RULO ADEDİ 3 3 3 3 3 3 3 STATIONS NUM. OF IDLERS RULO AÇISI 30° 30° 30° 30° 30° 30° 30° THROUGH ANGLE DONUŞ RULO ARALIĞI 2000 mm <5-7" RETURN IDLER SPACING TAŞIYICI RULO ARALIĞI 1000 mm CARRYING IDLERS SPACING 39" GERDİRME MESAFESİ 440 mm TENSIONING LENGTH 17"

- 84. KONİK KIRICILAR / CONE CRUSHERS

- 85. : Mb Adjustment Gear l^pjfcL"-

- 86. [ VlNhfef

- 87. Tah rik Volanı . I ^Bf HK TrampReleasePistons Ana Gövde Main Frame

- 88. Each section of the crusher has been designed and manufactured by aiming long service life and easy operation. Main bearing shell is equipped with two stage sealing system against dust. Labyrinth seal system is used in primary stage and rubber seal system is used in the secondary stage. Main body is welded by our certified welders and subjected to stress removal process. Head and eccentric is manufactured from special alloy steel cast that can withstand high crushing loads and metal parts in the material. Upper and lower main shaft is manufactured from chrome molybdenum alloy forged steel. Again pinion and main gear are manufactured from special alloy forged steel and their surfaces are hardened with induction and they are ground. Mantle is designed in a way that can hide balancing weights on eccentric and provide protection against the abrasion caused by flow of crushed material.

- 89. i u ^ ^ afin"" M c m a i a ^ Gear & Pinion GURSAN Cone Crusher - our solution for increasing your production capacity without increasing your operation and maintenance costs by using our cone crusher designed especially for processing abrasive and hard materials. In hard and abrasive material processing applications, roller bearing

- 90. system of GURSAN cone crusher makes it superior not only from impact crushers but also from other cone crushers with bronze hydrostatic bearing. Its roller bearings, which work with low friction, enable a higher portion of electric motor power to be transformed into crushing energy. Thanks to low friction, the machine not only generates lower heat but also needs smaller lubrication unit, less lubricating oil and smaller cooling unit. Since GURSAN cone crusher does not have upper bearings its inlet is completely open and this enables problem free operation and homogenous feeding into crushing chamber in coarse

- 91. feeding applications. Hydraulic pistons around body of the machine provide protection against metal parts that may be in feed material. These pistons, which pull upper body to lower body, senses the excess load when metal enters in the machine and release upper body until metal part pass through the machine. Stroke value of these pistons for releasing parts does not change and it does not depend on settings of the machine. The same pistons enable cleaning of the material collected in the machine by lifting upper body in case of electric failure during operation. When needed, additional

- 92. cleaning area can be obtained by opening hydraulic setting. GURSAN cone crusher is equipped with dynamic setting system, which enables

- 93. settings to be done during operation and from remote locations. This system powered by hydraulic power unit performs its function by squeezing and releasing bowl on mantle of the machine via a screwing mechanism driven by hydraulic motor. This system operated by a single button enables fine setting in order to stabilize abrasion effects. Thanks to its rapid releasing option, the same mechanism enables rapid removal of bowl housing without requiring removal of upper body. The same system also utilizes a hydraulic locking mechanism

- 94. that fixes setting values. This lock ensures settings remain unchanged. High technology bearing system of GURSAN cone crusher enables it to

- 95. operate at high RPM. This high RPM combined with aggressive eccentric stroke and wide angle crushing chamber ensure optimum capacity and cubic shape of the product. High crushing reduction is obtained especially in secondary applications.

- 96. TEKNİK SPESİFİKASYONLAR / TECHNICAL SPECIFICATION! TEKNİK SPESİFİKASYONLAR / TECHNICAL SPECIFICATIONS 1 1 K950 K1150 ■

- 97. GÜÇ POWER 132 kw 180 HP 200 kw 270 HP AĞIRLIK WEIGHT 11. 200 kg 24. 700 Lbs 17. 000 kg 37. 500 Lbs TAHRİK DEVİRİ FLY WHEEL RPM 850 - 1000 dev/dak 850-1000 rpm

- 98. KIRICI KAVİTE SEÇİMİ / CRUSHER CAVITY A SELECTION A Min. A B Minim BESLEME AÇIKLIĞI FEED OPENING

- 99. K>r>c> Kavite Besleme tyar 5> Aç>kl>ğ> Feed Aç>kl> < MPH^ I g Opening num Settin 1 Crusher Cavity I

- 100. K950 | Kaba Coarse 195 mm / 7. 7" 22 mm / 0. 86" r Orta Medium 127 mm / 5" 16 mm / 0. 63" / İnce Fine 95 mm / 3. 74" 13 mm / 0. 51"

- 101. K1150 Kaba Coarse 240 mm / 9. 45" 22 mm / 0. 86" Orta Medium 165 mm / 6. 5" 16 mm / 0.63" / B İnce Fine 92 mm / 3.62" 13 mm / 0.51" MIN. AYAR AÇIKLIĞI MINIMUM SETTING ÜRÜN GRADASYONU / PRODUCT GRADATION

- 102. Ürün Boyutu K>r>c> ayar aç>k!>ğ> / Crusher closed side setting Product Size 13 mm 16 mm 19 mm 22 mm 25 mm 32 mm 38 mm 45 mm 51 mm 1/2" 5/8" 3/4" 7/8" 1" 1-1/4" 1-1/2" 1-3/4" 2" 102 mm / 4" 100 89 mm / 3-1/2" 100 96 76 mm / 3" 100 95 90 70 mm / 2-3/4" 98 92 86 64 mm / 2-1/2" 100 95 88 81 57 mm / 2-1/4" 97 91 83 74 51 mm / 2" 100 94 86 76 65

- 103. 45 mm / 1-3/4" 100 100 97 88 79 66 55 38 mm / 1-1/2" 100 96 91 80 68 56 45 32 mm / 1-1/4" 97 90 83 70 56 46 38 25 mm / 1" 100 99 90 82 72 58 45 36 29 22 mm / 7/8" 99 93 86 74 64 48 38 30 25 19 mm / 3/4" 94 87 80 65 54 40 32 26 21 16 mm / 5/8" 87 80 69 55 46 34 28 22 18 13 mm / 1/2" 80 69 58 47 39 28 23 19 16 10 mm / 3/8" 63 52 44 37 28 21 17 14 12 8 mm / 5/16" 54 46 37 31 25 19 15 13 10 6 mm / 1/4" 44 36 32 26 21 16 13 11 9 5 mm/4 M 35 32 26 21 18 14 11 9 7

- 104. 4 mm / 5/32" 30 28 23 18 15 12 10 8 6 2 mm/8 M 26 24 20 16 12 9 7 5 4 Gradasyon ve kapasiteler besleme gradasyonuna, kırma odasının durumuna, malzemenin özgül ağırlığına, malzemenin temizliğine, nem miktarına ve kırılabilirliğine bağlıdır. The gradation and capacities shown are dependent on the feed gradation, the crushing chamber, the material cleanliness, its moisture and its crushability. TEKNİK SPESİFİKASYONLAR / TECHNICAL SPECIFICATIONS

- 105. KQC 0 50

- 106. A B C STANDART KASNAK ÇAPI D STANDART FLY WHEEL DIAMETER E F

- 107. AYAR DURUMU G MAX. SETTING POSITION MİN. AYAR DURUMU H MİN. SETTING POSITION J BOŞALTMA AĞIZI ÇAPI DISCHARGE OPENING DIEMETER 01360 mm K ÇANI SÖKMEK İÇİN GEREKEN YÜKSEKLİK CLEARANCE REQUIERED FOR REMOVING BOWL ASSEMBLY TAHRİK KOVANINI SÖKMEK İÇİN MESAFE (KIRICI EKSENİNDEN) CLEARANCE REQUIERED FOR REMOVING COUNTER SHAFT ASSEMBLY (FROM CRUSHERS CENTER)

- 108. ÜST GÖVDEYİ SÖKMEK İÇİN GEREKEN YÜKSEKLİK CLEARANCE REQUIERED FOR REMOVING HEAD ASSEMBLY K I R I C I K A P A S İ T E L E R İ / CRUSHER CAPACITIES 13 mm 1/2" 16 mm 5/8" 19 mm 3/4" 22 mm 7/8" 25 mm 1" 32 mm 38 mm 45 mm 1-1/4" 1-1/2" 1-3/4"

- 109. K950 mt/h 120-150 130-180 150-200 165-220 200-290 210-310 235-330 245-350 st/h 130-165 145-200 165-220 180-240 220-320 230-340 260-360 270-385 K1150 mt/h 155-190 170-220 190-240 220-270 245-300 280-350 300-375 320-400 st/h 170-210 185-240 210-265 240-295 270-330 310-385 330-410 350-440 GURSAN

- 110. İNŞAAT MAKİNALARI SANAYİ LTD. ŞTİ. I CONSTRUCTION MACHINES INDUSTRY LTD. CO. Küçük Sanayi 3. Cadde No: 101 06930 Sincan - ANKARA / TURKEY Tel : +90. 312 269 20 23 - 269 32 67 ■ Fax : +90. 312 269 32 38 w e b : w w w . g u r - s a n . c o m . t r • e- mail: i n f o @ g u r - s a n . c o m . t r Les broyeur â percussion reversibles son t utilises dans les installations de fragmenta- tion, de criblage, les applications sec- ondares et tertiaires et dans le concassage

- 111. des mineraux naturels allant de ceux ten- dres comme le calcaire a ceux durs et abrasifs comme le caillou de ruisseau. Grace â leurs hautes vitesses de rotor, ils produisent de hautes quantites de sable et de granulats. Surtout leur capacite d'ac- cepter du gros materiau dans les applica- tions tertiaires rend ces machines preferables â ses equivalents.

- 112. GIFT YONLU DARBELI KIRICILAR 1 RROYEURAPERCUSSION REVERSIBLE

- 113. HI/ PORTE DE INSPECTION YAN ASTAR/ BLINDAGE LATER BOTAIRE - m mim flu îi m DARBE PERDESİ/ X ECRAN Mİ17ARBRE iijr ROTOR/ ROTOR I / Cc: V

- 114. Le rotor et la chambre de broyage sont conçus de maniere que 1e materiau soit casse sans frottement et uniquement sous l'effet de l'percussion pour assurer un maximum de vie â lab piece d'usure et aux batoires et un taux minimal de poudre dans le produit. Toutes les machines sont vendues avec l'alimentateur â vibration pour une bonne alimentation. Repartissant d'une façon reguliere tout le materiau qui entre sur toute la largeur de la machine, l'alimentateur assure une vie egale et plus longue aux pieces sujettes â l'usure et un fonc- tionnement de la machine en pleine capacity Alors que les ecranes de broyage reglables, possibles d'etre approches ou eloignes du rotor marchent dans un sens, les batoires dont les extremites tournees vers 1'autre sens sont connus assurent la situation per- manente de la repartition du produit et permettent l'utilisation des batoires au niveau maximum.

- 115. RROYERRA PERMISSION

- 116. REVERSIRIE ^um ■ Tipt

- 117. Pour la maintenance, le corps superieur peut s'ouvrir sur les deux cötes â l'aide d'un systeme hydraulique, les batoires, les blindages laterales et les autres pieces d'usures peuvent etre facilement rem- places.. Grace au systeme d'attach e des batoires, l'utilisation en surete des batoires en alliage â haute teneur de chrome a ete rendue possible et une haute resistance â l'usure a ete obtenue. iiM

- 118. • J i® RI^ H âti İk Mm

- 119. Les caracteristiques expliquees en haut rend economique l'utilisation du con- casseur â percussione reversible meme dans la fragmentation du materiau le plus dur. Geçen-Ce qui passe (mm)

- 120. A B C D E F G H J

- 121. mm inch mm inch mm inch mm inc mm inch mm inch mm inch mm inch mm inch

- 122. K60 650 25" 950 37" 800 31" 1370 54' ' 285 11" 1854 73" 2675 105" 1685 66" 1905 75"

- 124. K61 1300 51" 1640 65" 1250 49" 2185 f $ ' 285 11" 1854 73" 2675 105" 1685 66" 1905 75"

- 126. SPESİFİKASYONLAR / SPECIFICATIONS TECHNIQUES

- 127. ROTOR ÇAPI ROTOR GENİŞLİĞİ LARCEUR TAHRİK ENTRAINEMENT BESLEME AĞIZI GEN. BESLEME AĞIZI BOYU DIAMETRE DE DE ROTOR LARCEUR DE LA HAUTEUR DE LA ROTOR BOUCHE D'ALIMENTATION BOUCHE D'ALIMENTATION

- 128. mm inch mm inch mm inch mm inch Hp kw

- 129. K60 650 25" 285 11" 1100 43' 620 24" 125 90

- 131. K61 1300 51" 285 11" 1100 43' 1240 49" 220 160

- 132. ROTOR DEVRİ TOUR DE MAKS. BESLEME ÖLÇ. MAKS. BESLEME ÖLÇ. ÇEKİÇ ADEDİ KAPASİTE CAPACITE ROTOR (SERT MALZEME) DIMENTION NOMBREDE MARTEAUX (YUMUŞAK MALZEME) MAXIMUM DIMENTION MAXIMUM

- 133. D'ALIMENTATION D'ALIMENTATION (MATERIAU DUR) (MATERIAU TENDRE) mtph stph rpm mm inch mm inch

- 134. K60 60 2.5" 150 6" 2 60-80 70-90 995

- 136. K61 60 2.5" 150 6" 2 110-160 995