TPM: Focused Improvement (Kobetsu Kaizen) Poster

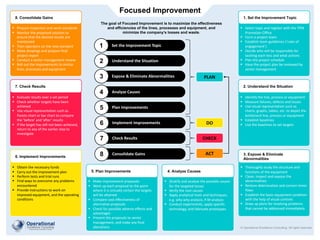

- 1. Focused Improvement © Operational Excellence Consulting. All rights reserved. The goal of Focused Improvement is to maximize the effectiveness and efficiencies of the lines, processes and equipment, and minimize the company’s losses and waste. § Prepare inspection and work standards § Monitor the proposed solution to ensure that the desired results are maintained § Train operators on the new standard § Make drawings and prepare final project report § Conduct a senior management review § Roll out the improvements to similar lines, processes and equipment 8. Consolidate Gains § Evaluate results over a set period § Check whether targets have been achieved § Use visual representation such as Pareto chart or bar chart to compare the ‘before’ and ‘after’ results § If the target has still not been achieved, return to any of the earlier step to investigate 7. Check Results § Obtain the necessary funds § Carry out the improvement plan § Perform tests and trial runs § Find ways to overcome any problems encountered § Provide instructions to work on improved equipment, and the operating conditions 6. Implement Improvements § Make improvement proposals § Work up each proposal to the point where it is virtually certain the targets will be attained § Compare cost effectiveness of alternative proposals § Check for possible adverse effects and advantages § Present the proposals to senior management, and make any final alterations 5. Plan Improvements § Stratify and analyze the possible causes for the targeted losses § Verify the root causes § Apply analytical tools and techniques, e.g. why-why analysis, P-M analysis § Conduct experiments, apply specific technology, and fabricate prototypes 4. Analyze Causes § Select topic and register with the TPM Promotion Office § Form a project team § Establish team guidelines (‘rules of engagement’) § Decide who will be responsible for tackling each loss and what actions § Plan the project schedule § Have the project plan be reviewed by senior management 1. Set the Improvement Topic § Identify the line, process or equipment § Measure failures, defects and losses § Use visual representation such as charts, graphs, tables, etc. to depict the bottleneck line, process or equipment § Establish baselines § Use the baselines to set targets 2. Understand the Situation § Thoroughly study the structure and functions of the equipment § Clean, inspect and expose the abnormalities § Restore deterioration and correct minor flaws § Establish the basic equipment condition with the help of visual controls § Draw up plans for resolving problems that cannot be addressed immediately 3. Expose & Eliminate Abnormalities Expose & Eliminate Abnormalities 3 Understand the Situation 2 Set the Improvement Topic 1 Analyze Causes 4 Check Results 7 Implement Improvements 6 Plan Improvements 5 Consolidate Gains 8 PLAN ACT CHECK DO

- 2. Focused Improvement © Operational Excellence Consulting. All rights reserved. The goal of Focused Improvement is to maximize the effectiveness and efficiencies of the lines, processes and equipment, and minimize the company’s losses and waste. § Prepare inspection and work standards § Monitor the proposed solution to ensure that the desired results are maintained § Train operators on the new standard § Make drawings and prepare final project report § Conduct a senior management review § Roll out the improvements to similar lines, processes and equipment 8. Consolidate Gains § Evaluate results over a set period § Check whether targets have been achieved § Use visual representation such as Pareto chart or bar chart to compare the ‘before’ and ‘after’ results § If the target has still not been achieved, return to any of the earlier step to investigate 7. Check Results § Obtain the necessary funds § Carry out the improvement plan § Perform tests and trial runs § Find ways to overcome any problems encountered § Provide instructions to work on improved equipment, and the operating conditions 6. Implement Improvements § Make improvement proposals § Work up each proposal to the point where it is virtually certain the targets will be attained § Compare cost effectiveness of alternative proposals § Check for possible adverse effects and advantages § Present the proposals to senior management, and make any final alterations 5. Plan Improvements § Stratify and analyze the possible causes for the targeted losses § Verify the root causes § Apply analytical tools and techniques, e.g. why-why analysis, P-M analysis § Conduct experiments, apply specific technology, and fabricate prototypes 4. Analyze Causes § Select topic and register with the TPM Promotion Office § Form a project team § Establish team guidelines (‘rules of engagement’) § Decide who will be responsible for tackling each loss and what actions § Plan the project schedule § Have the project plan be reviewed by senior management 1. Set the Improvement Topic § Identify the line, process or equipment § Measure failures, defects and losses § Use visual representation such as charts, graphs, tables, etc. to depict the bottleneck line, process or equipment § Establish baselines § Use the baselines to set targets 2. Understand the Situation § Thoroughly study the structure and functions of the equipment § Clean, inspect and expose the abnormalities § Restore deterioration and correct minor flaws § Establish the basic equipment condition with the help of visual controls § Draw up plans for resolving problems that cannot be addressed immediately 3. Expose & Eliminate Abnormalities Expose & Eliminate Abnormalities 3 Understand the Situation 2 Set the Improvement Topic 1 Analyze Causes 4 Check Results 7 Implement Improvements 6 Plan Improvements 5 Consolidate Gains 8 PLAN ACT CHECK DO

- 3. © Operational Excellence Consulting. All rights reserved. 3 Operational Excellence Consulting is a management training and consulting firm that assists organizations in improving business performance and effectiveness. Based in Singapore, the firm’s mission is to create business value for organizations through innovative design and operational excellence management training and consulting solutions. For more information, please visit www.oeconsulting.com.sg